Hydraulic double cylinder or multi-cylinder synchronous control system

A synchronous control, hydraulic system technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems of low control accuracy, inability to adapt, slow response speed, etc., and achieve synchronous control accuracy High, good synchronous control effect, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

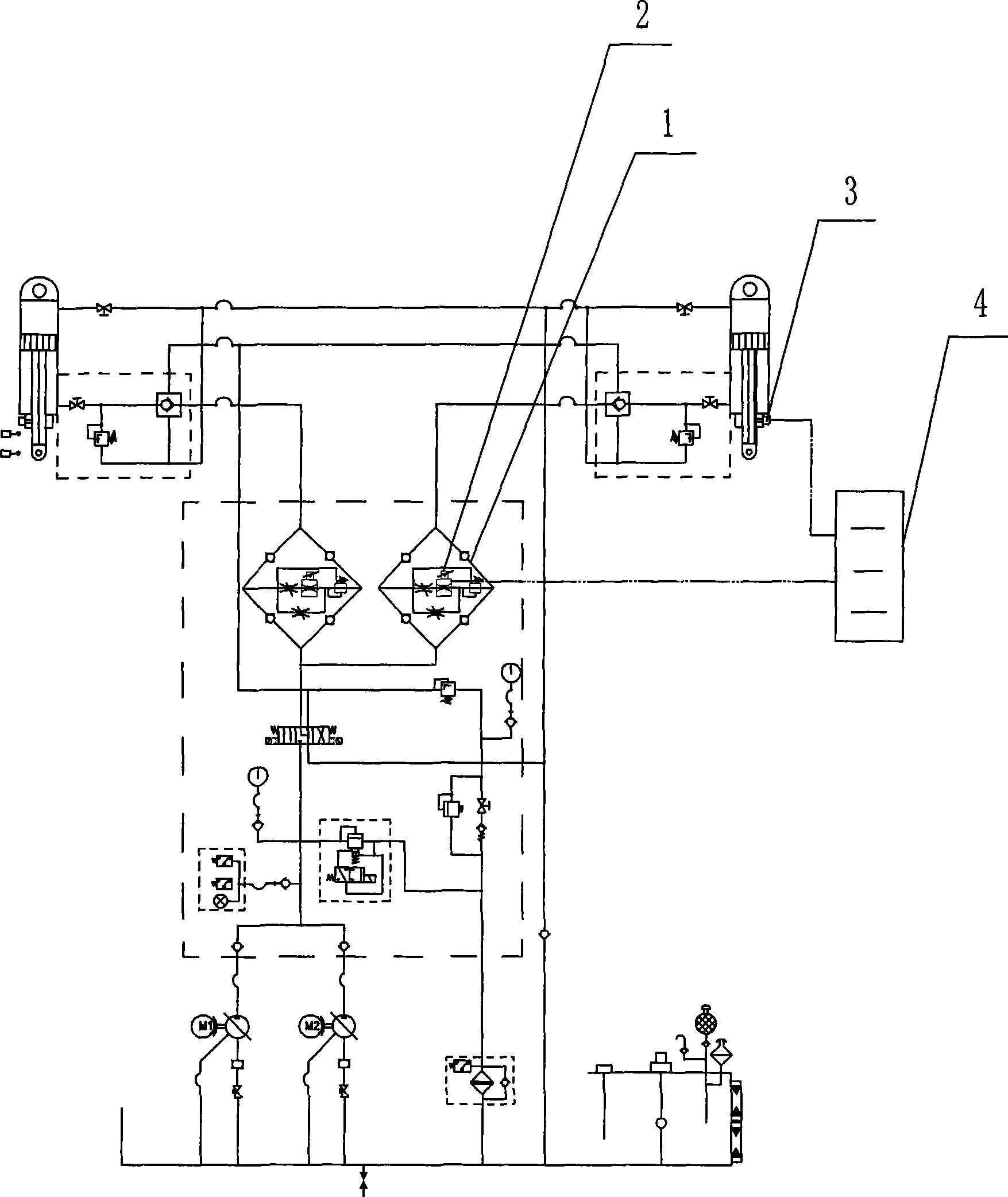

[0009] Such as figure 1 As shown, the synchronous control system of the present invention is combined with the hydraulic system, and the control system is mainly composed of a rectifying plate 1, an electro-hydraulic proportional speed regulating valve 2, a hydraulic cylinder stroke detection device 3 and a PLC controller 4; the oil inlet circuit of the hydraulic system The rectifying plate 1 with electro-hydraulic proportional speed regulating valve 2 is connected to the center, and the oil will enter the hydraulic cylinder of the hydraulic system through the rectifying plate 1 with electro-hydraulic proportional speed regulating valve 2; each hydraulic cylinder is equipped with a hydraulic cylinder The stroke detection device 3 is responsible for inputting the stroke detection signal to the PLC controller 4, and the PLC controller 4 inputs the proportional speed regulation signal to the electro-hydraulic proportional speed regulating valve 2 according to the received stroke d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com