System for differential recovery of potential energy of boom of oil liquid hybrid power excavating machine

An oil-liquid mixing and recovery system technology, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of difficult to widely use potential energy recovery systems, large throttling loss of control valves, and expensive energy storage components, so as to save fuel. , Reduce the energy conversion link, the effect of strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

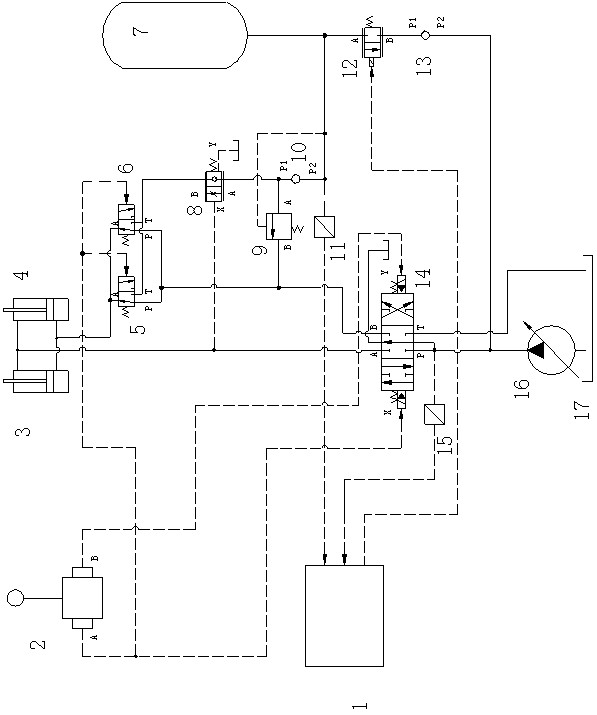

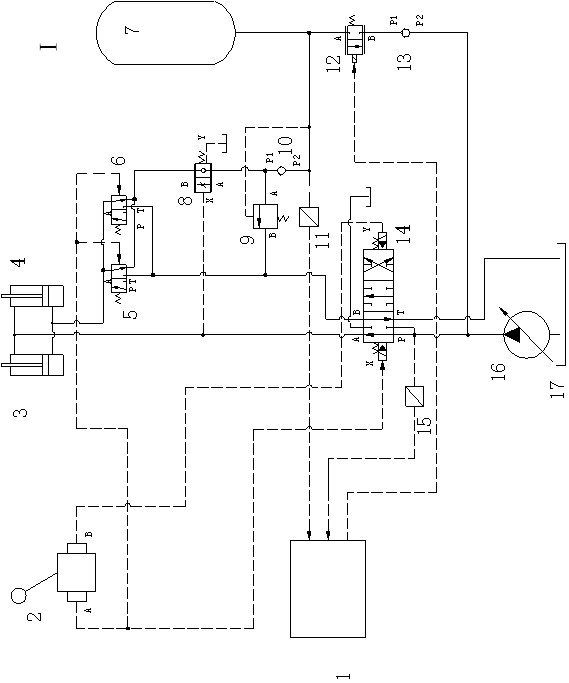

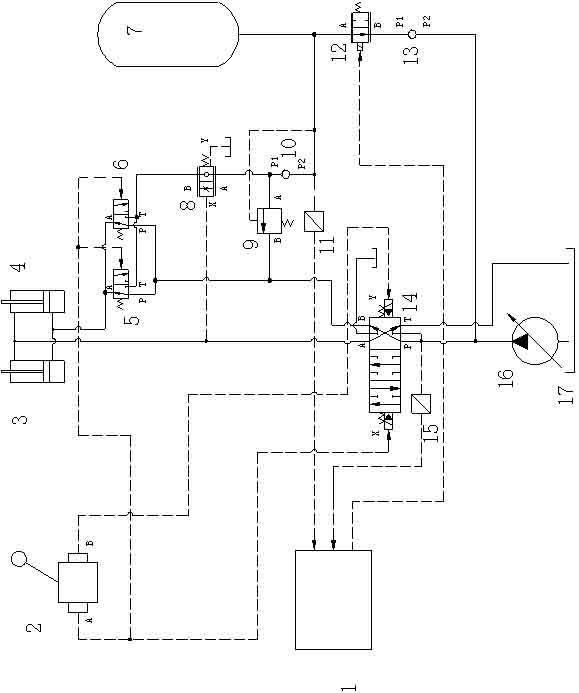

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the oil-hydraulic hybrid excavator boom potential energy differential recovery system includes a controller 1, a pilot control handle 2, a boom hydraulic cylinder 3, a boom hydraulic cylinder 4, a two-position three-way hydraulic control reversing valve 5, two Three-way hydraulic control reversing valve 6, accumulator 7, directional throttle valve 8, hydraulic control overflow valve 9, one-way valve 10, pressure sensor 11, solenoid valve 12, one-way valve 13, multi-way valve 14 , pressure sensor 15, variable pump 16, fuel tank 17; the fuel tank 17 is connected with the variable pump 16, the variable pump 16 is connected with the P port of the multi-way valve 14, the T port of the multi-way valve 14 is connected with the fuel tank 17, the multi-way valve 14 The pilot control X port is connected to the A port of the pilot oil circuit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com