Single spindle automatic lathe for sequential operations by moving cutters along axes parallel to principal axis

A technology for moving tools and spindle axes, applied in the field of single-axis automatic lathes, can solve the problems of inconvenient maintenance and adjustment, less tool types and configurations, and high user cost, achieve a reasonable overall layout, reduce feed accuracy and repeat positioning accuracy. requirements, the effect of protecting the machined surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

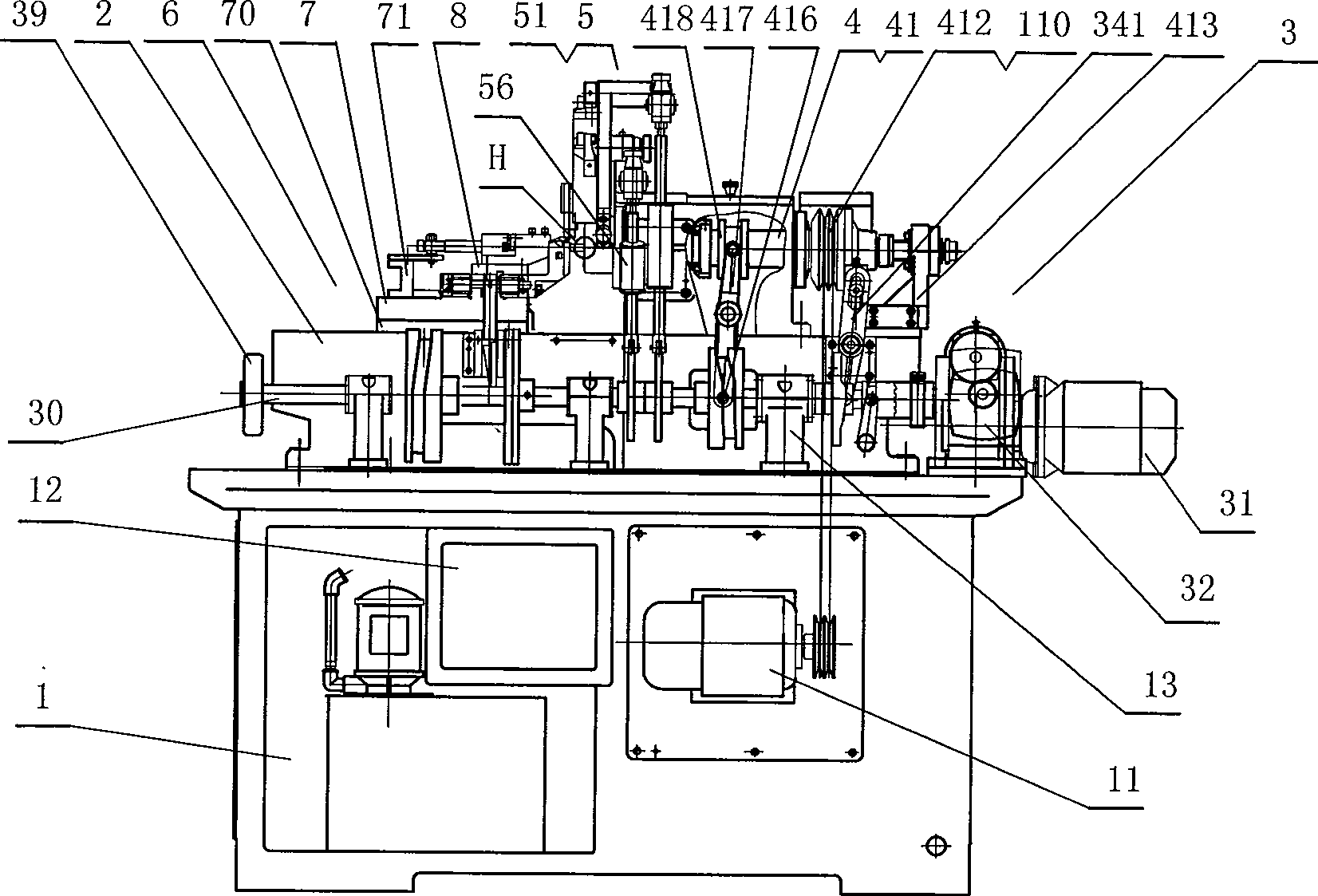

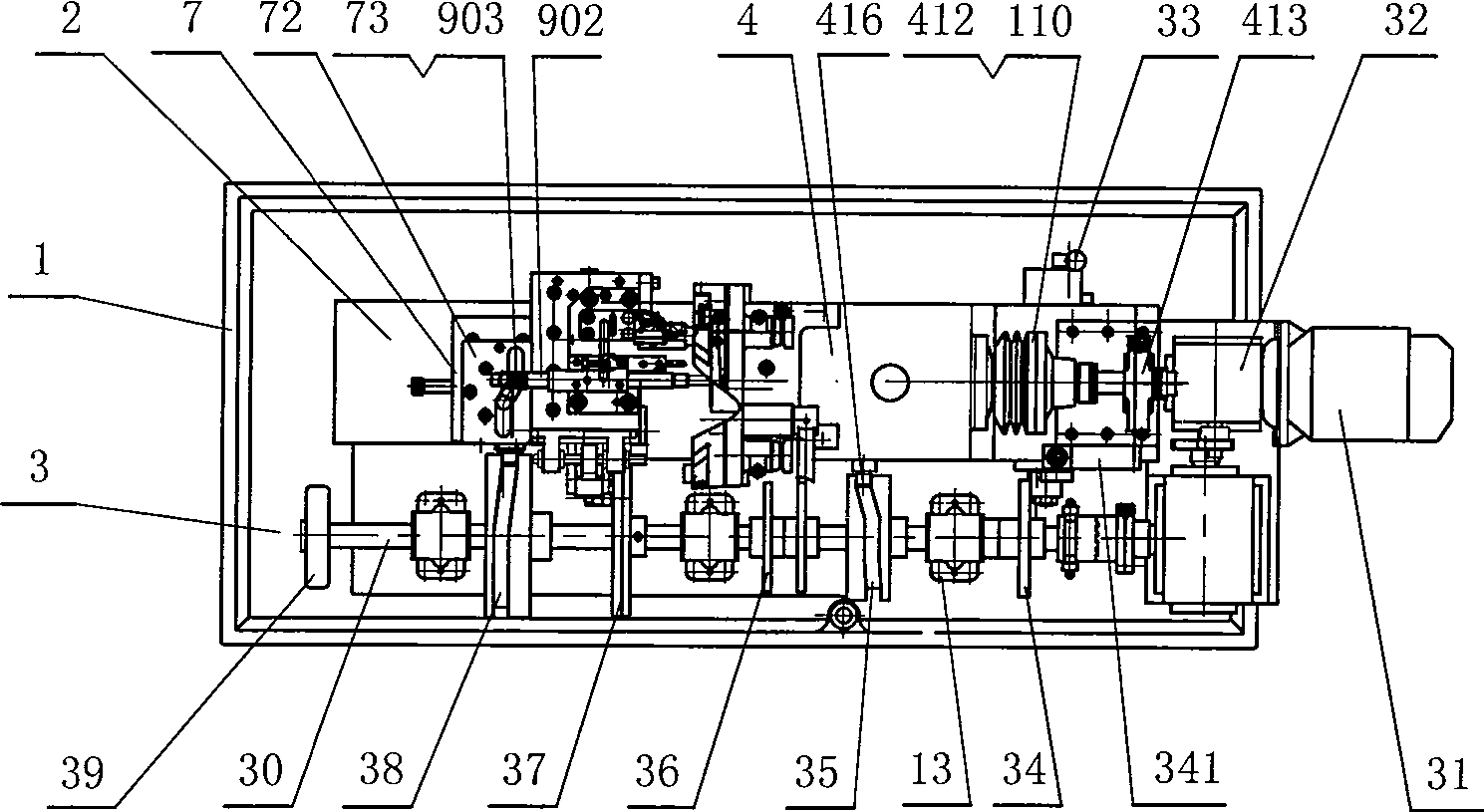

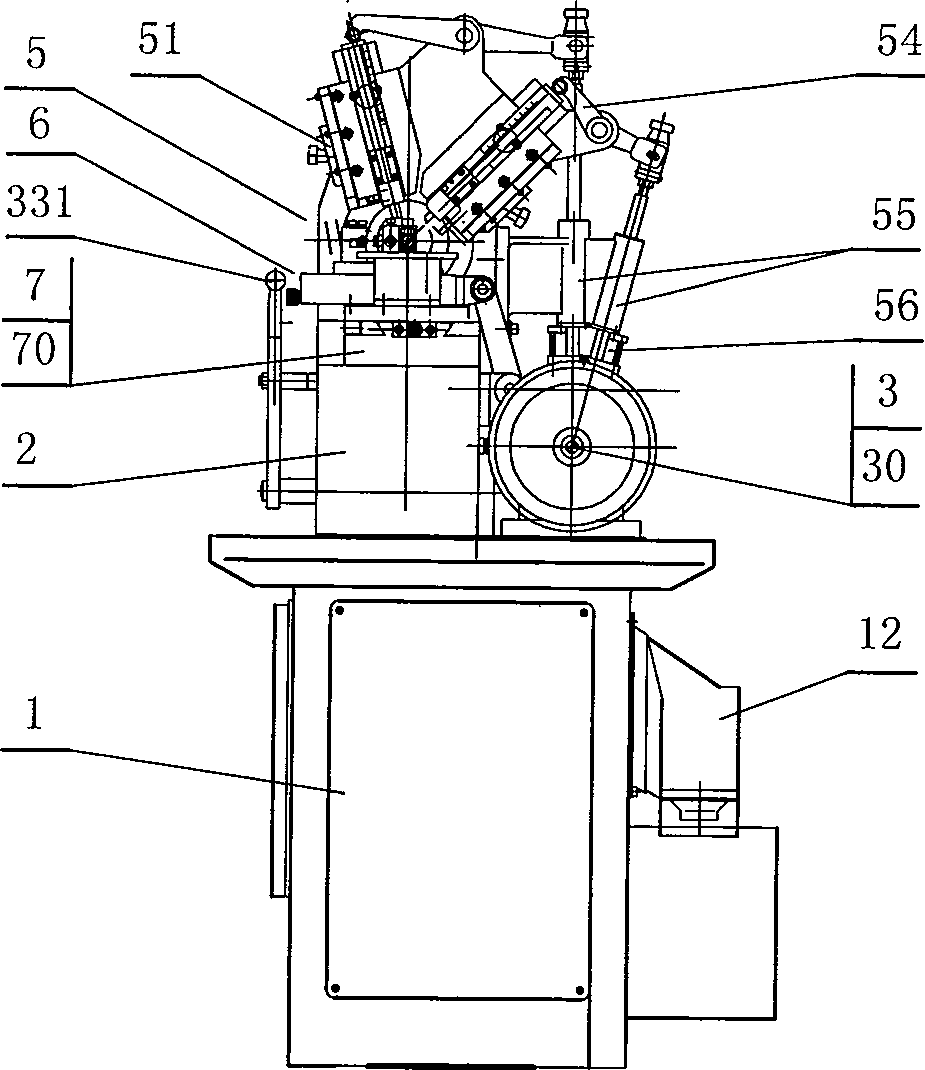

[0036]As shown in the accompanying drawings, a single-axis automatic lathe based on the parallel spindle axis moving the tool sequentially, it includes a cavity-shaped base 1, the cavity of the base 1 is provided with a spindle motor 11; in order to facilitate the smooth discharge of chips, the base The upper part of the cavity of 1 is provided with a half-moon-shaped chip outlet 12 that runs through transversely; the top of the cavity of the base 1 is provided with a bed 2 and a control device 3 parallel to the bed 2. The control device 3 mainly includes a control shaft 30 for controlling The shaft 30 is supported by the support 13, and the control shaft 30 is provided with a manipulation hand wheel 39, a longitudinal carriage feed cam 38, a horizontal carriage feed cam 37, a vertical knife holder feed cam 36, a blank clamping cam 35, and a blank clamping cam 35. Send into cam 34 and control clutch 33, and be connected with control motor 31 through control reduction box 333, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com