Synchronous control method and synchronous control device for double driving motors at double sides

A dual-side drive, synchronous control technology, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as low synchronization accuracy and low shutdown accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

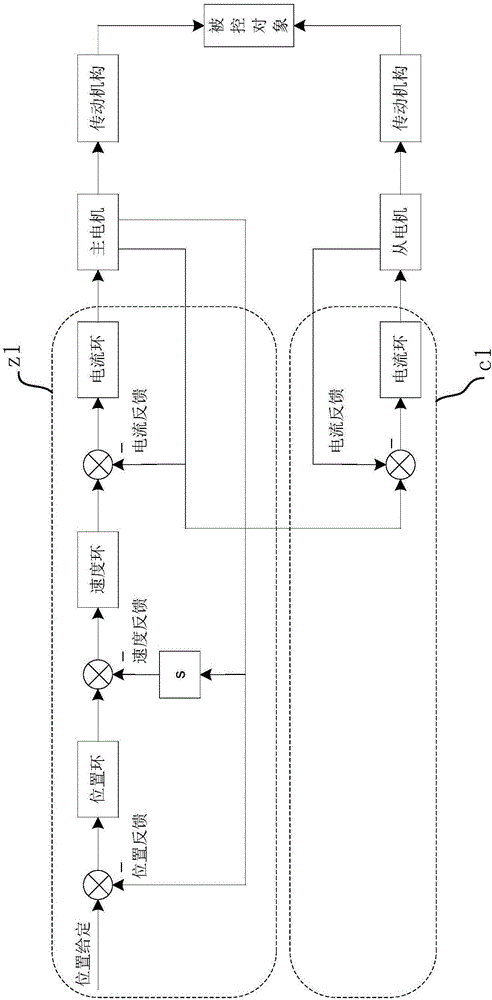

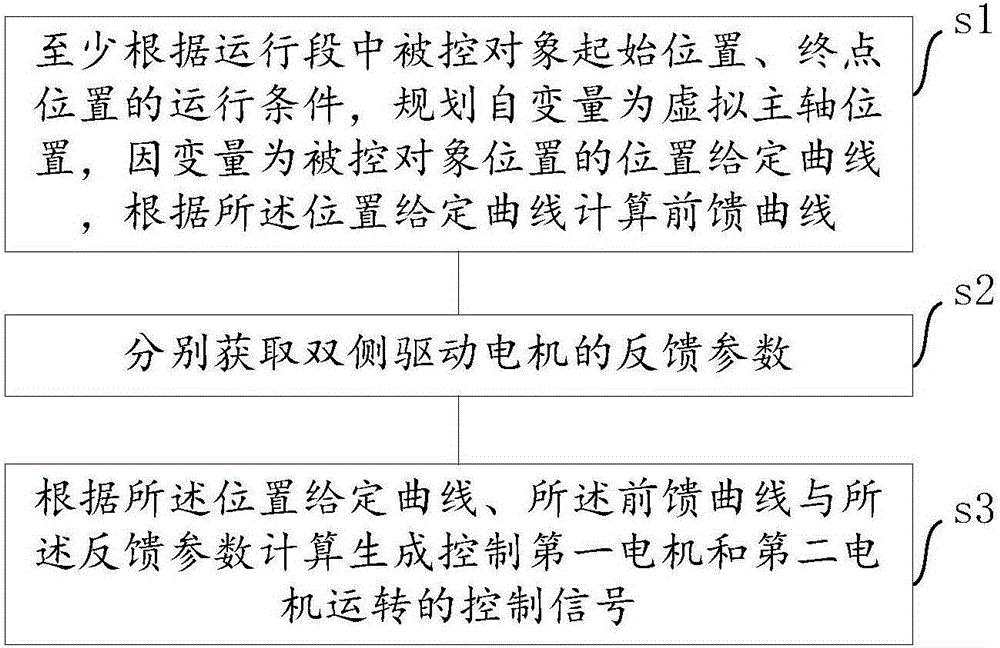

[0063] Such as figure 2 As shown, a synchronous control method of a double-sided drive motor proposed by an embodiment of the present invention can be applied to a synchronous control device of a double-sided drive motor, especially a quasi-rigid synchronous control device (that is, a quasi-rigid The synchronous control device refers to the transmission mechanism connecting the double-sided motor and the controlled object as a flexible transmission mechanism); the double-sided drive motor in the double-sided drive motor synchronous control device drives the same controlled object, and the controlled object is controlled. During the driving process, the position of the controlled object moves from the initial position to the end position;

[0064] The method for synchronous control of the double-sided driving motor comprises the steps of:

[0065] Step s1, at least according to the operating conditions of the starting position and the end position of the controlled object in ...

Embodiment 2

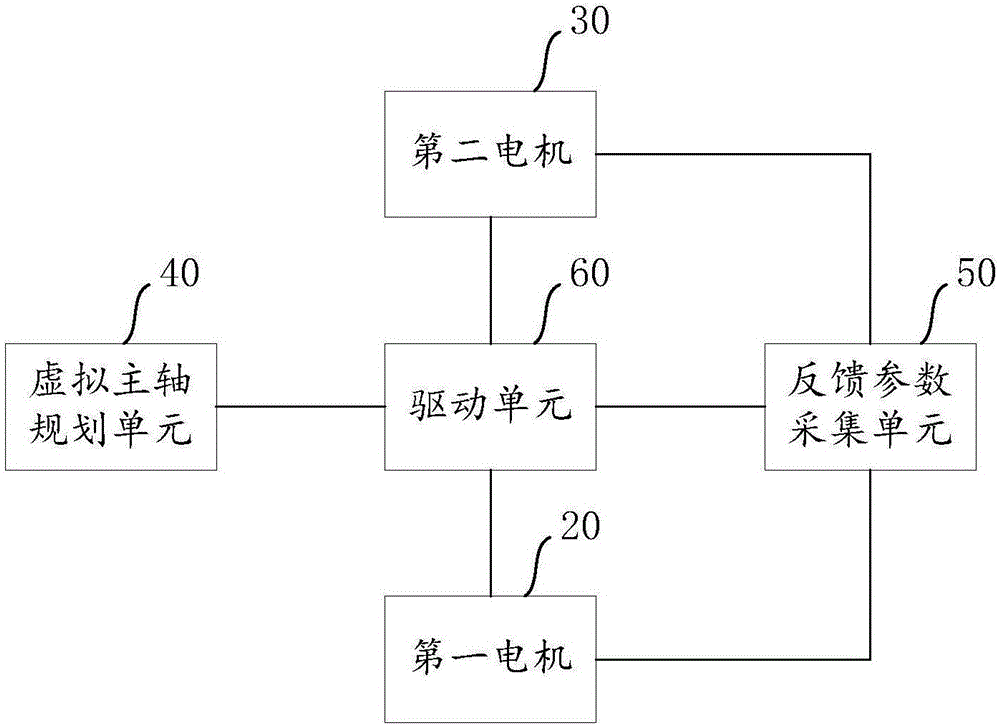

[0113] Such as image 3 , Figure 4 and Figure 5 As shown, a synchronous control device for a double-sided drive motor proposed in an embodiment of the present invention can be controlled by the synchronous control method for a double-sided drive motor described in the first embodiment above, and the synchronous control method described in the second embodiment The synchronous control method of the double-sided driving motors can directly adopt the synchronous control method of the double-sided driving motors provided in the first embodiment. The specific implementation method can refer to the relevant content described in the first embodiment above, and will not be repeated here. .

[0114] The synchronous control device for the drive motors on both sides consists of:

[0115] Accused 10;

[0116] The first motor 20 drives the first end of the controlled object 10 through the first transmission mechanism 21;

[0117] The second motor 30 drives the second end of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com