N-doped porous carbon supported metal catalyst, and preparation method and application thereof

A nitrogen-doped porous carbon and metal catalyst technology is applied in the preparation of heterocyclic compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc. Low price, excellent catalytic activity and stability, water and thermal stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0039] Preparation Example 1: Preparation of nitrogen-doped porous carbon material-supported Pt catalyst

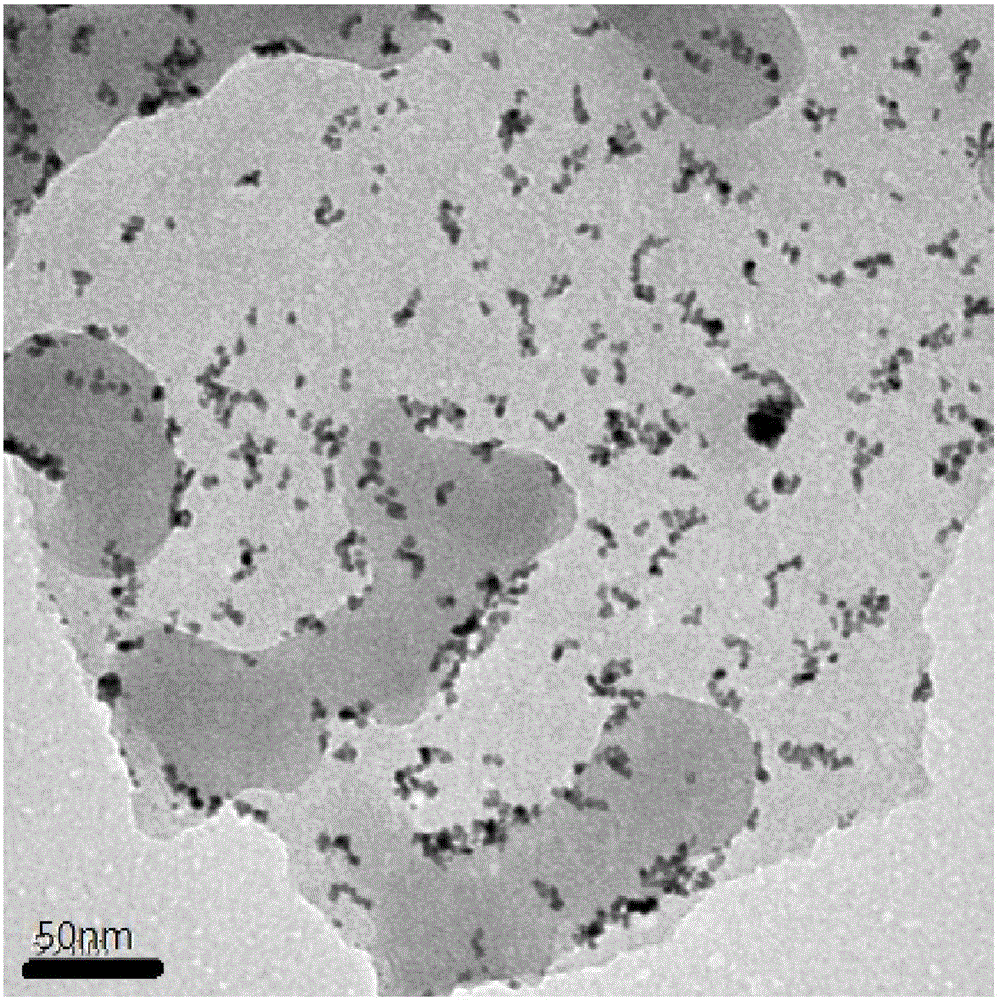

[0040] 1 kg of cleaned bamboo shoots was cut into pieces, heated to dryness in an oven at 70° C., and the obtained solid was ground into powder. Take 2g of powder and add it to 20mL of dilute sulfuric acid with a weight percentage of 1.5%, stir and mix evenly, then move to a hydrothermal reaction kettle, react at 180°C for 8 hours, filter, wash, and dry to obtain a brown solid. Afterwards, the obtained dried solid was calcined in a tube furnace in a nitrogen gas atmosphere, and kept at 550° C. for 5 hours. After the tube furnace was lowered to room temperature, the sample was taken out to obtain a nitrogen-doped porous carbon material with a nitrogen content of about 7.0at% and a specific surface area of 180m 2 / g. Take 1.0 g of the prepared nitrogen-doped porous carbon material, mix with 50 mL deionized water, 5 mL H 2 PtCl 6 The solutions (Pt concentration 0.01g / m...

preparation Embodiment 2

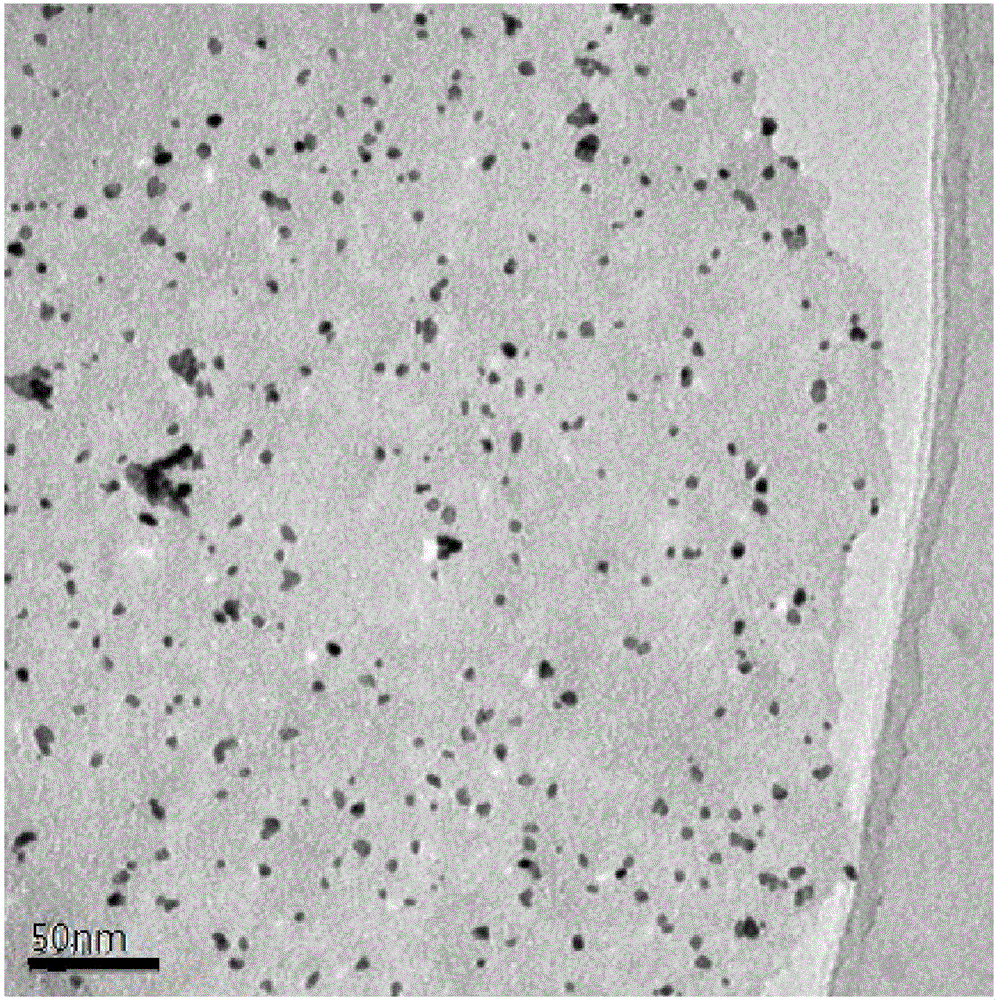

[0042] Except that the carbonization temperature was changed to 850° C., the nitrogen-doped carbon material and the Pt-supported catalyst were prepared according to the same method as Preparation Example 1. The elemental analysis results show that the nitrogen content of the material is 2.8at%, and the BET test results show that the specific surface area is about 650m 2 / g, figure 2 It is the TEM picture of the Pt catalyst supported by nitrogen-doped porous carbon prepared according to the present example, such as figure 2 As shown, the Pt nanoparticles in the material are uniformly dispersed on the surface of the carbon material, and the particle size is about 3.5nm.

preparation Embodiment 3

[0043] Preparation Example 3: Preparation of nitrogen-doped porous carbon material-supported Au catalyst

[0044] The nitrogen-doped porous carbon material-supported Au catalyst was prepared according to the same method as in Preparation Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com