Slow-release chlorine dioxide solid disinfectant

A chlorine dioxide and disinfectant technology, which is applied in the direction of disinfectant, biocide, bactericide, etc., can solve the problems of storage, transportation and use inconvenience, the need to make and use it now, and the change of slow-release performance, etc., to achieve chlorine dioxide The effect of high substance content, convenient packaging and transportation, and long release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

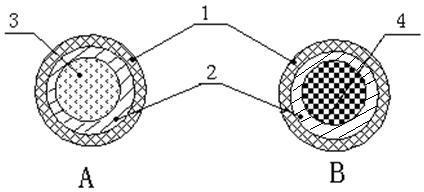

Image

Examples

Embodiment 1

[0021] Embodiment 1 The preparation of slow-release chlorine dioxide solid disinfectant

[0022] 1. Prepare PVA solution a:

[0023] Weigh 24g of polyvinyl alcohol (PVA) into 150mL of pure water, then add 250mL of ethanol, stir evenly, and make PVA solution a.

[0024] 2. Prepare PMMA solution b:

[0025] Weigh 12 g of polymethyl methacrylate (PMMA) and add it to 1000 ml of ethyl acetate, stir while adding, and make PMMA solution b.

[0026] 3. Prepare sodium chlorite microcapsules (named as microcapsules A):

[0027] (1), weigh 10g of solid sodium chlorite (NaClO 2 ), after grinding, spray with 50mL of PVA solution a, while stirring continuously until the spraying is completed, and then put it into a vacuum drying oven at 50°C for 12 hours to obtain NaClO coated with PVA 2 Particle A', i.e. NaClO 2 / PVA.

[0028] (2), the NaClO 2 / PVA particles A' are sprayed with 100mL of PMMA solution b, while stirring continuously, after the spraying is completed, put in a vacuum dr...

Embodiment 2

[0035] Embodiment 2 The slow-release chlorine dioxide solid preparation disinfectant is used for the disinfection of drinking water

[0036] According to the treatment of 100 tons of drinking water per day, add 4 kg of chlorine dioxide disinfectant prepared by the method of embodiment 1, within 6-8 days, the concentration of chlorine dioxide in the water can be maintained at 0.04-0.10 mg / L, which meets the "Drinking Water Sanitation" Standard" (GB5749-2006), the requirement for residual chlorine dioxide in the tip water to be greater than 0.02mg / L.

Embodiment 3

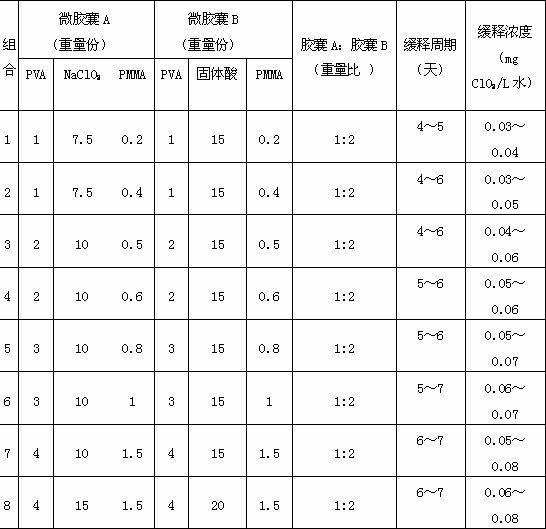

[0038] In addition, other different combinations were also tested according to the above process, and 100 tons of drinking water was still treated per day. Adding 4 kg of chlorine dioxide disinfectant prepared by the above method can maintain the concentration of chlorine dioxide in water at 0.03 to 0.08 mg / L for 4 to 7 days (See Table 1 for details), which meets the requirement that the residual chlorine dioxide in the tip water should be greater than 0.02mg / L in the Hygienic Standard for Drinking Water (GB5749-2006).

[0039] Table 1 The effect of chlorine dioxide solid disinfectant prepared in different proportions for on-site disinfection

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com