Vertical forced synchronous hydraulic driving device of continuous transonic speed wind tunnel nozzle section semi-flexible-wall throat piece

A driving device and forced synchronization technology, applied in the field of continuous transonic wind tunnel test, can solve the problems of inability to provide high rigidity of lateral connection, large spatial motion range, low control precision, etc., to ensure normal working efficiency, rotational inertia, etc. Small size and good spatial reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

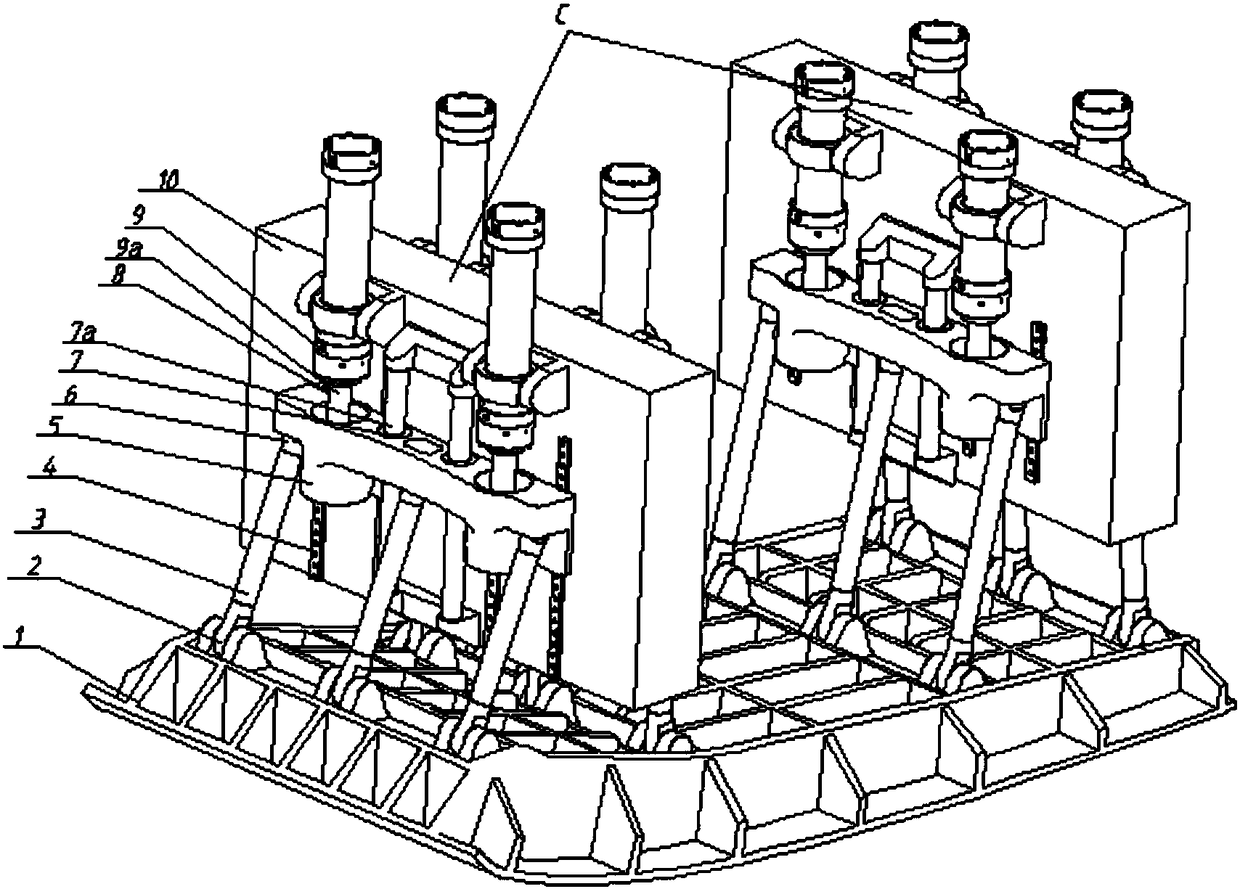

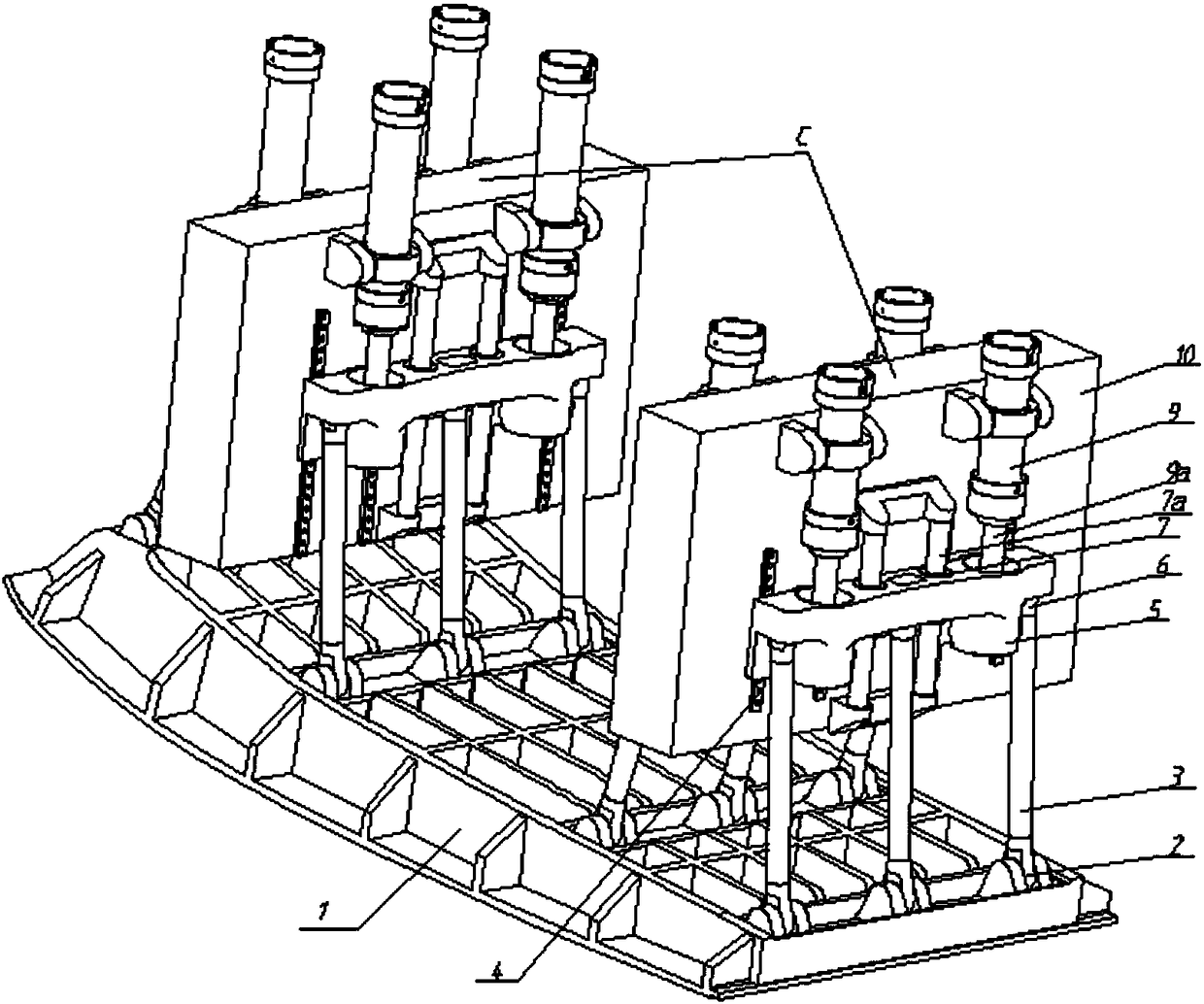

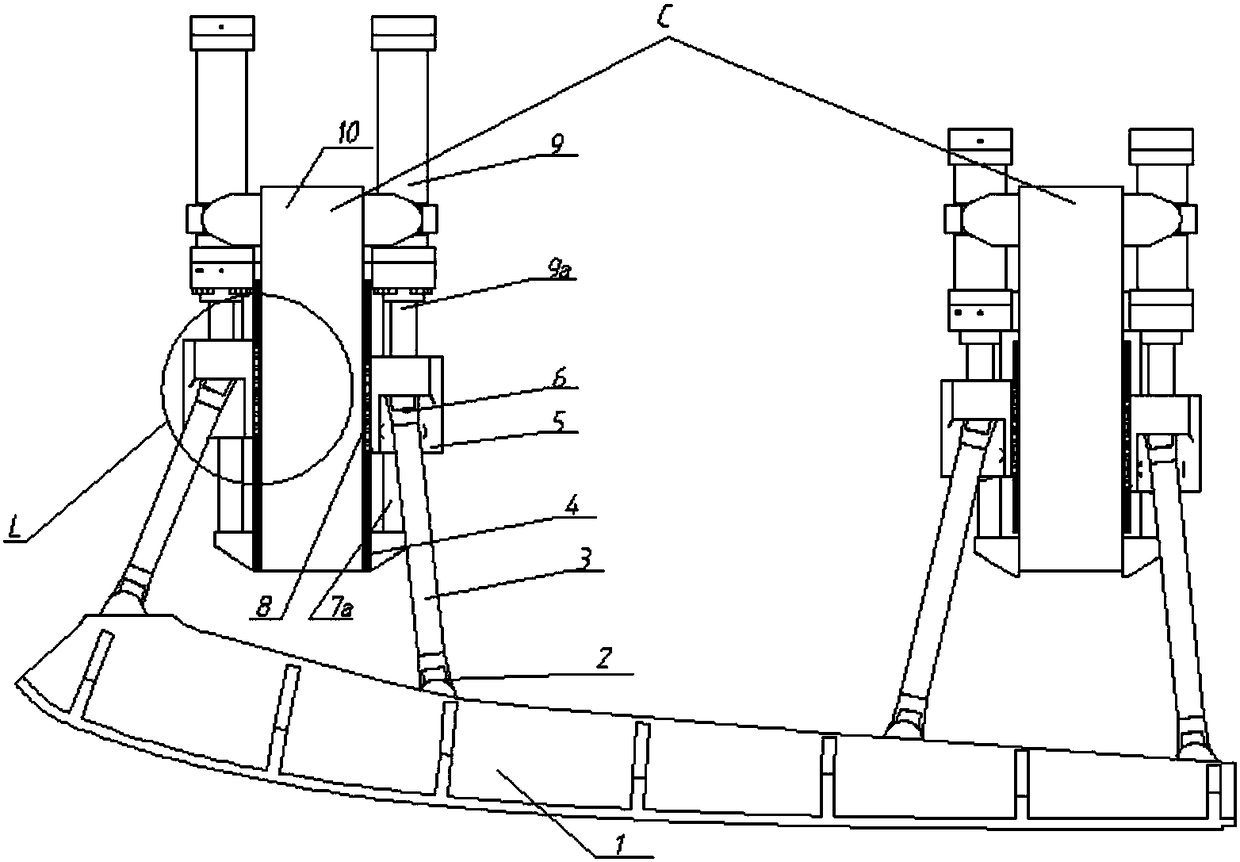

[0029] Embodiment 1: as figure 1 As shown, a vertical forced synchronous hydraulic drive device for the semi-flexible throat block of a continuous transonic wind tunnel nozzle section, comprising two units C, each unit C comprising a vertically arranged mounting seat (10), Two groups of parallel driving devices arranged symmetrically front and back are fixed on each mounting base (10); in each group of driving devices, there are two sets of guide rails (4) arranged vertically and parallel symmetrically on the left and right, and the guide rails (4) are fixed on On the mounting base (10); each set of guide rails (4) includes two vertically parallel guide rails (4); on each guide rail, a slide block (8) is arranged, and the slide block (8) can be mounted on the corresponding guide rail (4) slide up, and the slide blocks (8) on the four guide rails (4) on the left and right sets are arranged symmetrically; the slide table (5) is vertically and parallelly installed on the slide bl...

Embodiment 2

[0031] Embodiment 2: The main structure of this example is the same as that of Embodiment 1. In order to ensure the synchronous precision of driving in the group, the present invention arranges two slide blocks (8) with a certain installation distance on each group of guide rails (4). Each group of slide blocks (8) shares the same slide table (5), which compulsorily guarantees the synchronization of the two drives in each group from the mechanical level.

Embodiment 3

[0032] Embodiment 3: The main structure of this example is the same as that of Embodiment 1. In order to optimize each group of driving forces, the present invention has three groups of six hydraulic drive cylinders (9) for active displacement control, and another group of two hydraulic drive cylinders (9) ) is force passive control, and adopts vertical driving form in structure. P is a moving pair, and R is a rotating pair. The driving device is a 2P-3RR plane redundant mechanism composed of two horizontal hydraulic drive cylinders (9) and three driving connecting rods (3). Ensure the safety and reliability of the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com