A kind of Widmanstatten titanium alloy with compound lamellar structure and preparation method thereof

A technology of Widmanstatten structure and lamellar structure, which is applied in the field of titanium alloy with Widmanstatten structure and its preparation, can solve the problems of loss of tensile plasticity and fracture toughness, low tensile strength and plasticity of titanium alloy, and achieve plasticity and toughness optimization. , Improve the application potential, improve the effect of the degree of twists and turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

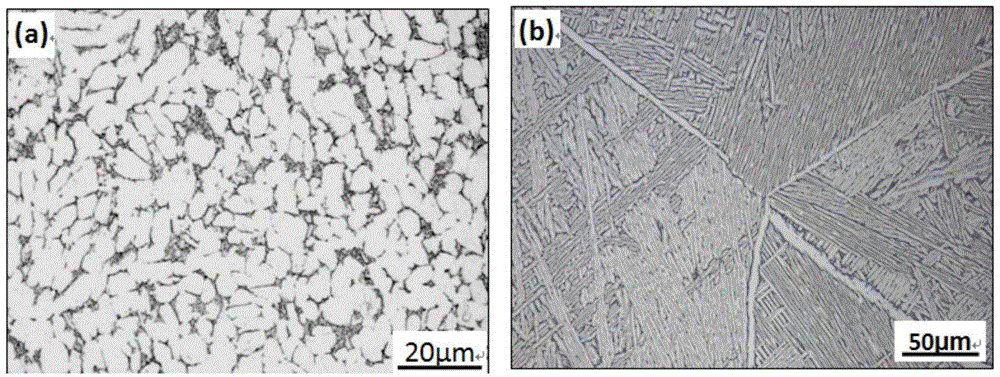

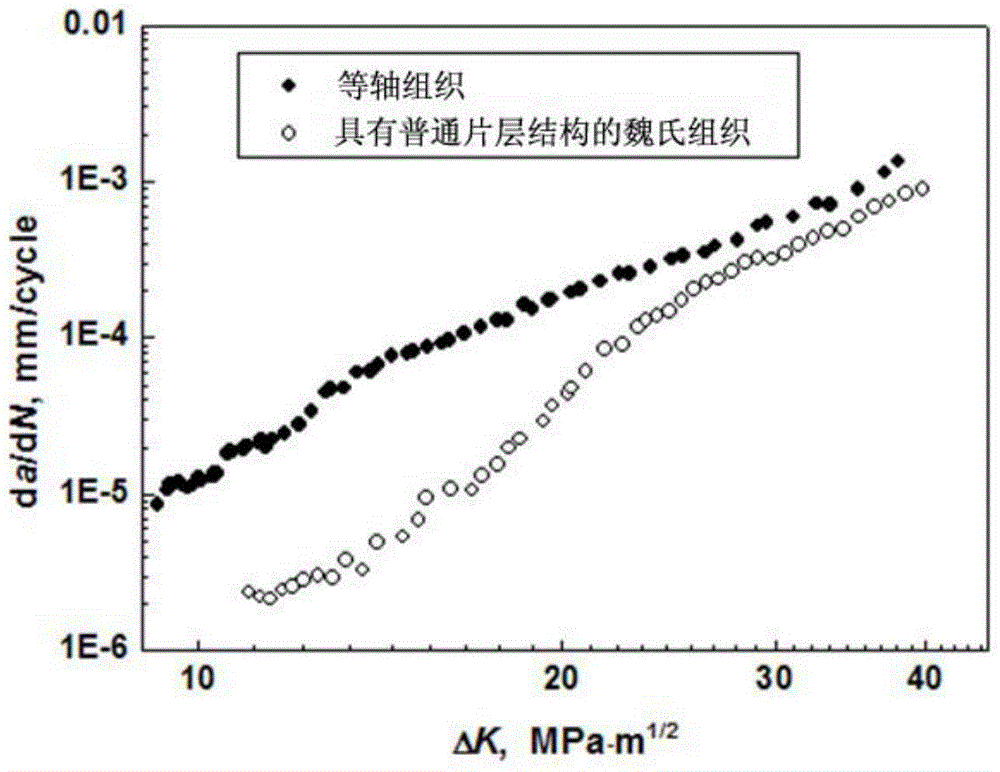

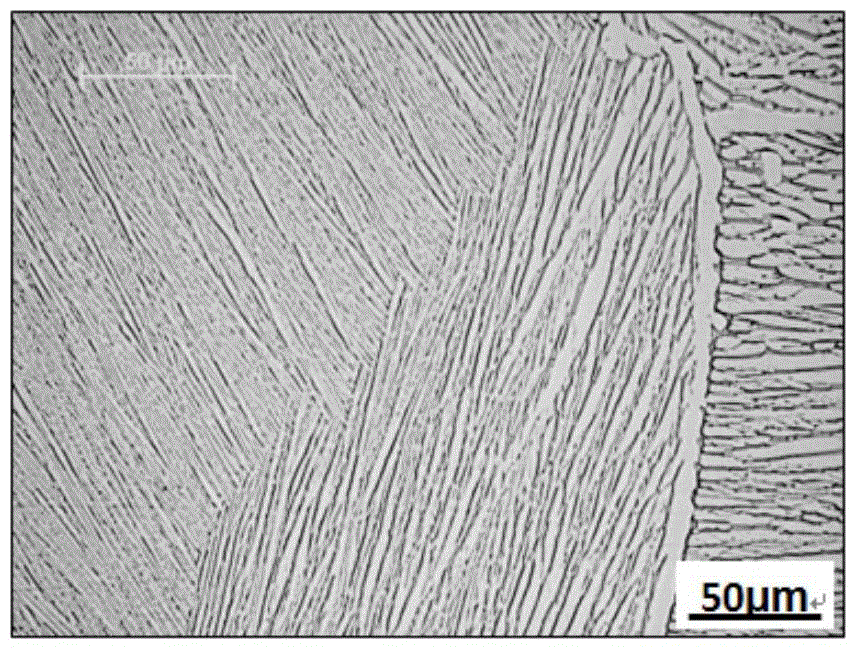

[0045] This embodiment is to control and optimize the TC4 titanium alloy whose nominal composition is Ti-6Al-4V. The titanium alloy with ordinary lamellar structure obtained in Comparative Example 1 was heat-treated at 920°C, 940°C, and 960°C, and then air-cooled to room temperature after being kept for 1 hour. When the Widmanstatten structure is heat-treated in the two-phase region, phase transformation occurs first on both sides of the β phase, and part of the α phase transforms into a β phase. After a certain period of time, it is cooled at a certain speed, and the β phase between the original α sheets transforms into fine particles. The secondary α-sheets obtained in the composite sheet structure, that is, there are fine secondary α-sheets between the original coarser α-sheets. The schematic diagram of the composite sheet structure is shown in Figure 7 as shown in (a), Figure 7 (b) is the SEM micromorphology of the composite lamellar structure obtained by heat-treating ...

Embodiment 2

[0052] This embodiment is to control and optimize the TA15 titanium alloy, and the temperature of the α / β phase complete transformation point of the TA15 titanium alloy is 985±5°C. Firstly, the TA15 titanium alloy billet with equiaxed structure was heat treated at 1030° C., and kept for 1 hour to obtain a titanium alloy with ordinary lamellar structure. It is then heat-treated at a temperature of 970°C and held for 1 hour to obtain a titanium alloy with a Widmanstatten structure with a composite lamellar structure. About 70%.

[0053] Table 4 compares the mechanical properties of the Widmanstatten structure between the optimized composite lamellar structure and the common lamellar structure of TA15 titanium alloy. It can be seen that the tensile strength, tensile plasticity, fracture toughness and fatigue crack growth resistance of the composite lamellar structure The ability is comprehensively superior to ordinary lamellar tissue.

[0054] Table 4 Comparison of mechanical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com