Preparation method of multifunctional cellulose elastic aerogel

A cellulose gel and cellulose technology, which is applied in the preparation of cellulose airgel and the field of preparation of multifunctional cellulose elastic airgel, can solve the problem of complex preparation methods, low mechanical strength, and no Elasticity and other issues, to achieve the effect of expanding the application range, excellent magnetic properties, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

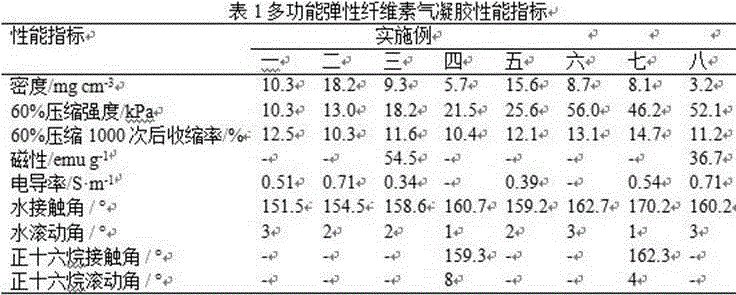

Embodiment 1

[0019] Weigh 10g of sugarcane waste residue, add 1L of deionized water to soak, crush and mechanically stir for 3h to make a 0.01g / mL cellulose suspension; take 300mL of cellulose suspension, put it in a 500mL round bottom flask, add 4g of Sodium chlorate and 1.2mL acetic acid were mechanically stirred at 75°C for 3 hours for pretreatment, washed with deionized water to obtain a modified cellulose suspension; then dispersed in ethanol, vacuum-filtered and formed, at 60°C Dry to form a cellulose gel; finally the cellulose gel is placed in N 2 Carbonization at 800°C for 4 hours under atmosphere to obtain multifunctional elastic cellulose airgel. The properties are shown in Table 1.

Embodiment 2

[0021] Weigh 7g of cotton fiber, crush it, put it in a 500mL round bottom flask, add 400mL of deionized water, 1g of sodium chlorite and 0.3mL of acetic acid, mechanically stir at 80°C for 2.5h for pretreatment, and wash with deionized water clean to obtain a modified cellulose suspension; then disperse it in acetone, form it by vacuum suction filtration, and dry at 60°C to form a cellulose gel; finally, the cellulose gel is placed in N 2 Carbonization at 1000°C for 3 hours under atmosphere to obtain multifunctional elastic cellulose airgel. The properties are shown in Table 1.

Embodiment 3

[0023] Weigh 20 g of nanocellulose, add 400 mL of deionized water, and stir mechanically for 2 h to prepare a 0.05 g / mL purified cellulose suspension; weigh 0.4 g Fe 3 o 4 Nanoparticles were added to a 250mL polytetrafluorothermal tank; 120mL of purified cellulose suspension was added to a polytetrafluorohydrothermal tank, magnetically stirred for 10min, ultrasonicated for 30min, and reacted at 160°C for 8h to obtain cellulose / Fe3iron tetroxide nanocomposite suspension; then it was dispersed in acetone, formed by suction filtration, and dried at 60°C to form a cellulose / ferric oxide nanocomposite gel; finally the composite gel was placed in N 2 Carbonization at 800°C for 2 hours under atmosphere to obtain multifunctional elastic cellulose airgel. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com