Automatic fuel gas supercharging device and method of gas water heater

A technology for gas water heaters and booster devices, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as combustion, failure of gas water heaters to ignite normally, and combustion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

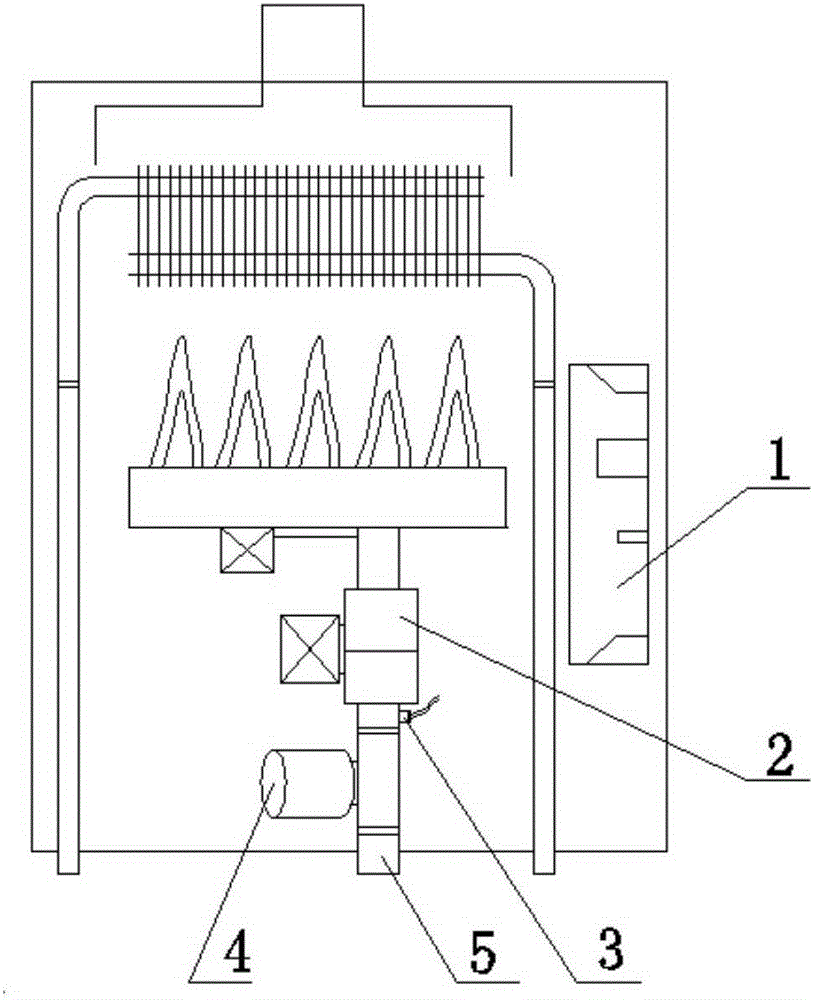

[0041] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a gas automatic supercharging device for a gas water heater provided by the present invention.

[0042] The present invention provides a gas automatic booster device for a gas water heater, which includes a controller 1 and a proportional valve 2 controlled by the controller 1, and pressure sensors are sequentially arranged in the air inlet of the proportional valve 2 or in the gas channel 5 in front of the air inlet 3 and the gas booster pump 4, wherein the controller 1 receives the gas pressure detected by the pressure sensor 3 and compares it with the preset value to control the opening and closing or operation of the gas booster pump 4 to adjust the output pressure of the gas booster pump 4, Make the pressure before the gas valve reach the preset value range during combustion.

[0043] As a preferred technical solution, in this embodiment, the controller 1 is connected with an alarm device...

Embodiment 2

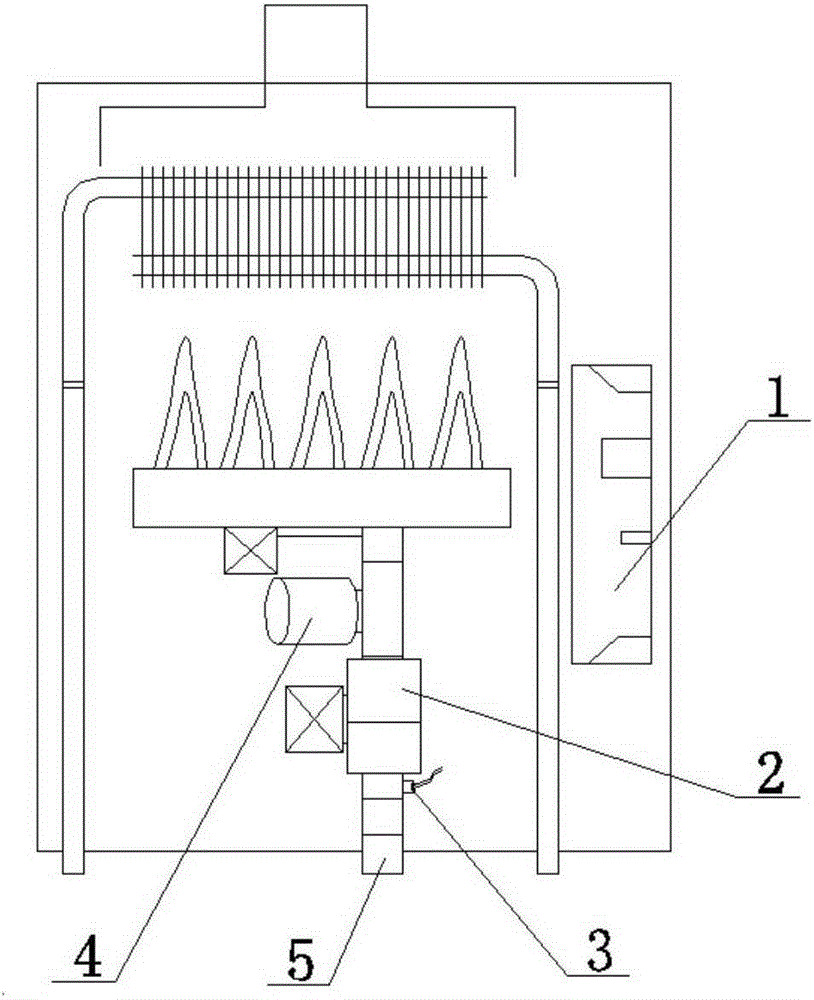

[0046] Please combine figure 2 , Figure 2 is a schematic structural view of the gas water heater gas automatic booster device provided by Embodiment 2 of the present invention.

[0047] The differences between this embodiment and Embodiment 1 are:

[0048] A pressure sensor 3 and a gas booster pump 4 are sequentially arranged in the gas outlet of the proportional valve or in the gas channel 5 in front of the gas outlet.

[0049] Other uniform structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

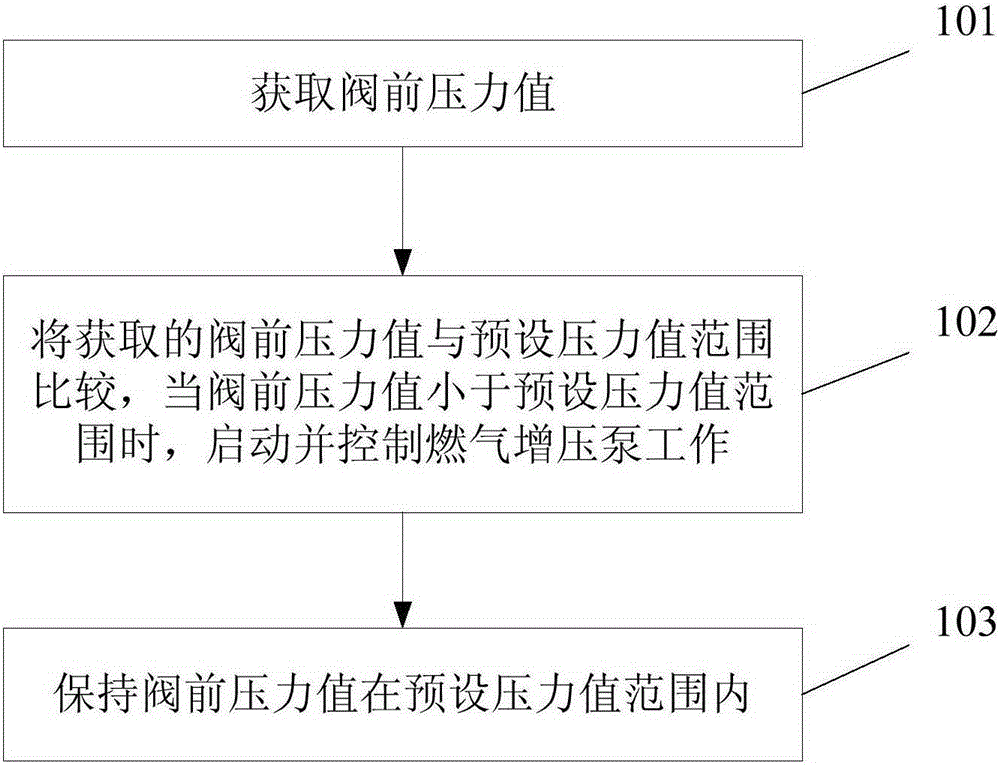

[0051] Please refer further image 3 , image 3 It is a flowchart of the gas automatic pressurization method for a gas water heater provided in this embodiment.

[0052] This embodiment provides a gas water heater gas automatic boosting method, which is controlled by using the gas water heater gas automatic boosting device in Embodiment 1 or Embodiment 2. The method includes:

[0053] Step 101 obtains the pre-valve pressure value of the proportional valve;

[0054] The pressure sensor in the intake pipe detects the pre-valve pressure signal and transmits it to the controller, and the controller obtains the pre-valve pressure value according to the pre-valve pressure signal.

[0055] It should be noted that, in this embodiment, the pre-valve pressure value can be obtained before the gas water heater is ignited, which is used to judge whether the gas pre-valve pressure reaches the pre-valve pressure required for the ignition of the hot gas water heater, so as to ensure the nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com