Three-motor synchronous control system and control method for suspension conveyer chain

A technology of synchronous control and three motors, which is applied in the control system, AC motor control, and control of multiple AC motors. It can solve the problems of different moving speeds and different motor speeds, which cannot be ignored, and achieve fast response and synchronous control. High precision, avoid the effect of big ups and downs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

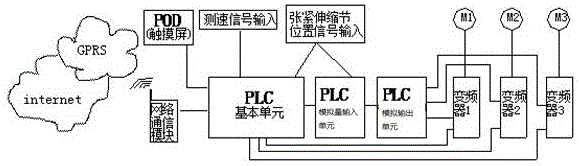

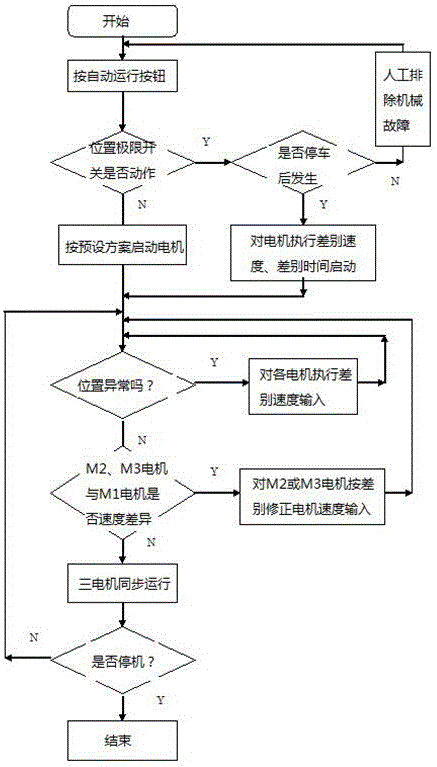

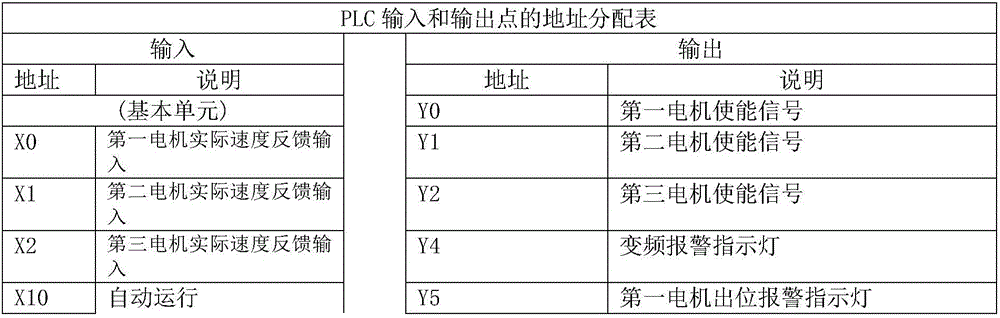

[0054] Inverter selection: Inverter 1, Inverter 2 and Inverter 3 all use Delta VFD037M43B, whose input voltage is three-phase 380V, output power is 3.7 kilowatts, and has RS485 communication. PLC selection: Among them, the PLC basic unit adopts DVP64EHR3 of Delta EH series PLC, the PLC analog input unit adopts DVP04AD-H2, and the PLC analog output unit DVP04DA-H2, in which the input points are all 32 points, the output points are all 32 points, there are four One-way analog input and four-way analog output, with RS485 communication. See the table below for the address allocation of the input of the PLC analog input unit and the output point of the PLC analog output unit.

[0055]

[0056]

[0057] POD adopts Delta's B07S411 touch screen with a screen size of 7 inches and a resolution of 800×480; 65536 true colors; with three communication ports, supporting RS485\RS422\RS232 communication.

[0058] When the encoder is installed on the motor shaft of the finished product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com