Method and device for manufacturing stator with skewed slots

A manufacturing method and technology for a manufacturing device, which are applied in the field of the manufacture of a stator with a slanted slot and the manufacturing device thereof, can solve the problems such as the inability to pull out the central column 8 straightly and the complicated structure, so as to reduce damage and improve the space factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the form for implementing this invention is demonstrated in detail based on drawing.

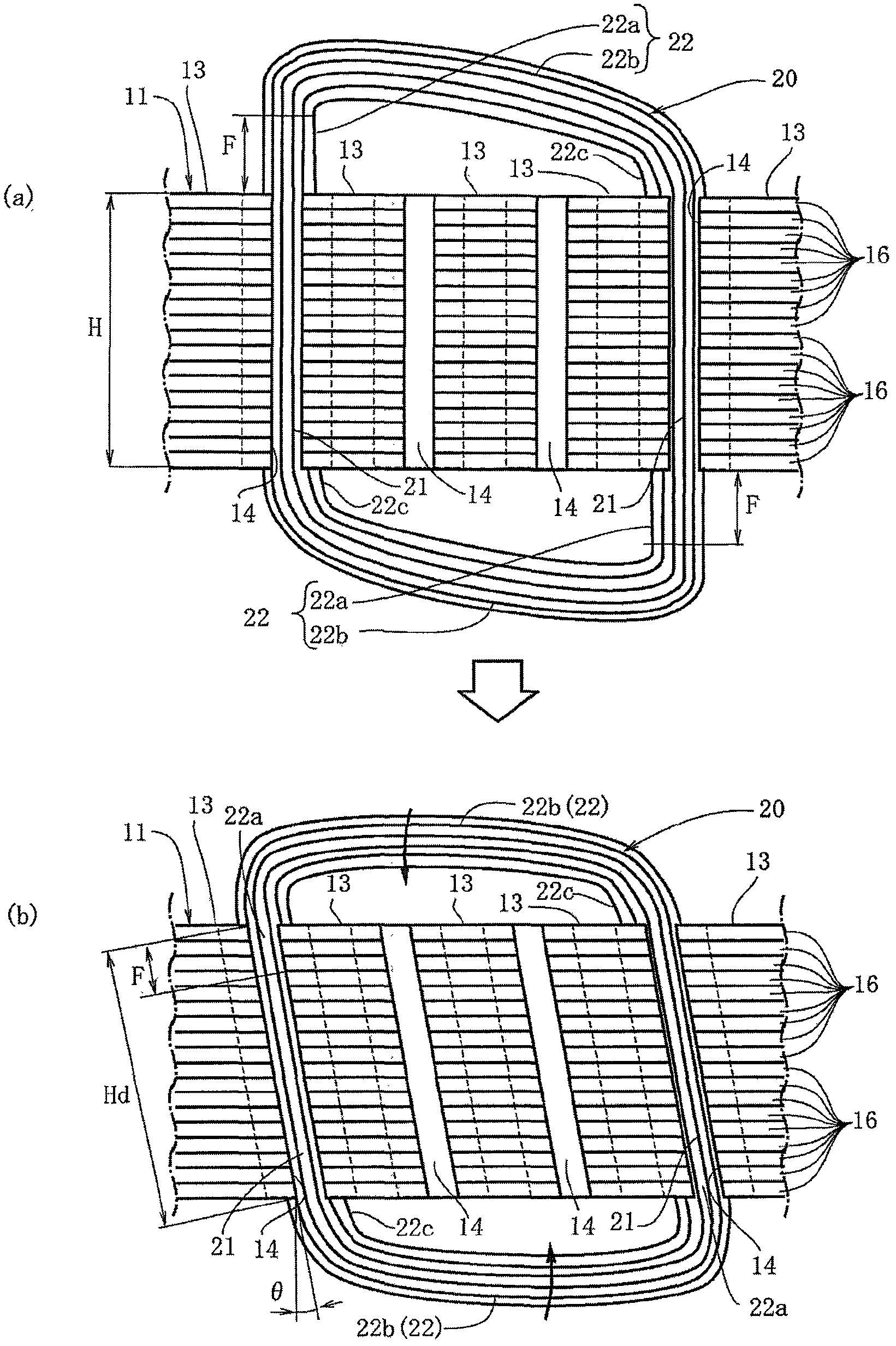

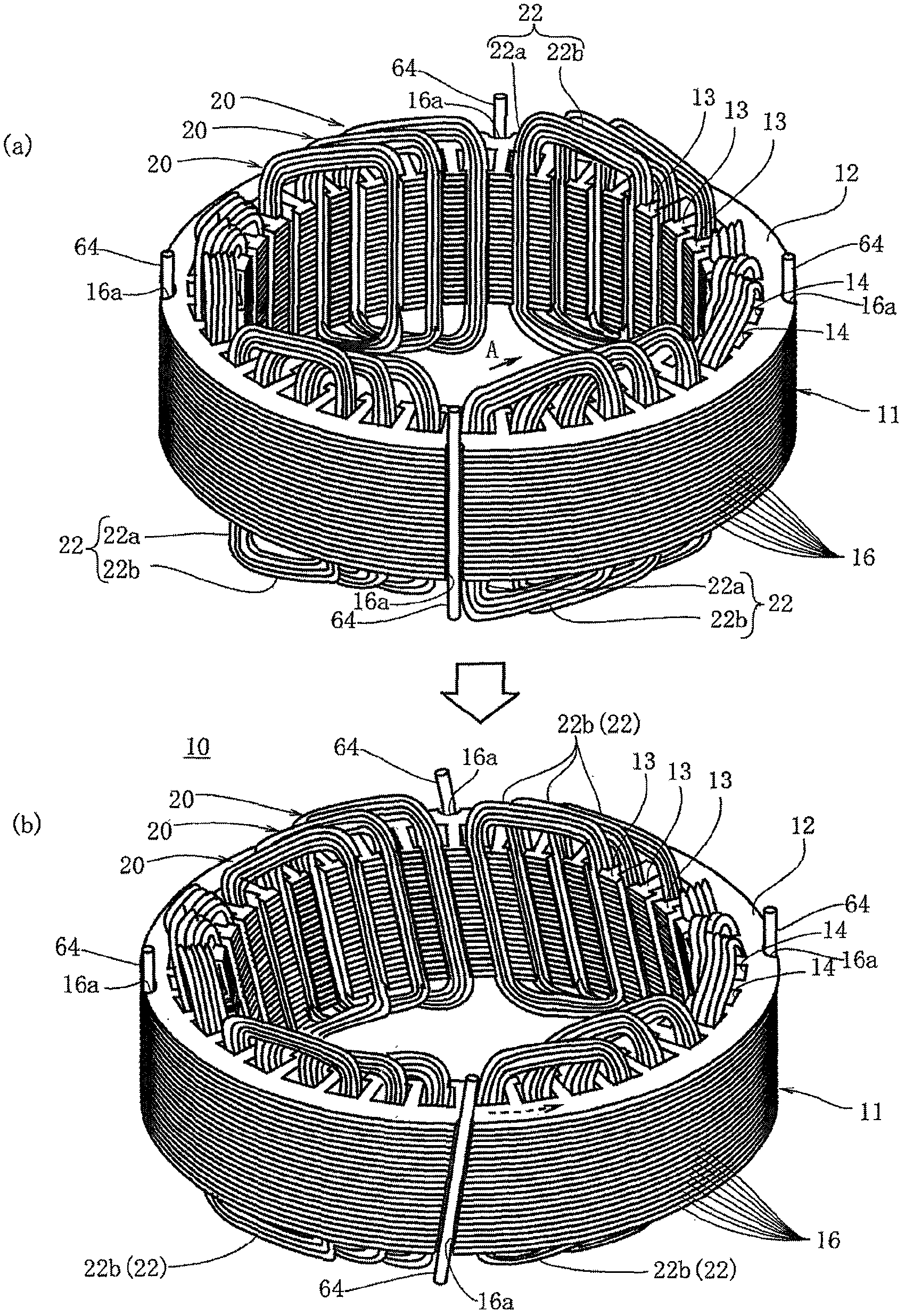

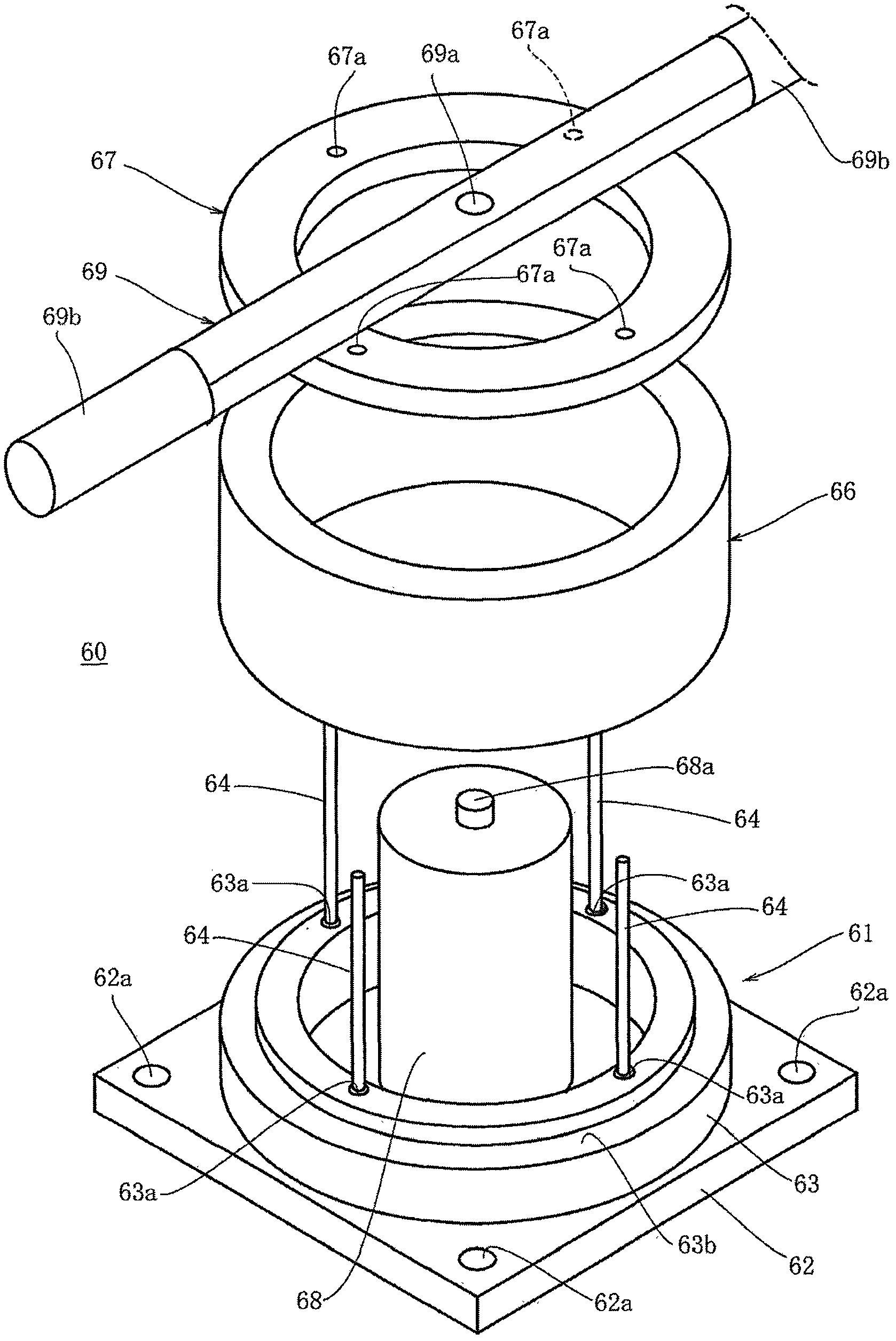

[0041] Such as figure 1 and figure 2 As shown, the manufacturing method of the stator with skewed slots of the present invention is as follows: the ring-shaped coil 20 is inserted into each slot 14 parallel to the axial direction of the stator core 11 in a winding manner, and then twisted so that each magnetic metal The pieces 16 are gradually staggered in the circumferential direction, and the stator core 11 is formed by laminating a plurality of magnetic metal pieces 16 . The stator core 11 is made of a magnetic material having an annular portion 12 and a plurality of teeth 13 ( figure 2 ), between a plurality of teeth 13 is formed a coil edge portion 21 ( figure 1 ), a plurality of grooves 14, and a plurality of teeth 13 protrude from the inner peripheral surface of the annular portion 12 at the center of the annular portion 12.

[0042] That is, the stator core 11 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com