Controlled release formulation of solid chlorine dioxide

A technology of chlorine dioxide and slow-release agent, applied in the direction of biocide, disinfectant, animal repellent, etc., can solve the problems of short storage period, inconvenient use, complicated equipment, etc., and achieve convenient storage and transportation, convenient use, and production simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

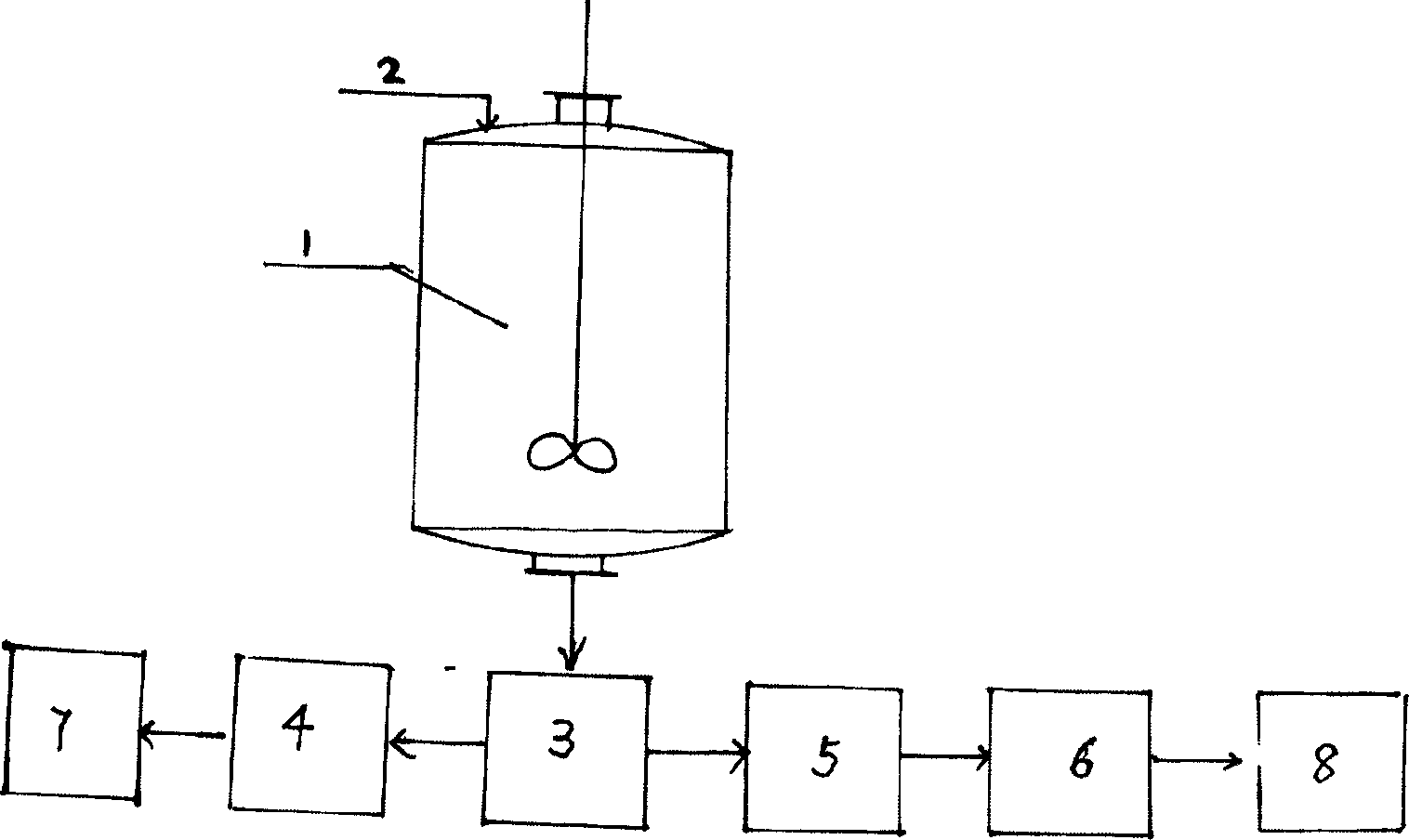

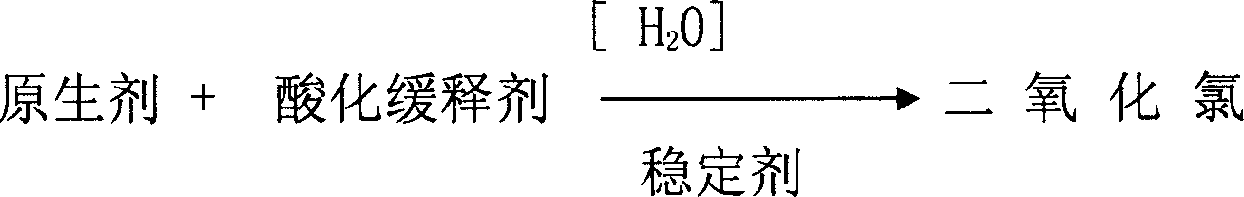

Method used

Image

Examples

example 1

[0014] Dry 10 parts of sodium chlorite, 3 parts of calcium carbonate, 2 parts of sodium bicarbonate, 10 parts of carboxymethyl cellulose, 16 parts of benzyltriethylammonium chloride, 10 parts of ferric chloride, zinc chloride 8 parts, 30 parts of anhydrous aluminum trichloride, and 11 parts of diatomaceous earth were respectively added to a mixer, stirred and mixed for 30 minutes, and discharged to obtain a solid chlorine dioxide slow-release agent powder containing 6% chlorine dioxide. The above-mentioned powders are packed in sealed plastic bags of 1g / bag, 2g / bag, 5g / bag, 10g / bag, 1KG / bag, 5KG / bag as required. When in use, the packaging bag is pricked with a needle, and the powder absorbs the moisture in the environment to release chlorine dioxide slowly.

[0015] Cut the bagged solid chlorine dioxide sustained-release agent powder, put the powder in a vessel, add water (a small amount) to release chlorine dioxide quickly.

[0016] Pour the solid chlorine dioxide sustained-...

example 2

[0019] Dry 30 parts of sodium chlorite, 40 parts of benzyltriethylammonium chloride, 6 parts of ammonium sulfate, 10 parts of ferric chloride, 10 parts of aluminum trichloride, 2 parts of sodium bicarbonate, 2 parts of diatomaceous earth Pour into the mixer respectively, stir and mix for 30 minutes, and discharge. Obtain the solid chlorine dioxide sustained-release agent powder containing chlorine dioxide 18%.

[0020] Powder packing is the same as example 1.

[0021] Tablet production, packaging, storage, and use methods are the same as in Example 1.

example 3

[0023] Add 17 parts of dry sodium chlorite, 10 parts of calcium carbonate, 45 parts of octadecyltrimethylammonium chloride, 15 parts of ferric chloride, 5 parts of aluminum trichloride, and 8 parts of diatomaceous earth. In the mixer, stir and mix for 30 minutes, and discharge. Obtain the solid chlorine dioxide slow-release agent powder containing chlorine dioxide 10%.

[0024] The production, packaging, storage and use methods of powder and tablet are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com