Oil coke slurry for float glass tank furnace and technology thereof

A float glass, oil coke slurry technology, applied in the petroleum industry, furnace type, furnace and other directions, can solve the problems of low control accuracy, limited use range, glass quality fluctuation, etc., to eliminate pollution problems, reduce fuel costs, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The mass percent of petroleum coke powder in the oil tar slurry is: 25-35%.

[0022] The preferred mass percent of petroleum coke powder in the oil tar slurry is: 29-31%.

[0023] With 5000kg of oil coke slurry prepared each time, the amounts of heavy oil and petroleum coke powder are calculated as follows.

[0024] Formula 1: heavy oil 3550kg petroleum coke powder 1450kg

[0025] Formula 2: heavy oil 3500kg petroleum coke powder 1500kg

[0026] Formula 3: heavy oil 3450kg petroleum coke powder 1550kg

[0027] Process method and process:

[0028] The application of oil coke slurry without any additives in the regenerator cross-flame 450-ton float glass tank kiln is as follows:

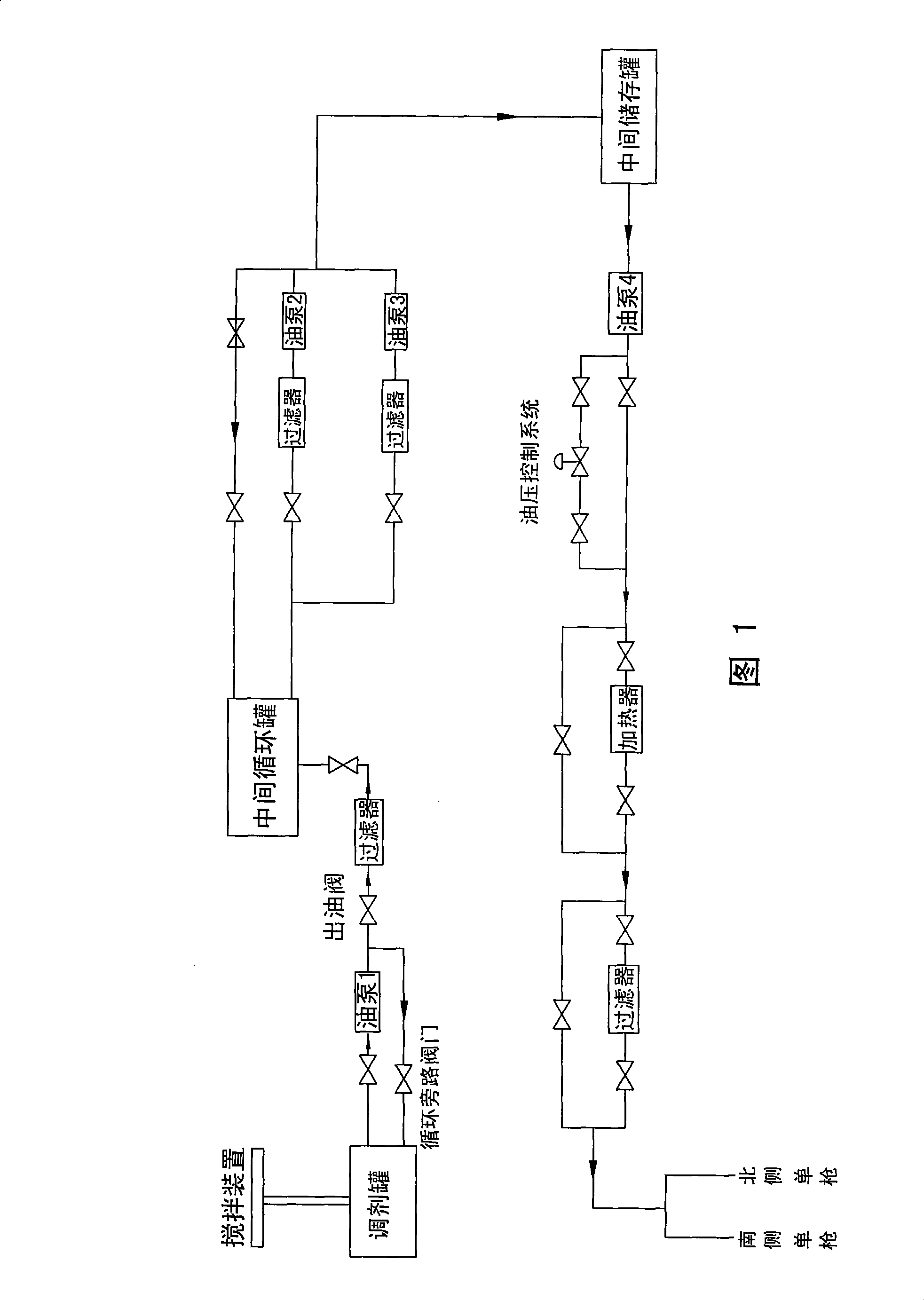

[0029] Process the petroleum coke powder into a particle size of 500-600 mesh, add the processed petroleum coke powder according to the proportion of 30% by mass at a heating temperature of 90°C to a preparation tank equipped with heavy oil to configure oil coke slurry, and stir it mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com