Desulfurizing method and synergistic agent thereof

A synergist, wet flue gas desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of not improving the efficiency of limestone-gypsum wet flue gas desulfurization and desulfurization, reducing the amount of limestone used, Solve problems such as increased sulfur content in coal, and achieve the effects of saving operating power, reducing water content, and enhancing reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

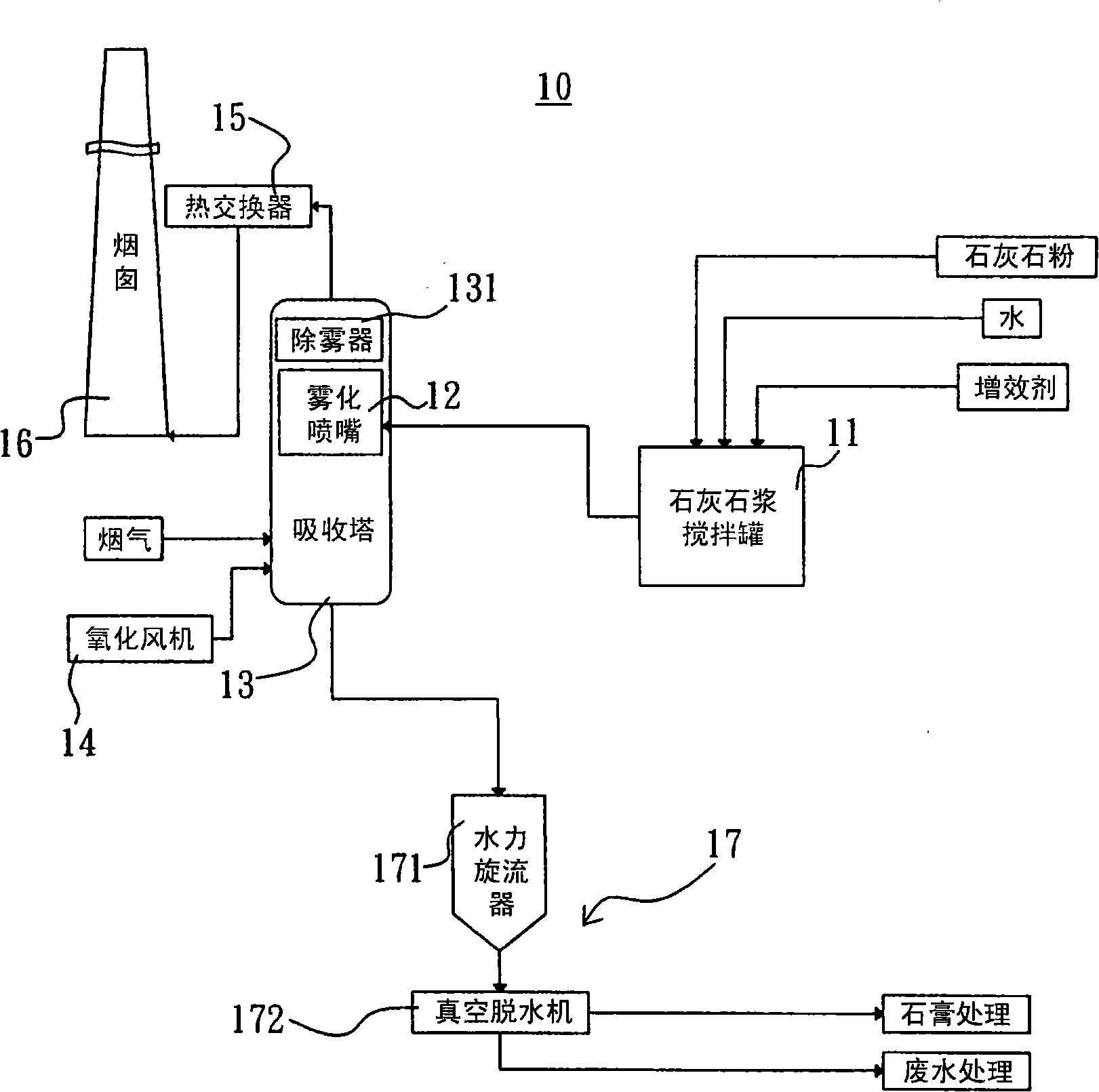

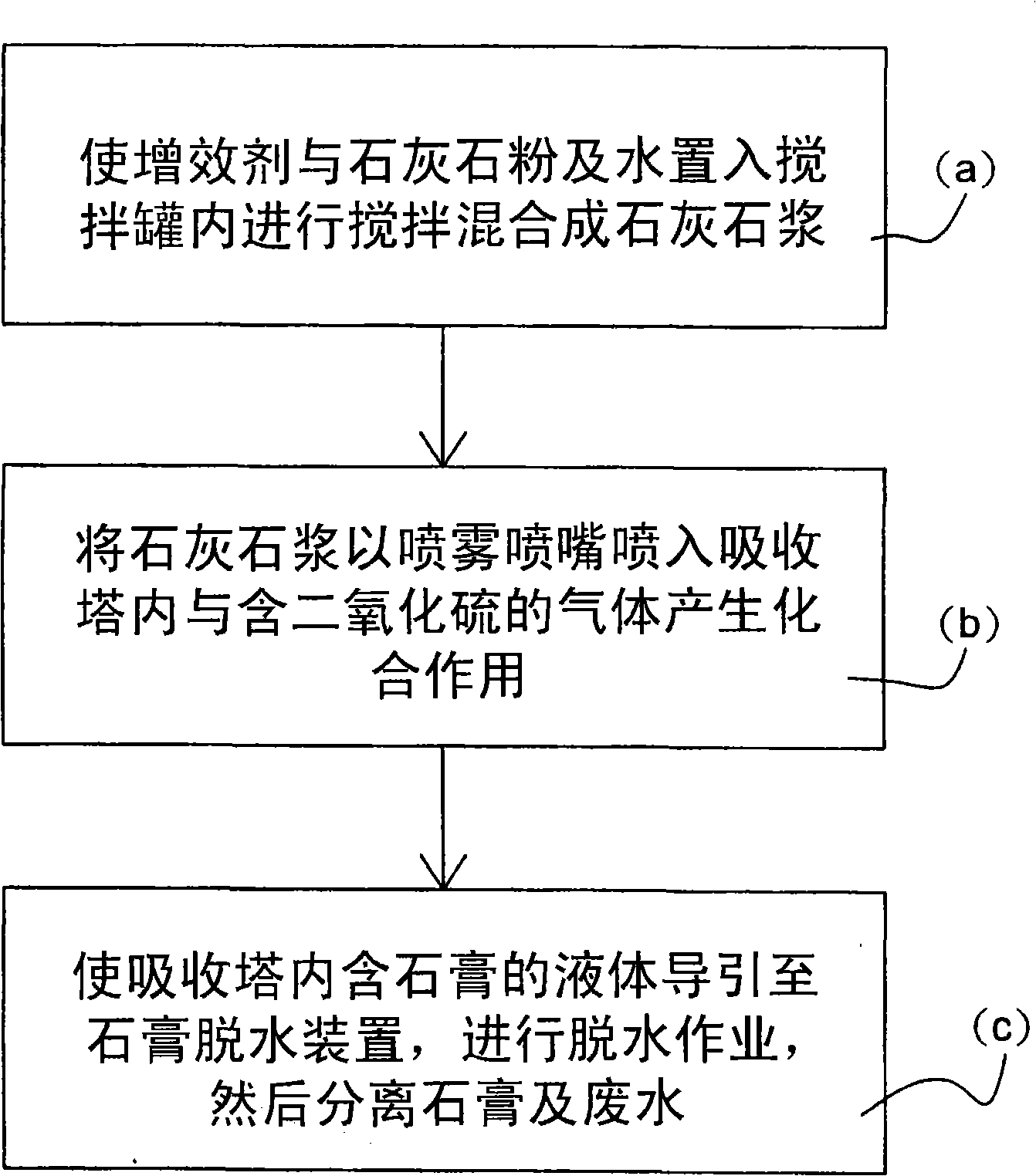

Method used

Image

Examples

Embodiment 1

[0063] Component Percentage

[0064] Dialkyl sulfosuccinate 70.0

[0065] Propylene glycol 10.0

[0066] Purified water 20.0.

Embodiment 2

[0068] Component Percentage

[0069] Dialkyl sulfosuccinate 35.0

[0070] Monoalkyl sulfosuccinate 35.0

[0071] Diethylene glycol 10.0

[0072] Purified water 20.0.

[0073] With the synergist of above-mentioned embodiment 1. and embodiment 2., utilizing the desulfurization method of the above-mentioned first embodiment, the synergist of the present invention is directly added into limestone slurry with different dosages (according to the amount of limestone slurry) and stirred In the tank, after mixing well, it enters the absorption tower with limestone slurry in the form of spray to participate in the desulfurization reaction, and the data obtained for improving the desulfurization efficiency are as follows:

[0074] Dosage (according to the amount of limestone slurry)

[0075] The above results show that the synergist of the present invention can improve the desulfurization efficiency of limestone slurry, thus reducing the amount of limestone used and the gene...

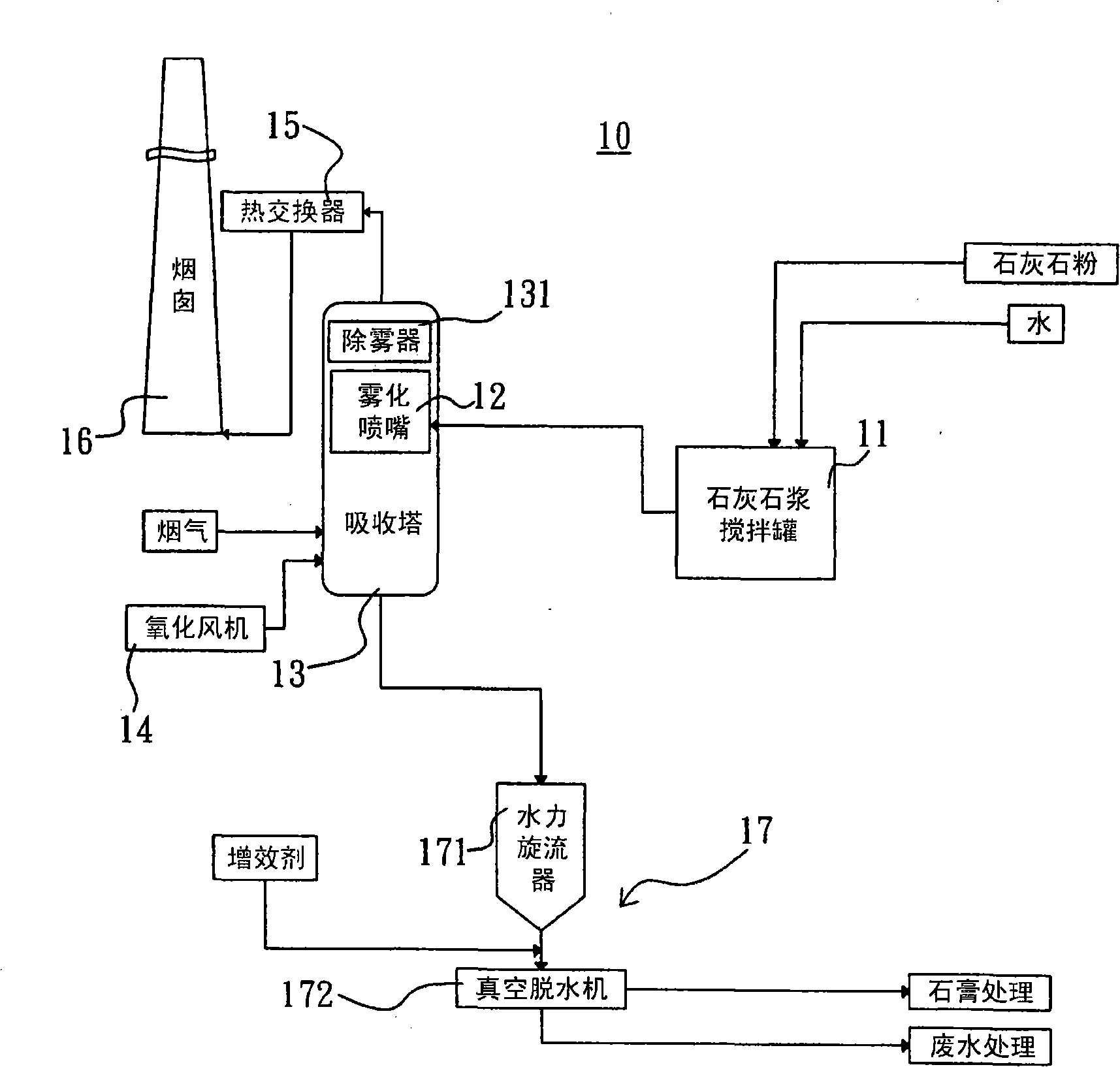

Embodiment 3

[0077] Component Percentage

[0078] Dialkyl sulfosuccinate 70.0

[0079] Diethylene glycol 10.0

[0080] Purified water 20.0.

[0081] With the synergist of the above-mentioned embodiment 3., utilizing the desulfurization method of the second embodiment above, the synergist of the present invention is directly added to the gypsum before the gypsum vacuum dehydrator with different dosages (in terms of gypsum slurry) pulp, such as image 3 As shown, the data obtained to improve the dewatering efficiency of gypsum slurry are as follows:

[0082] Dosage (according to the amount of gypsum slurry)

none

(0ppm)

two ten thousandths

(200ppm)

5 out of 10,000

(500ppm)

Water content of gypsum before dehydration

17.0%

17.0%

17.0%

Moisture content of gypsum after dehydration

10.1%

8.8%

8.2%

[0083] The above results show that the synergist of the present invention can help filter and impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com