Speed reducer lubrication discharge pipe structure

A reducer and tube structure technology, which is applied in the direction of gear lubrication/cooling, mechanical equipment, transmission parts, etc., can solve the problems of lubrication pump damage, flow pressure relief, affecting the effect of reducer bearings and gear lubrication, etc., to achieve the use of Long life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

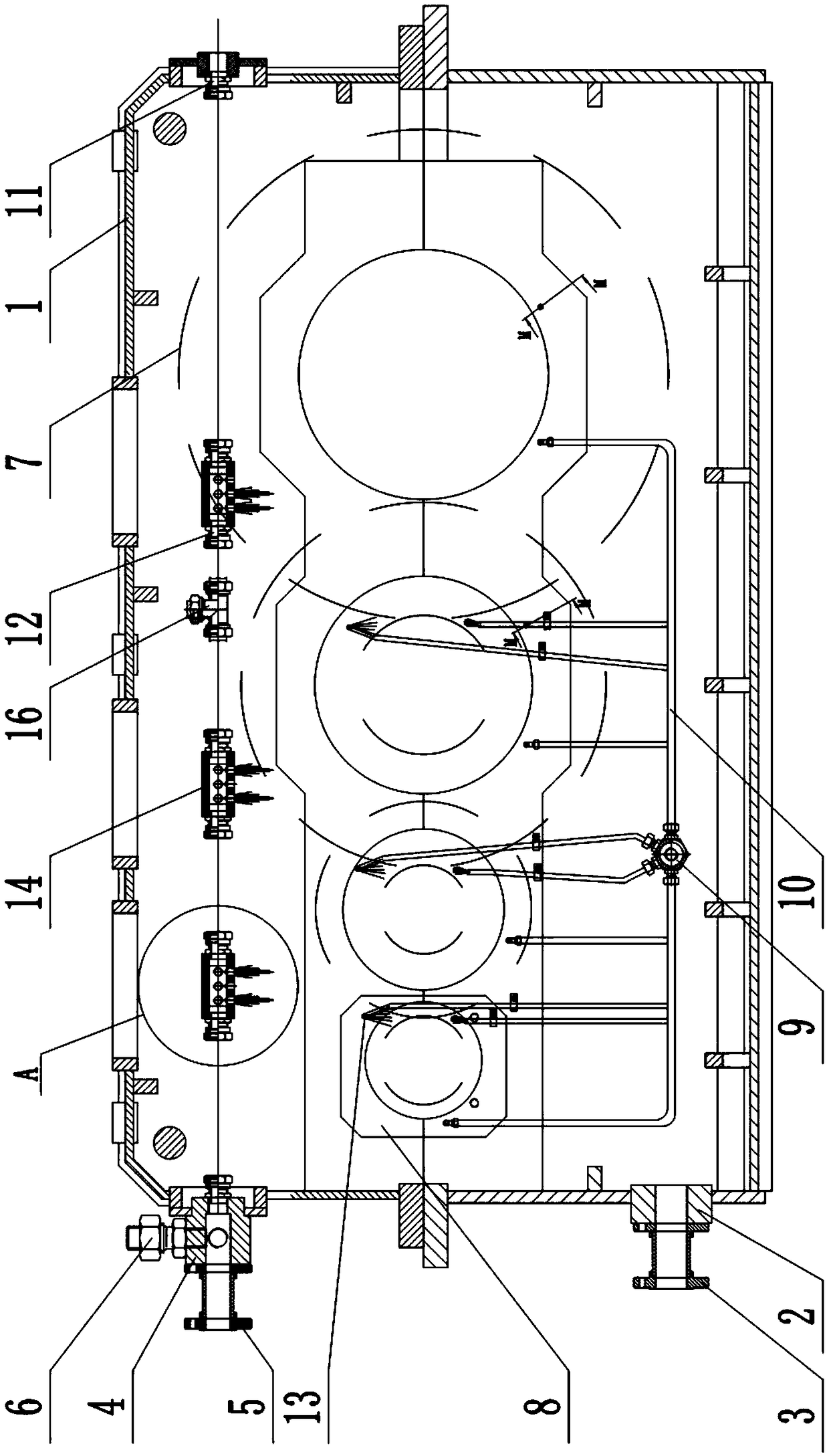

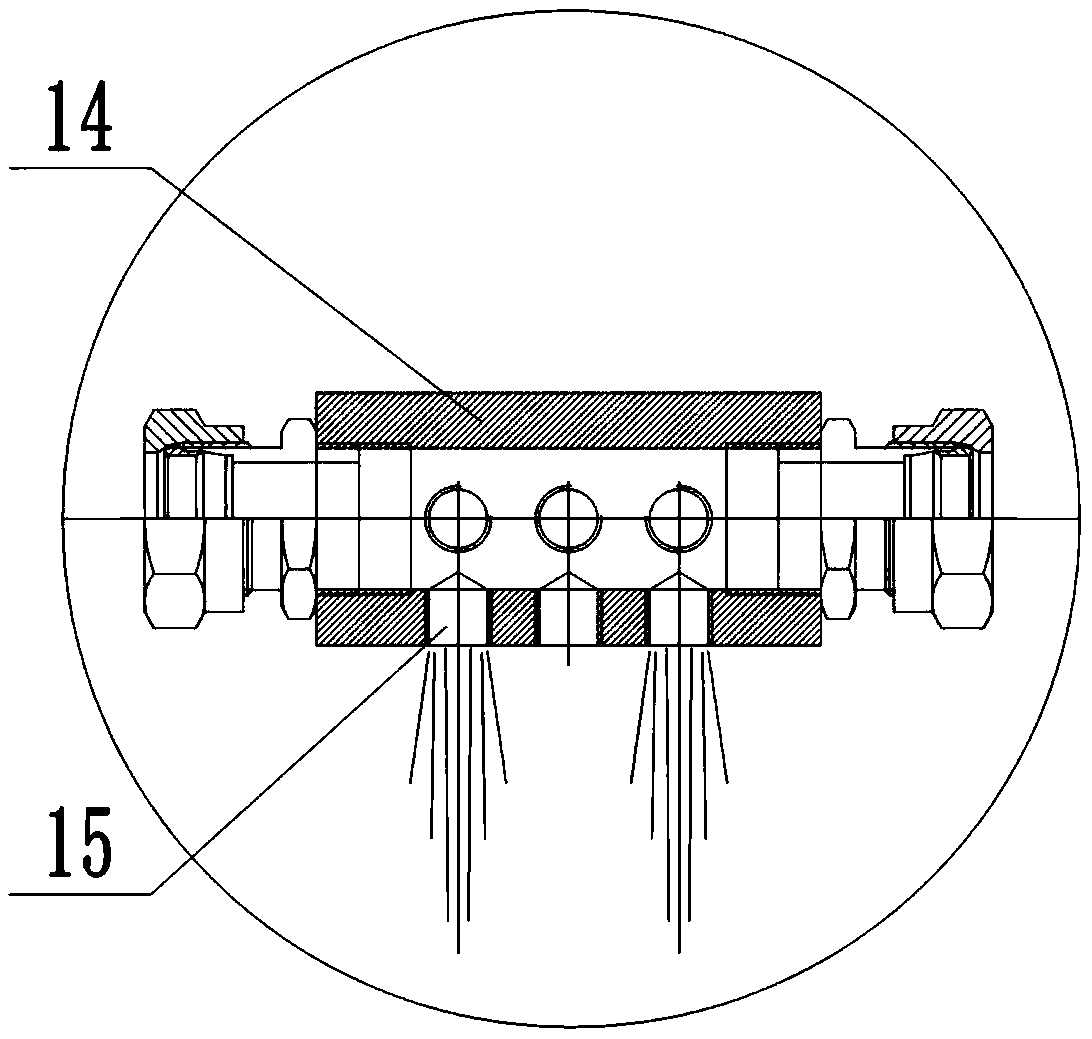

[0014] like figure 1 , 2 As shown, a reducer lubricating pipe structure, including a reducer case 1, is characterized in that an oil outlet pipe 2 is provided at the lower part of one side of the reducer case 1, and the other end of the oil outlet pipe 2 is connected with a lower flange 3. The flange 3 is connected to the oil suction hose for external lubrication, and the upper part of the reducer box 1 on the same side as the lower flange 3 is provided with an oil inlet pipe 4, and the other end of the oil inlet pipe 4 is connected to an upper flange 5, which is connected to the external lubrication The oil supply hose is connected, the upper end of the oil inlet pipe 4 is connected with a double outer wire ferrule joint 6, and the main distributor 9 is arranged under the several reducer gears 7 and several bearing chambers 8 in the reducer casing 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com