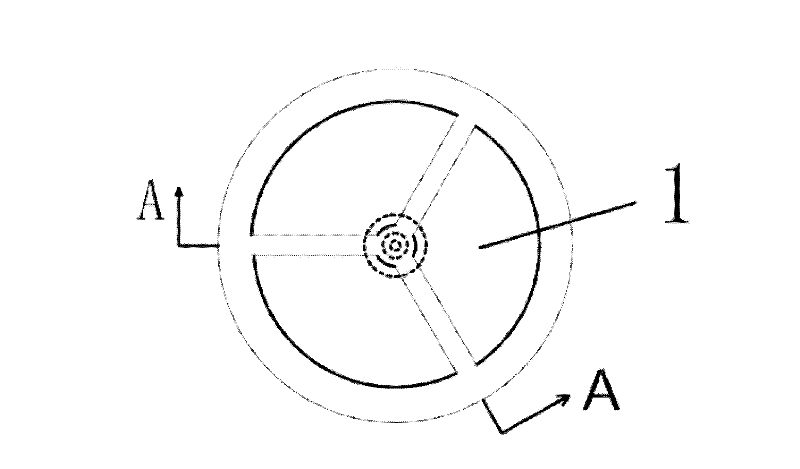

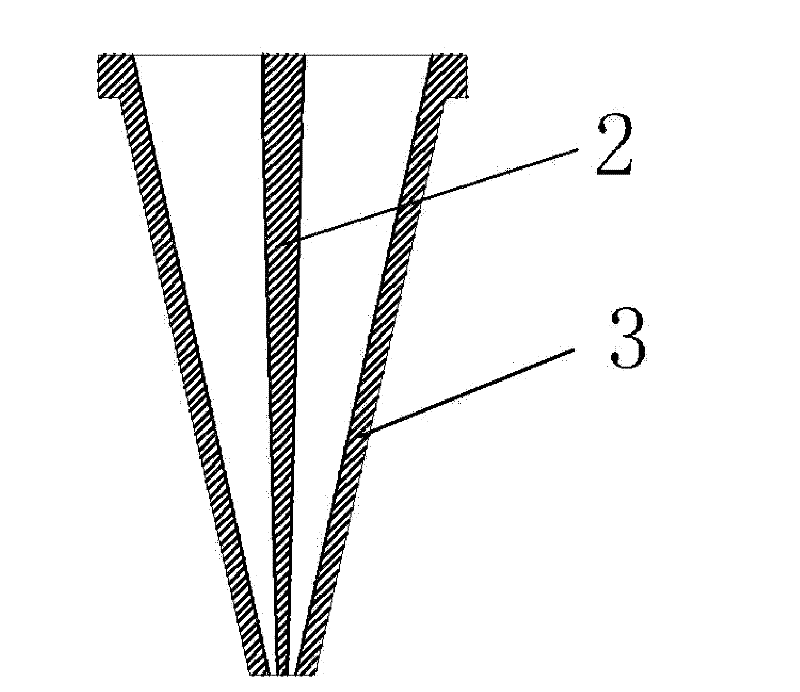

Hollow fiber ceramic membrane and preparation method thereof

A ceramic membrane and fiber technology, applied in the field of high filtration flux hollow fiber ceramic membrane and its preparation, can solve the problems of large equipment investment, complex process, difficult industrialization, etc., and achieve the effect of low cost and high filtration flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A. Weigh 4000 grams of aluminum hydroxide, 2000 grams of ash clay, 1000 grams of albite, 1000 grams of dolomite, 1000 grams of powdery borosilicate glass, 700 grams of carboxymethyl cellulose and 300 grams of glycerin in proportion Ask for ingredients;

[0036] B. Add the above-mentioned ceramic powder into a ball mill for ball milling for 4h, material: ball stone: water=1:2:1, and remove iron after passing through a 250 mesh sieve to obtain 20000 grams of ceramic slurry;

[0037] C, dehydrating the ceramic slurry prepared in the above step B through a mud press (TCYL hydraulic mud press) to obtain 11900 grams of mud cake, so that the mass content of water is 14%;

[0038] D, the mud cake of step C is added into the mud refining machine to carry out vacuum mud refining, and stale for 48h, obtain stale mud section 11900 grams, the mud refining machine is existing equipment (LN-65L vertical vacuum mud refining machine);

[0039] E. Put the stale mud section obtained in s...

Embodiment 2

[0043] A. Weigh 6000 grams of 200 mesh aluminum hydroxide, 1000 grams of 400 mesh ash clay, 500 grams of 400 mesh albite, 500 grams of 400 mesh dolomite, 1000 grams of 400 mesh powdery borosilicate glass, carboxymethyl 700 grams of cellulose and 300 grams of glycerin require ingredients in proportion;

[0044] B. Add the above-mentioned ceramic powder into a ball mill for ball milling for 4 hours, material: ball stone: water=1:2:1, and remove iron after passing through a 300-mesh sieve to obtain 20,000 grams of ceramic slurry;

[0045] C. Dehydrating the ceramic slurry prepared in the above step B through a mud press (TCYL hydraulic mud press) to obtain 11,500 grams of mud cake; the mass content of water is 17%;

[0046] D, the mud cake of step C is added into the mud refining machine to carry out vacuum mud refining, and stale for 60h to obtain 11500 grams of stale mud section, and the mud refining machine is an existing equipment (LN-65L vertical vacuum mud refining machine)...

Embodiment 3

[0051] A. Weigh 8000 grams of 400 mesh aluminum hydroxide, 1000 grams of 600 mesh ash clay, 100 grams of 600 mesh albite, 100 grams of 600 mesh dolomite, 600 grams of 400 mesh powdery borosilicate glass, carboxymethyl 100 grams of cellulose and 100 grams of glycerin require ingredients in proportion;

[0052] B. Add the above-mentioned ceramic powder into a ball mill for ball milling for 4h, material: ball stone: water=1:2:1, and remove iron after passing through a 250 mesh sieve to obtain 20000 grams of ceramic slurry;

[0053] C, dehydrating the ceramic slurry prepared in the above step B through a mud press (TCYL hydraulic mud press) to obtain 11900 grams of mud cake; the mass content of water is 20%;

[0054] D, the mud cake of step C is added into the mud refining machine to carry out vacuum mud refining, and stale for 72h to obtain 11900 grams of stale mud section, and the mud refining machine is an existing equipment (LN-65L vertical vacuum mud refining machine);

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com