Fire-proof paint modifier of tunnel based on polymer/clay intercalation modifying technology and production thereof

A fire-resistant coating and polymer technology, applied in the direction of coating, can solve the problems of coating moisture, coating peeling, coating surface corrosion, etc., and achieve the effect of improving barrier property, water resistance and good barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

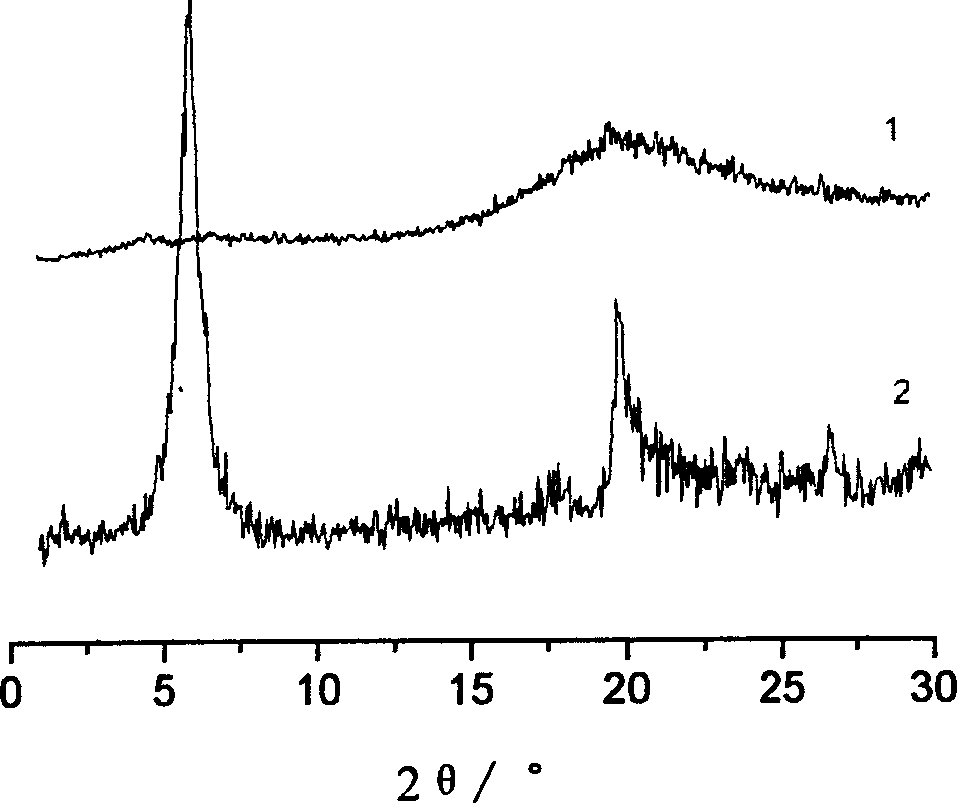

Image

Examples

Embodiment 1

[0030] Preparation of modified clay:

[0031] 1) Add 1Kg of montmorillonite and 50Kg of deionized water to the reactor in order, and stir at high speed for 5min;

[0032] 2) After raising the reaction kettle to 50°C, add 0.5Kg of organic intercalant cetyltrimethylammonium bromide and stir vigorously for 15 minutes, then stir at low speed for 4 hours, and cool to discharge;

[0033]3) Centrifugally separate the product and wash it repeatedly with ethanol-deionized water with a molar ratio of 1:1 until the centrifugal mother liquor does not appear to precipitate with a 0.1 mol / L silver nitrate solution;

[0034] 4) The cleaned product is vacuum dried at 90°C for 24 hours, and the product obtained is modified clay, which is packaged for later use.

[0035] Preparation of polymer / clay intercalation modification modifier (designed with the total raw materials as 50Kg):

[0036] 1) Take 1.5Kg of modified clay prepared by the above method and grind it in a ball mill tank for 3 hours, sta...

Embodiment 2~5

[0045] Change the dosage of the modified clay and amino resin solution in the formula, the dosage of the additive remains unchanged, and apply the modifier to the surface of the tunnel fireproof coating. The results are shown in Table 1.

[0046] Example

Embodiment 6

[0048] Preparation of modified clay:

[0049] 1) Add 3Kg of vermiculite and 150Kg of deionized water to the reactor in order, and stir at high speed for 5min;

[0050] 2) After raising the reaction kettle to 60°C, add 1.5Kg of organic intercalant octadecyltrimethylammonium chloride and stir vigorously for 15 minutes, then stir at low speed for 5 hours, and cool and discharge;

[0051] 3) Centrifugally separate the product and wash it repeatedly with ethanol-deionized water with a molar ratio of 1:1 until the centrifugal mother liquor does not appear to precipitate with a 0.1 mol / L silver nitrate solution;

[0052] 4) Dry the cleaned product under vacuum at 90°C for 24 hours. The resulting product is modified clay, ready for bottled.

[0053] Preparation of polymer / clay surface modifier:

[0054] 1) Take 2Kg of the modified clay prepared by the above method and grind it in a ball mill tank for 3 hours, static precipitation, drying, grinding, and sieving;

[0055] 2) Add 2Kg of modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com