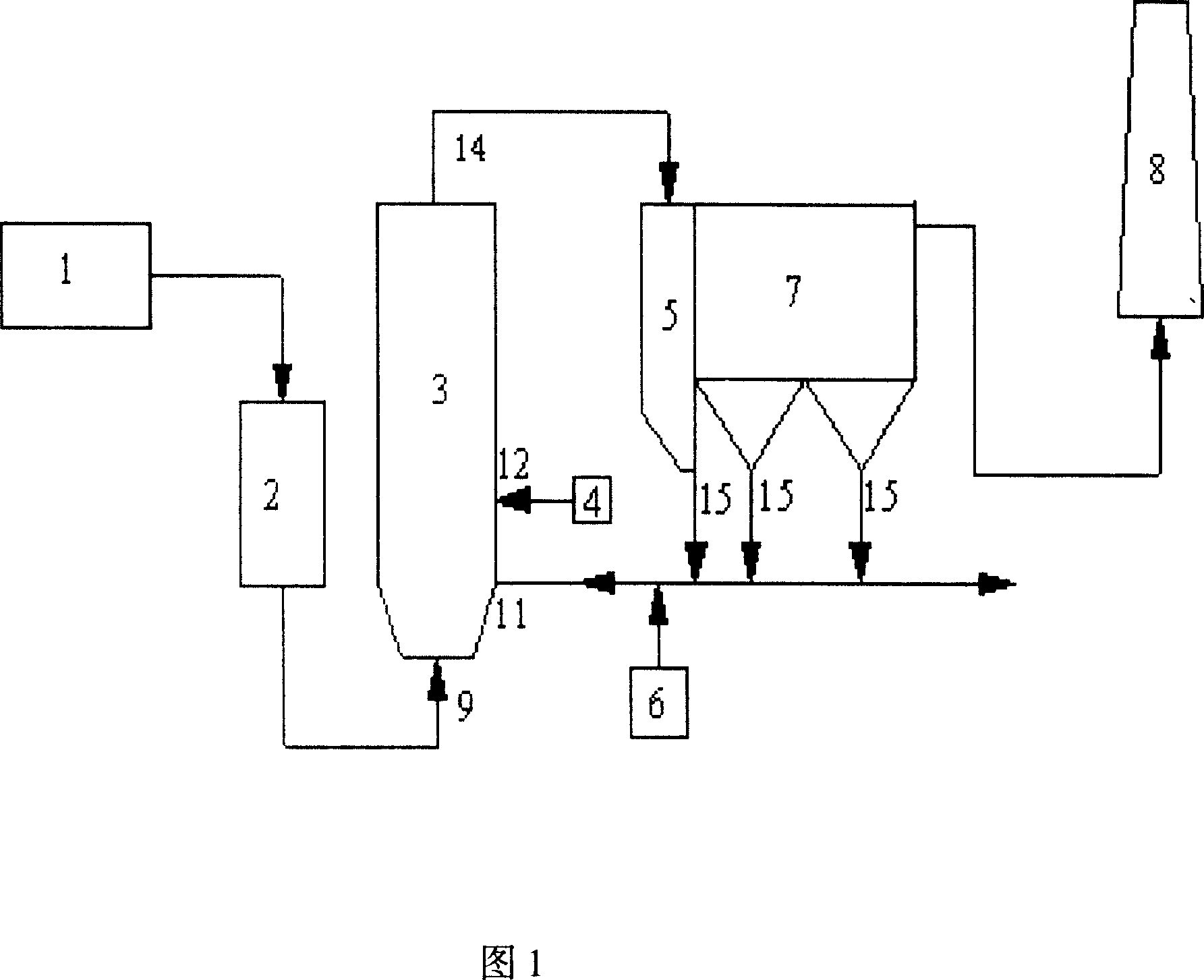

Method and apparatus for removing sulfur, nitrate and mercury simultaneously from boiler flue gas

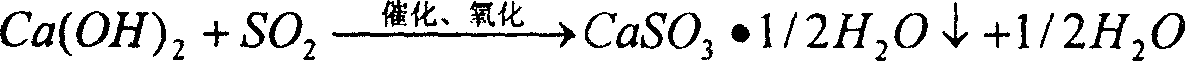

A technology for desulfurization, denitrification, mercury removal, and boiler flue gas, which is applied in the field of flue gas purification, can solve the problems of restricting flue gas purification engineering, sulfur oxides, nitrogen oxides and mercury are difficult to be removed at the same time, and achieve low cost and long-term The effect of high residence time and removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

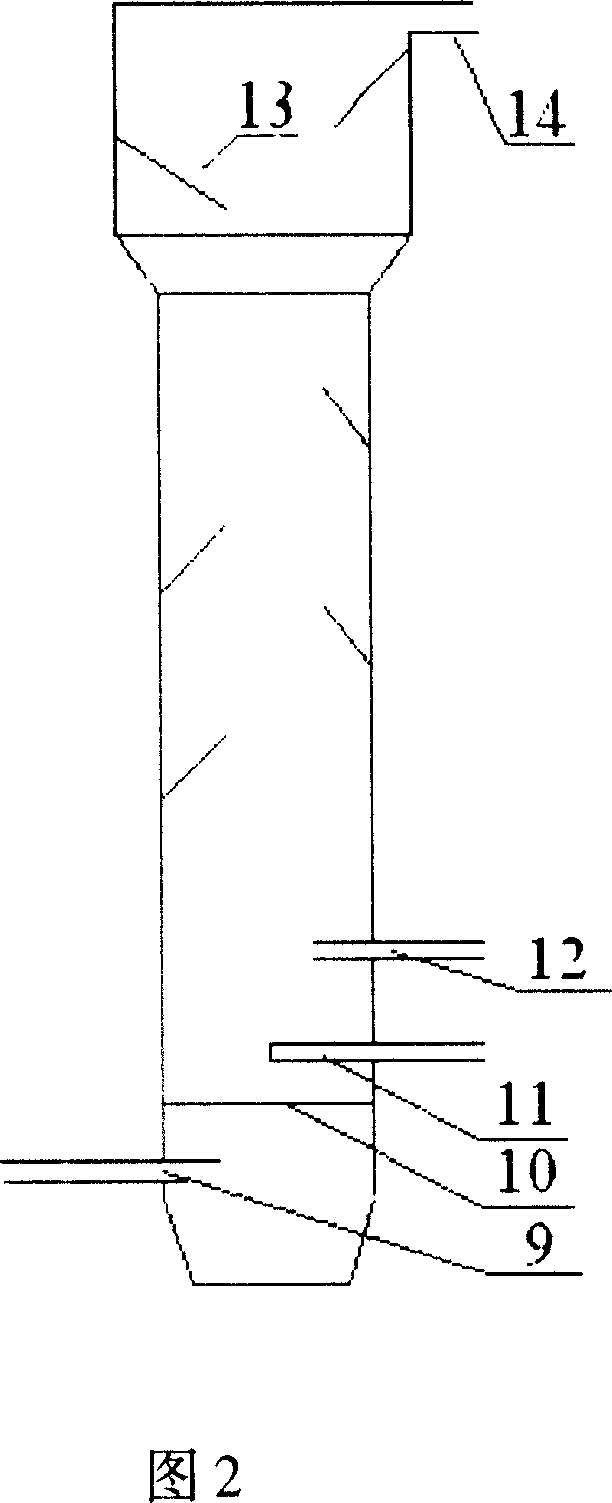

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Take fly ash 60, hydrated lime 38.4, and sodium chlorite 1.6 by weight unit, add the above materials into the digester, add water to mix, stir at 40°C for 4.0 hours, centrifugal dehydration and drying to obtain The highly active absorbent. Among them, the median diameter of fly ash is about 24 μm, and that of slaked lime is about 6 μm.

Embodiment 2

[0035] Embodiment 2: Take fly ash 30, slaked lime 68.4, sodium chlorite 1.0, sodium chloride 0.6 by weight unit, add the above-mentioned materials in the digester, add water to mix, stir at 60 ℃ for 2.0 hours, centrifuge The highly active absorbent is obtained by dehydration and drying.

Embodiment 3

[0036] Example 3: Take fly ash 40, slaked lime 58.4, and calcium hypochlorite 1.6 by weight unit, add the above materials into the digester, add water to mix, stir at a temperature of 80°C for 1.0 hour, centrifugal dehydration and drying to obtain The highly active absorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com