Multi-axis hydraulic synchronization control system, method and device

A hydraulic synchronization and control system technology, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of long lifting stroke, large volume of synchronous cylinder or synchronous motor, and high cost, and achieve The effect of simple structure, high precision of synchronous control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

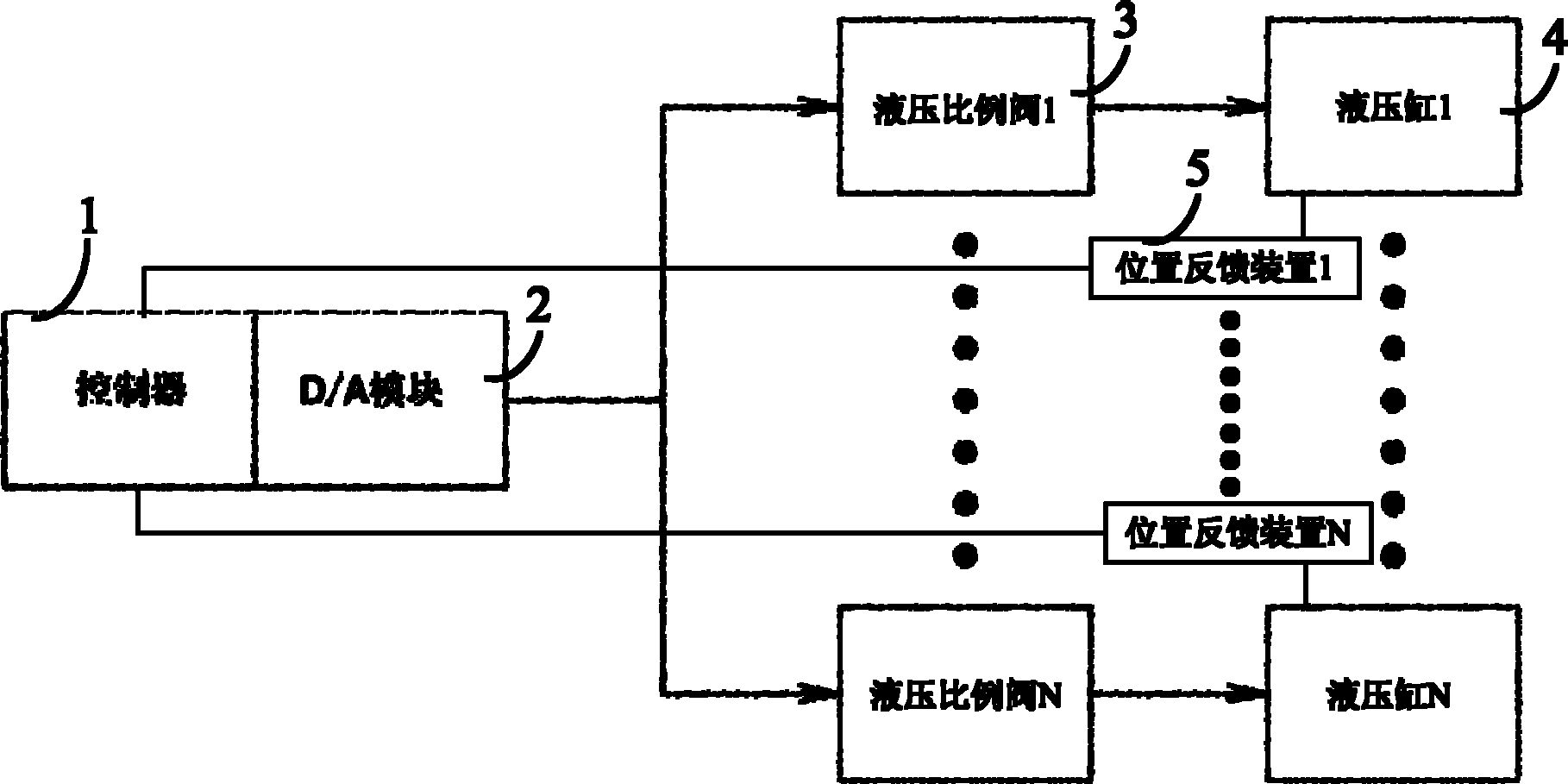

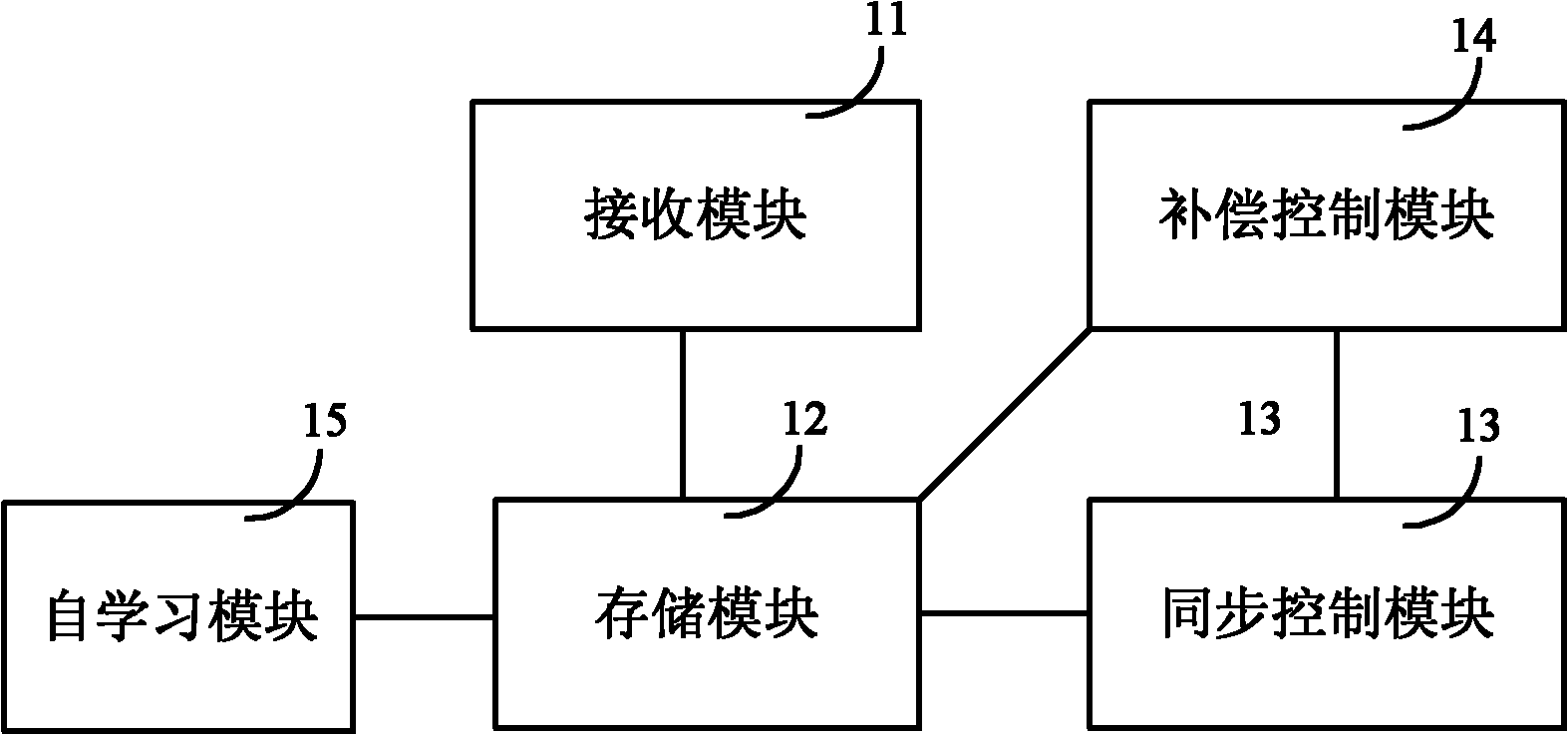

[0043] An embodiment of the present invention provides a multi-axis hydraulic synchronous control system, which can realize synchronous control of multiple hydraulic cylinders, such as figure 1 As shown, the system includes: a controller 1, a digital-to-analog conversion module 2 (D / A module), at least two hydraulic proportional valves 3 and a position feedback device 4 having the same number as the hydraulic proportional valves;

[0044] Wherein, the controller 1 is connected with each hydraulic proportional valve 3 via the digital-to-analog conversion module 2, and each hydraulic proportional valve 3 can drive a hydraulic cylinder 4 connected thereto; each position feedback device 5 is respectively connected with the controller 1, each Each position feedback device 5 can detect the position of a hydraulic cylinder 4, and deliver the detected position data to the controller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com