Multi-hydraulic cylinder synchronization control method

A synchronous control, multi-hydraulic cylinder technology, used in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc., can solve the problem that the movement accuracy cannot be guaranteed, the movement constraints of all cylinders, and the inability to coordinate the slave cylinder and the master cylinder. Speed matching and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

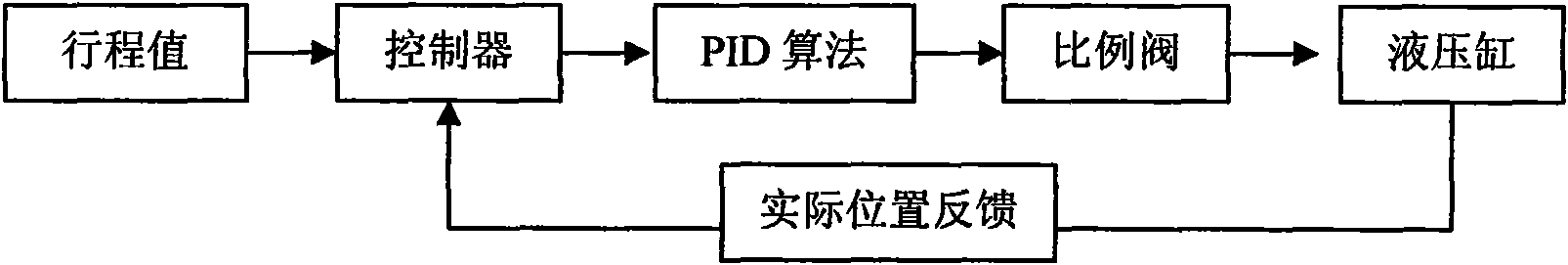

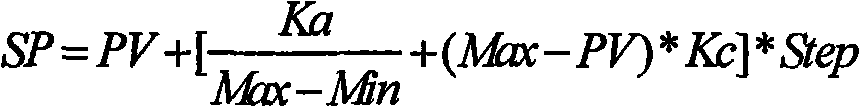

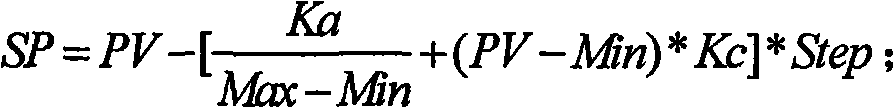

[0027] Each hydraulic cylinder has a displacement sensor to measure the actual displacement. A separate control loop such as figure 1 Shown: First, the controller judges whether the actual displacement value PV of the cylinder reaches the stroke value at a certain moment. If it reaches it, the value of SP is equal to the stroke value. If it does not reach it, the PID setting is calculated according to the actual position value PV of the hydraulic cylinder. Fixed value SP; then the PID algorithm calculates an output value according to the set value SP and PV, where the PID output value is the opening setting of the proportional valve. Send this PID output value to the input of the proportional valve, and the proportional valve will move the spool according to this value, causing the hydraulic cylinder to move. Since a closed-loop control is to be formed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com