Climbing device of hydraulic climbing formwork system and control method

A technology of hydraulic climbing formwork and hydraulic pump station, which is applied to high-rise buildings such as bridge main towers, piers, construction devices of water conservancy dams, and columns, can solve problems such as affecting construction efficiency and low synchronization control accuracy, and achieves fewer operators. , The effect of large bearing capacity and high synchronous control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

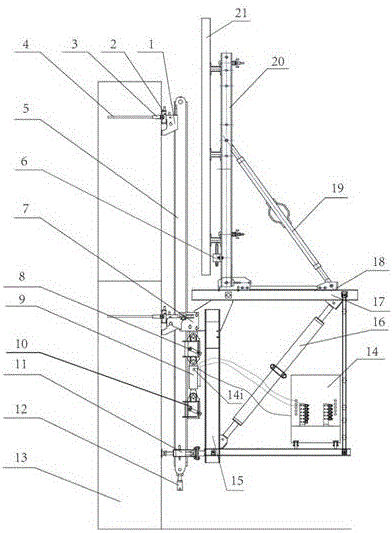

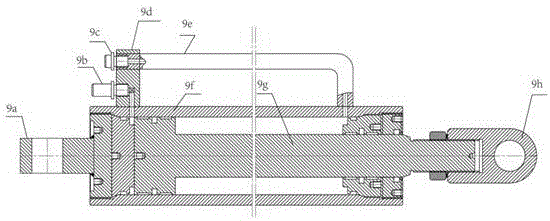

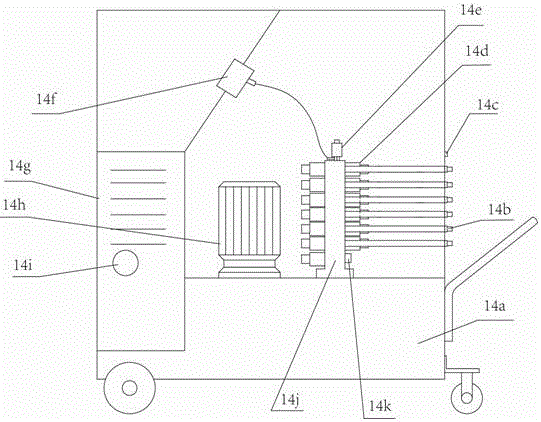

[0019] Such as figure 1 , 2 Shown, the present invention is provided with suspension device, track, stepping device, hydraulic pump station, bearing frame. The stepping device is provided with a plurality of climbing jacks 9, the two ends of each jack are respectively connected to the climbing box 8 and the climbing box 10, and the oil cylinder ends of the climbing jacks 9 are fixed with fixed fork lugs 9a, and the ends of the piston 9g are movable The connection structure is connected with a movable fork ear 9f, the fixed fork ear 9a is fixed together with the climbing box 8 through a pivot pin, and the movable fork ear 9f is reliably connected with the lower climbing box 10 through a pivot pin; a displacement sensor is fixed on the oil cylinder of the climbing jack 9, Real-time detection of the displacement value of the piston; the oil inlet 9b and the oil return port 9c of the climbing jack 9 are all installed on the oil nozzle block 9d and in the same direction as the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com