Patents

Literature

55results about How to "High precision of synchronous control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic double cylinder or multi-cylinder synchronous control system

InactiveCN101392771AImprove reliabilityImprove securityServomotorsFluid-pressure actuator componentsHydraulic cylinderSynchronous control

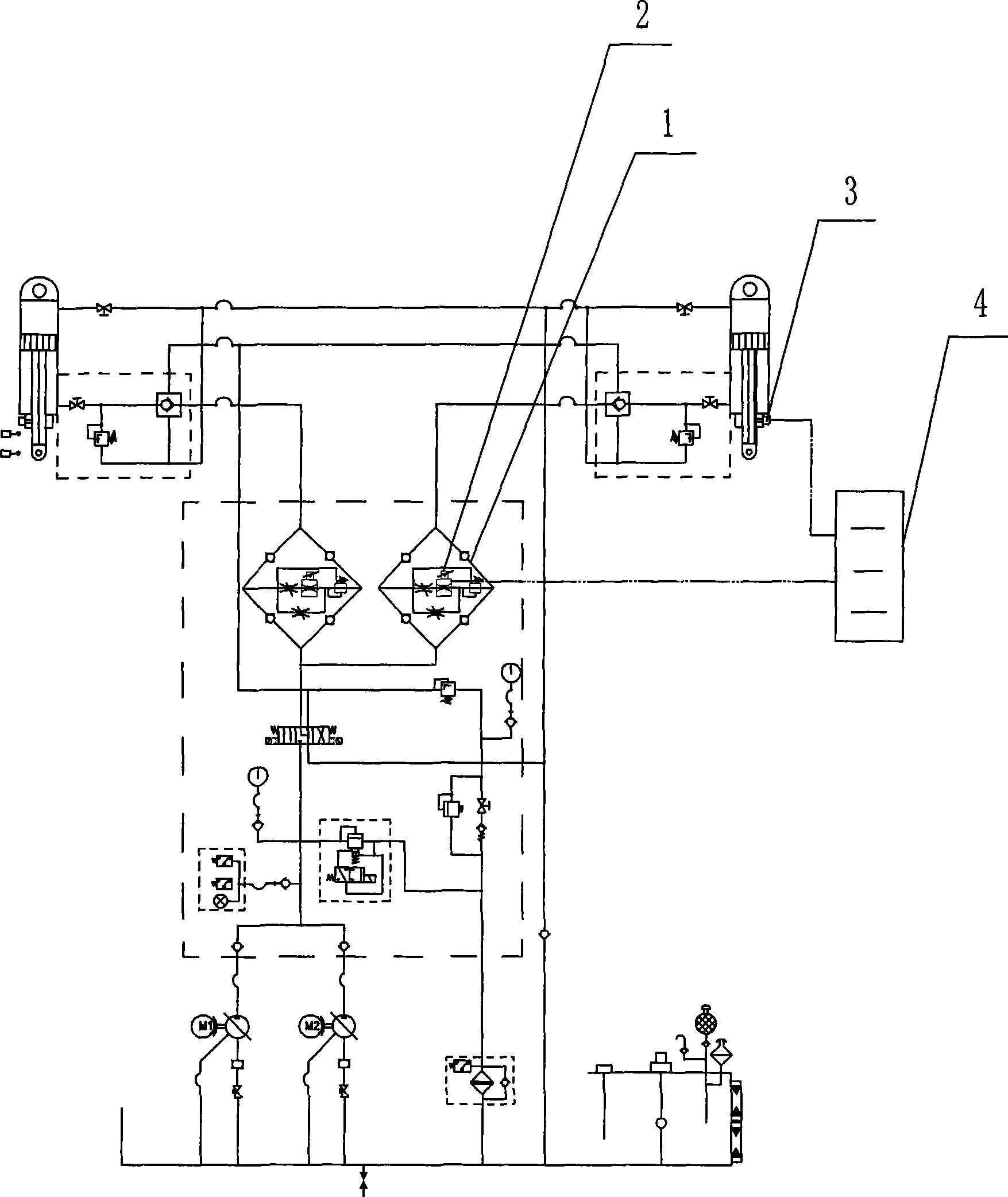

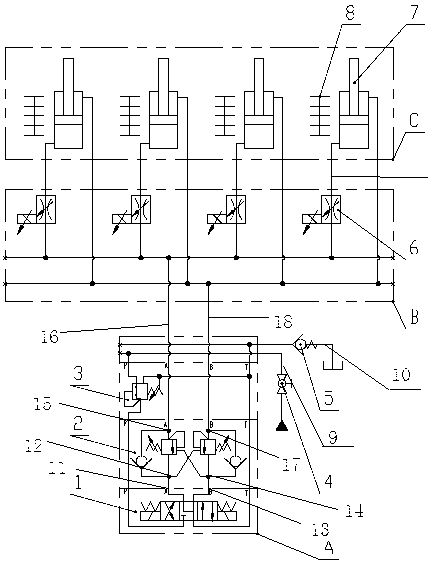

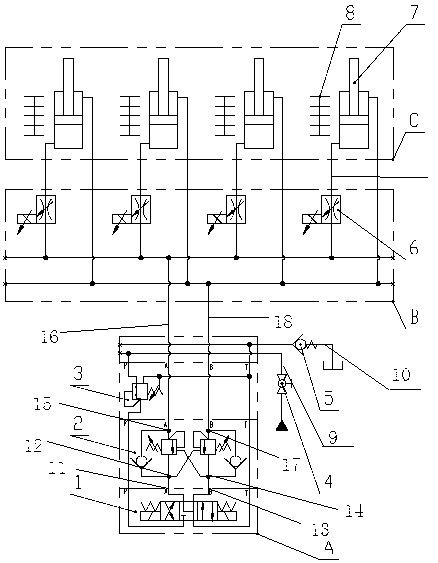

The invention relates to a synchronous control system with two hydraulic cylinders or a plurality of the hydraulic cylinders, which is combined with a hydraulic system and mainly comprises an eddy plate, an electro-hydraulic proportional speed control valve, hydraulic cylinder stroke detectors, and a PLC controller. The eddy plate with the electro-hydraulic proportional speed control valve is coupled in an oil feed path of the hydraulic system, and oil flows through the eddy plate with the electro-hydraulic proportional speed control valve and enters into hydraulic cylinders of the hydraulic system; and each hydraulic cylinder is provided with one hydraulic cylinder stroke detector which is in charge of inputting a stroke detection signal to the PLC controller, and the PLC controller inputs a proportional speed control signal to the electro-hydraulic proportional speed control valve according to the received stroke detection signal so as to control the proportional speed control valve to adjust the oil flow rate thereof. The control system can achieve the synchronous and precise running of the two hydraulic cylinders or the plurality of the hydraulic cylinders so as to improve the reliability and the safety of the running of the hydraulic system, and has the advantages of high synchronous control precision and fast response speed.

Owner:JIANGSU WUJIN HYDRAULIC HOIST

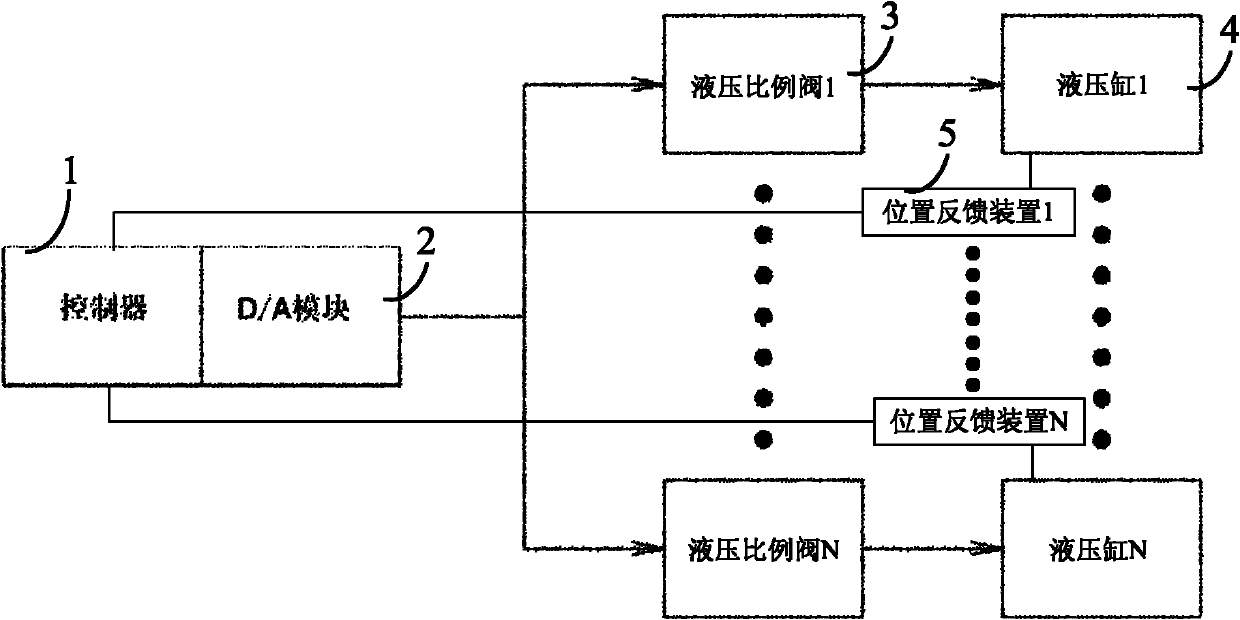

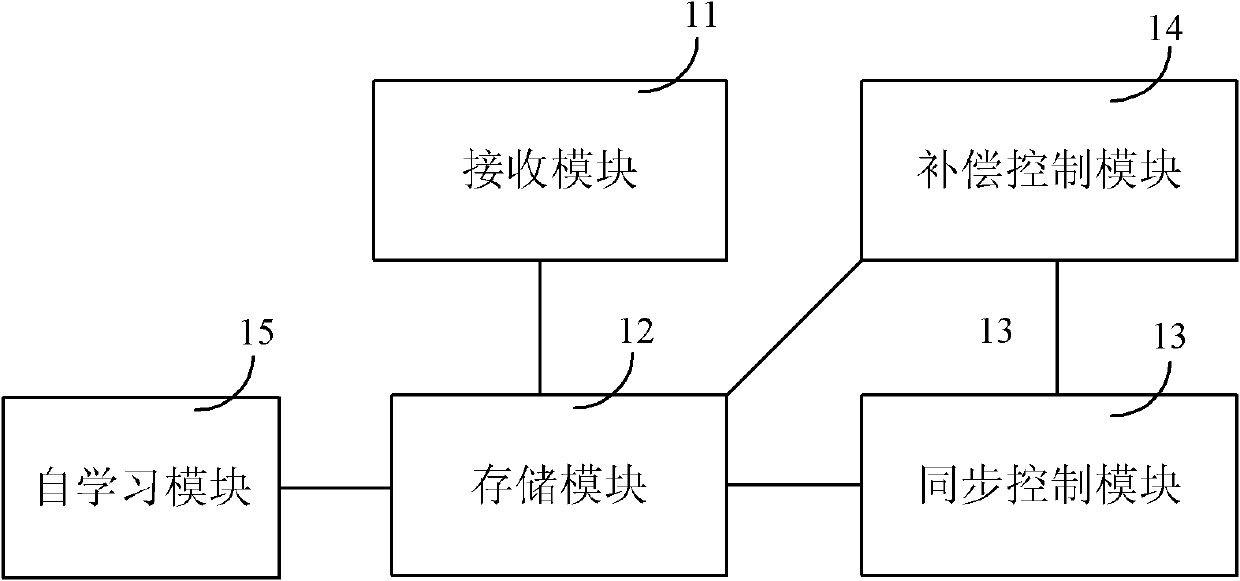

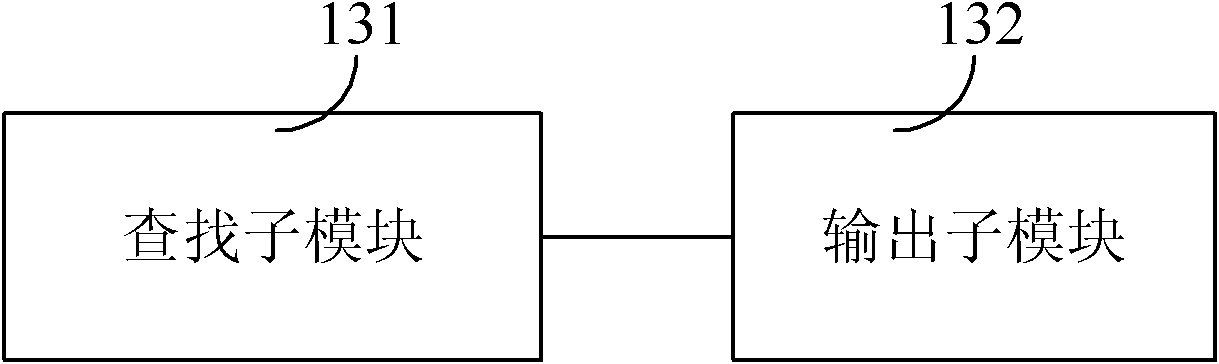

Multi-axis hydraulic synchronization control system, method and device

ActiveCN102086893ASimple structureHigh precision of synchronous controlServomotorsFluid-pressure actuator componentsHydraulic cylinderSynchronous control

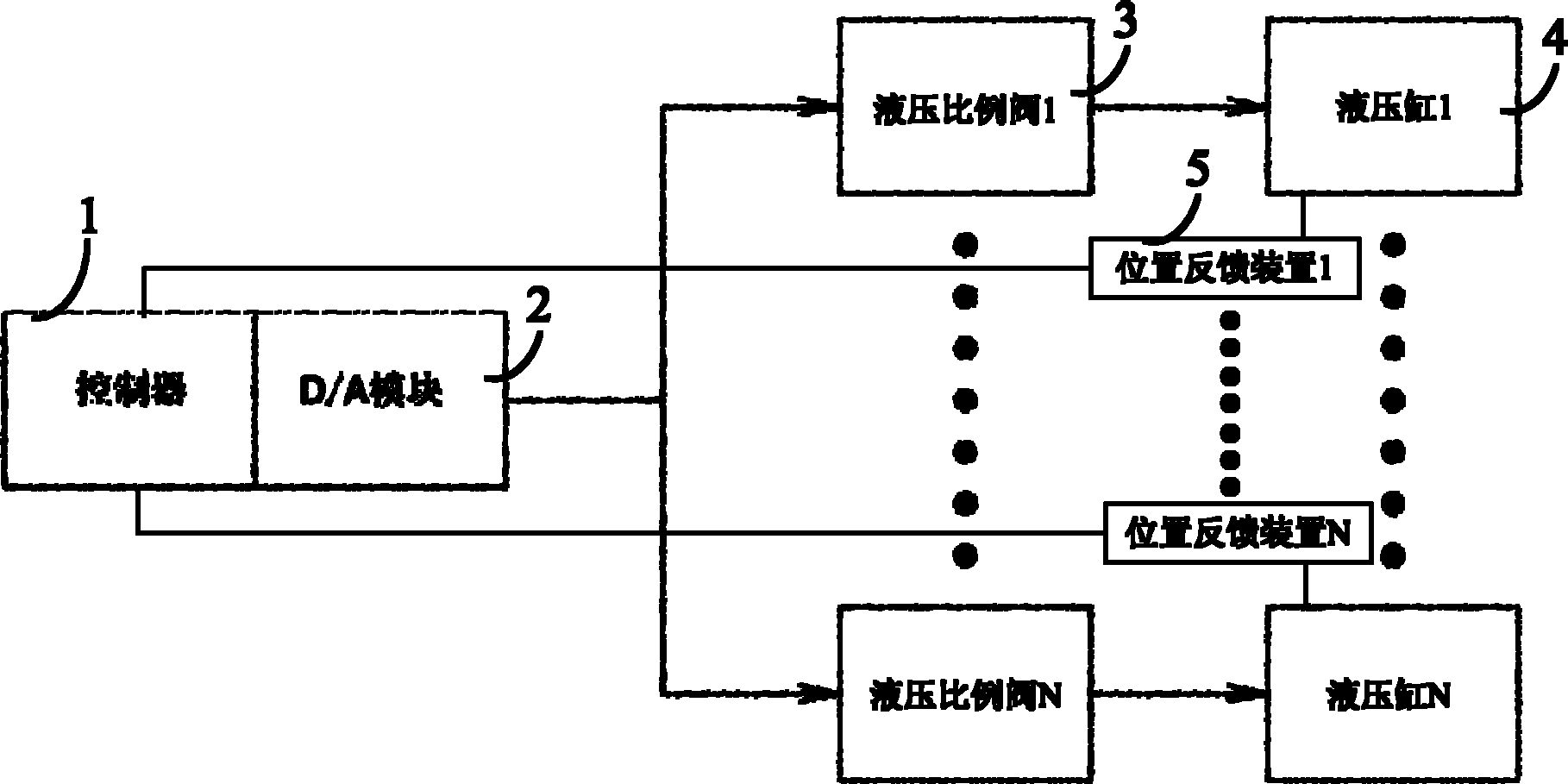

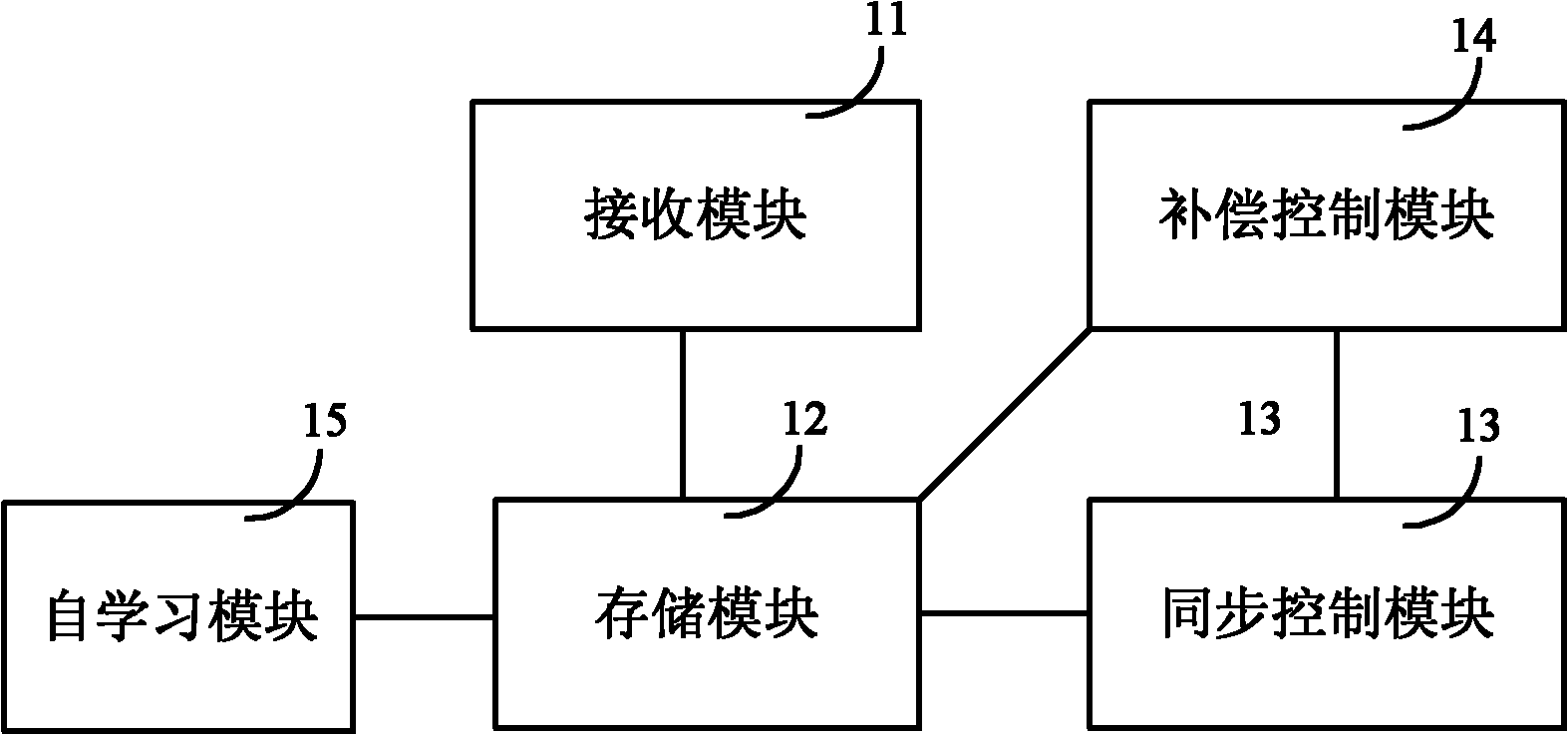

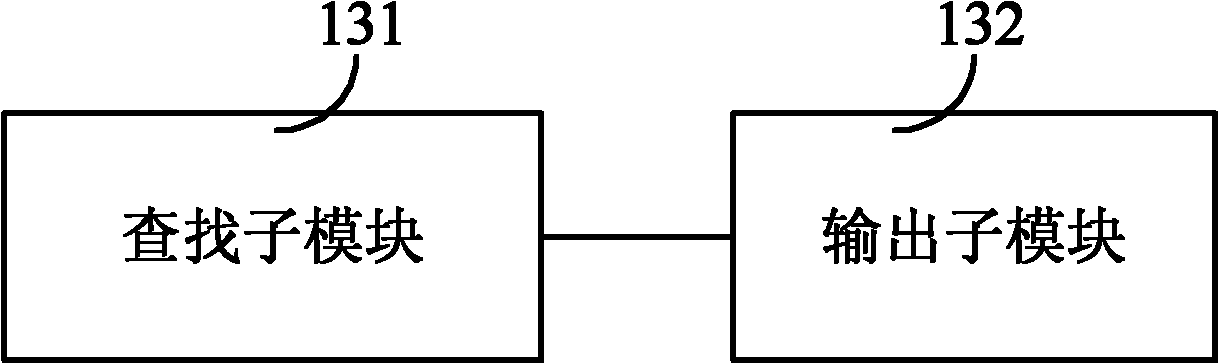

The invention discloses a multi-axis hydraulic synchronization control system, method and device, and belongs to the technical field of synchronization control. The system comprises a controller, a digital-to-analogue conversion module, at least two hydraulic proportional valves and position feedback devices the number of which is equal to the number of the hydraulic proportional valves; the controller is connected with each hydraulic proportional valve through the digital-to-analogue conversion module, and each hydraulic proportional valve can drive a hydraulic cylinder which is connected with each hydraulic proportional valve; each position feedback device is respectively connected with the controller, each position feedback device can detect the position of each hydraulic cylinder, andtransmits the detected position data to the controller; and the controller can control each hydraulic proportional valve according to the position data of each hydraulic cylinder transmitted by each position feedback device and by consulting the stored synchronization data of the controller. The multi-axis hydraulic synchronization control system has the advantages of simple structure, high synchronization precision and low cost, and can be used for solving the problems of low synchronization and high cost of the existing multi-axis hydraulic synchronization.

Owner:FANTAWILD DIGITAL FILM

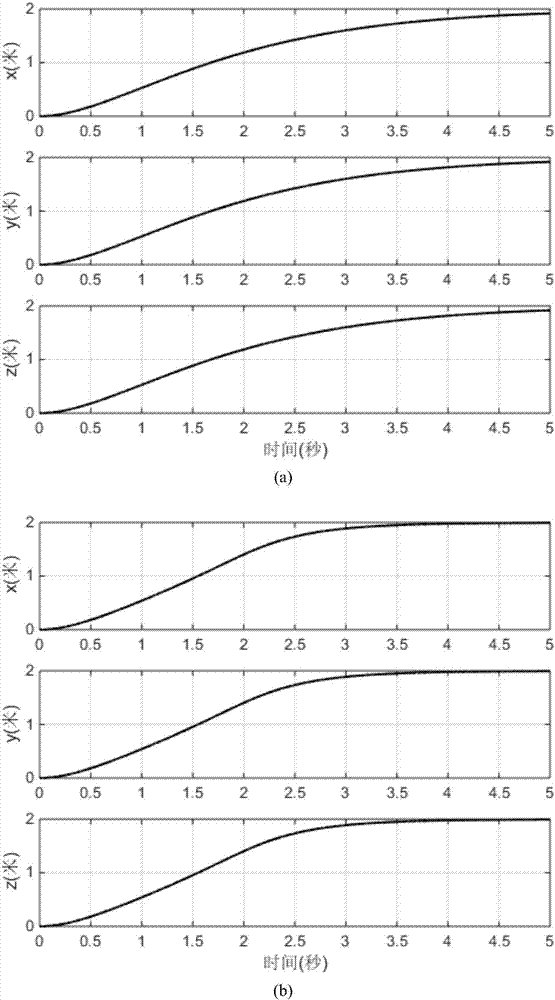

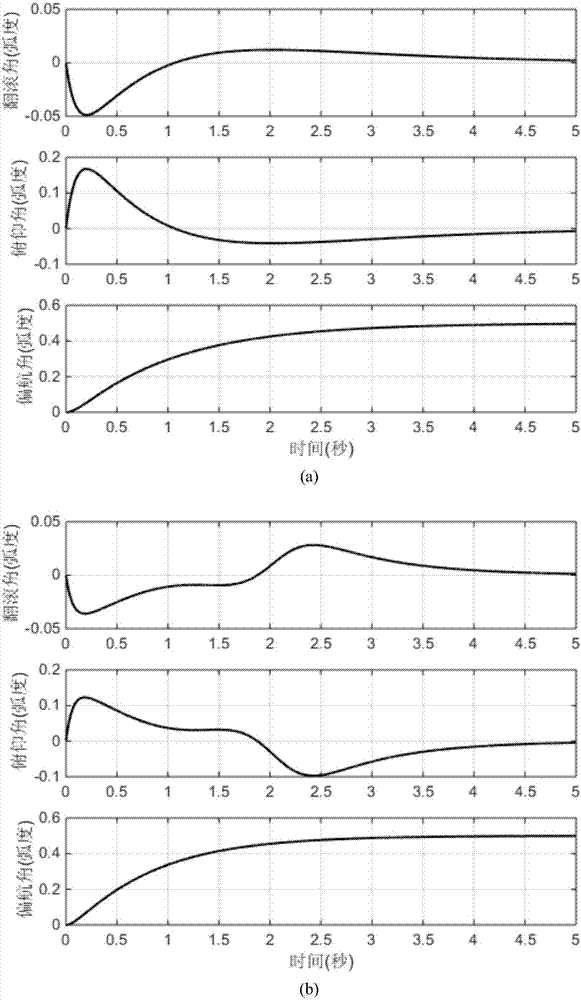

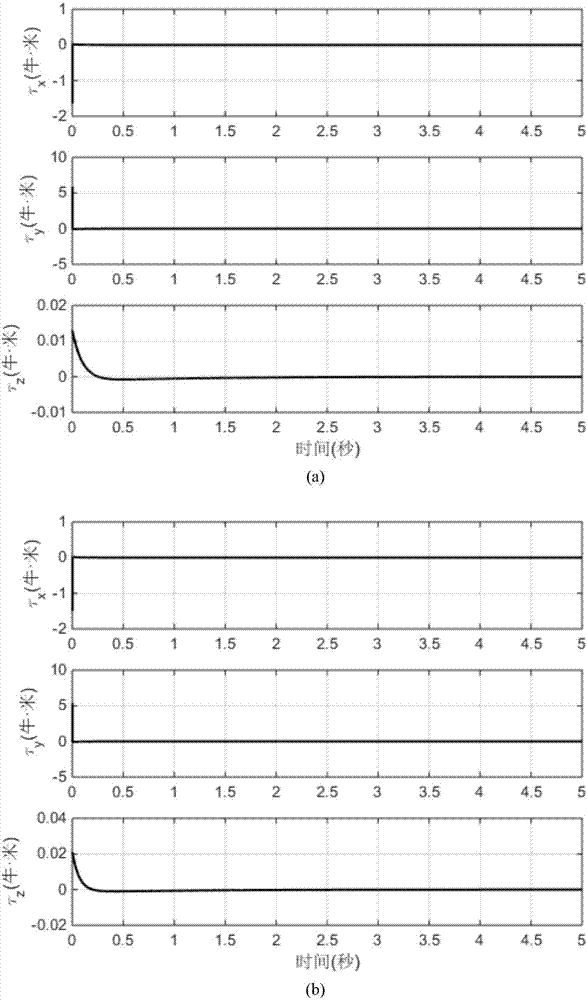

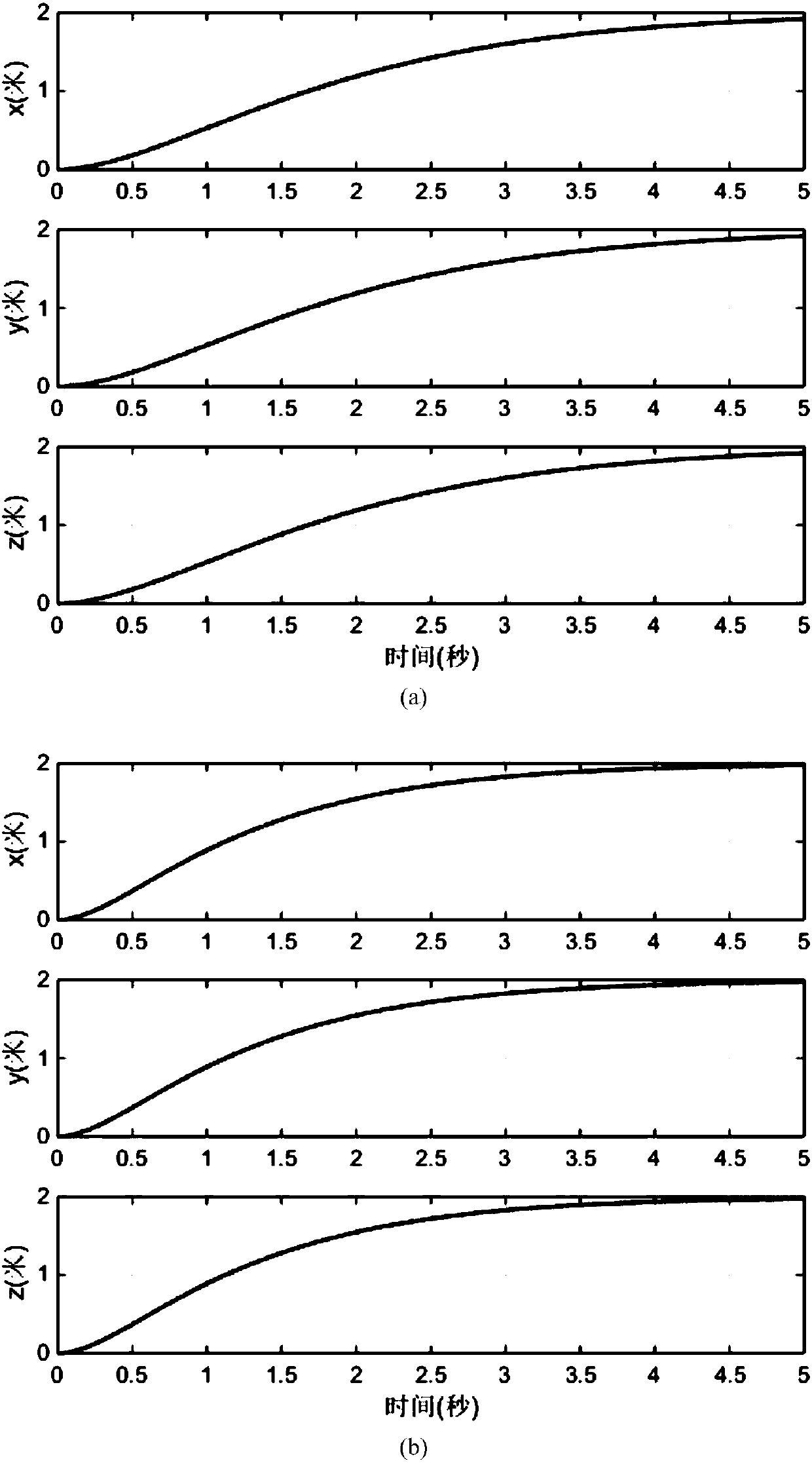

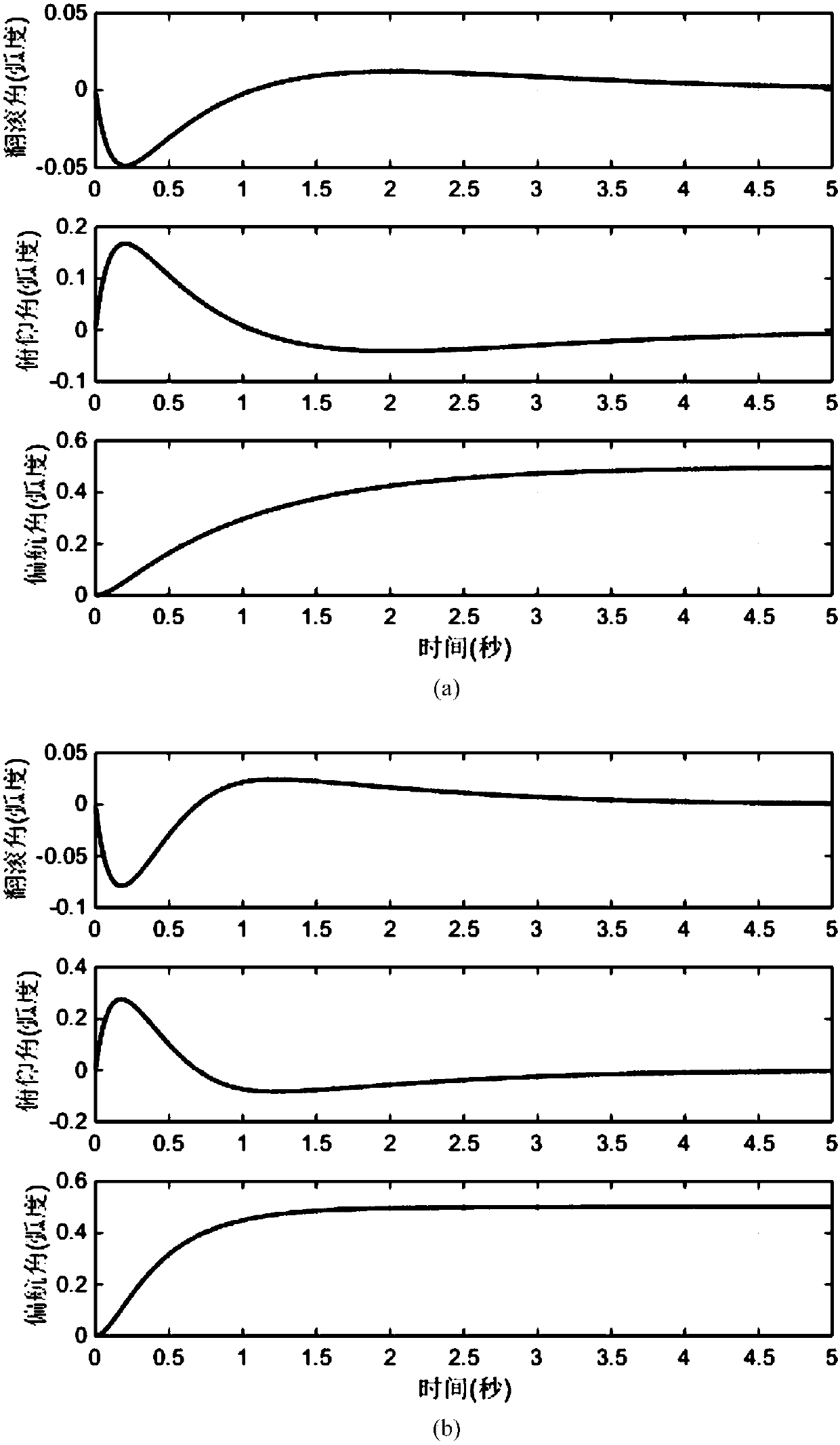

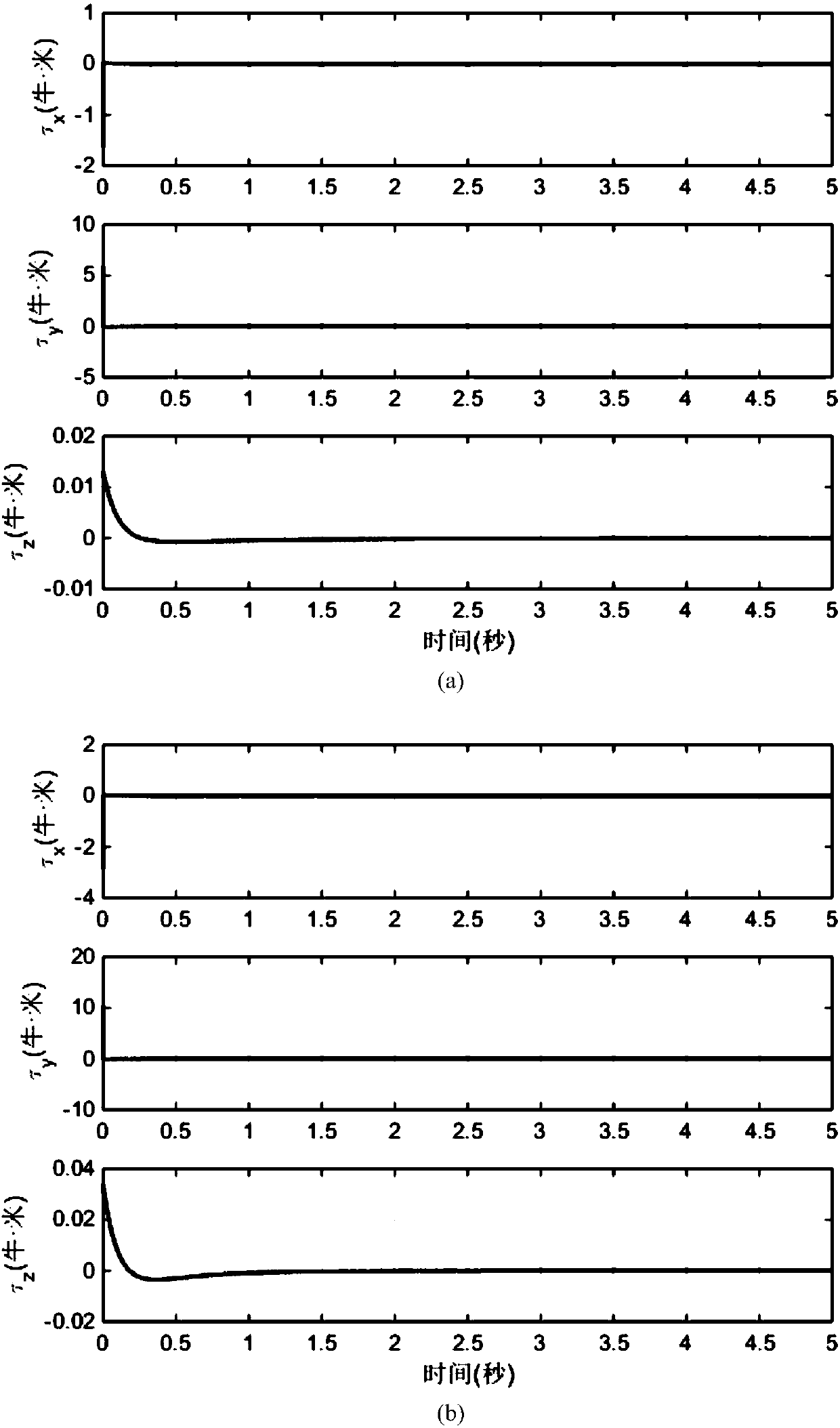

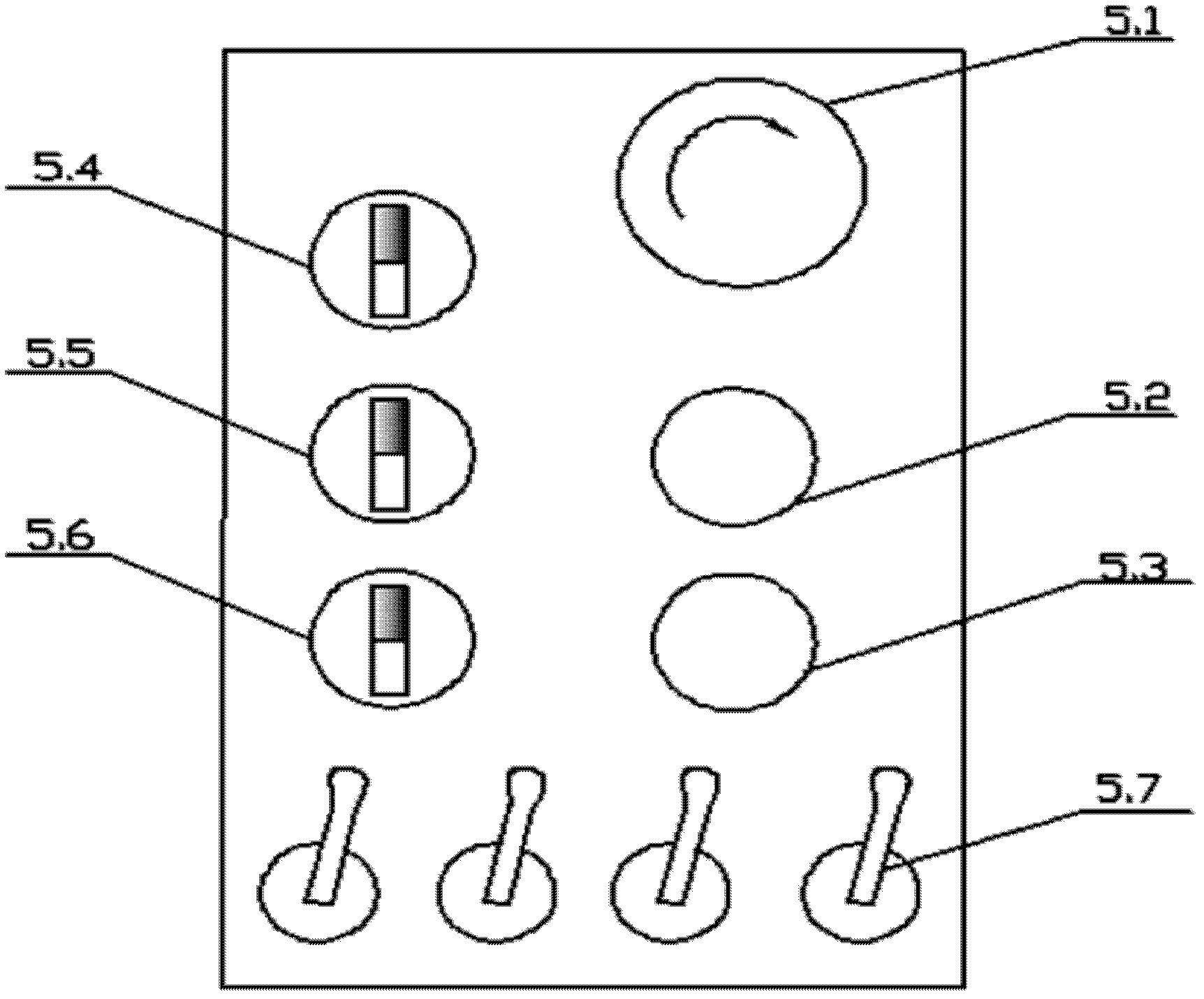

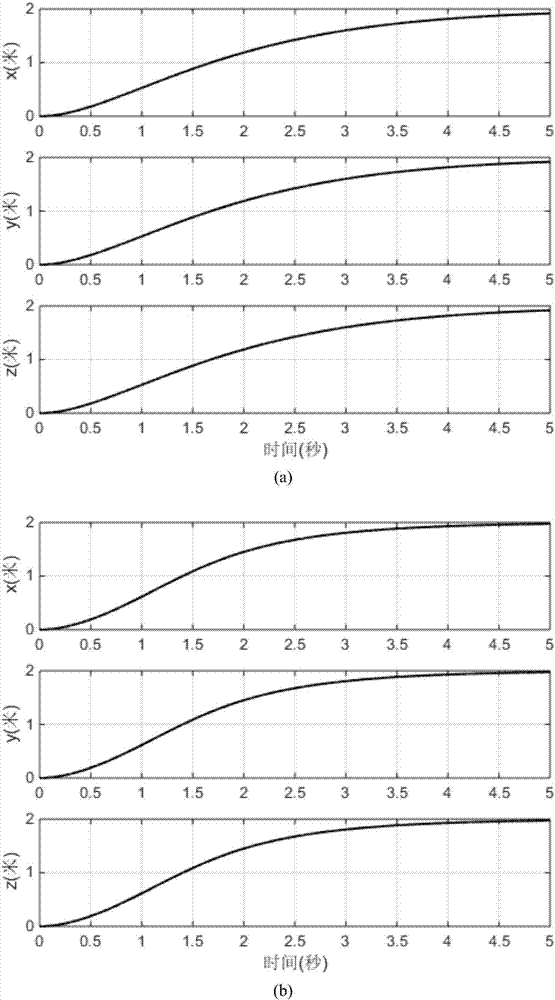

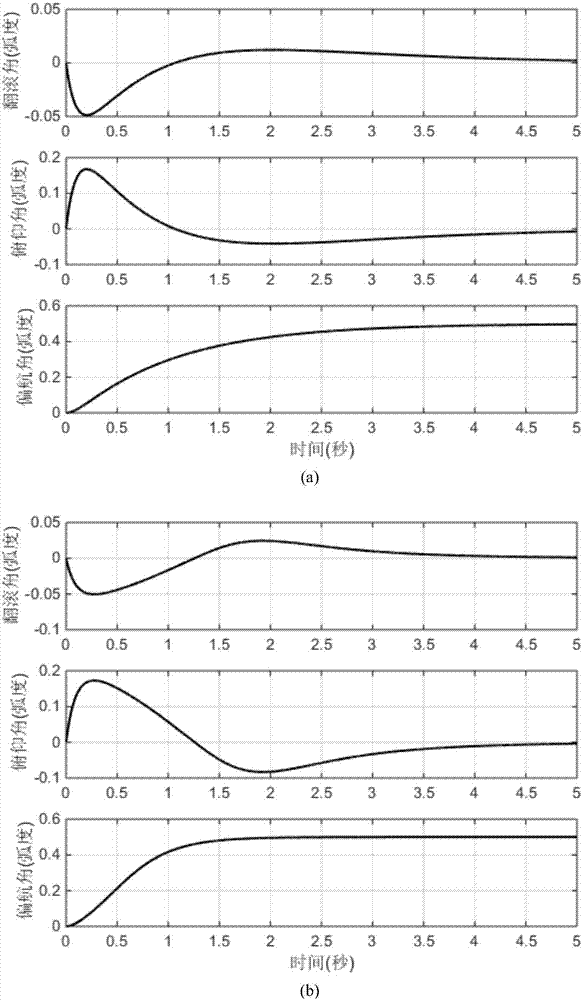

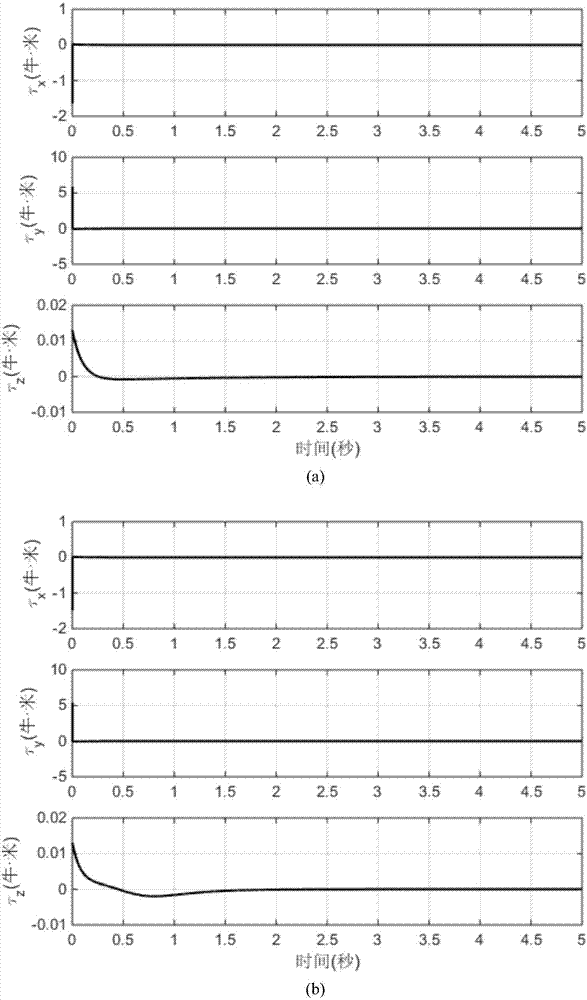

Quad-rotor aircraft nonlinear sliding mode pose control method based on error exponential function

ActiveCN107368088AMeet Fast Track Performance RequirementsHigh precision of synchronous controlAttitude controlPosition/course control in three dimensionsStabilization controlControl theory

The invention relates to a quad-rotor aircraft nonlinear sliding mode pose control method based on an error exponential function. The invention design a quad-rotor unmanned aerial vehicle nonlinear sliding mode pose control method by using a nonlinear sliding mode control method in allusion to a quad-rotor unmanned aerial vehicle system containing a dynamic execution mechanism. The design of a sliding mode surface is to ensure quick and stable convergence of the system. In addition, the robustness and the tracking accuracy of the system can be improved by adopting a nonlinear function to design the sliding mode surface. The quad-rotor aircraft nonlinear sliding mode pose control method based on the error exponential function realize quick and stable control of the system.

Owner:ZHEJIANG UNIV OF TECH

Four-rotor aircraft nonlinear sliding mode position and attitude control method based on single exponential function

ActiveCN107561931AMeet Fast Track Performance RequirementsHigh precision of synchronous controlAdaptive controlAttitude controlStabilization control

The invention provides a four-rotor aircraft nonlinear sliding mode position and attitude control method based on a single exponential function. For a four-rotor UAV (unmanned aerial vehicle) system having a dynamic execution mechanism, the invention designs the four-rotor UAV system nonlinear sliding mode position and attitude control method by utilizing a nonlinear sliding mode control method. The design of a sliding mode surface is to ensure fast and steady convergence of the system; and besides, since the sliding mode surface is designed based on a nonlinear function, robustness and tracking precision of the system can be improved. The four-rotor aircraft nonlinear sliding mode position and attitude control method based on the single exponential function realizes fast and stable control of the system.

Owner:ZHEJIANG UNIV OF TECH

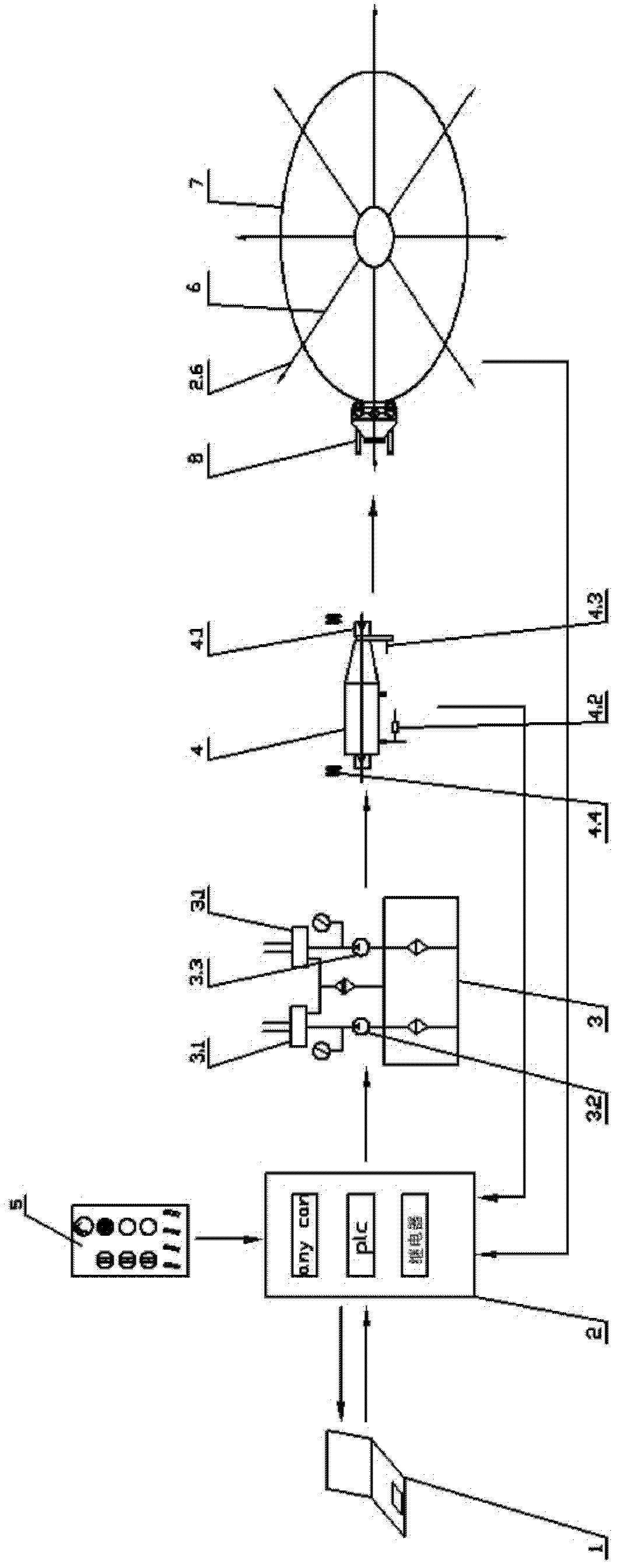

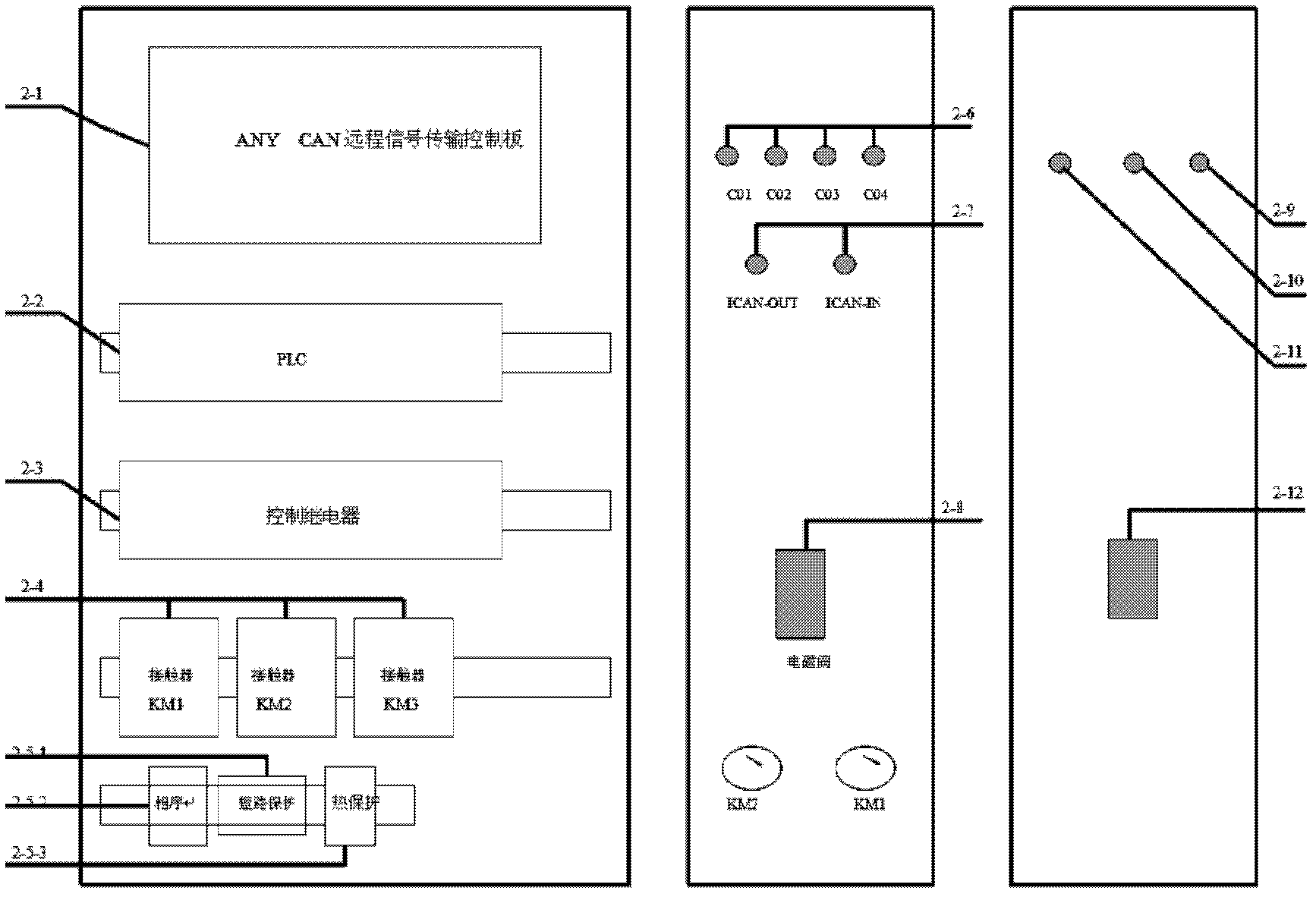

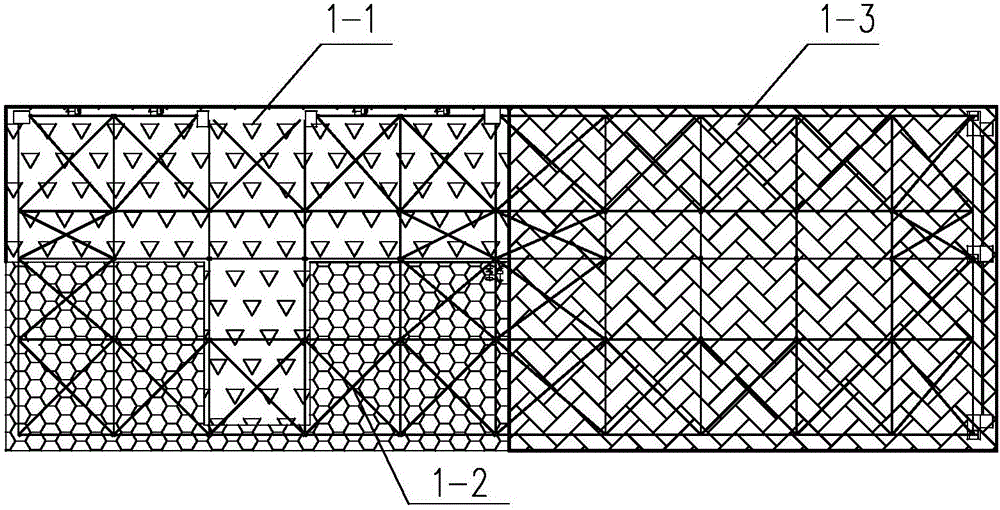

Synchronous computer controller device for overall tension and construction method

InactiveCN102331767ALarge capacityAdvanced and reasonable designTotal factory controlProgramme total factory controlSequence controlControl system

The invention discloses a synchronous computer controller device for overall tension and a construction method. The device comprises a mechanical system, a hydraulic system and a control system, wherein the mechanical system comprises a tensioned space cable structure, a steel tension cable and a tension tool, wherein the steel tension cable is connected with the tensioned space cable structure and the tension tool respectively; the hydraulic system comprises a hydraulic pump station, a hydraulic jack group and various hydraulic valves; the hydraulic jacks are connected with the hydraulic pump station; tensile force is applied to the tension tool; the control system comprises a computer and a main control cabinet; the main control cabinet is connected with a computer, the hydraulic systemand the mechanical system respectively; and the main control cabinet comprises a communication control board, a PLC (Programmable Logic Controller), a phase sequence control relay, various interface boards, a transmission line and a remote monitoring sensor. The device has the advantages of simple manufacturing process, economical efficiency, reasonable manufacturing cost, easiness and convenience for operating, high synchronous control accuracy and the like.

Owner:BEIJING ACAD OF BUILDING ENG +1

Quad-rotor aircraft nonlinear sliding mode pose control method based on double-exponential function

ActiveCN107368089AStable controlConvergent stabilityAttitude controlPosition/course control in three dimensionsControl theoryQuad rotor

The invention relates to a quad-rotor aircraft nonlinear sliding mode pose control method based on a double-exponential function. The invention designs a quad-rotor unmanned aerial vehicle system nonlinear sliding mode pose control method by using a nonlinear sliding mode control method in allusion to a quad-rotor unmanned aerial vehicle system containing a dynamic execution mechanism. The design of a sliding mode surface is to ensure quick and stable convergence of the system. In addition, the robustness and the tracking accuracy of the system can be improved by adopting a nonlinear function to design the sliding mode surface. The quad-rotor aircraft nonlinear sliding mode pose control method based on the double-exponential function provided by the invention realize quick and stable control of the system.

Owner:ZHEJIANG UNIV OF TECH

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642AReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

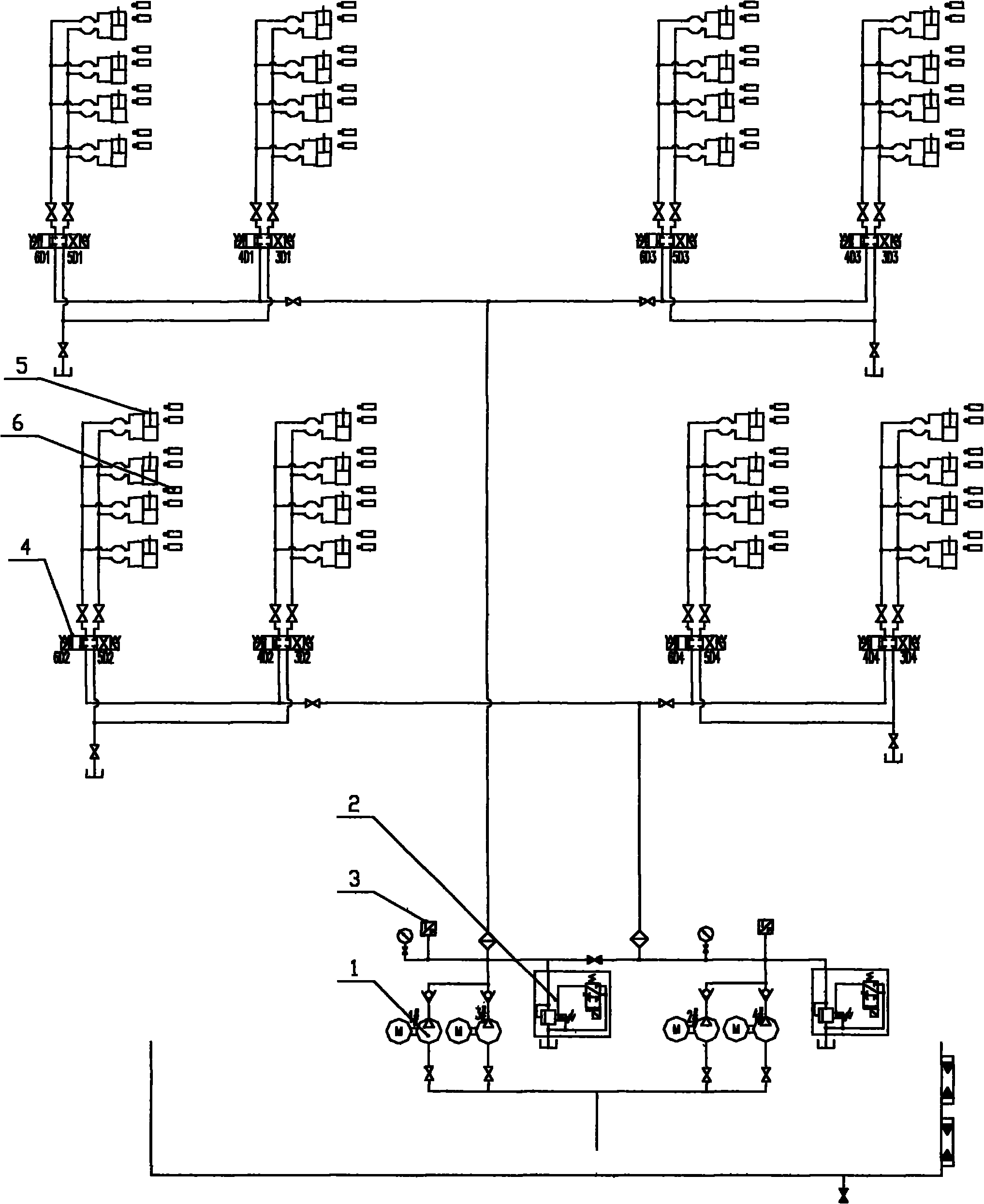

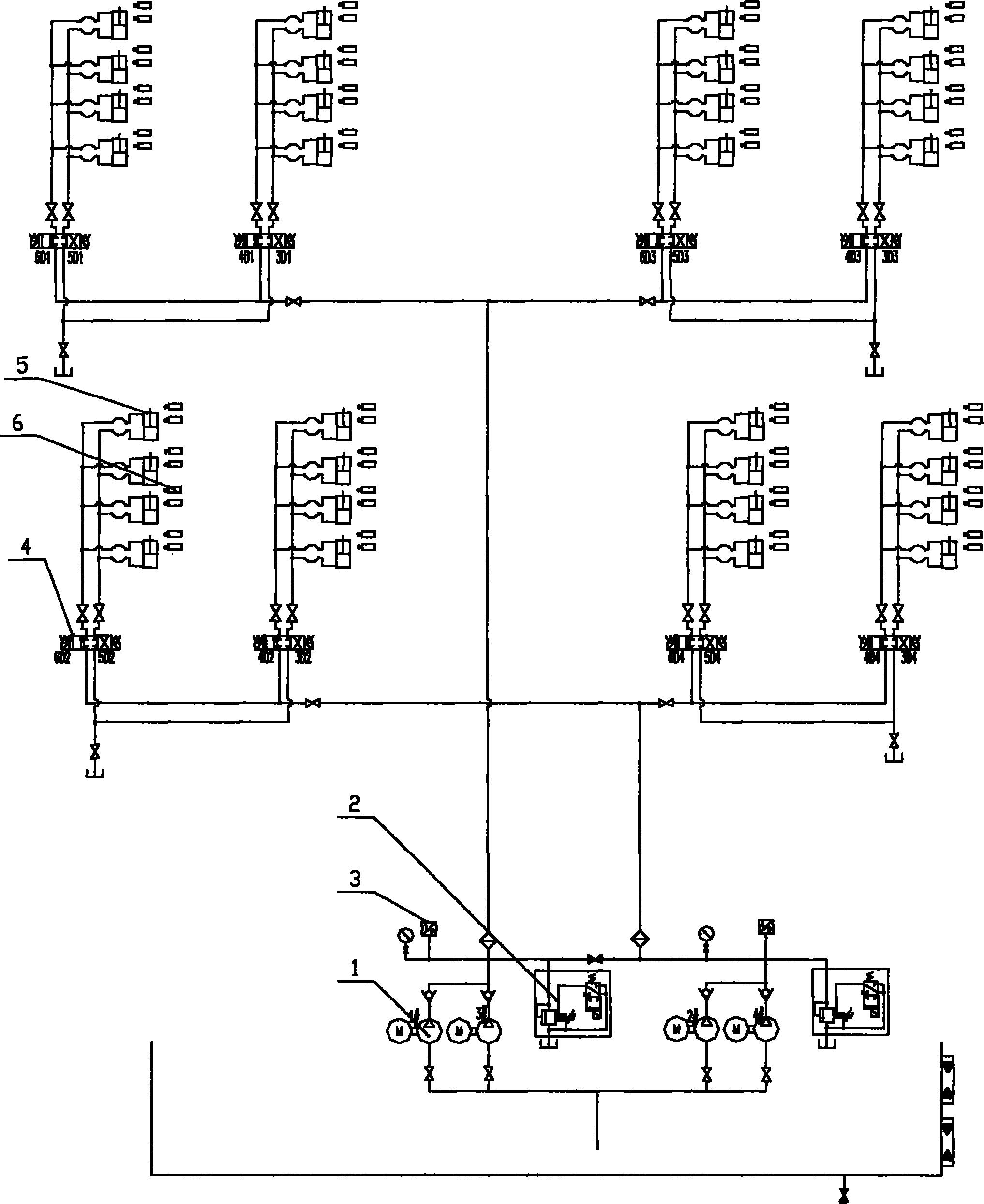

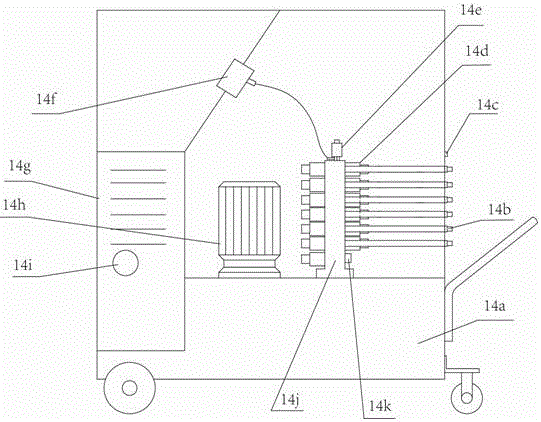

Lifting pull-plug pin system of self-installed production platform

InactiveCN102011386AHigh precision of synchronous controlImprove stabilityArtificial islandsUnderwater structuresElectrical controlEngineering

The invention relates to a lifting pull-plug pin system of self-installed production platform of a one-pile multi-cylinder pull-plug pin in lifting of a marine production platform. The lifting pull-plug pin system comprises 32 pull-plug pin hydraulic cylinders, 32 platform main pin shafts, a hydraulic control system of a pull-plug pin hydraulic cylinder and an electrical control system, wherein an oil pump motor group of the hydraulic control system of the pull-plug pin hydraulic cylinder is connected with the pull-plug pin hydraulic cylinders through a three-position four-way electromagnetic change-over valve after being connected with an electromagnetic overflow valve bank and a pressure transformer in series, the telescopic end of each pull-plug pin hydraulic cylinder is fixedly connected with a pull-plug pin hydraulic cylinder pin shaft, each pull-plug pin hydraulic cylinder pin shaft is fixedly connected with a platform main pin shaft, the electrical control system comprises a programmable controller PLC and a monitoring device which is arranged in the pull-plug pin hydraulic cylinder for monitoring whether the platform main pin shaft is plugged to a correct position, and the monitoring device is connected with the programmable controller PLC. The synchronous control precision of the 32 pull-plug pin hydraulic cylinders and the stability of the system are high.

Owner:CHANGZHOU HYDRAULIC COMPLETE EQUIP

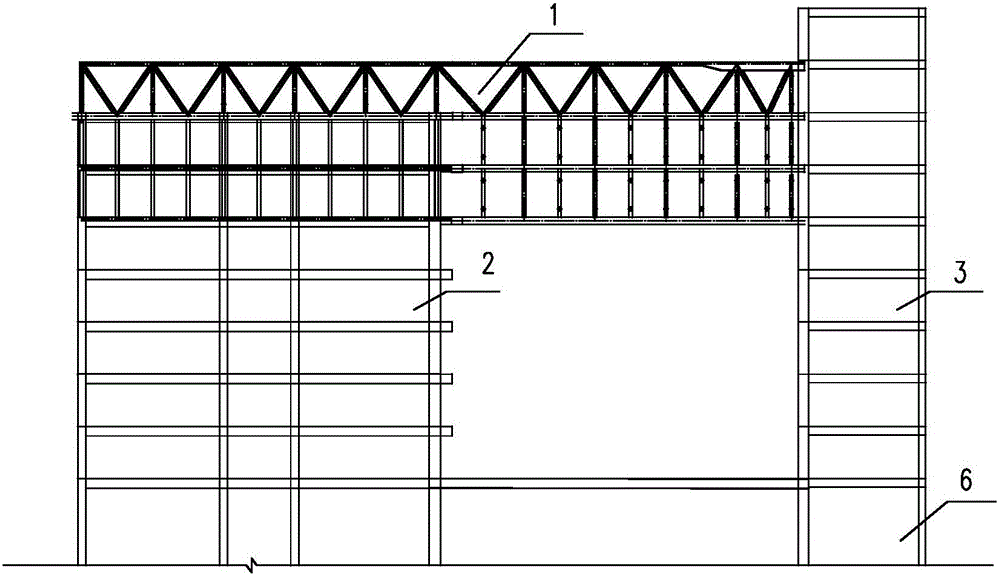

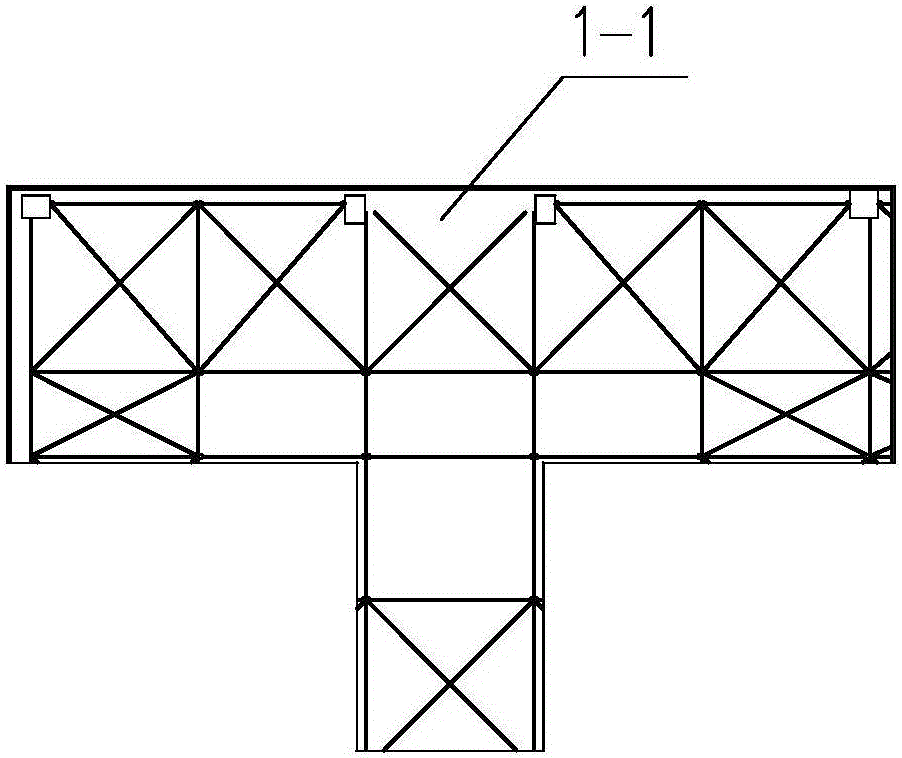

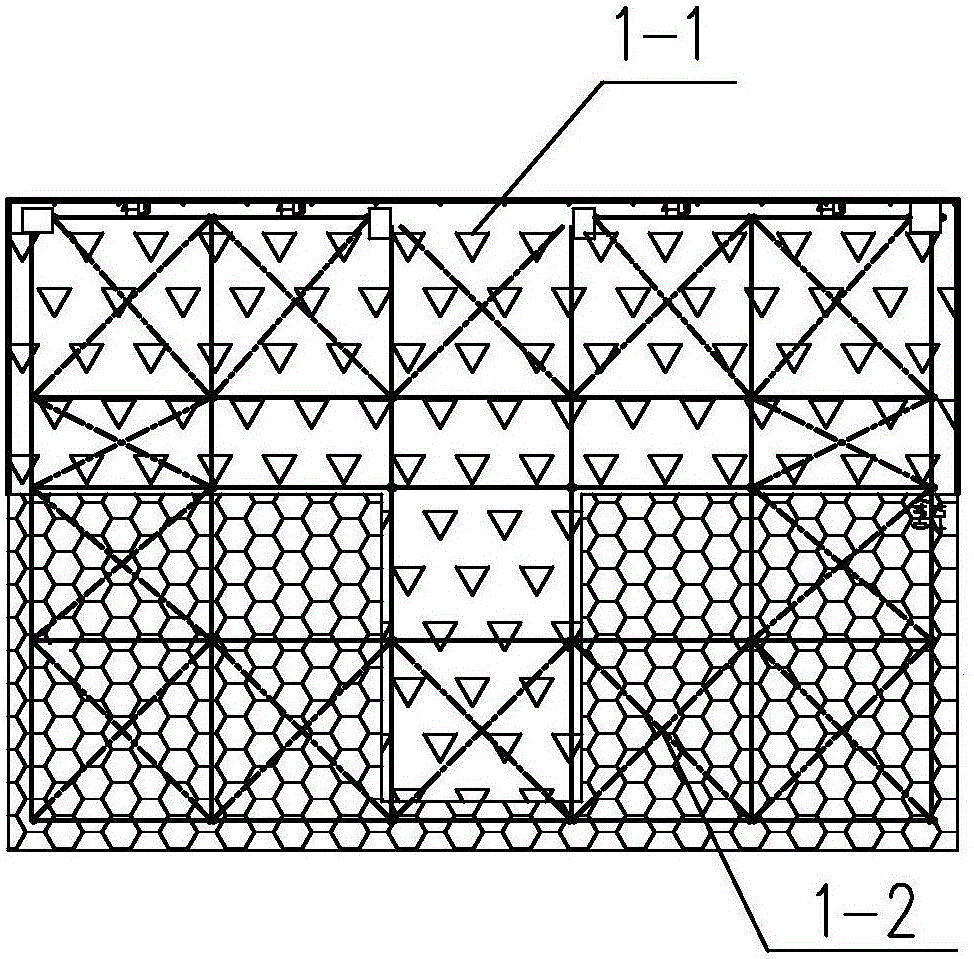

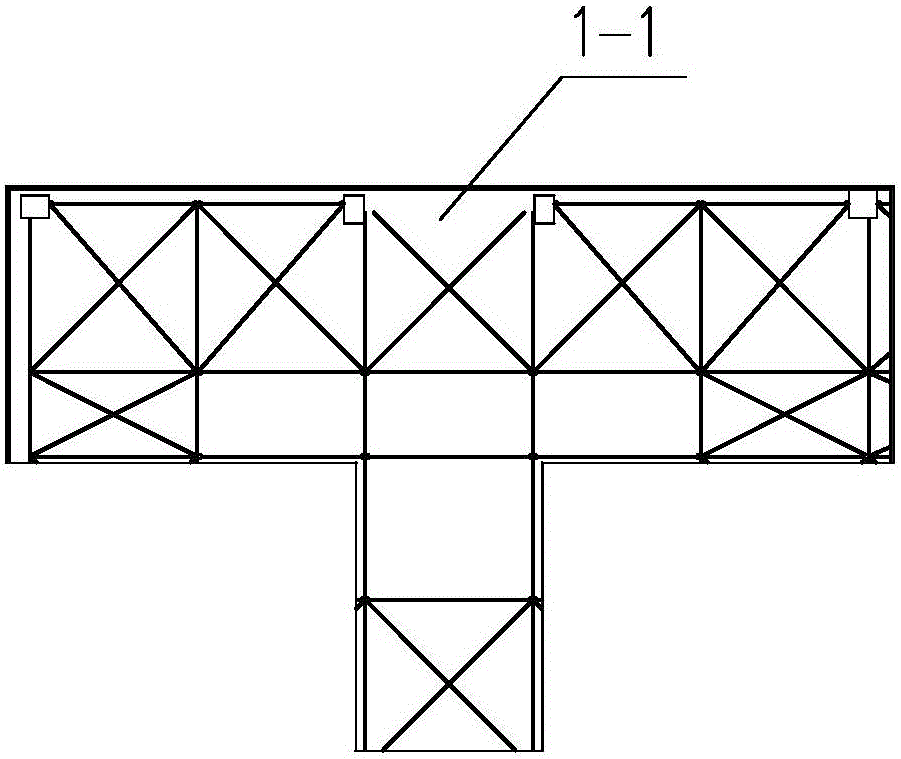

Construction method for long-span overhung specially-shaped limit exceeding structure steel corridor

ActiveCN106013419AStrong targetingSave man hoursBuilding material handlingArchitectural engineeringEngineering

The invention discloses a construction method for a long-span overhung specially-shaped limit exceeding structure steel corridor. The method includes the following steps that firstly, the steel corridor is divided into construction units, wherein the inner part of a corridor structure and middle strip blocks of an upper steel structure of a corridor overhung part are classified as the first construction unit, the remaining part of the corridor overhung part is classified as the second construction unit, and a corridor suspension part is classified as the third construction unit; secondly, a high-altitude bulk assembly method and a cantilever installation method are adopted for finishing construction of the first construction unit on a floor panel of a tower A; thirdly, construction of the second construction unit is finished through integral lifting; and fourthly, construction of the third construction unit is finished through sliding after integral lifting. The high-altitude bulk assembly technology, the integral lifting technology, the sliding after integral lifting technology and the like are applied, work hours are reduced, the material cost and equipment cost are saved, and the requirements for integral control over multiple aspects of the construction process, the quality, the safety, the schedule, the cost and the like are met.

Owner:中建六局第一建设有限公司 +1

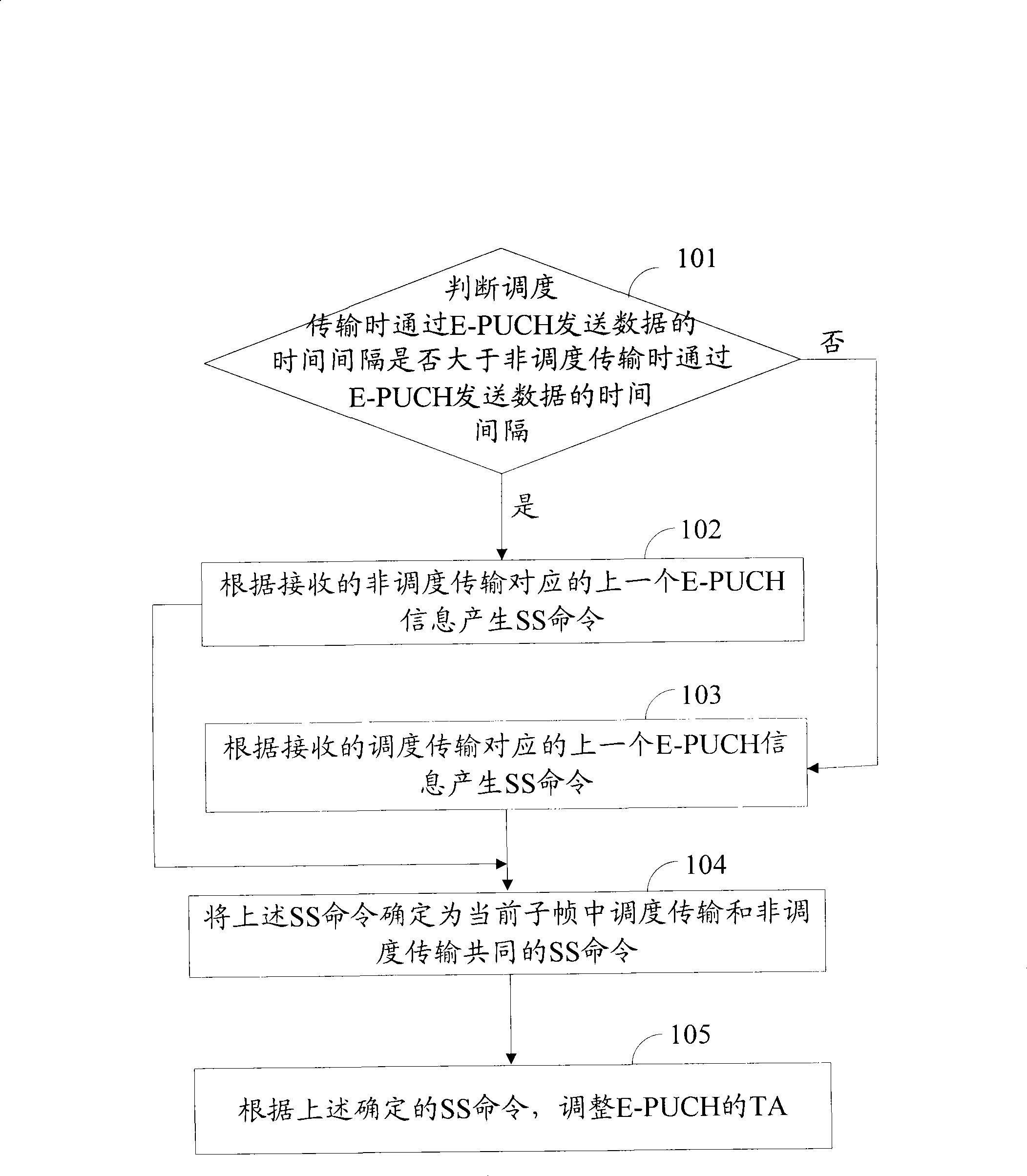

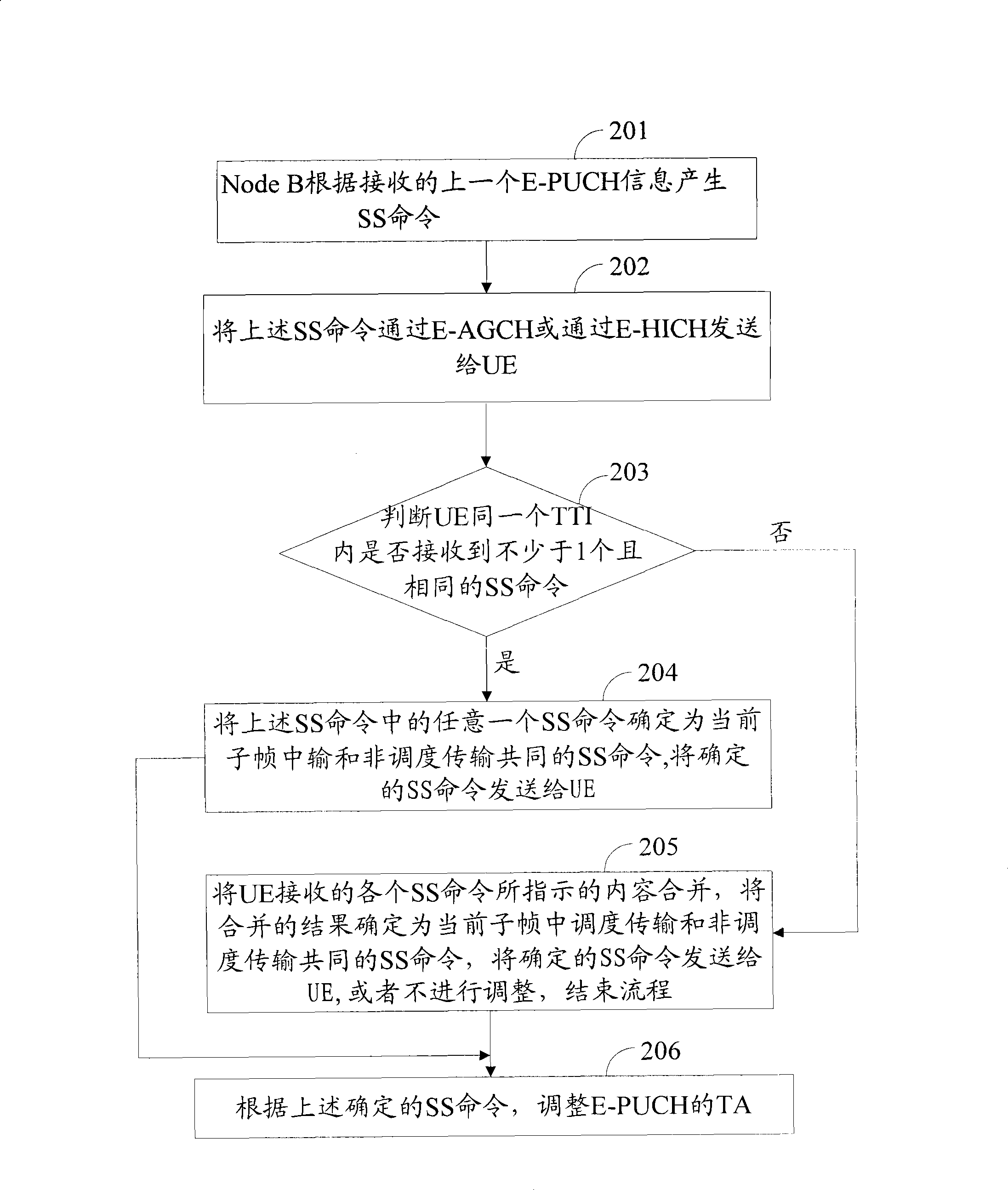

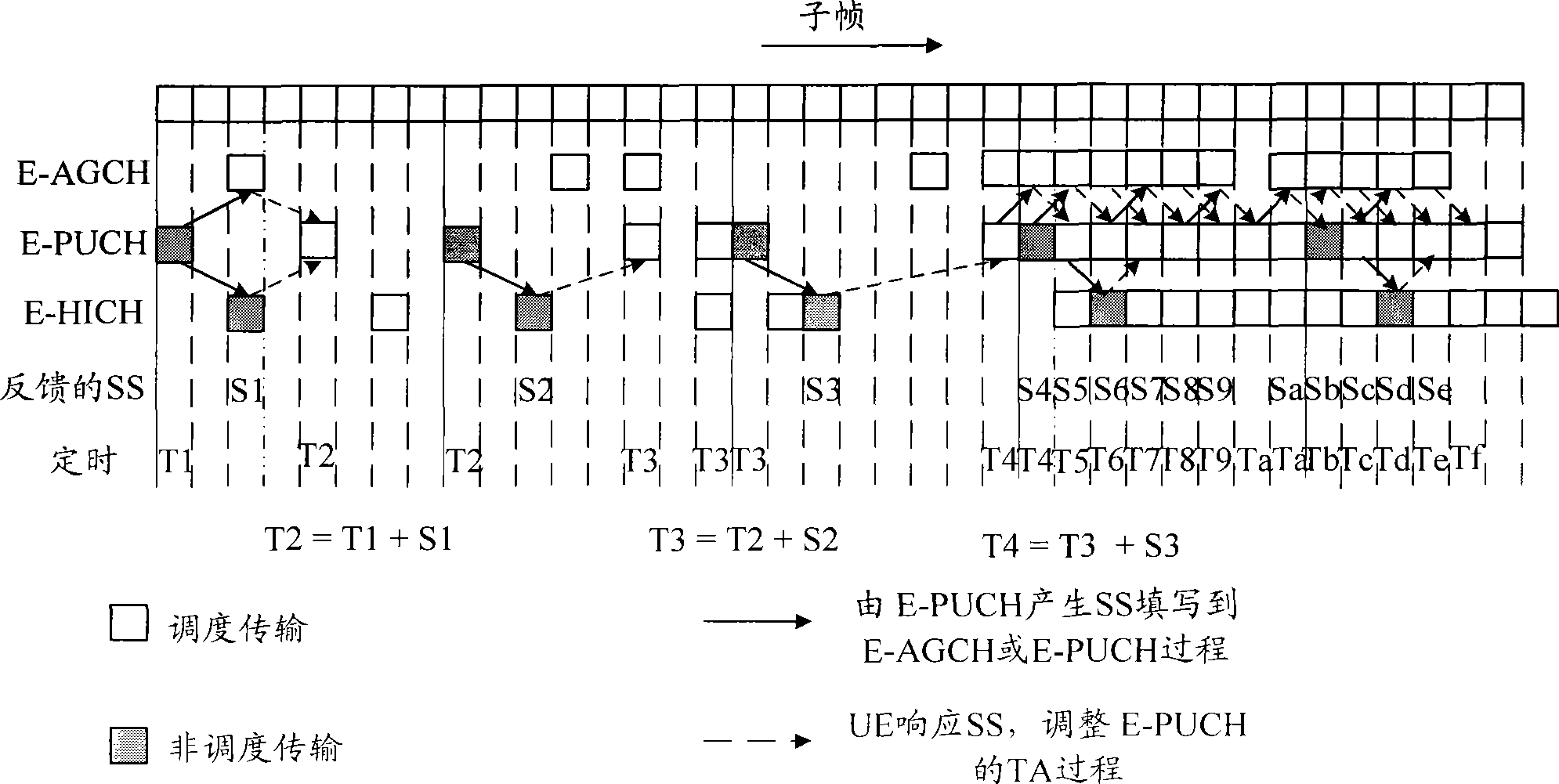

Synchronization control method and apparatus in high-speed uplink packet access technique

ActiveCN101499846AHigh precision of synchronous controlAvoid Independent Synchronous ControlRadio transmission for post communicationDistributed computingTiming advance

Owner:DATANG MOBILE COMM EQUIP CO LTD

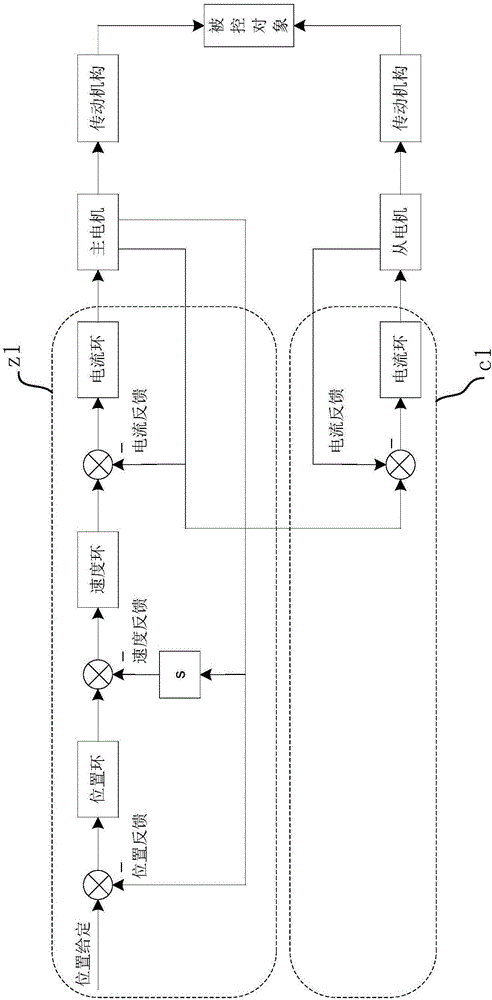

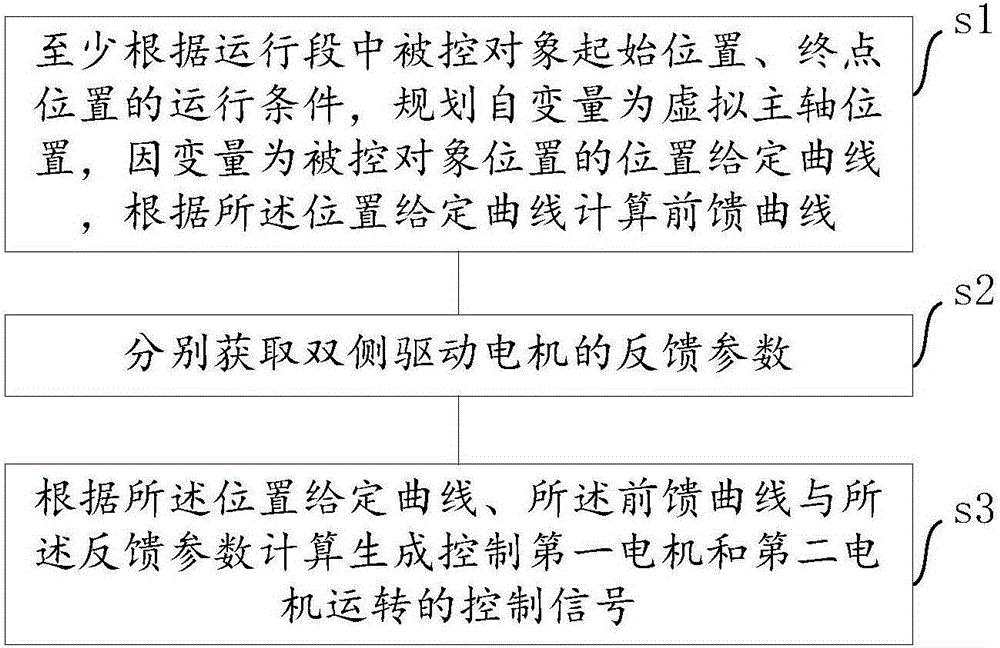

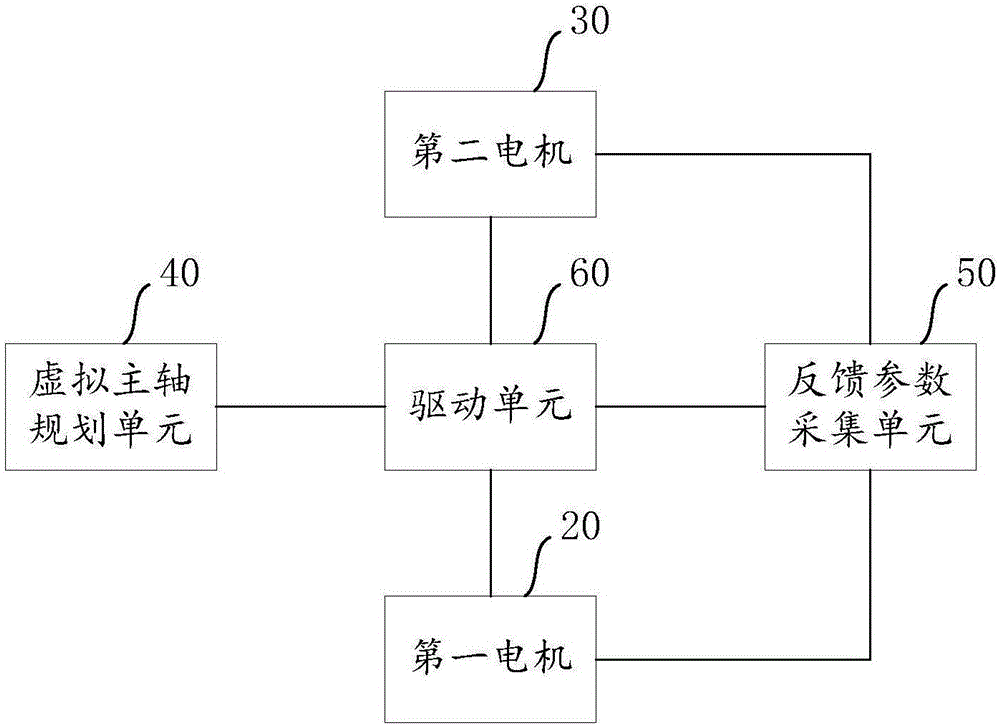

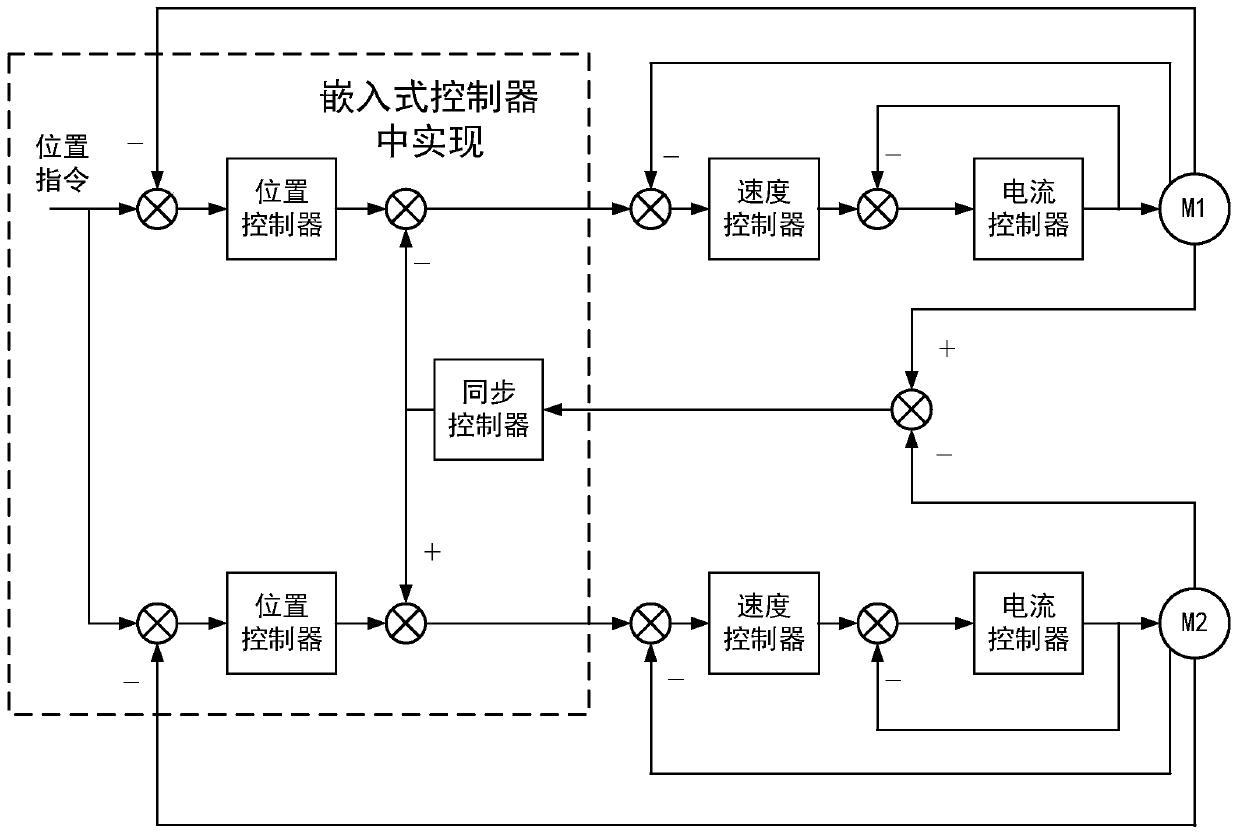

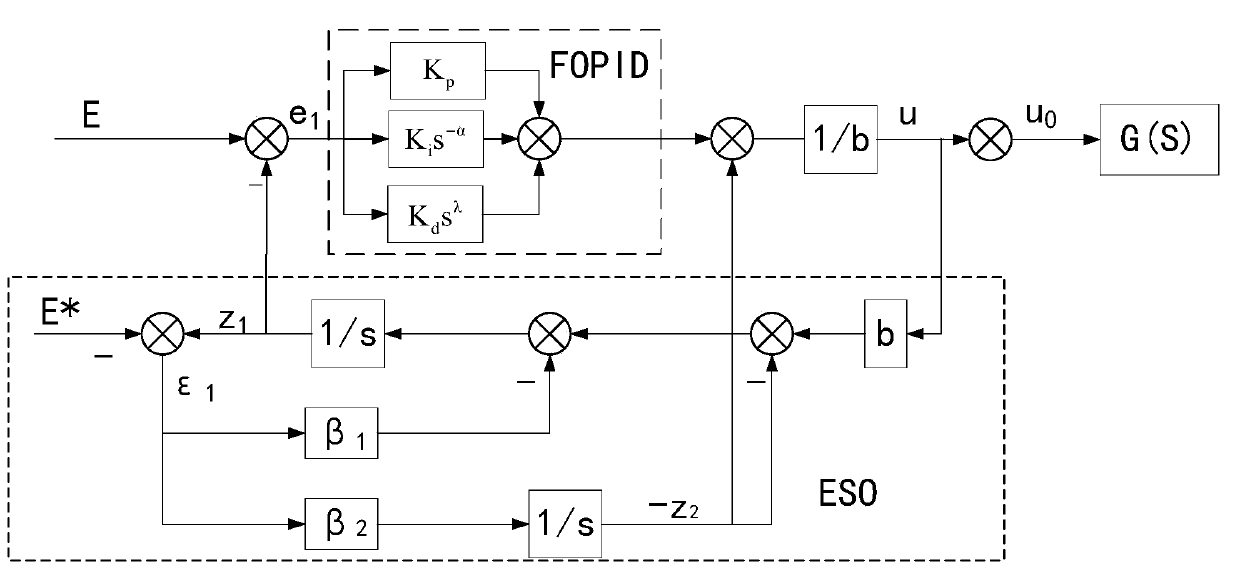

Synchronous control method and synchronous control device for double driving motors at double sides

ActiveCN106773683AHigh precision of synchronous controlHigh control precisionAdaptive controlControl signalSynchronous control

The invention relates to a synchronous control method and a synchronous control device for double driving motors at double sides, wherein the method and the device relate to the field of control technology for double driving motors at the double sides. The method and the device mainly aim to improve synchronous control precision of the double driving motors at the double sides to a controlled object. The method comprises the steps of at least according to operation conditions of a controlled object starting position and a controlled object ending position in an operation period, planning a position-preset curve in which an independent variable is at a virtual main axis position and a dependent variable is at a controlled object position, and calculating a feedforward curve according to the position-preset curve, wherein the feedforward curve comprises a speed feedforward curve which corresponds with the position-preset curve, and a torque feedforward curve that corresponds with the position-preset curve; respectively acquiring feedback parameters of the double driving motors at the double sides; and generating a control signal for controlling operation of the first motor and the second motor according to the position-preset curve, the feedforward curve and the feedback parameters. Compared with prior art, the synchronous control method and the synchronous control device have advantages of high control precision and effective improvement of synchronous control precision of the double driving motors at the double sides to the controlled object.

Owner:北京二十一世纪科技发展有限公司

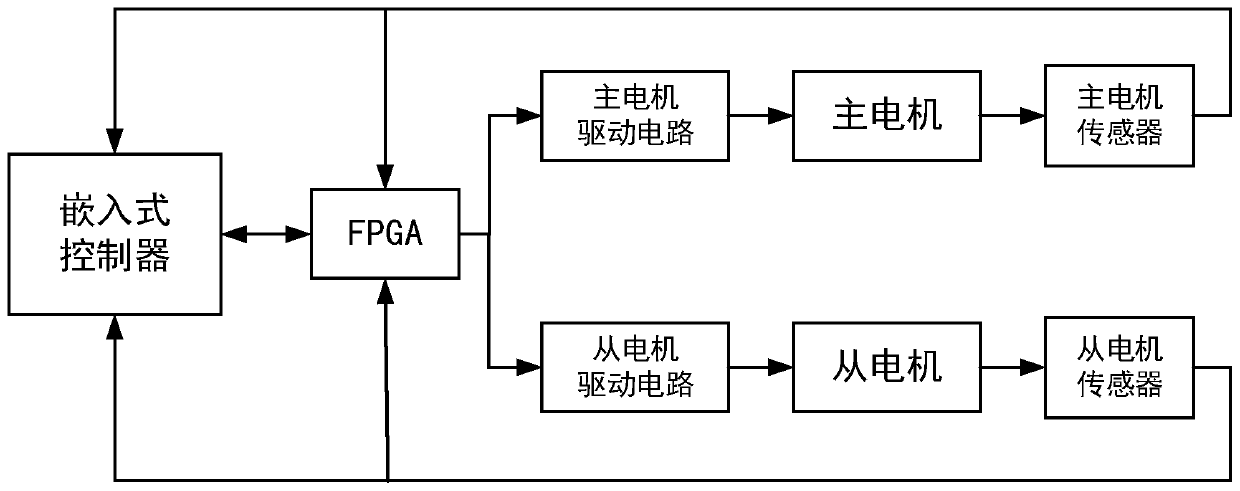

Dual-motor synchronous control device and method

PendingCN111464073AHigh precision of synchronous controlImprove your own precisionAC motor controlElectric motor controlSynchronous controlControl system

The embodiment of the invention discloses a dual-motor synchronous control device and method, relates to the technical field of electromechanical control, and can improve dual-motor synchronous control precision and reduce the response period of a speed loop and a current loop of a master-slave motor servo system. The method is characterized in that an embedded controller, an FPGA controller, a master motor driving circuit, a slave motor driving circuit, a master motor, a slave motor, a master motor sensor and a slave motor sensor are included, wherein the embedded controller is connected withthe FPGA controller through a bus, the FPGA controller is connected with the master motor driving circuit and the slave motor driving circuit, the master motor is connected with the master motor driving circuit, the master motor sensor is connected with the master motor, the slave motor is connected with the slave motor driving circuit, and the slave motor sensor is connected with the slave motor. The method is advantaged in that the method is suitable for a dual-motor synchronous control system.

Owner:NANJING INST OF TECH

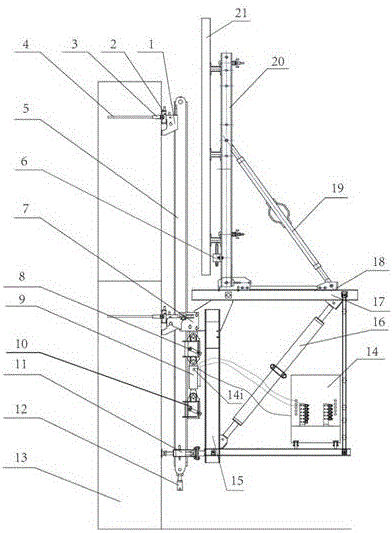

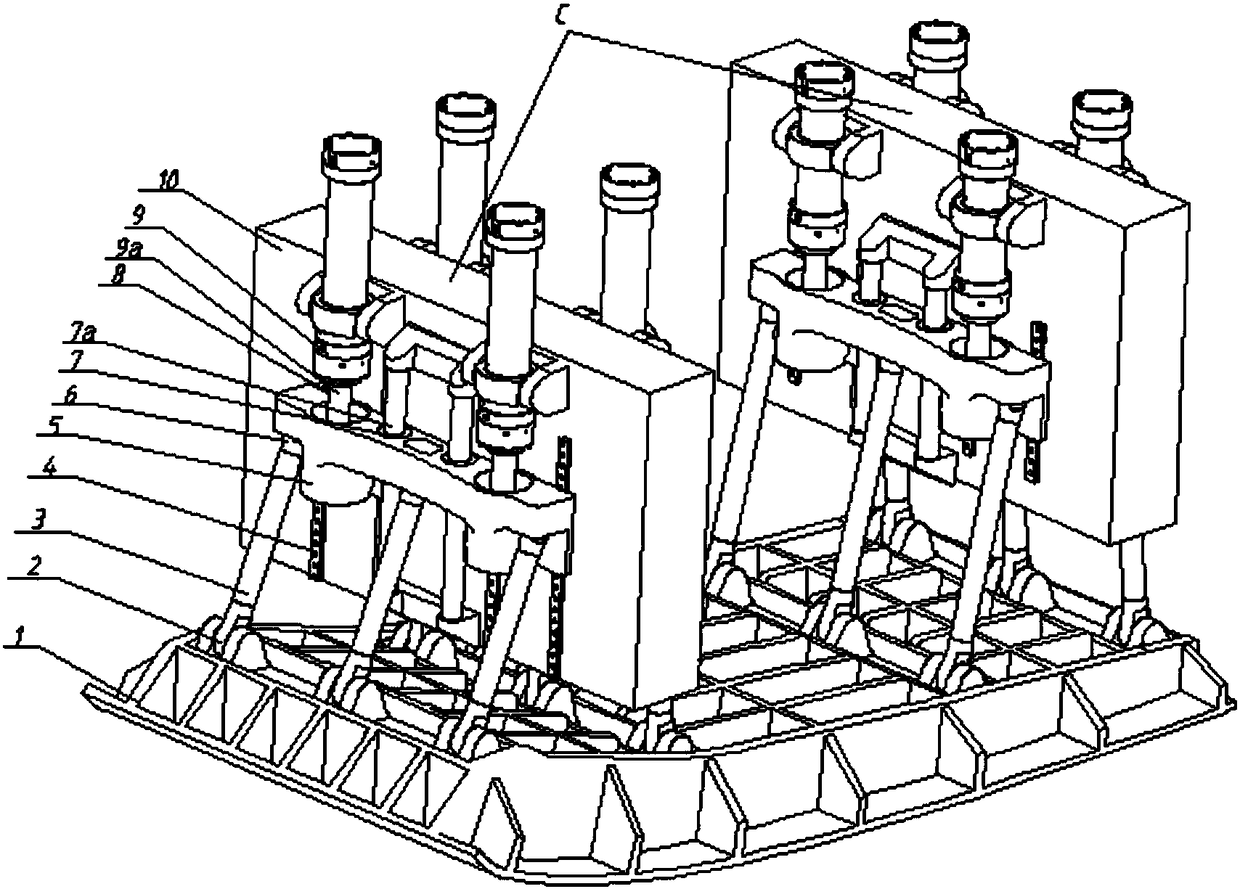

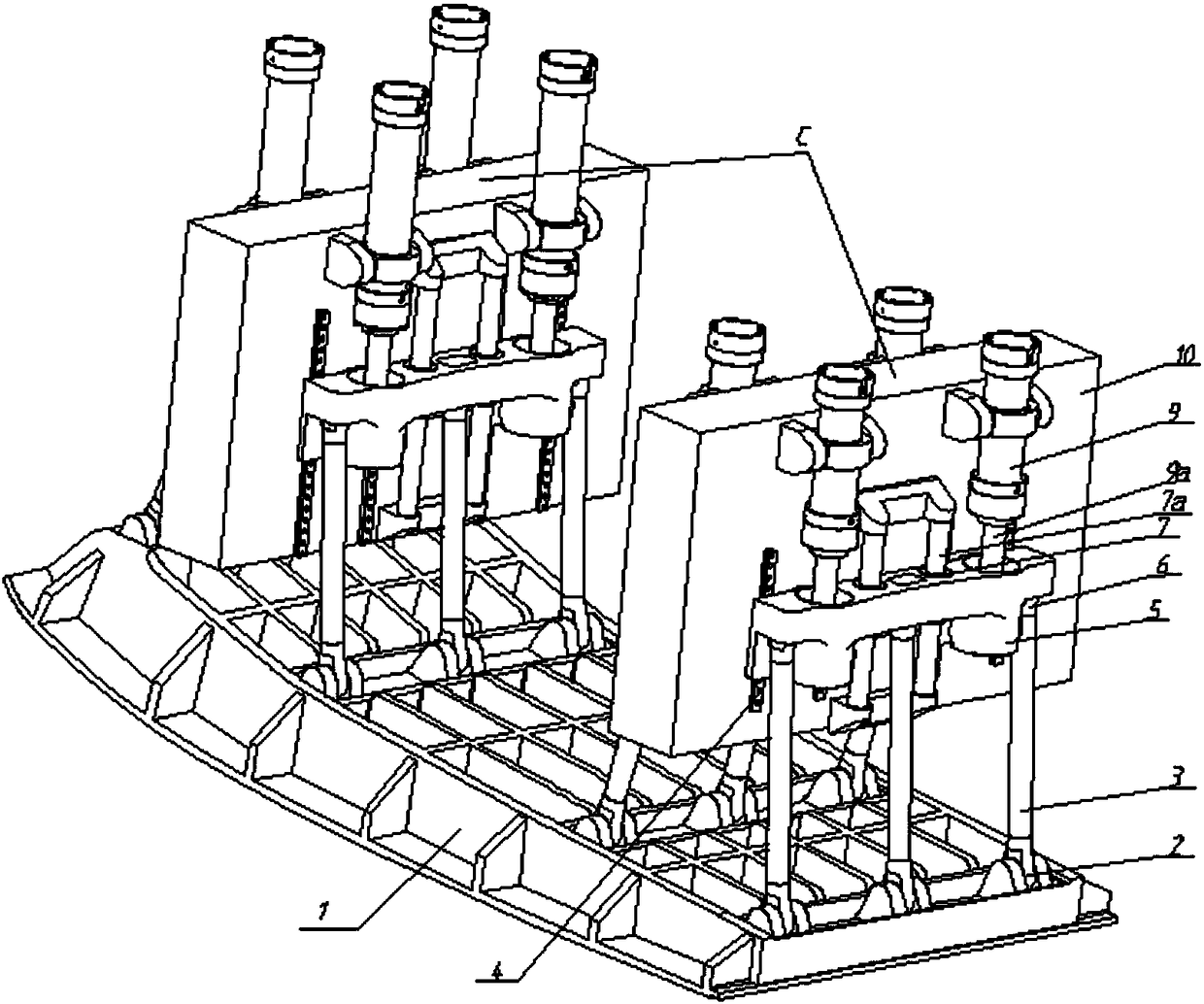

Climbing device of hydraulic climbing formwork system and control method

InactiveCN106567333AImprove bearing capacityHigh precision of synchronous controlDamsDykesSynchronous controlHydraulic pump

A climbing device of a hydraulic climbing formwork system is provided with a lifting device, a track, a step device, a hydraulic pump station and a bearing frame. Fixed fork lugs are fixed to the cylinder ends of climbing jacks, the ends of pistons are connected with movable fork lugs through movable connection structures, the fixed fork lugs and the movable fork lugs are reliably connected with upper climbing boxes and lower climbing boxes through shaft pins; displacement sensors are fixed to the cylinders of the climbing jacks; inlet openings and return openings of the climbing jacks are installed on nozzle blocks and are in the same direction with the axial direction of the cylinders, wherein the return openings are higher than the inlet openings, and the return openings are connected to return cavities in the climbing jacks; and a main control center performs controlling through setting the climbing parameter setting step, the jack cylinder synchronization control strategy and the safety protection strategy. The climbing device of the hydraulic climbing formwork system has the advantages that a set of pumping stations controls multiple climbing points simultaneously, the bearing capacity is great, climbing of multiple formworks can be realized simultaneously, the synchronous control precision is high, fewer operators are needed, and safety and reliability are realized.

Owner:GUIZHOU ROAD & BRIDGE GRP +1

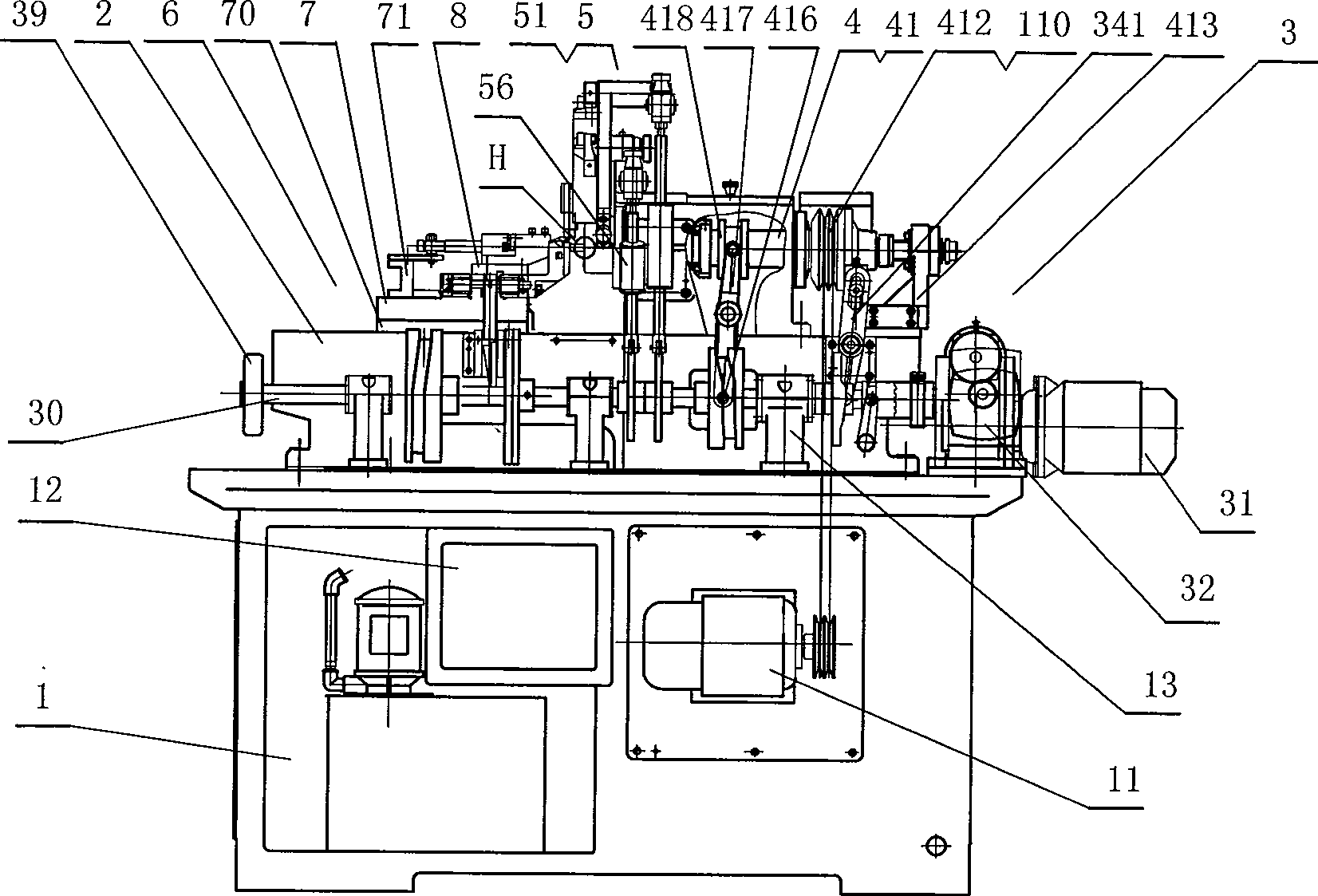

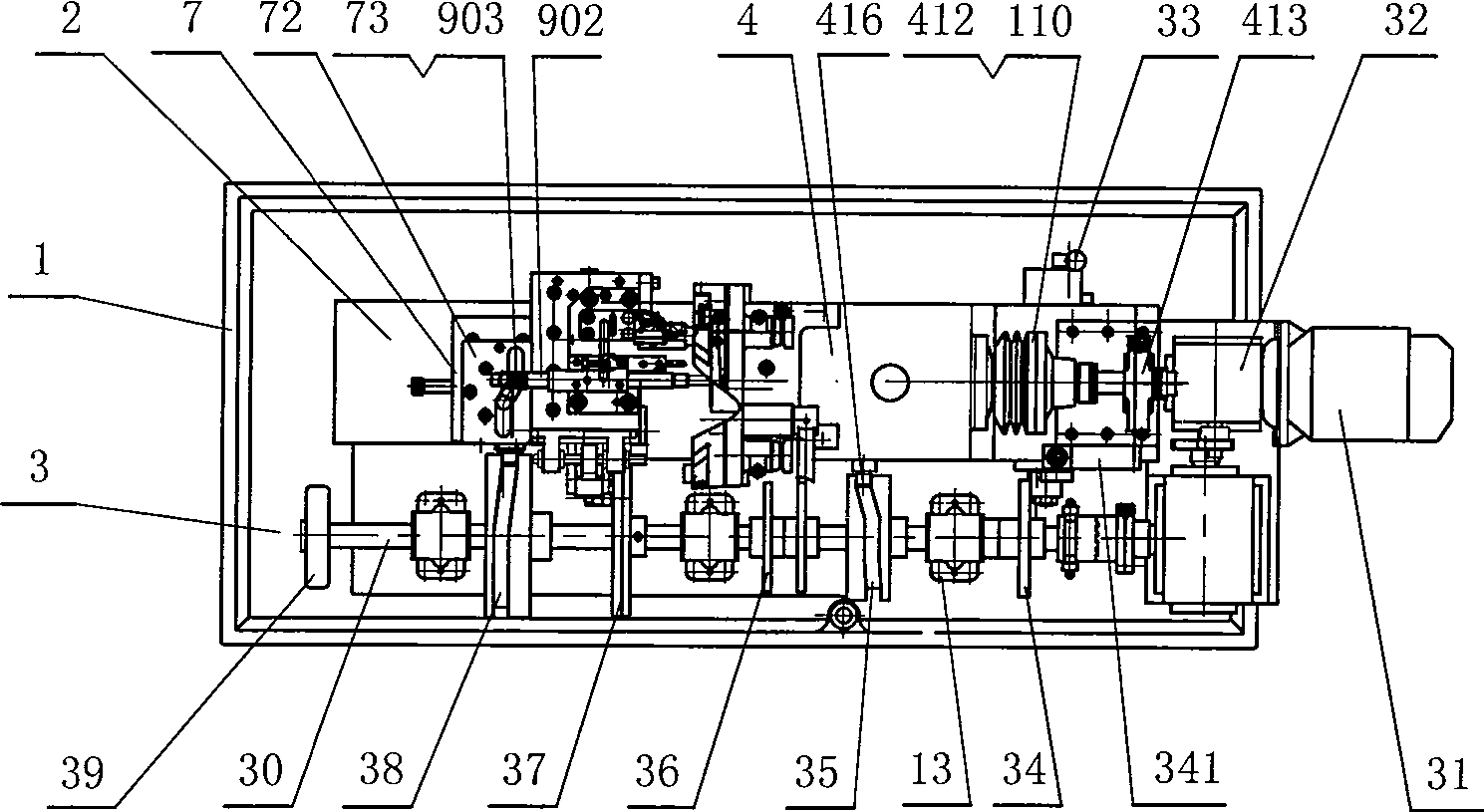

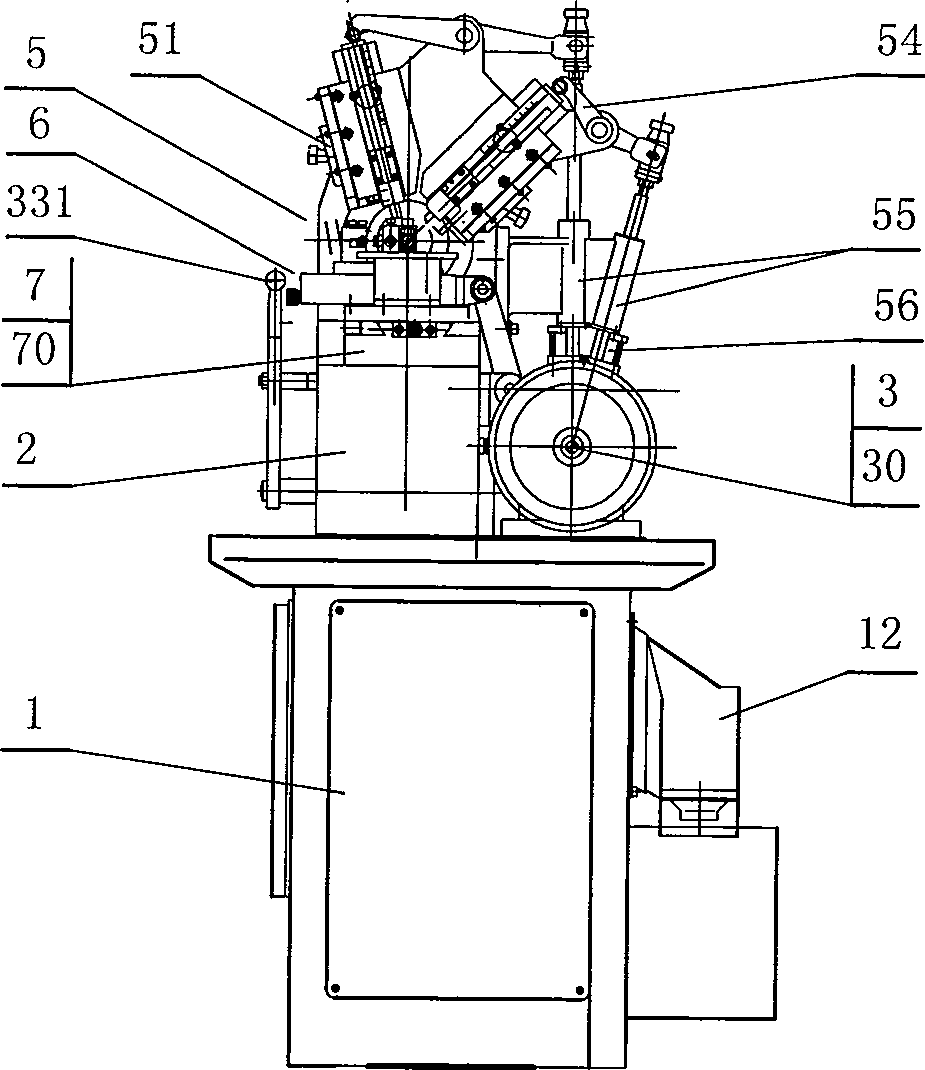

Single spindle automatic lathe for sequential operations by moving cutters along axes parallel to principal axis

InactiveCN100482387CExpand the scope of processing technologySimple structureAutomatic/semiautomatic turning machinesFeeding apparatusReducerCam

An automatic single-shaft lathe based on the sequential job of its cutting tool moving parallelly to the axis of mainshaft is composed of base, lathe body, control unit parallel to lathe body and consisting of control shaft, control motor with speed reducer, workpiece blank feeding cam and clamping cam and the advancing cams for vertical, transverse and longitudinal tool carriages, mainshaft box with mainshaft and elastic clamp on said mainshaft, belt wheel, advancing clamp unit, and horizontal tool carriage consisting of longitudinal and transverse tool carriers, cutting tool and workpiece feeder.

Owner:湘潭市江南凌志科技有限公司

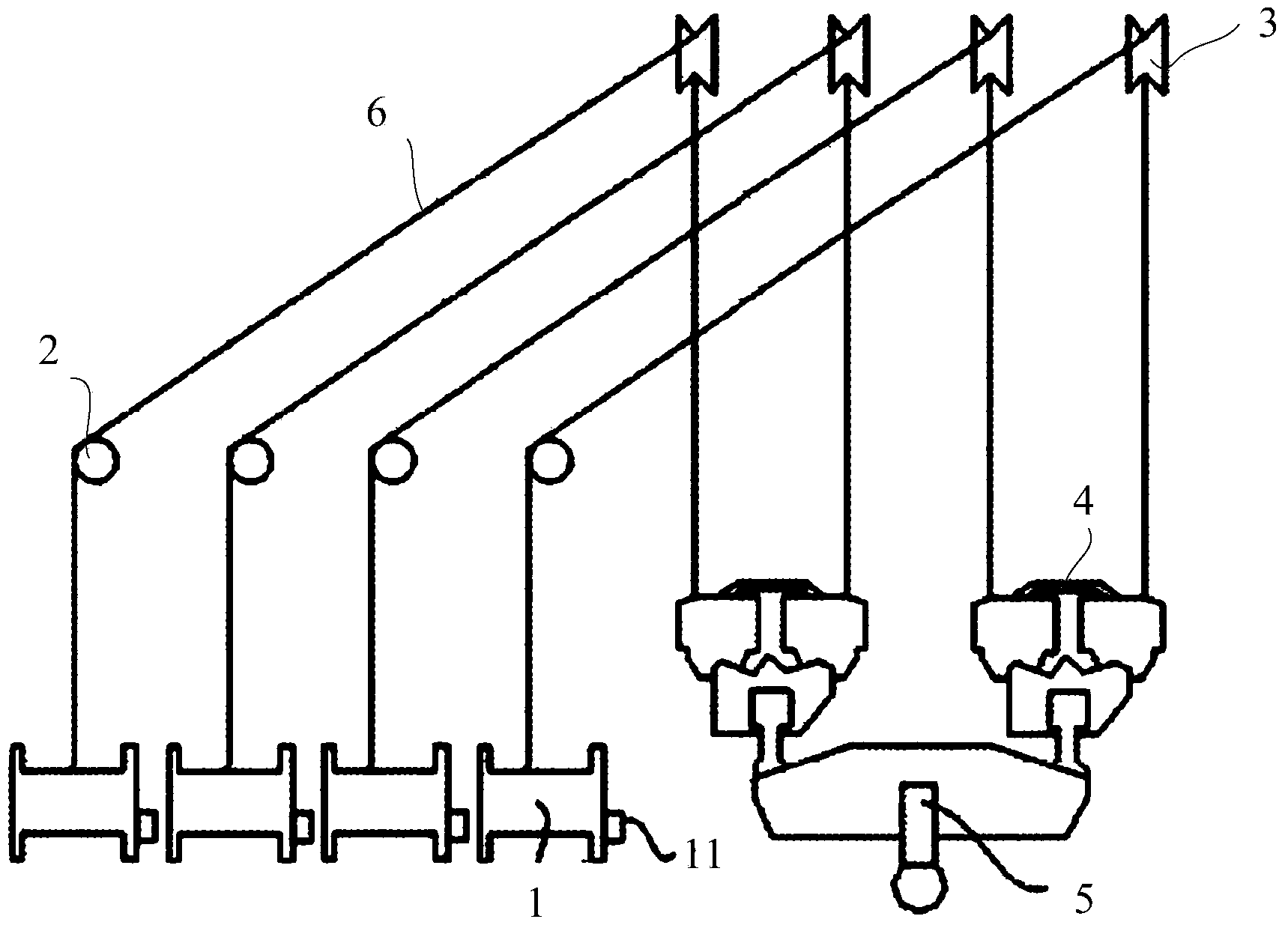

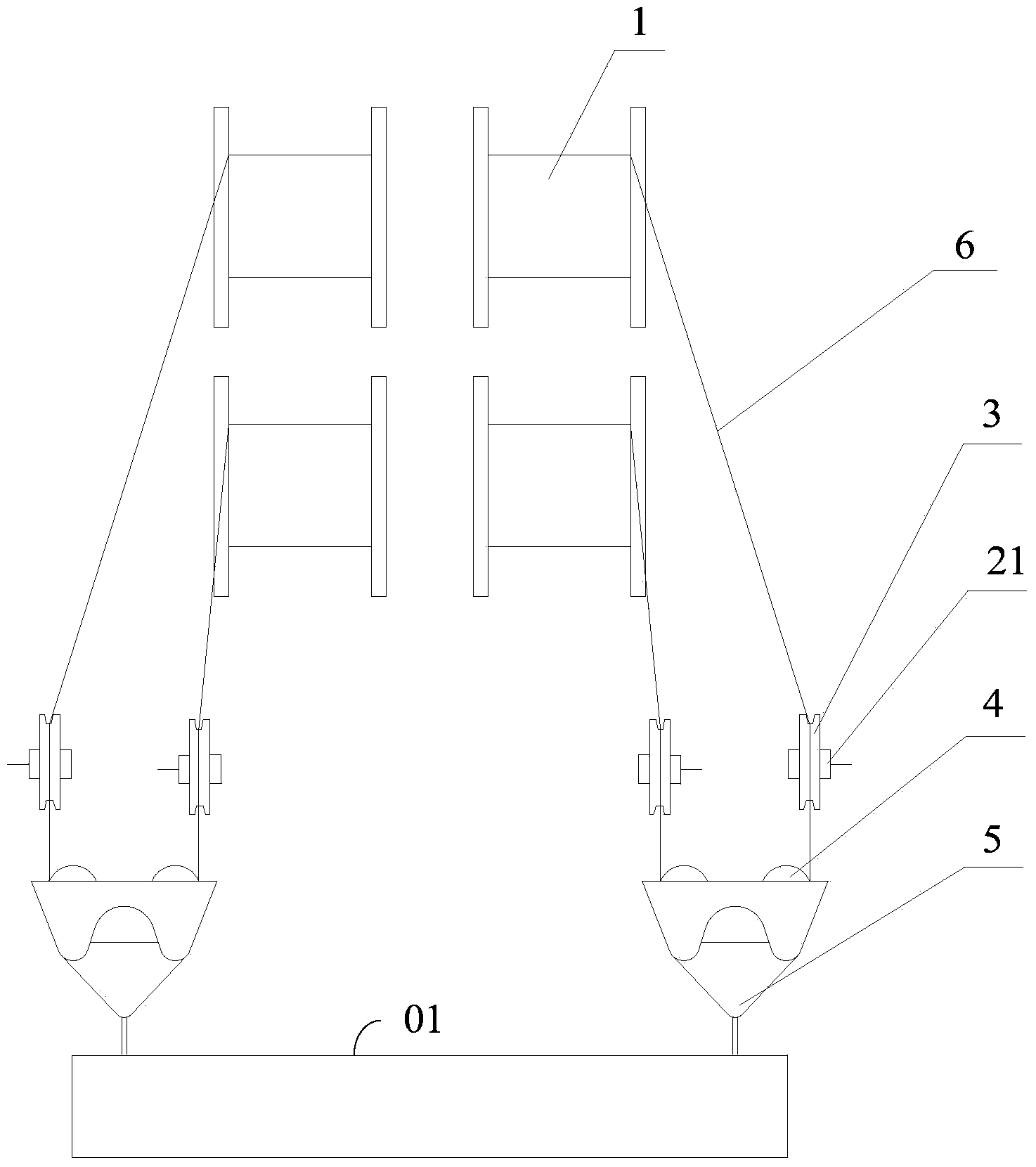

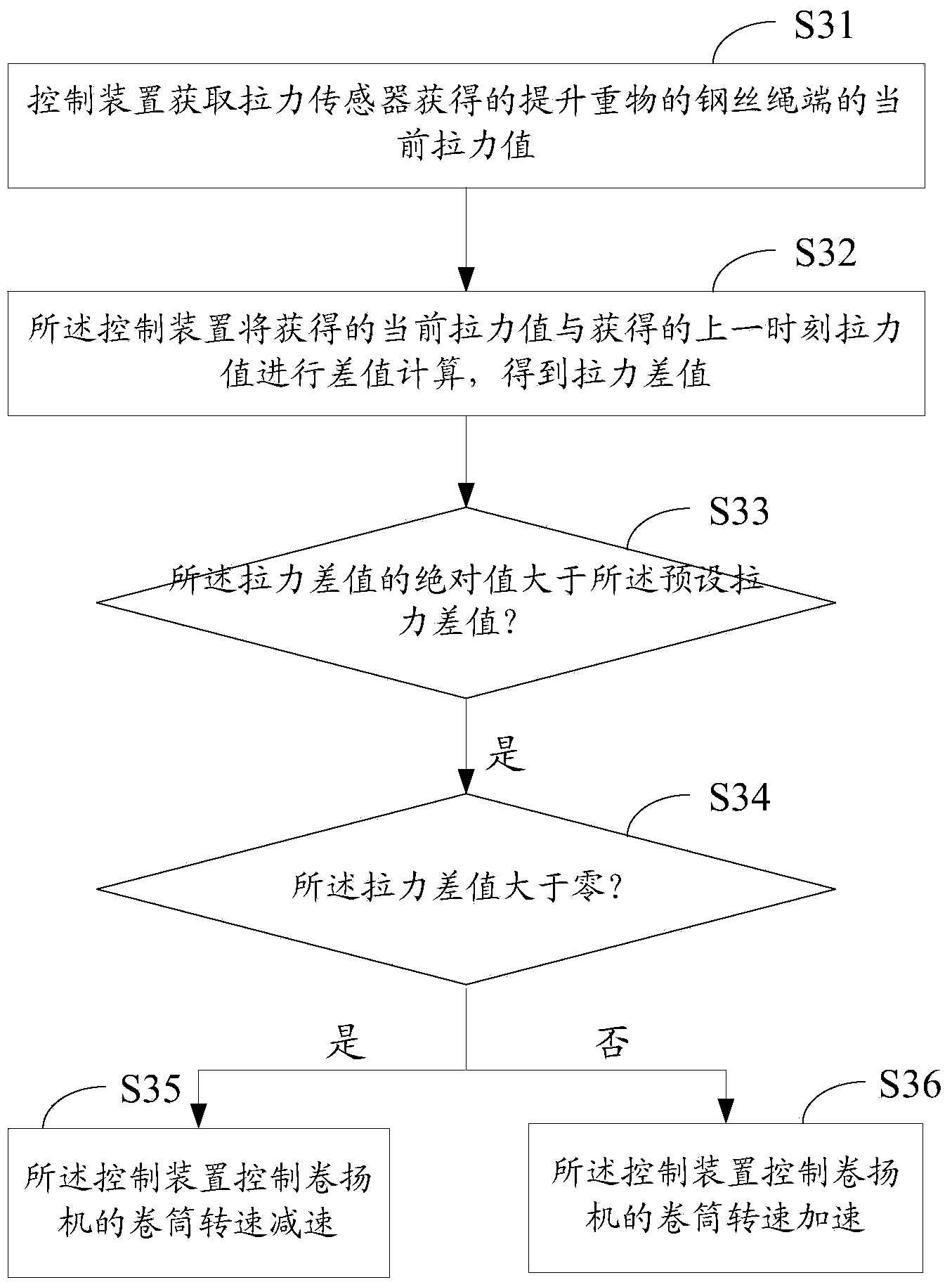

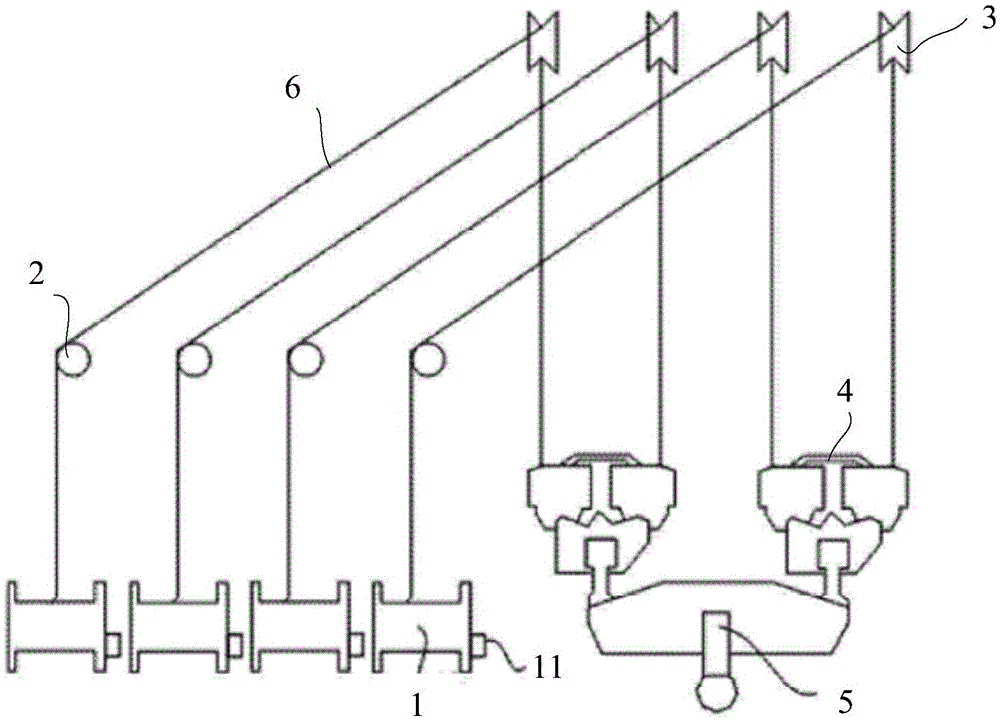

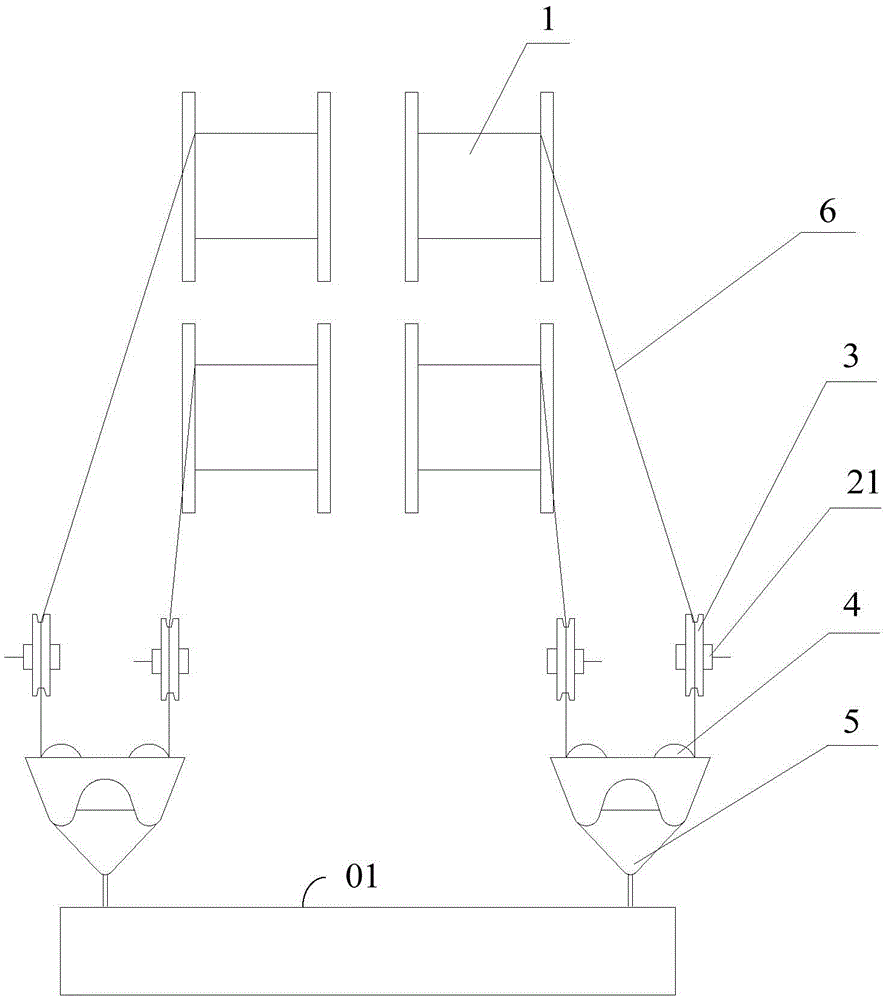

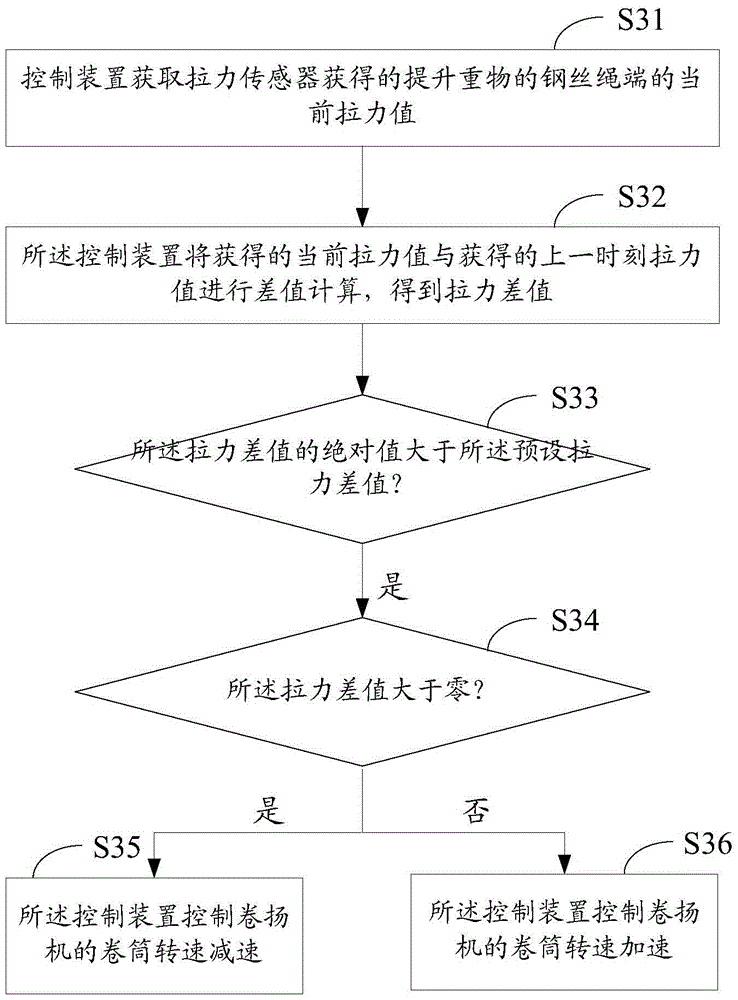

Multi-winch synchronization control method and control system

ActiveCN103523701AAccurate balance lift controlHigh precision of synchronous controlWinding mechanismsPull forceSynchronous control

The invention provides a multi-winch synchronization control method and control system. The control system comprises a control device and a plurality of pull force sensors. Each pull force sensor is hinged to one arm head pulley of a multi-winch synchronization mechanism. The control device connected with the pull force sensors acquires a current lifting pull force value, obtained by the pull force sensors, at a steep wire rope end, and performs deviation calculation on the current pull force value and the previous pull force value to obtain a pull force difference value; under the circumstance that the absolute value of the current pull force value is larger than the preset pull force difference value pre-stored by the control device, when the pull force different value is larger than zero, the control device controls winding drums of the winches to slow down, and when the pull force difference value is smaller than zero, the control device controls the winding drums of the winches to accelerate. Due to the fact that the steel wire rope end is close to a hanging hook, balance lifting control of the hanging hook can be accurate by the control method collecting pull force value of the steel wire rope end, and multi-winch synchronization control precision can be increased effectively.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

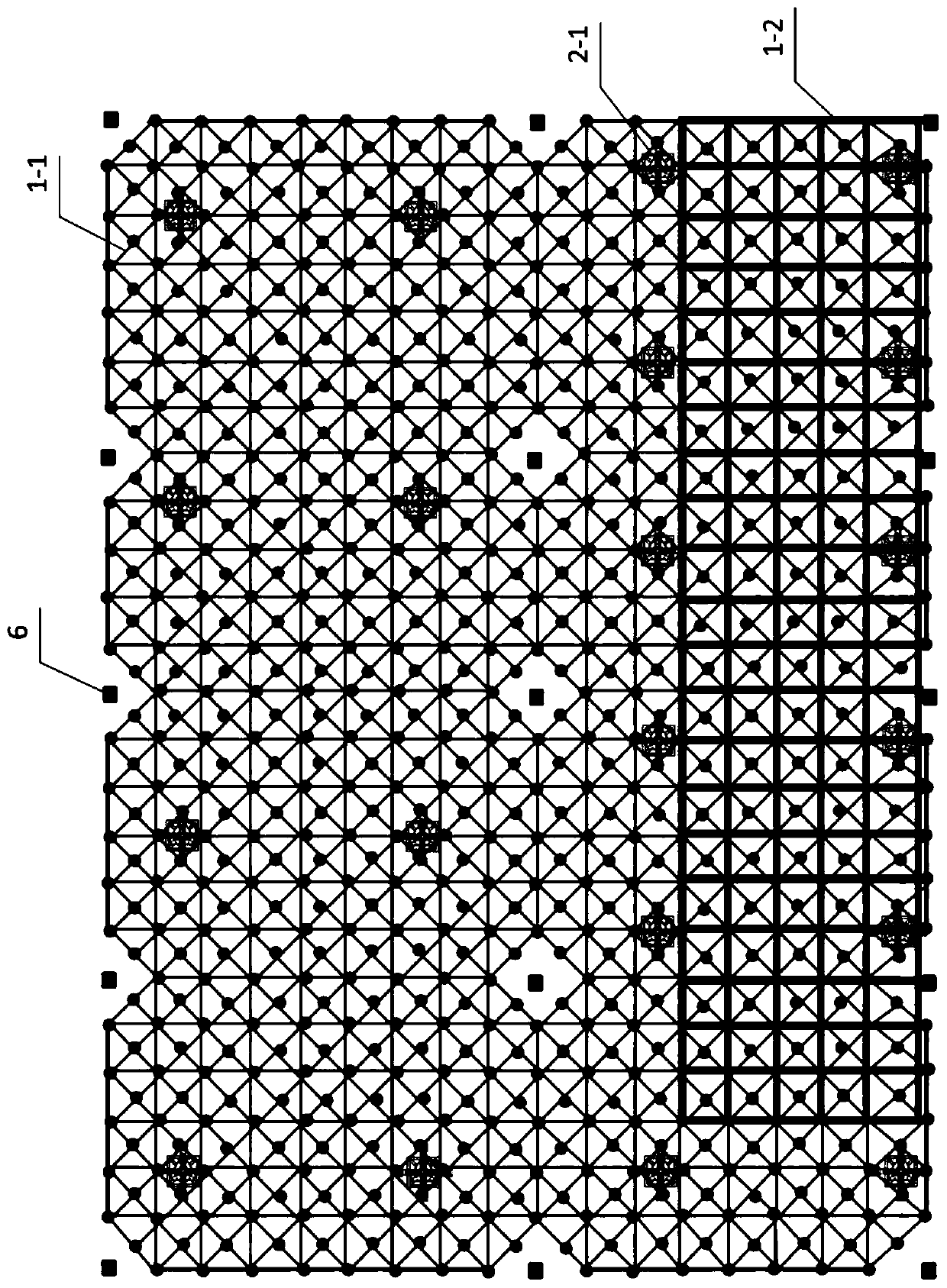

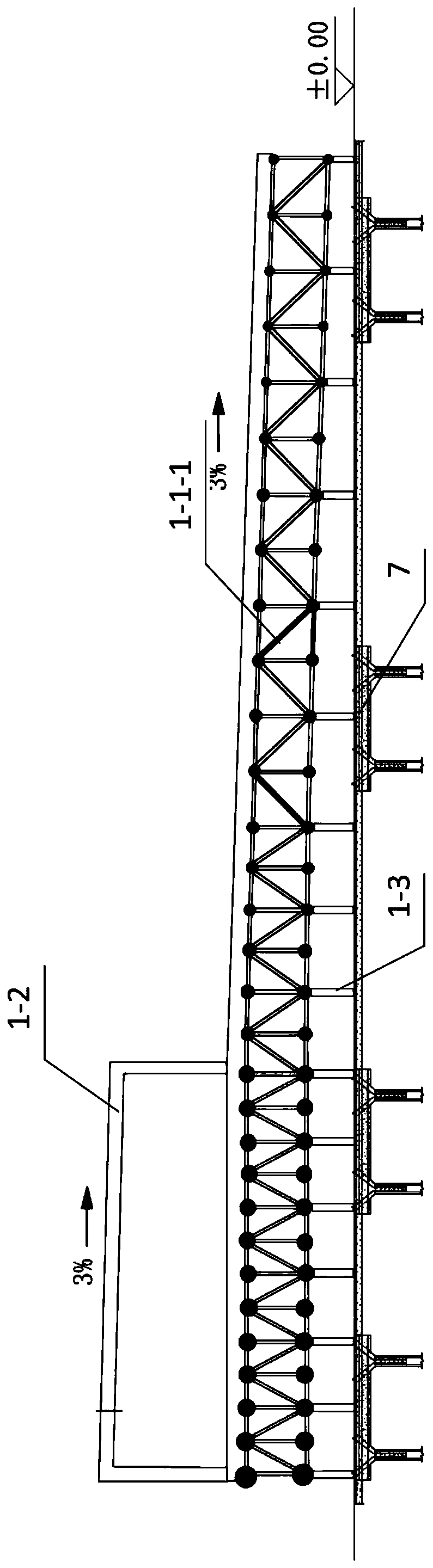

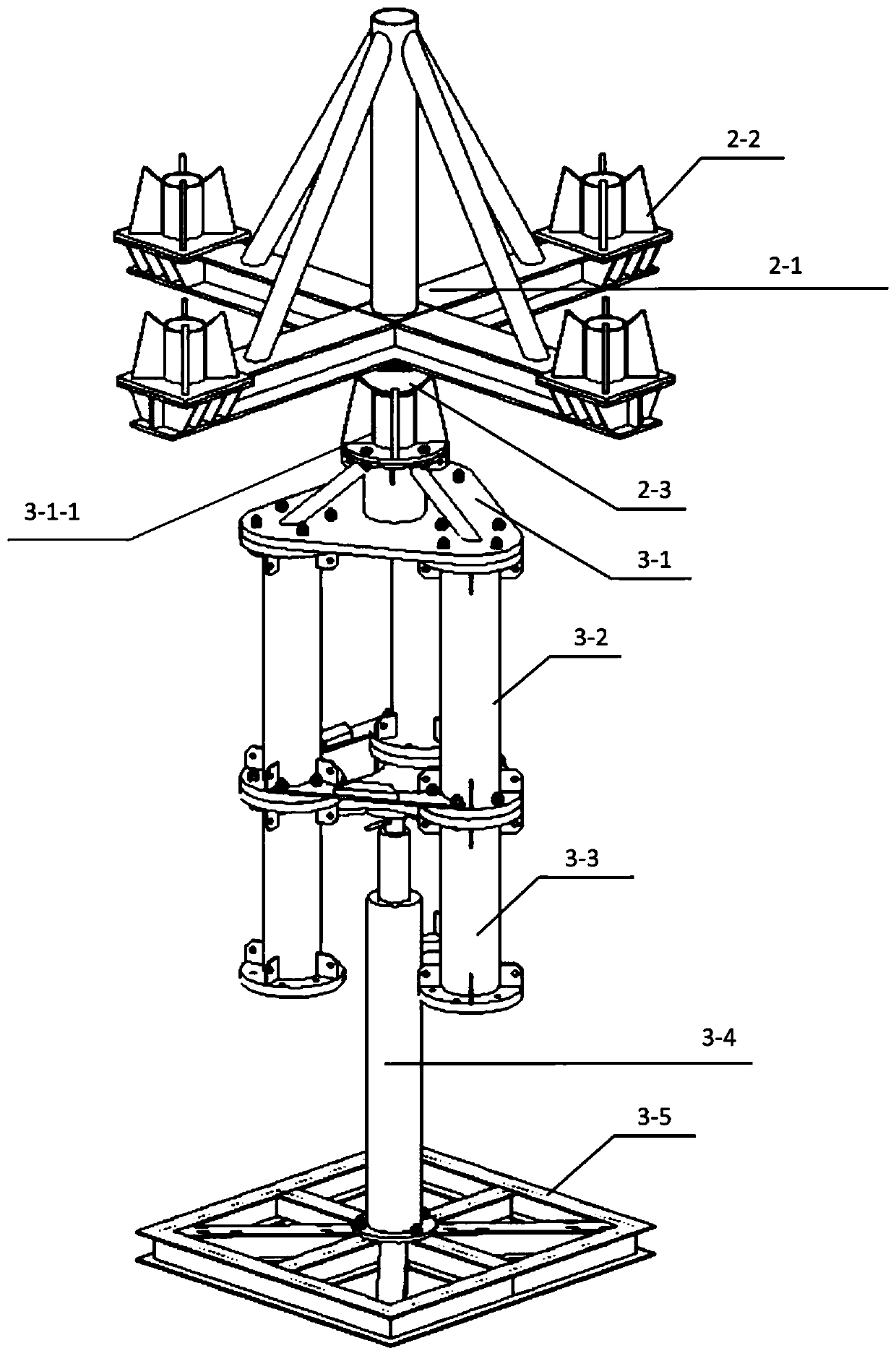

Large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method

ActiveCN110820950AReduced ground assembly heightGuaranteed installation qualityLifting framesBuilding constructionsButtressArchitectural engineering

The invention discloses a large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method. The method comprises the following steps that 1, acorresponding number of jacking foundations are constructed on a terrace according to a plurality of set jacking point locations; 2, after the terrace is hardened, ground splicing and acceptance inspection of combined steel structures are performed; 3, jacking equipment is installed, and jacking is performed; 3.1, ground assembling of crossed joists is performed on the multiple set jacking pointlocations; 3.2, the crossed joists are lifted to the positions of net rack upper chord balls; 3.3, hemispherical hinged supports are concentrically welded to the bottoms of the crossed joists; 3.4, the combined steel structures achieve supporting conversion from net rack lower chord balls supported by buttresses to the net rack upper chord balls supported by jacking frames through a jack; 3.5, synchronous jacking is performed; 3.6, supplementing and splicing installing of net rack support position balls and connecting rod pieces thereof can be performed, and then the whole structure falls backin position. Overhead operation can be greatly reduced, and safety and reliability are achieved.

Owner:中建六局第一建设有限公司 +1

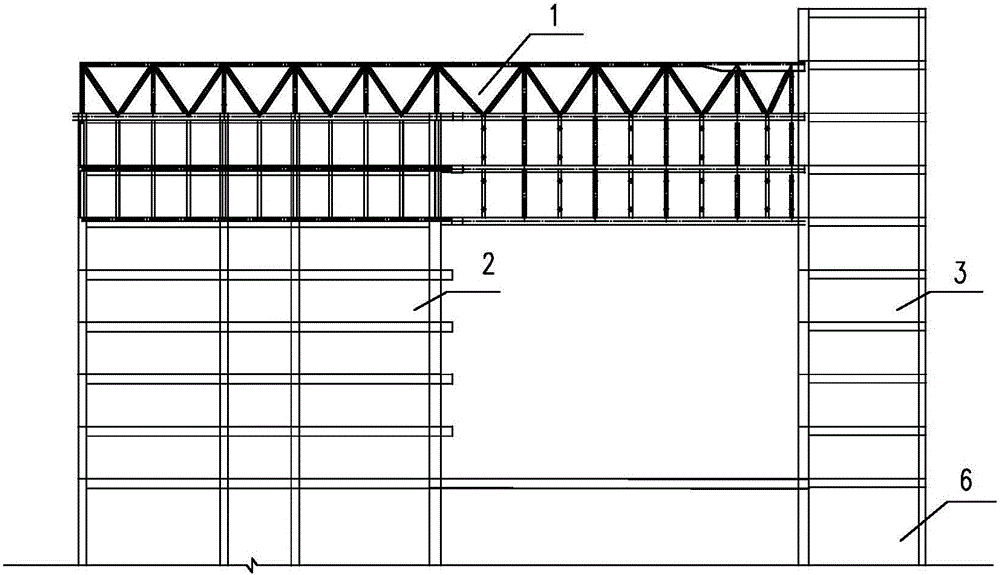

Construction method for large-span overhung ultra-limit structure

ActiveCN106013453ASolve the problem that cannot be builtReduce security risksBuilding constructionsArchitectural engineeringTower

The invention discloses a construction method for a large-span overhung ultra-limit structure. The method includes the following steps that 1, construction unit classification is carried out on the ultra-limit structure, wherein the internal part of the structure and a middle strip block of an upper steel structure of the overhung part of the structure are classified as a first construction unit, and the rest part of the overhung part is classified as a second construction unit; 2, construction of the first construction unit is completed on a tower floorboard through a high-altitude assembly method and a cantilever installation method; 3, construction of the second construction unit is completed through integral lifting and slipping after integral lifting. According to the method, the multiple technologies of high-altitude assembly, integral lifting, slipping after integral lifting and the like are adopted, labor time is shortened, material expense and equipment expense are reduced, and the requirement for integral control over the construction technology, quality, safety, progress, cost and the like is met.

Owner:中建六局第一建设有限公司 +1

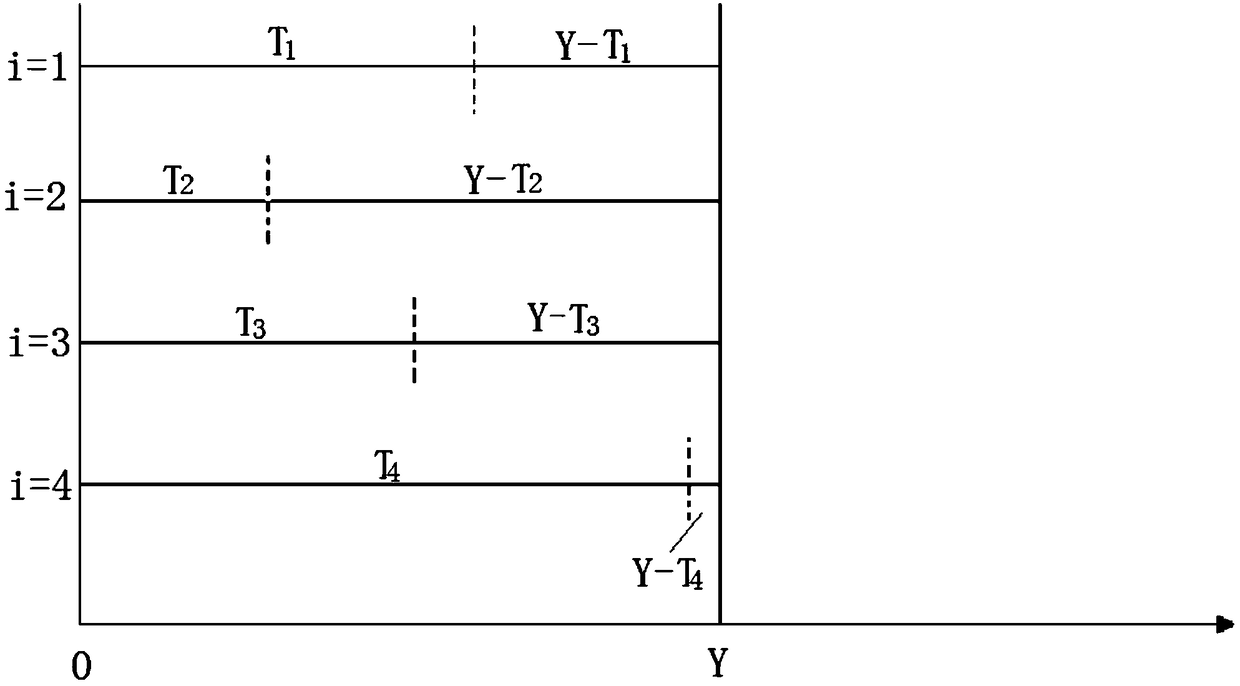

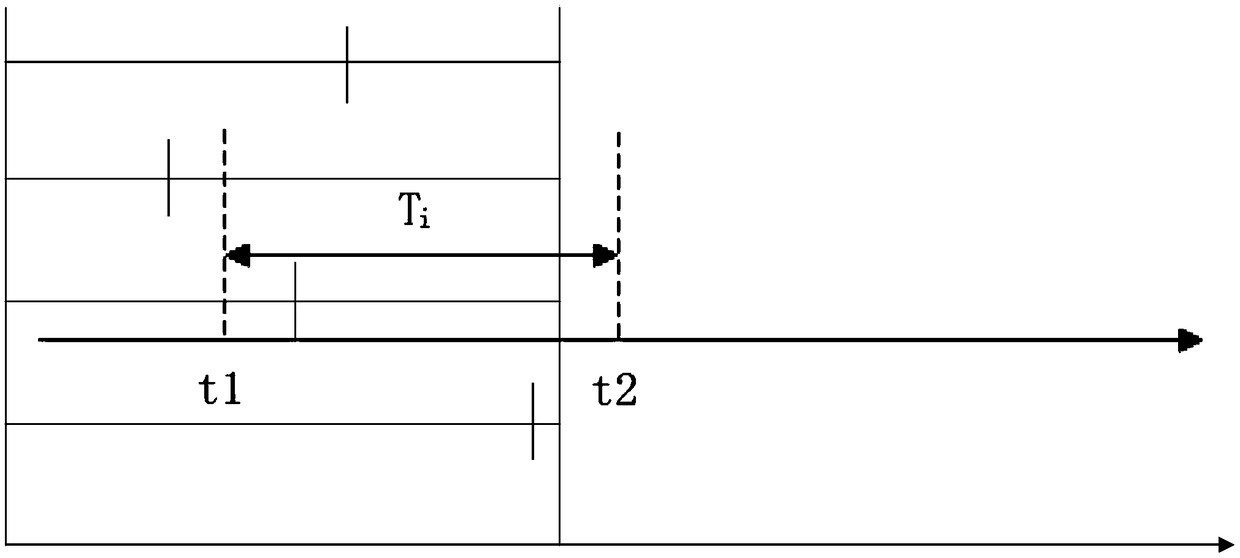

Bus-based servo motor synchronous control method

InactiveCN109361330AHigh precision of synchronous controlLow costSingle motor speed/torque controlAutomatic controlControl system

The invention provides a bus-based servo motor synchronous control method and belongs to the technical field of automatic control. The bus-based servo motor synchronous control method comprises: allowing a control system to send dry running commands to servo drivers, and acquiring response delay time Ti of a corresponding servo motor of each servo driver by bus measuring; comparing the response delay times of the servo motors, and selecting the maximum value; setting overall delay value Y greater than or equal to the maximum value; allowing the control system to delay for Y-Ti time and then send commands to the servo drivers. The bus-based servo motor synchronous control method helps solve the problem that the prior structure or control program is complex. The bus-based servo motor synchronous control method is suitable for synchronous control of servo motors in a system.

Owner:广东旭展科技有限公司

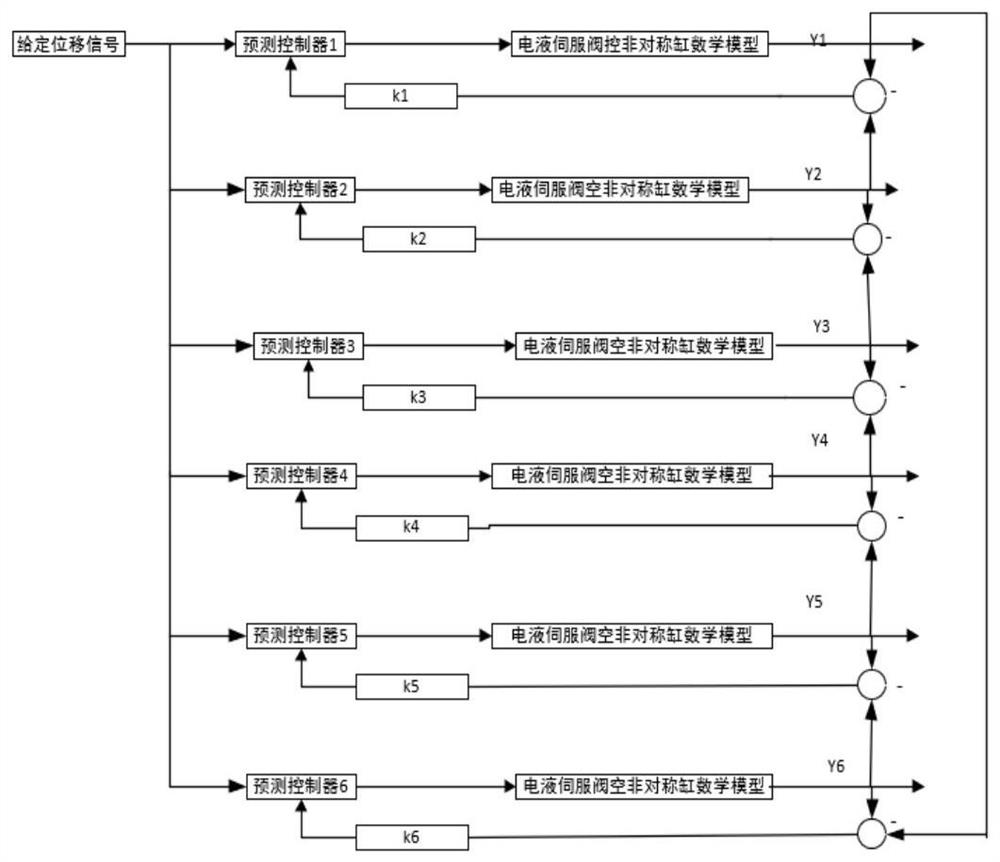

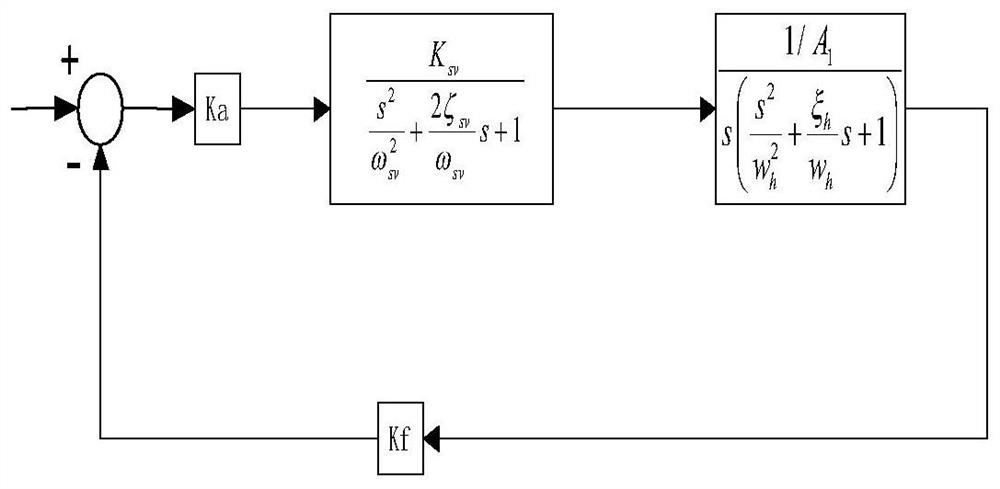

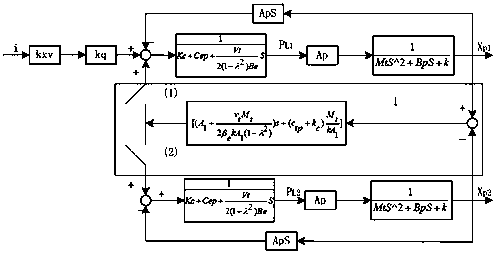

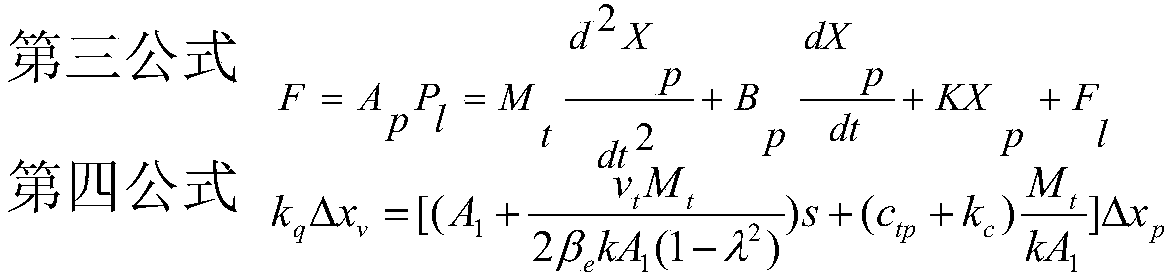

Synchronous control method based on parallel movement of multiple hydraulic cylinders of heave compensation platform

ActiveCN113431814AImprove position control performanceHigh precision of synchronous controlServomotorsServometer circuitsHydraulic cylinderSynchronous control

The invention discloses a synchronous control method based on parallel movement of multiple hydraulic cylinders of a heave compensation platform. The synchronous control method comprises the following steps that a mathematical model of an electro-hydraulic servo valve controlled asymmetric hydraulic cylinder system is established; a predictive controller is designed based on the established mathematical model, an optimal control law is obtained, and a single electro-hydraulic servo channel is controlled to achieve accurate position tracking; and a synchronous compensation controller is designed based on the predictive controller in combination with an annular coupling control strategy, synchronous errors among six hydraulic cylinders are compensated, and synchronous control over multiple electro-hydraulic servo valve controlled asymmetric cylinder channels is achieved. Position control over the single electro-hydraulic servo valve control asymmetric cylinder channel and synchronous control over multiple electro-hydraulic servo valve control asymmetric cylinder channels are achieved, the position control precision and synchronous control performance of the system are improved, and it is guaranteed that the heave compensation platform operates stably to compensate irregular movement of a ship.

Owner:JIANGSU UNIV OF SCI & TECH

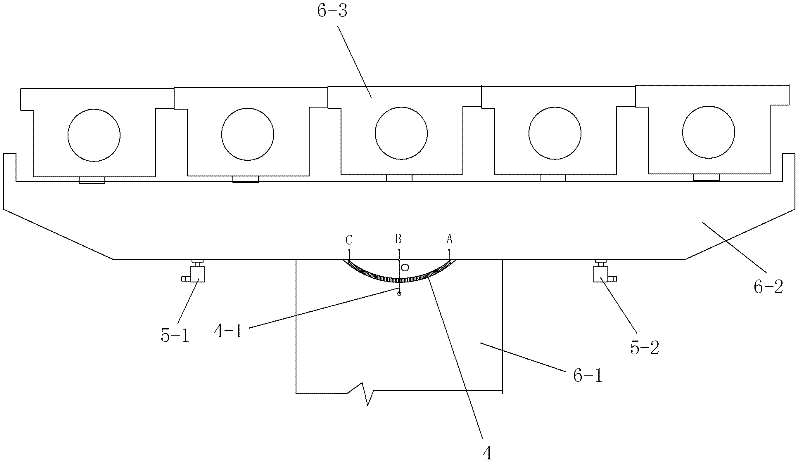

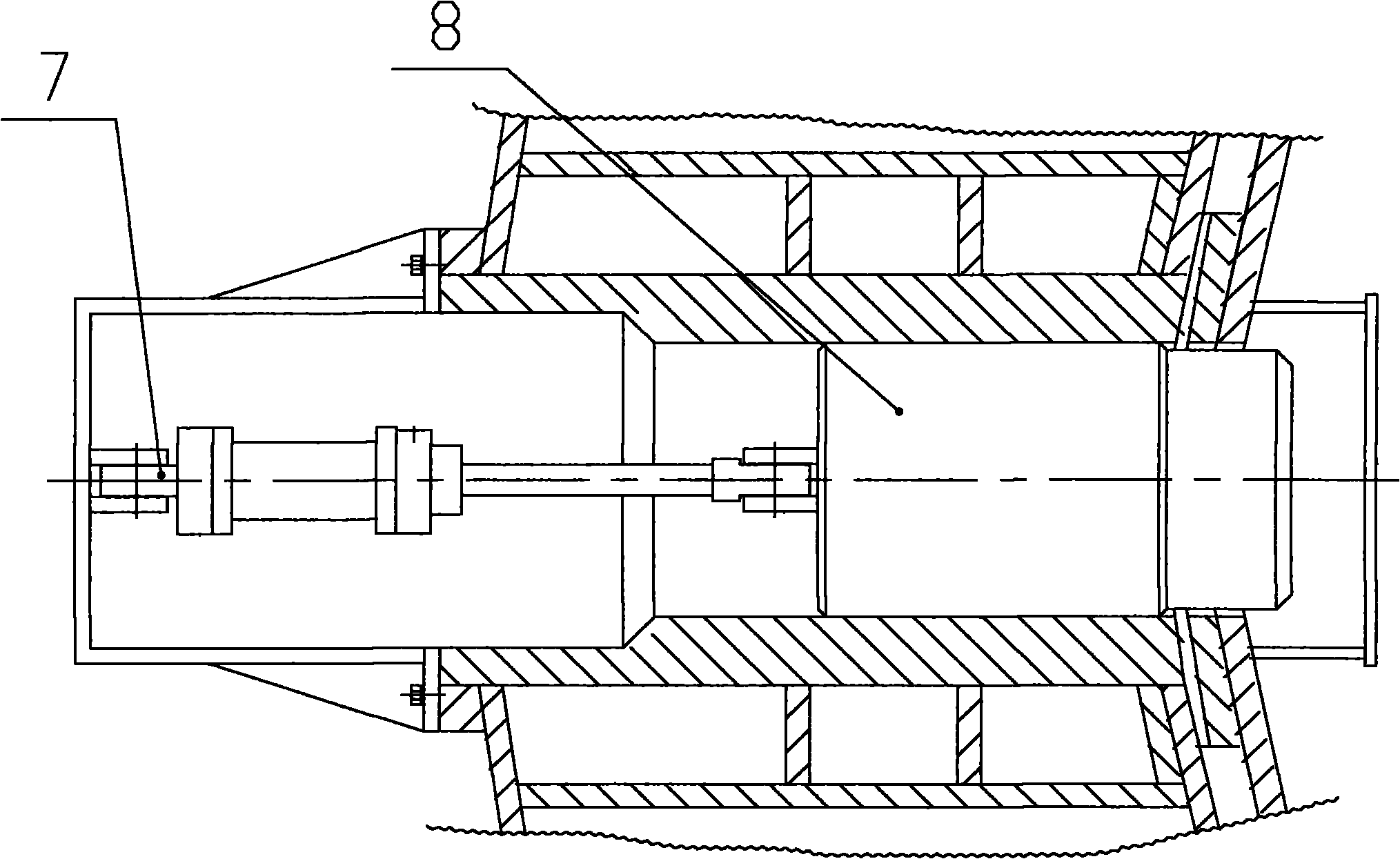

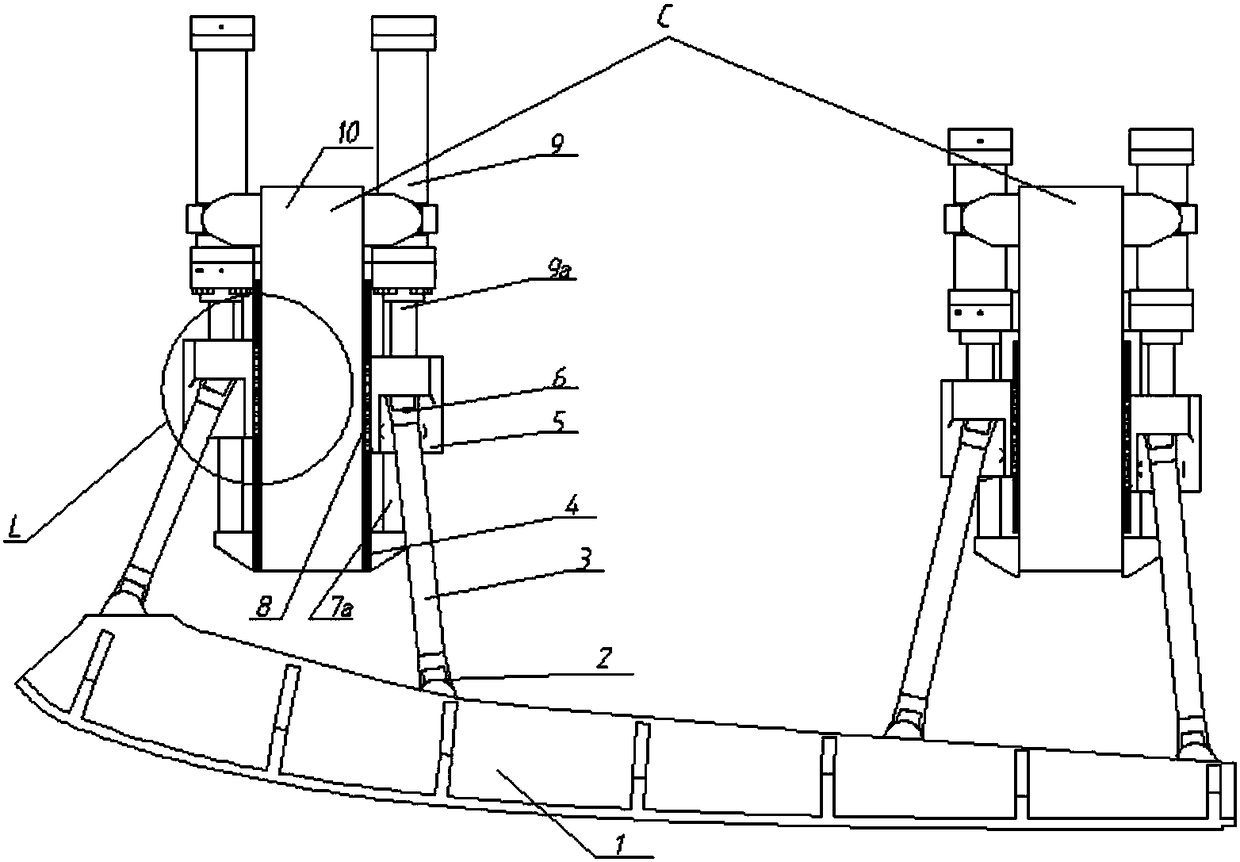

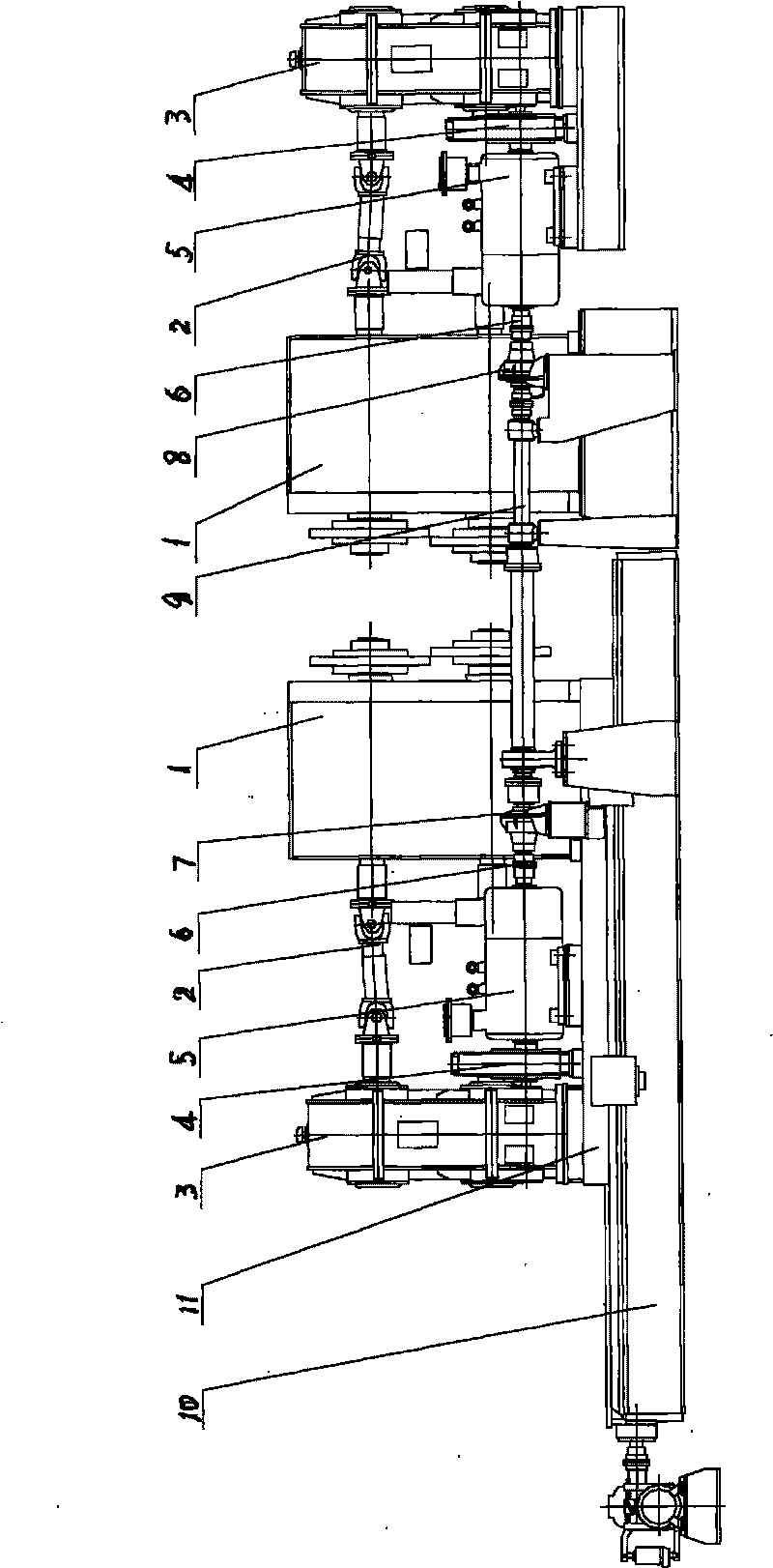

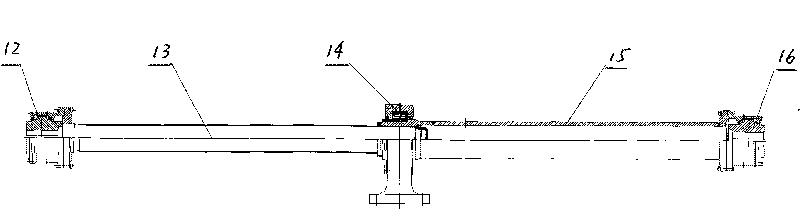

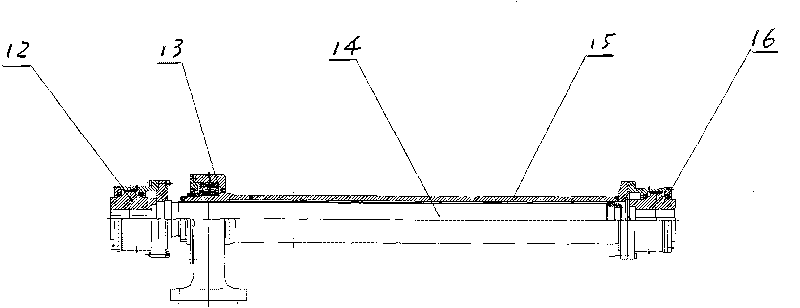

Vertical forced synchronous hydraulic driving device of continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece

The invention discloses a vertical forced synchronous hydraulic driving device of a continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece. By the vertical forced synchronous hydraulic driving device of the continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece, planar three-degree-of-freedom movement of the continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece is implemented, a guiding element guide track sliding block and a driving element hydraulic driving cylinder are arranged vertically, synchronism of the same group of drivers is ensured forcedly on the mechanical level by an integrated sliding table, and the mechanism principle of the whole vertical forced synchronous hydraulic driving device of the continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece in a longitudinal plane is a planar three-degree-of-freedom ten-rod mechanism. The vertical forced synchronous hydraulic driving device of the continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece has the characteristics of good integral rigidity, simple structure, spacemultiplexing, capability of eliminating a lateral force, high synchronization precision, large driving load, high stability, high anti-impact ability, high safety and reliability and the like.

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所 +1

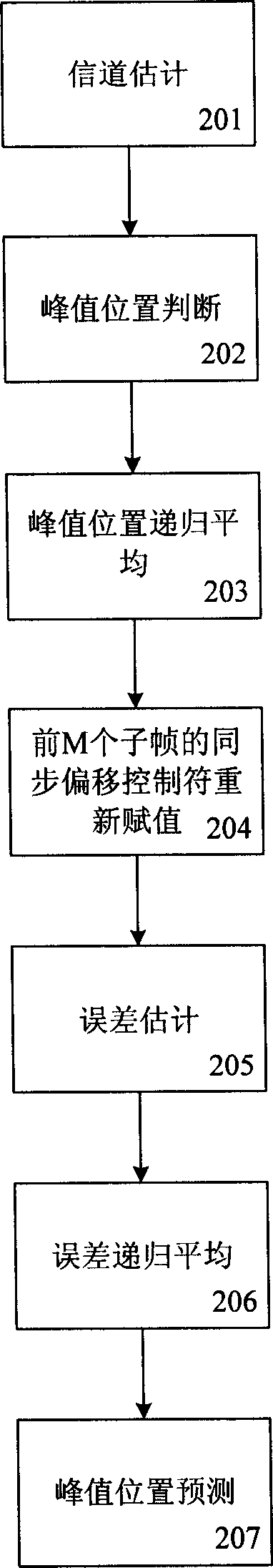

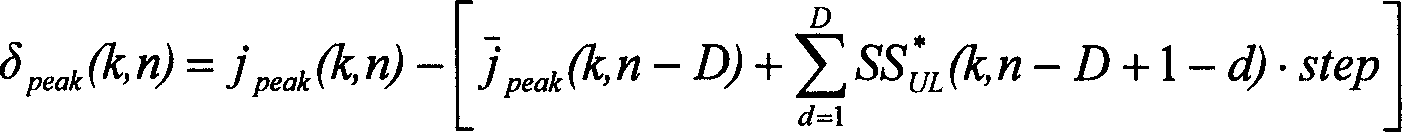

Predicted method of upload synchronous tracking in time-division duplex radio communication system

InactiveCN1758567AAccurate peak positionAccurately estimate peak positionRadio transmission for post communicationCommunications systemSynchronous control

A predicting method of up link synchronous tracking in time division duplex ratio communication system includes estimating all up link channels between terminal and each antenna by base station, obtaining peak value position of current sub frame on each terminal by calculating average power of all antennas, carrying out recursive average for said peak value position ( PVP ), reassigning SS of individual sub frame with its frequency being regulated when number sum of current sub frame and delay sub frame can be divided exactly by regulated frequency, calculating out error between predictive PVP and estimated PVP and carrying out recursive average on the error, adding recursive average result with predictive PVP to obtain predictive PVP of the sub frame.

Owner:ZTE CORP

Multi-axis hydraulic synchronization control system, method and device

ActiveCN102086893BSimple structureHigh precision of synchronous controlServomotorsFluid-pressure actuator componentsHydraulic cylinderSynchronous control

The invention discloses a multi-axis hydraulic synchronization control system, method and device, and belongs to the technical field of synchronization control. The system comprises a controller, a digital-to-analogue conversion module, at least two hydraulic proportional valves and position feedback devices the number of which is equal to the number of the hydraulic proportional valves; the controller is connected with each hydraulic proportional valve through the digital-to-analogue conversion module, and each hydraulic proportional valve can drive a hydraulic cylinder which is connected with each hydraulic proportional valve; each position feedback device is respectively connected with the controller, each position feedback device can detect the position of each hydraulic cylinder, and transmits the detected position data to the controller; and the controller can control each hydraulic proportional valve according to the position data of each hydraulic cylinder transmitted by each position feedback device and by consulting the stored synchronization data of the controller. The multi-axis hydraulic synchronization control system has the advantages of simple structure, high synchronization precision and low cost, and can be used for solving the problems of low synchronization and high cost of the existing multi-axis hydraulic synchronization.

Owner:FANTAWILD DIGITAL FILM

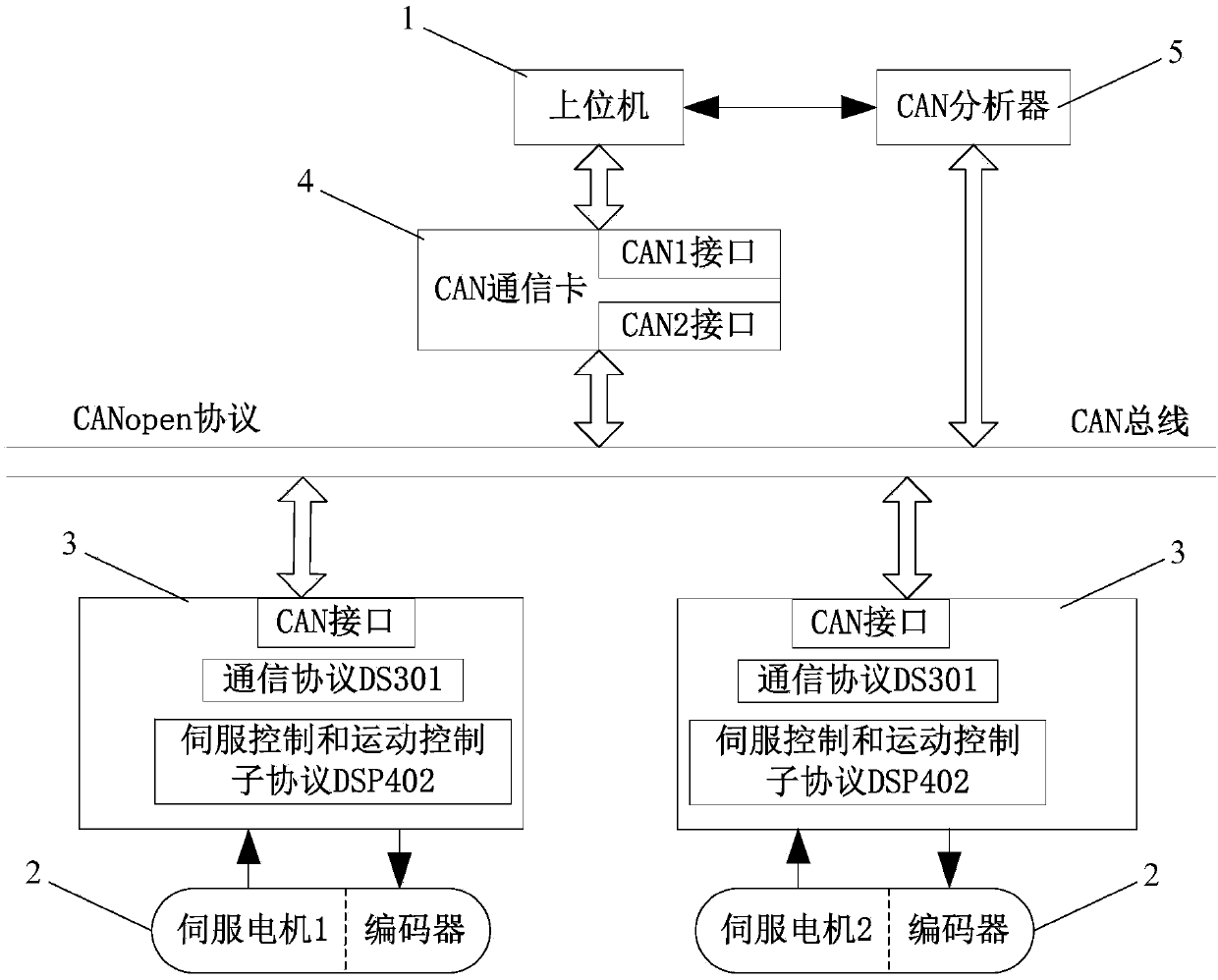

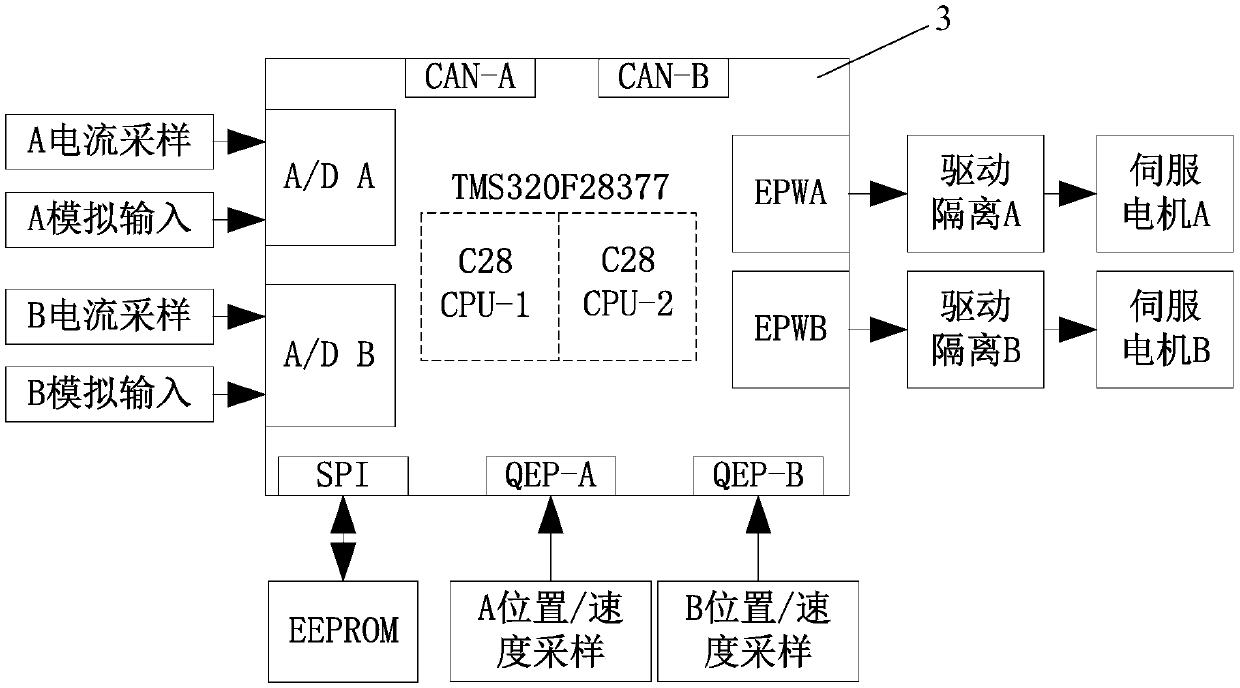

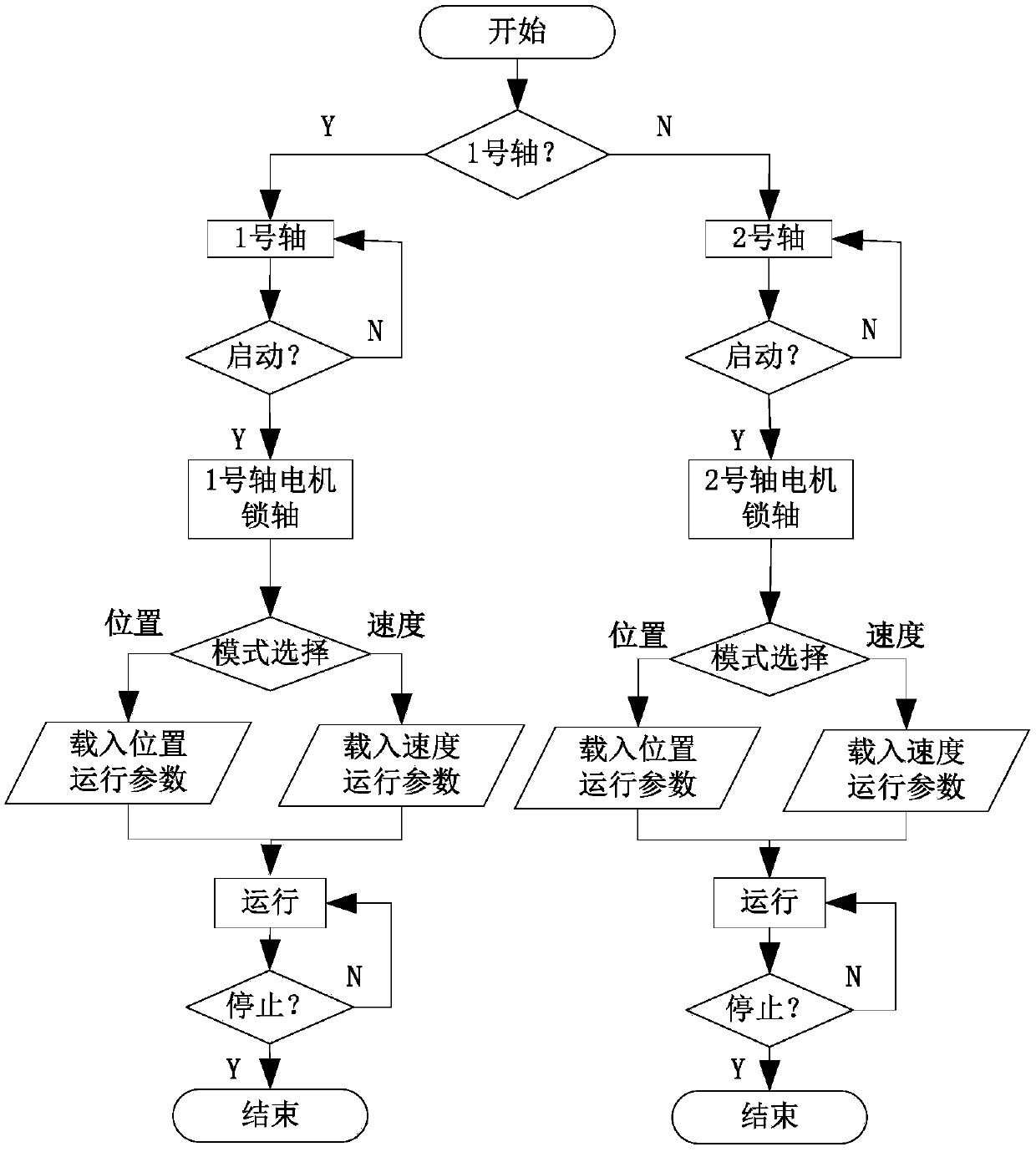

Double-shaft motor driving system and method based on dual-core processing

InactiveCN111384876AHigh precision of synchronous controlReduce hardware design sizeMultiple dynamo-electric motors speed regulationDual coreEngineering

The invention discloses a double-shaft motor driving system based on dual-core processing. The system comprises an upper computer, two servo motors and a server driver, wherein the upper computer is used for transmitting a motion command; the servo driver comprises a dual-core DSP with two CPUs, the dual-core DSP is in communication with the upper computer through a CAN bus, the dual-core DSP is used for receiving the motion command sent by the upper computer, the CPUs and the servo motors establish communication in a one-to-one correspondence mode, the CPUs are used for controlling the servomotors to operate according to the motion command and obtaining feedback data of encoders of the servo motor, and single-shaft operation control or double-shaft alternate operation control or double-shaft synchronous operation control over the two servo motors is achieved through the two CPUs. According to the invention, the motion control strategy is flexible and diverse, the synchronous controlprecision of the system can be improved, the dynamic response capability and the data transmission capability are high, and the reliability of the system can be improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

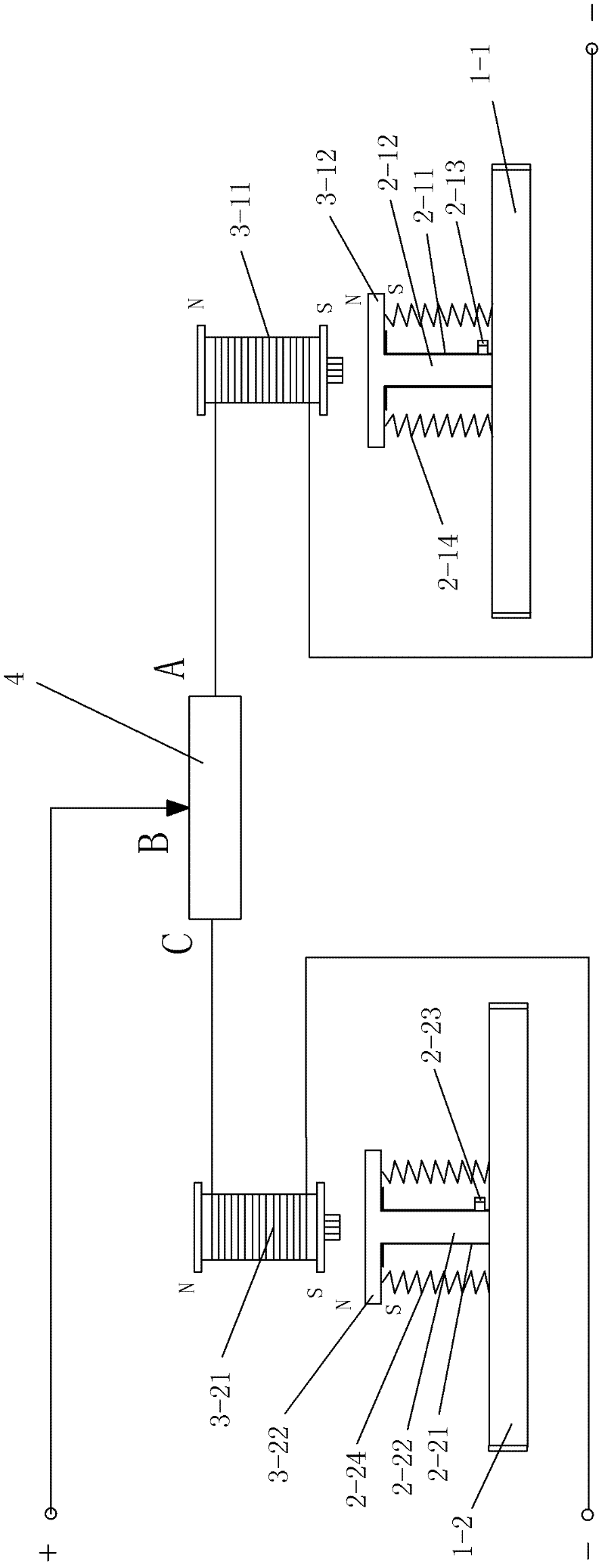

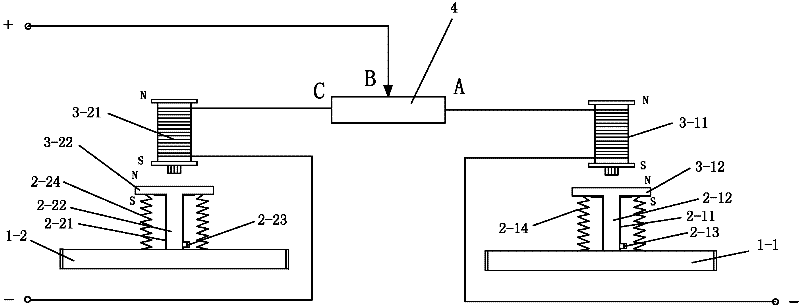

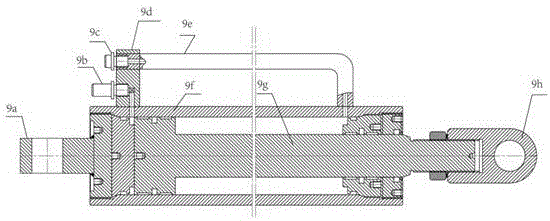

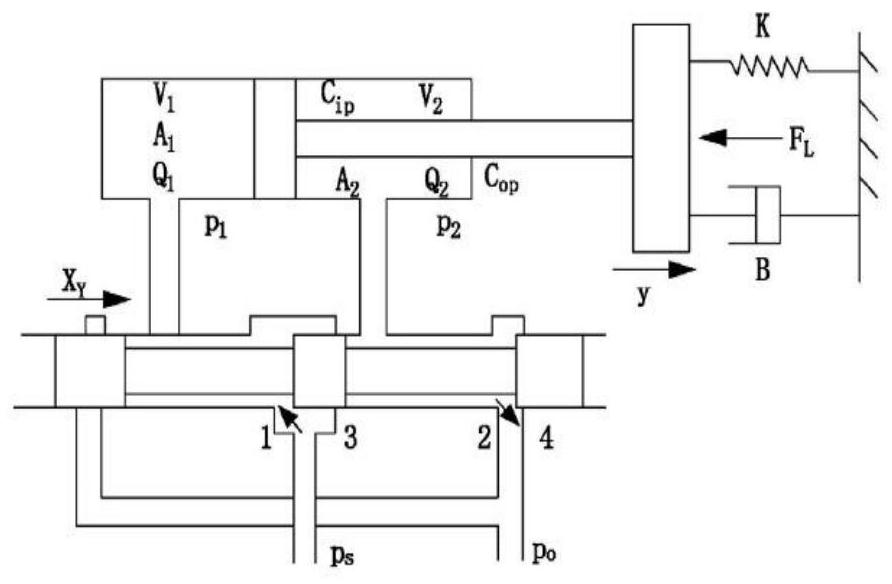

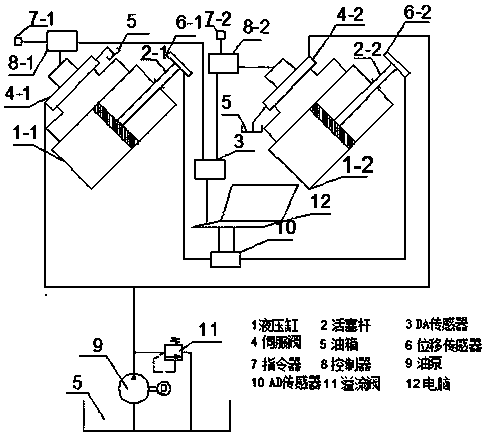

Double hydraulic cylinder flow compensation synchronous erection device and control method thereof

InactiveCN108180180AHigh synchronization accuracyCalculation data is accurateServomotor componentsServomotorsHydraulic cylinderControl theory

The invention relates to a double hydraulic cylinder flow compensation synchronous erection device and a control method thereof. The double hydraulic cylinder flow compensation synchronous erection device is mainly composed of hydraulic cylinders, piston rods, an oil pump, servo valves, an oil tank, displacement sensors, controllers, an overflow valve, a computer and the like. The first displacement sensor and the second displacement sensor detect the displacement of the first piston rod and the second piston rod, a detection result is converted through an AD converter, data are transmitted tothe computer, the difference between the displacement of the first displacement sensor and the displacement of the second displacement sensor is calculated by the computer, and the result is sent tothe first controller and the second controller through a DA converter; according to the displacement difference of the first piston rod and the second piston rod, the size of valve elements of the first servo valve and the second servo valve is adjusted many times, so that the flow of the valve elements of the first servo valve and the second servo valve can be changed till the displacement difference of the first piston rod and the second piston rod is zero. The double hydraulic cylinder flow compensation synchronous erection device and the control method thereof solve the problems that a flow dividing synchronous device is poor in eccentric load resisting capacity, low in synchronizing precision and poor in reliability, improve the synchronizing precision and the responding speed, and improve safety and stability.

Owner:HARBIN UNIV OF SCI & TECH

Mechanical synchronizer for main driving motor of disc shear

InactiveCN101702605AImprove cutting accuracyExtended service lifeElectric motor speed/torque regulationCouplingSynchronous control

The invention provides a mechanical synchronizer for the main driving motor of a disc shear, applied to the metallurgical machinery industry. The overall mechanical synchronizer comprises a shear body, a main driving reducer, a main driving motor, a first crown gear coupling, a fixed-side rigid synchronizing shaft, a second crown gear coupling, a spline shaft, a spline housing and a third crown gear coupling, wherein the other end of the fixed-side rigid synchronizing shaft is connected with the third crown gear coupling; the output end of a moving-side cycloidal pinwheel reducer is connected with the second crown gear coupling; the second crown gear coupling is connected with the spline shaft, a middle supporting seat, the spline housing and the third crown gear coupling; the middle supporting seat adopts rolling bearings to support the spline housing; a guiding device which can be extracted or retracted in the spline housing is arranged at the head part of the spline shaft. The mechanical synchronizer has the advantages of novel and scientific design, convenient adjustment, assembly and disassembly, stable and safe synchronous operation, long service life, high motor synchronous control accuracy and high shearing precision of disc shear.

Owner:SHENYANG HEAVY MACHINERY GROUP

Novel hydraulic synchronous control system for shield tunneling machine segment conveying trolley

PendingCN109704223AHigh precision of synchronous controlImprove practicalityUnderground chambersServomotor componentsSynchronous controlActuator

The invention discloses a novel hydraulic synchronous control system for a shield tunneling machine segment conveying trolley. The novel hydraulic synchronous control system comprises a control valvegroup, a proportional velocity regulating valve group and an actuator. The actuator comprises at least four lifting oil cylinders, each lifting oil cylinder is internally provided with a magnetostrictive displacement sensor, and the magnetostrictive displacement sensors transmit detection signals to a controller. The proportional velocity regulating valve group includes at least four proportionalvelocity regulating valves, and the proportional velocity regulating valves are in one-to-one correspondence with the lifting oil cylinders. The control ends of the proportional velocity regulating valves are connected with the controller. A rodless cavity of each lifting oil cylinder is connected with a service port of the control valve group through the corresponding proportional velocity regulating valve. A rod cavity of each lifting oil cylinder is connected to another service port of the control valve group. The novel hydraulic synchronous control system can perform real-time detection and feedback on the displacement of each lifting oil cylinder, and adjust the input flow rate of each lifting oil cylinder in real time to realize high-precision synchronization of each lifting oil cylinder in the lifting and lowering process, so that tunnel construction efficiency is effectively improved, and personal safety hazards are avoided.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

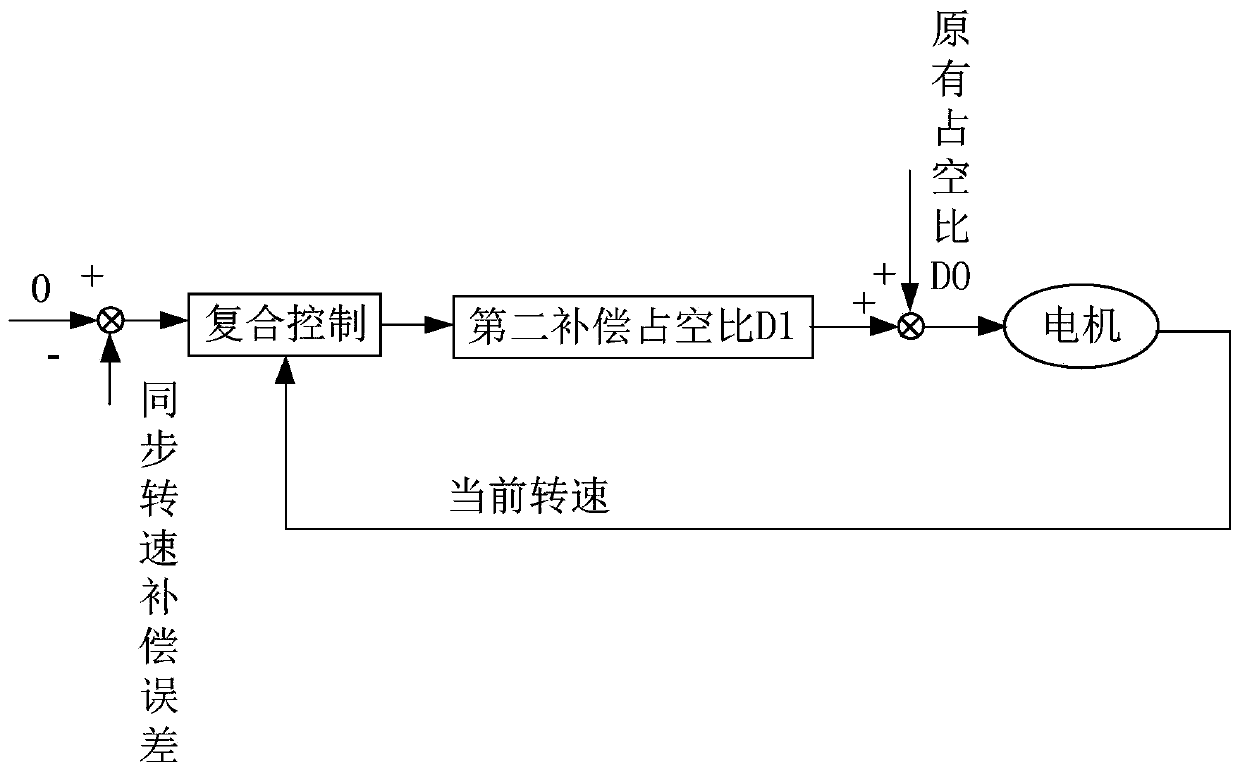

Multi-motor synchronous drive control method, device and system

ActiveCN111293927AImprove synchronicityReduce loadMultiple dynamo-electric motors speed regulationControl engineeringElectric machinery

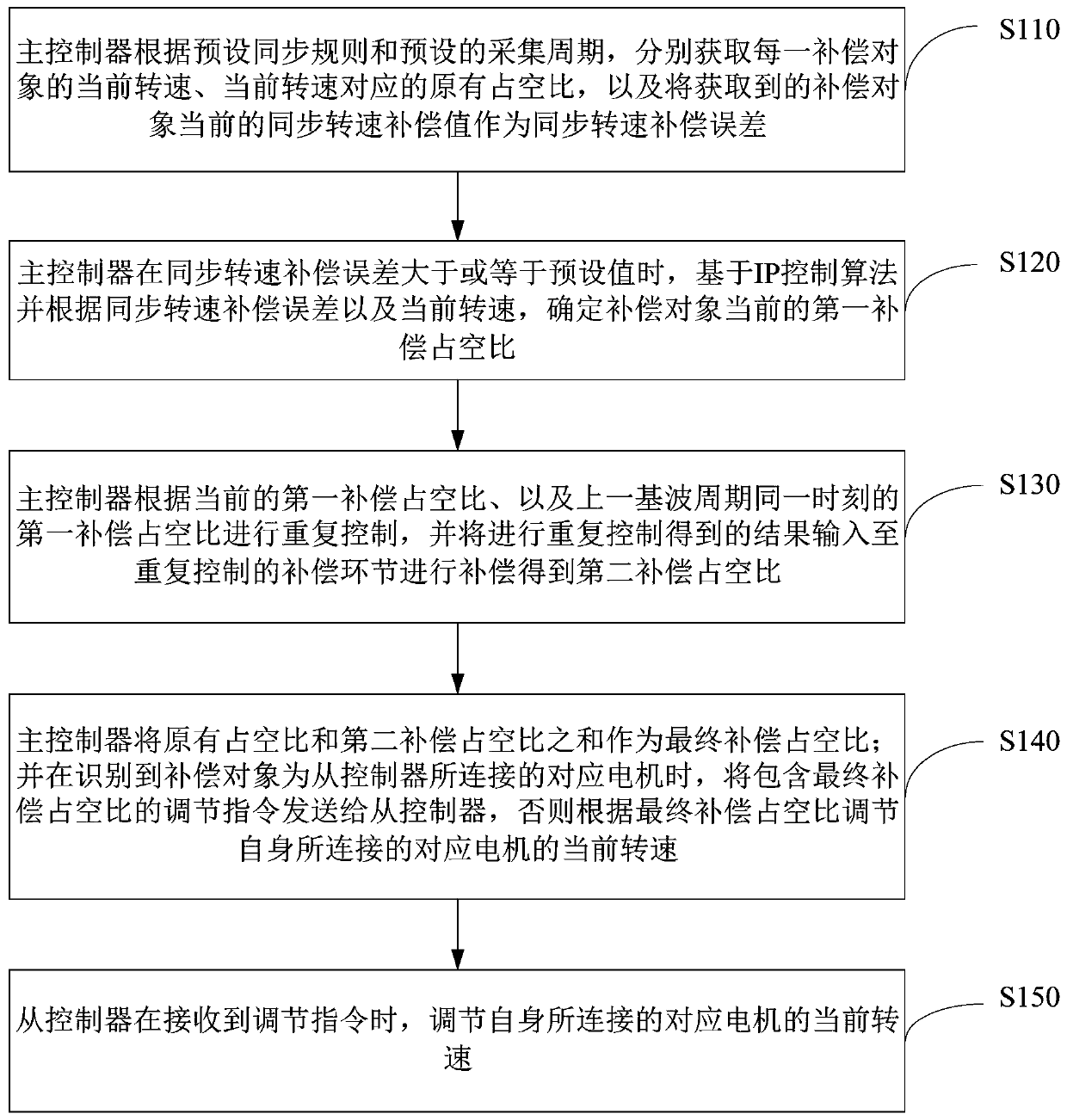

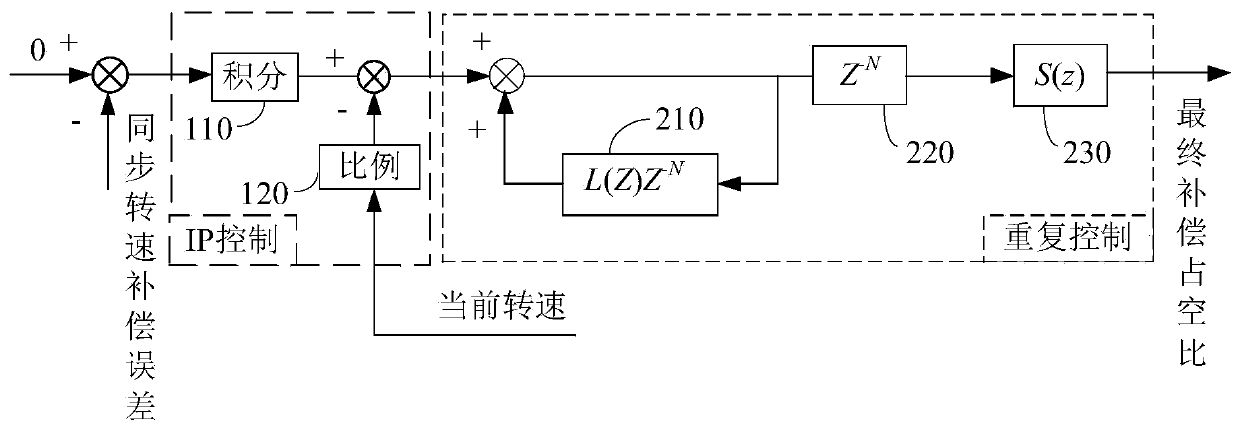

The embodiment of the invention relates to a multi-motor synchronous drive control method, device and system. A main controller respectively acquires the current rotating speed of each compensation object and the corresponding original duty ratio, and takes the current synchronous rotating speed compensation value of the compensation object as a synchronous rotating speed compensation error so asto determine a current first compensation duty ratio of the compensation object based on an IP control algorithm; the main controller performs repetitive control according to the first compensation duty ratio and inputs obtained results into a compensation link to obtain a second compensation duty ratio; the main controller takes the sum of the original duty ratio and the second compensation dutyratio as a final compensation duty ratio, and sends an adjusting instruction containing the final compensation duty ratio to a slave controller when it is recognized that the compensation object is the corresponding motor of a slave controller; and when the slave controller receives the adjusting instruction, the slave controller adjusts the current rotating speed of the corresponding motor connected with the slave controller. According to the invention, the synchronization control precision is high, so that the synchronization effect of multiple motors can be effectively improved when the synchronization of the multiple motors is controlled.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

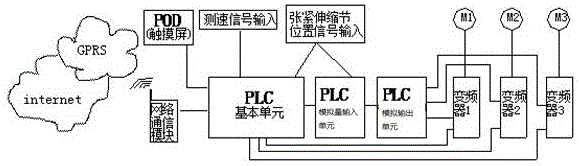

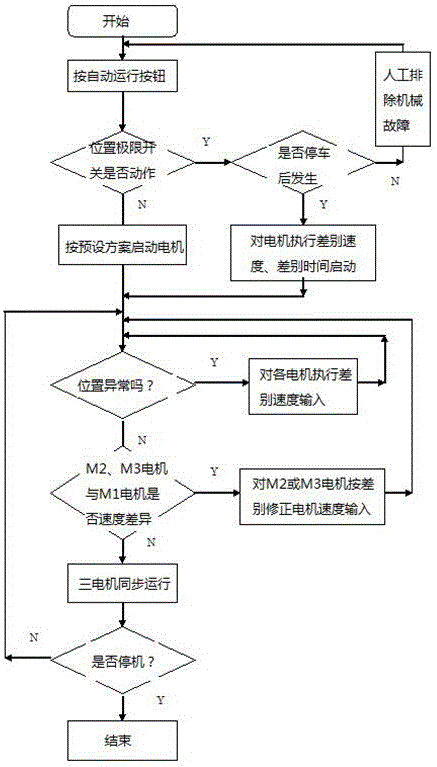

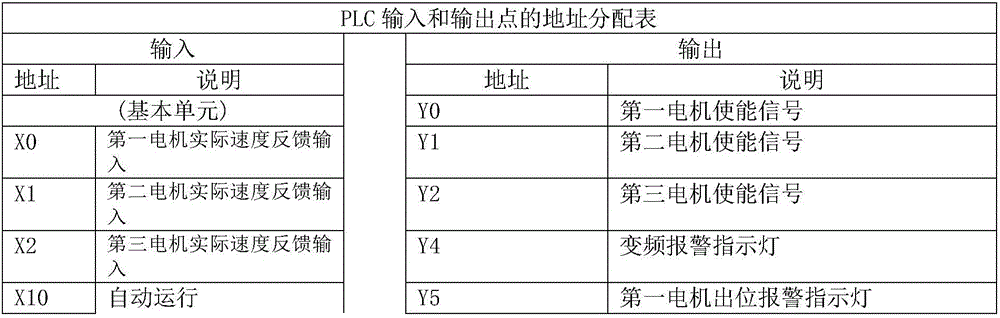

Three-motor synchronous control system and control method for suspension conveyer chain

InactiveCN106787975AEasy maintenance and operationHigh precision of synchronous controlAC motor controlMultiple ac dynamo-electric motors controlSpeed measurementFrequency changer

The invention relates to a three-motor synchronous control system and control method for a suspension conveyer chain. A PLC basic unit, a PLC analog input unit and a PLC analog output unit are connected in sequence; the output end of the PLC analog output unit is connected with a frequency converter 1, a frequency converter 2 and a frequency converter 3 separately; the frequency converter 1, the frequency converter 2 and the frequency converter 3 are connected with a motor M1, a motor M2 and a motor M3 respectively; the PLC basic unit is connected with a network module, a POD touch screen, a speed measurement signal input part, the frequency converter 1, the frequency converter 2 and the frequency converter 3 separately; and the PLC basic unit and the PLC analog input unit are in signal input connection with each tensioning expansion joint position separately. By adoption of the three-motor synchronous control system and control method, a quite troublesome problem that alarming, caused by a non-mechanical fault, of a position limit switch can only be started by human intervention of a user can be solved, so that use efficiency of equipment is improved.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

Synchronous control method and control system for multiple winches

ActiveCN103523701BAccurate balance lift controlHigh precision of synchronous controlWinding mechanismsPull forceControl system

The invention provides a multi-winch synchronization control method and control system. The control system comprises a control device and a plurality of pull force sensors. Each pull force sensor is hinged to one arm head pulley of a multi-winch synchronization mechanism. The control device connected with the pull force sensors acquires a current lifting pull force value, obtained by the pull force sensors, at a steep wire rope end, and performs deviation calculation on the current pull force value and the previous pull force value to obtain a pull force difference value; under the circumstance that the absolute value of the current pull force value is larger than the preset pull force difference value pre-stored by the control device, when the pull force different value is larger than zero, the control device controls winding drums of the winches to slow down, and when the pull force difference value is smaller than zero, the control device controls the winding drums of the winches to accelerate. Due to the fact that the steel wire rope end is close to a hanging hook, balance lifting control of the hanging hook can be accurate by the control method collecting pull force value of the steel wire rope end, and multi-winch synchronization control precision can be increased effectively.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

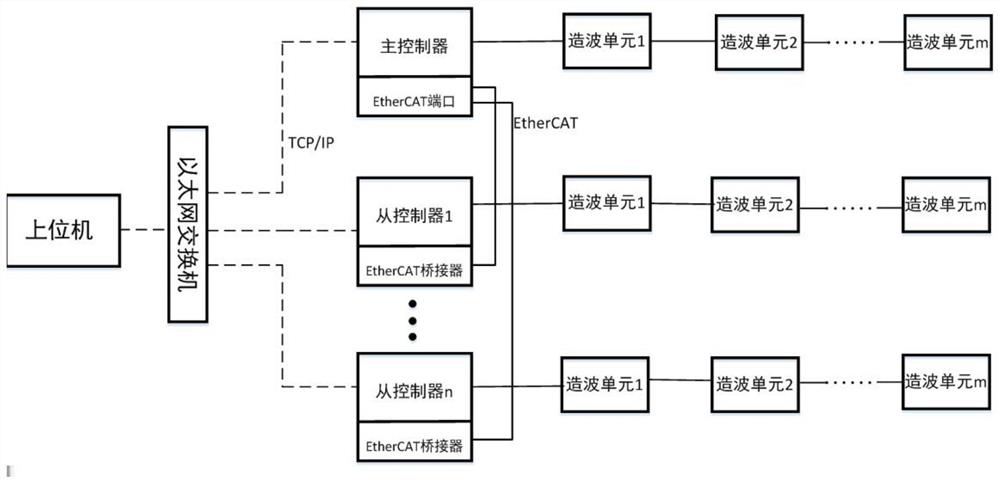

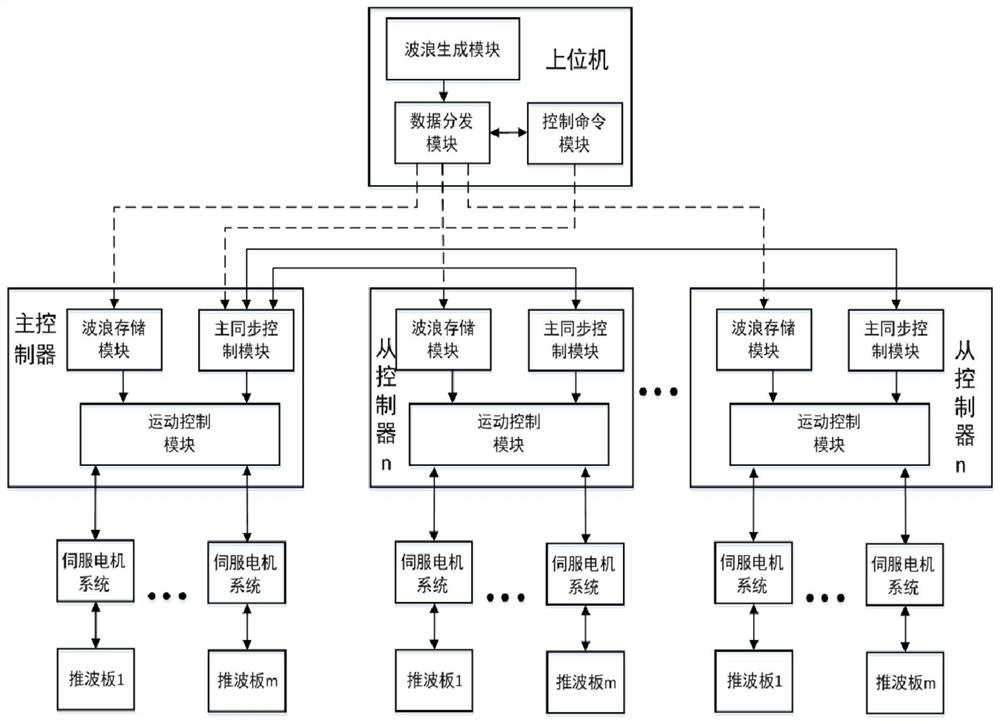

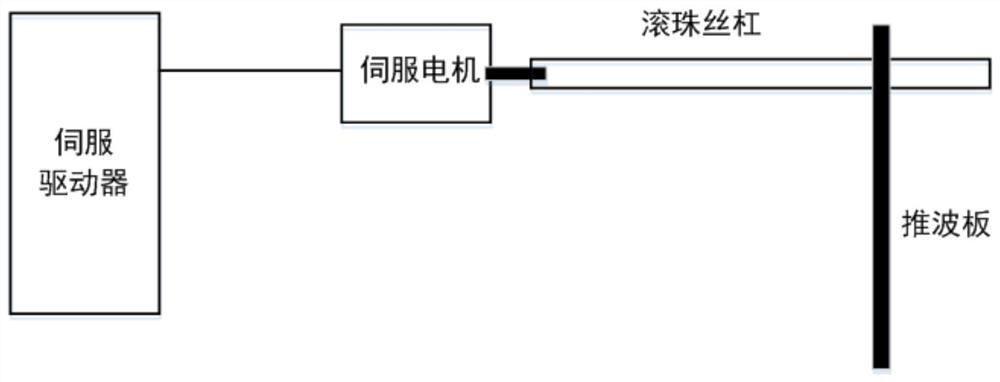

A wave generator control system based on multi-controller synchronous control

InactiveCN108445830BHigh precision of synchronous controlHigh communication rateProgramme control in sequence/logic controllersMachine controlSynchronous control

The invention discloses a wave machine control system based on multi-controller synchronous control. The wave machine control system comprises a host computer, a main controller, slave controllers, anEtherCAT bridge and a wave making unit. The host computer transmits control instruction information for the wave machine to the main controller in real time, the main controller transmits the controlinstruction to the plurality of slave controllers in real time, the slave controllers transmit the control instruction information of the wave machine to the wave making unit in real time, the wave making unit makes waves according to the control instruction information; wherein the master controller and the slave controllers are all PC-based soft PLCs. The system achieves the effect of multi-controller synchronous control through the EtherCAT bridge, so that a large wave-making system having hundreds of servo axes can also be synchronously controlled, and the synchronous control has high precision and good real-time performance.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com