Fire-proof paint modifier of tunnel based on polymer/clay intercalation modifying technology and production thereof

A technology of fire retardant coating and polymer, applied in the direction of fire retardant coating, coating, etc., can solve the problems of coating moisture, coating peeling, low bonding strength, etc., to achieve good barrier properties, improve barrier properties and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

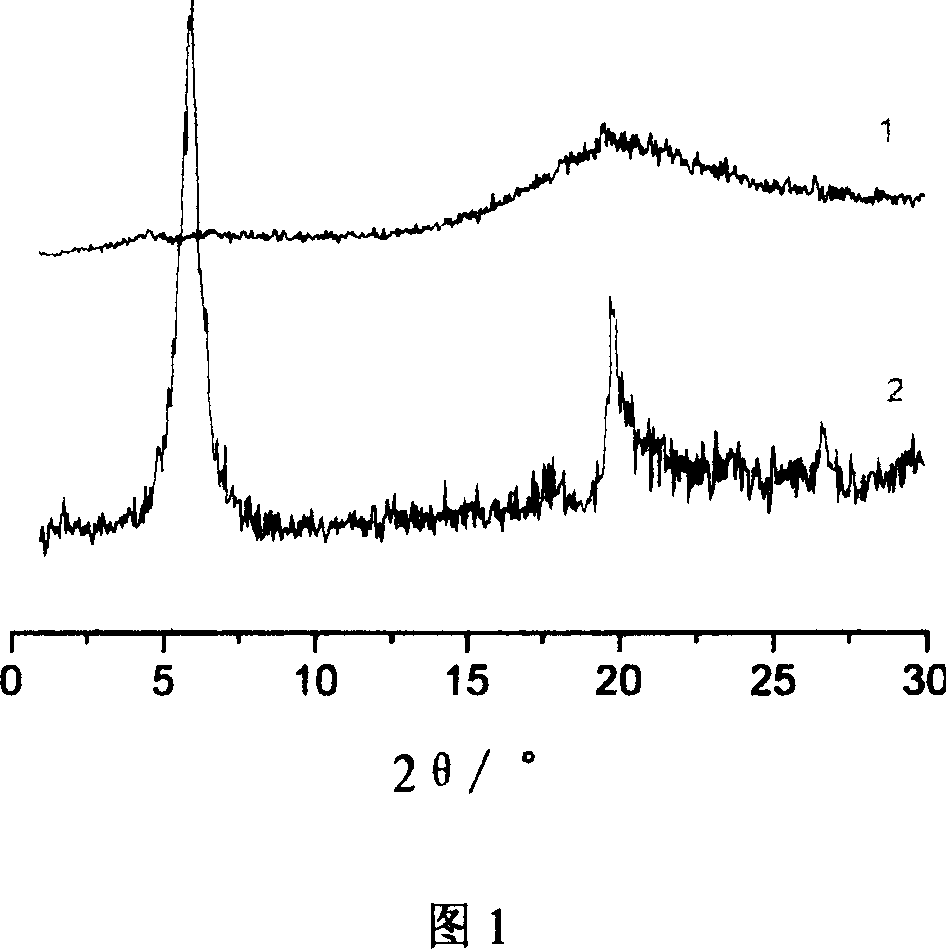

Image

Examples

Embodiment 1

[0030] Preparation of modified clay:

[0031] 1) Add 1Kg of montmorillonite and 50Kg of deionized water into the reaction kettle in sequence, and stir at high speed for 5 minutes;

[0032] 2) After raising the reaction kettle to 50°C, add 0.5Kg of organic intercalation agent hexadecyltrimethylammonium bromide and stir vigorously for 15 minutes, then stir at low speed for 4 hours, and then cool and discharge;

[0033]3) Centrifuge the product, and wash it repeatedly with ethanol-deionized water with a molar ratio of 1:1 until no precipitation occurs in the centrifuged mother liquor when tested with 0.1mol / L silver nitrate solution;

[0034] 4) Vacuum-dry the cleaned product at 90° C. for 24 hours, and the obtained product is modified clay, which is packed for later use.

[0035] Preparation of polymer / clay intercalation modification modification agent (designed with the sum of raw materials as 50Kg):

[0036] 1) Get 1.5Kg of the modified clay prepared by the above method and ...

Embodiment 2~5

[0045] The amount of modified clay and amino resin solution in the formula was changed, and the amount of additives was kept unchanged. The modifier was applied to the surface of the tunnel fireproof coating. The results are shown in Table 1.

[0046] Table 1

[0047] Example

Embodiment 6

[0049] Preparation of modified clay:

[0050] 1) Add 3Kg of vermiculite and 150Kg of deionized water into the reaction kettle in sequence, and stir at high speed for 5 minutes;

[0051] 2) After raising the reaction kettle to 60°C, add 1.5Kg of organic intercalation agent octadecyltrimethylammonium chloride and stir vigorously for 15 minutes, then stir at a low speed for 5 hours, and then cool and discharge;

[0052] 3) Centrifuge the product, and wash it repeatedly with ethanol-deionized water with a molar ratio of 1:1 until no precipitation occurs in the centrifuged mother liquor when tested with 0.1mol / L silver nitrate solution;

[0053] 4) Vacuum dry the washed product at 90° C. for 24 hours. The obtained product is modified clay, which is bottled for later use.

[0054] Preparation of polymer / clay surface modifiers:

[0055] 1) Take 2Kg of the modified clay prepared by the above-mentioned method and grind it with water for 3 hours in a ball mill tank, settling statical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com