Manufacturing device of stator with skewed slots

A technology for manufacturing devices and stators, which is applied in the manufacture of stator/rotor bodies, etc., which can solve the problems of thickness differences in the stacking direction and difficulty in obtaining uniform quality stators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

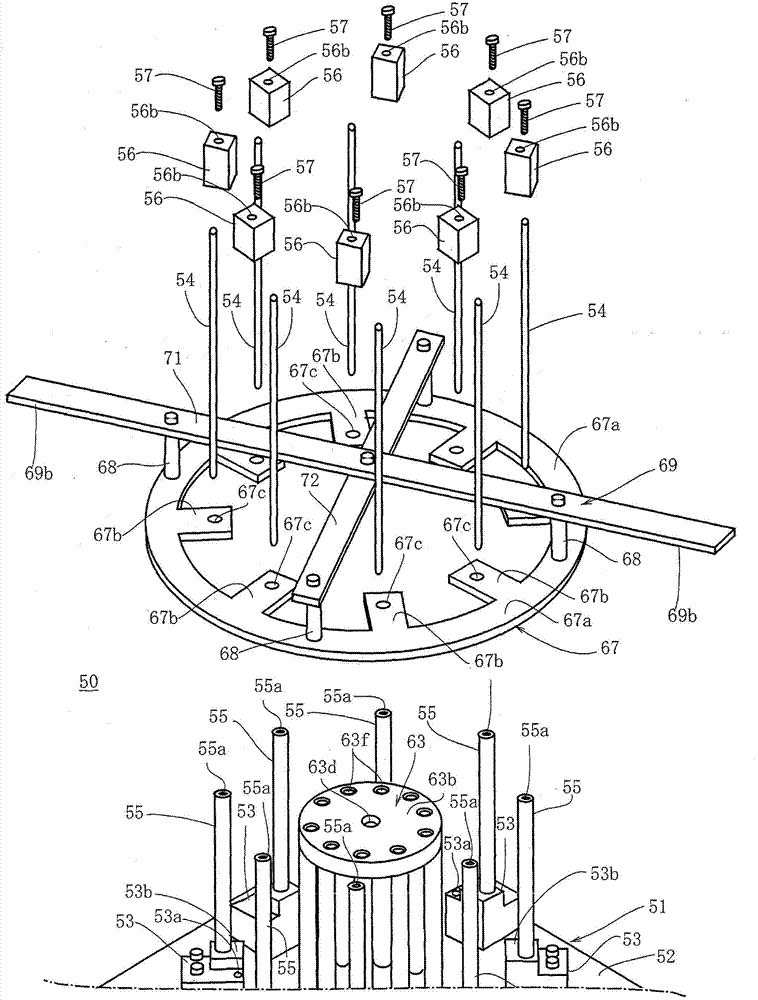

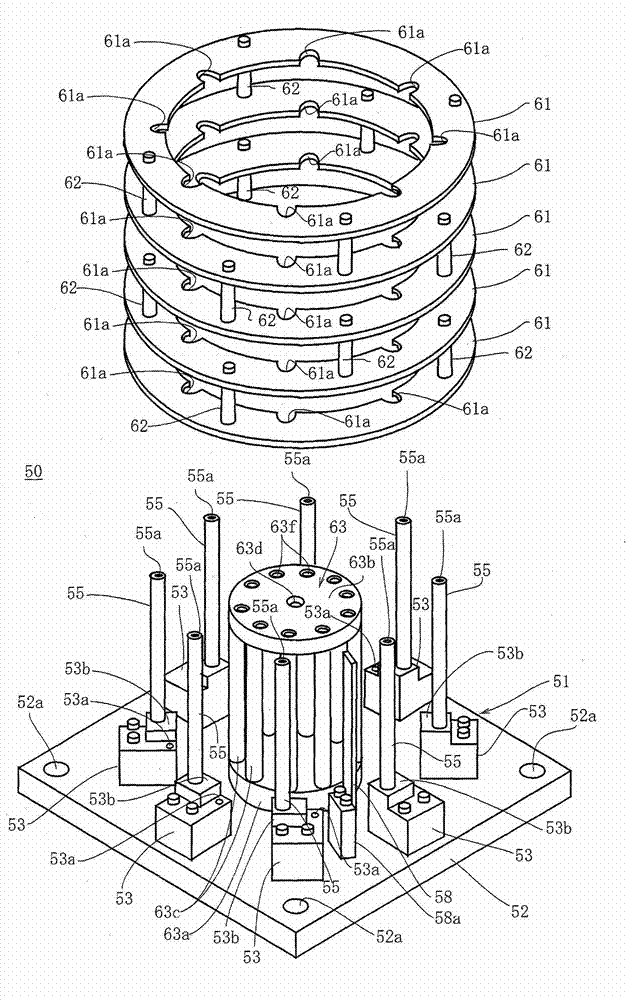

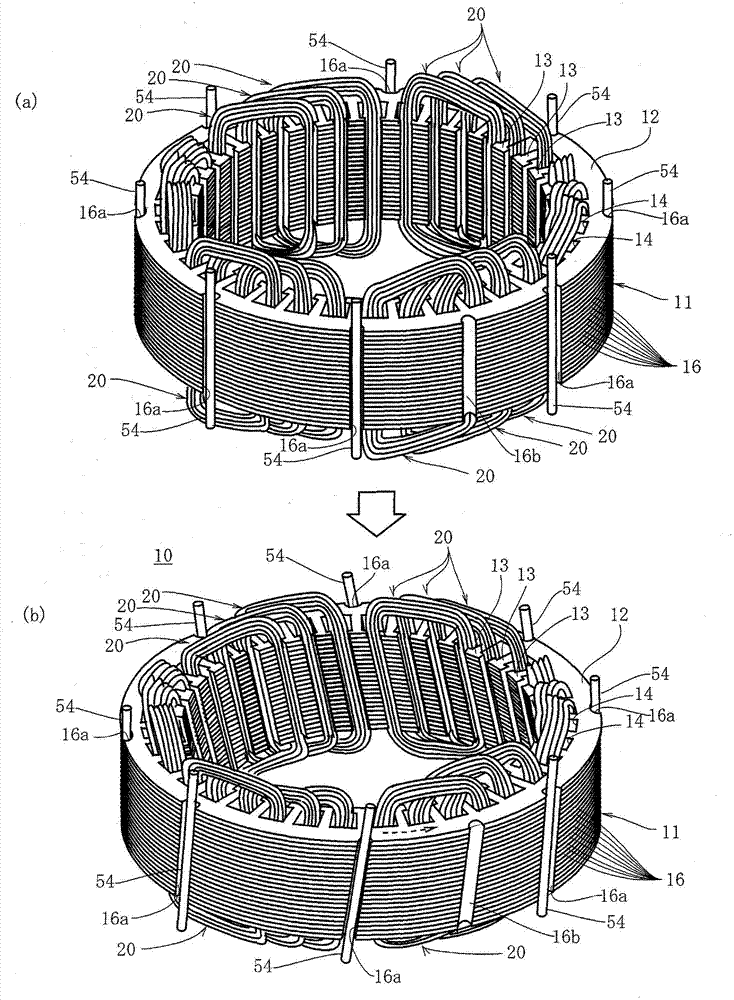

[0034] Next, preferred modes for implementing the present invention will be described in detail based on the drawings.

[0035] like image 3 As shown, in the manufacturing device of the stator with skewed slots of the present invention, the ring-shaped coil 20 is inserted into each slot 14 parallel to the axial direction of the stator core 11 in a winding manner, and then twisted so that each magnetic metal sheet 16 are gradually staggered in the circumferential direction, wherein the stator core 11 is formed by laminating a plurality of magnetic metal sheets 16 .

[0036] Among them, the stator core 11 is made of a magnetic material having an annular portion 12 and a plurality of teeth 13, and a plurality of slits 14 for accommodating the stator coil 20 are formed between the plurality of teeth 13, and the plurality of teeth 13 are formed from the above-mentioned The inner peripheral surface of the annular portion 12 protrudes from the center of the annular portion 12 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com