Wide-range metal plate belt edge-cutting device

A metal strip and wide-ranging technology, which is applied in the direction of shearing devices, metal processing equipment, shearing equipment, etc., can solve the problems that medium and thin plate shearing cannot be realized at the same time, so as to improve operating efficiency, reduce equipment investment, and reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

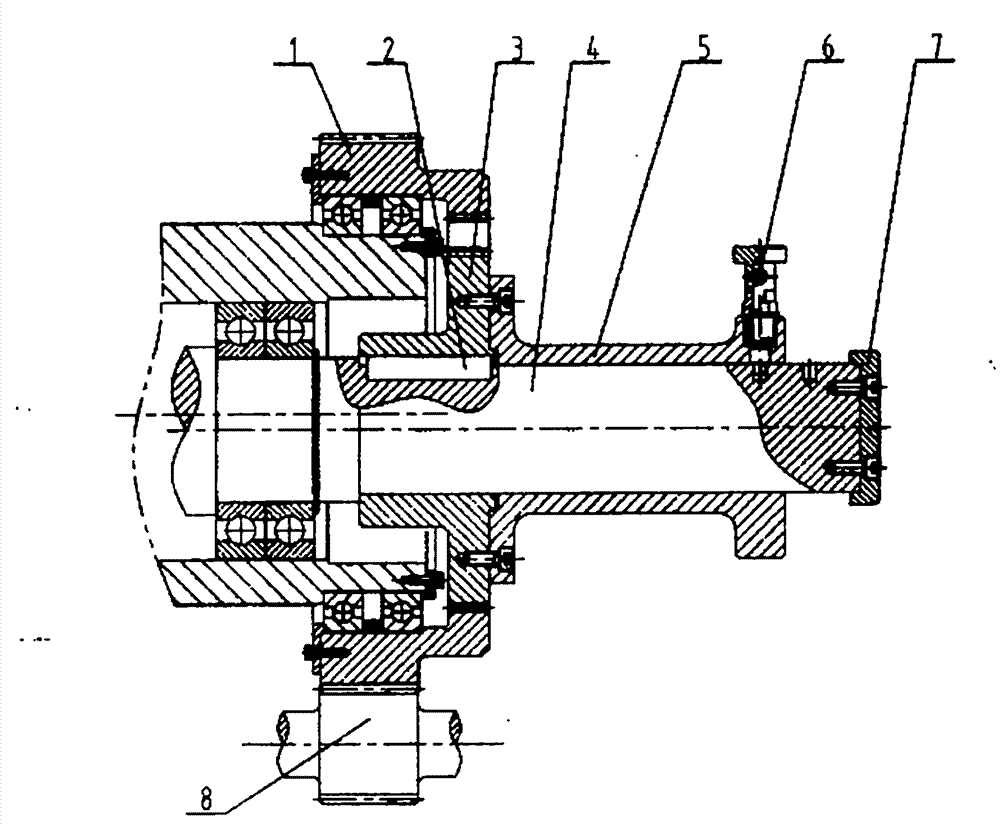

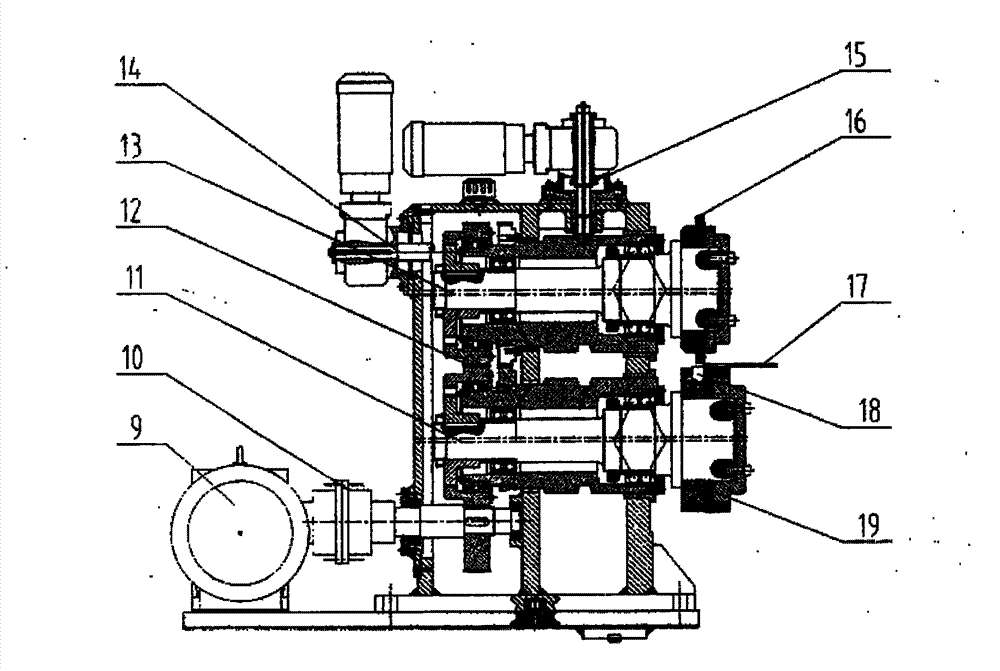

[0016] Such as figure 1 , figure 2 Shown, the present invention mainly is made up of components such as idler gear 1, flat key 2, spur gear 3, cutter shaft 4, push-pull sleeve 5, positioning device 6, baffle plate 7, power gear 8. The cutter shaft 4 has a positioning step surface near the big end, the outer circle of the cutter shaft 4 is installed with a flat key 2 near the step, and there are two positioning pin holes near the outer circle of the rear end, and the rear end of the cutter shaft 4 is fixed with a baffle 7; spur gear 3 is internally meshed with the idler gear 1, and the spur gear 3 is fixedly connected with the push-pull sleeve 5 to form a clearance fit with the cutter shaft 4, relying on the flat key 2 to transmit power, and at the same time guided by the flat key 2, it can move axially; the push-pull sleeve 5 The rear end boss is designed with a quick positioning device 6, which can realize the quick positioning of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com