Water-based composite resin and preparation method thereof

A composite resin, water-based technology, applied in the field of water-based composite resin and its preparation, can solve problems such as demulsification, and achieve the effects of preventing demulsification, improving corrosion resistance, and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

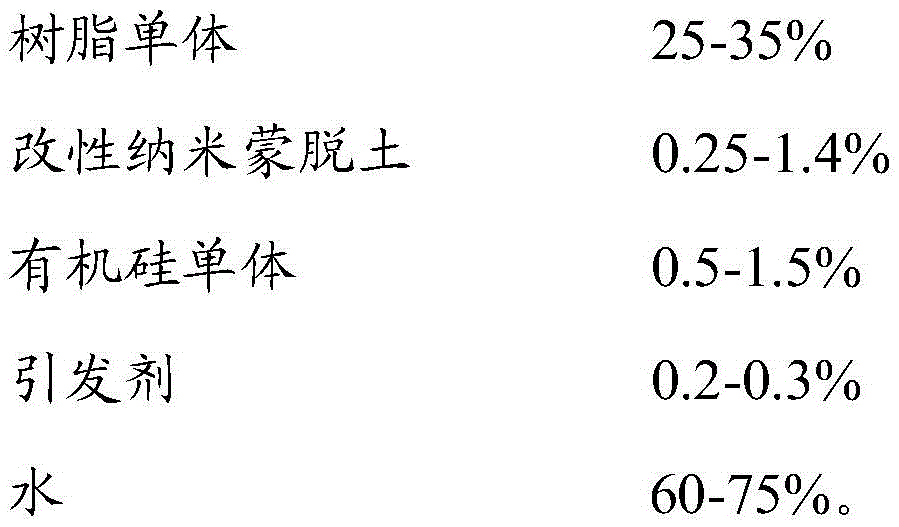

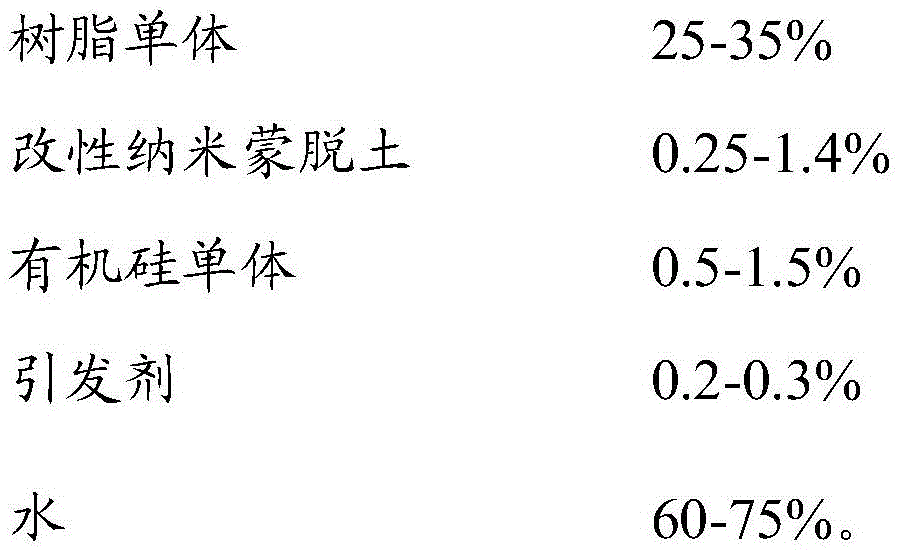

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of this modified nanometer montmorillonite is as follows:

[0028] preparing a nano-montmorillonite aqueous solution with a mass fraction of 2-5%;

[0029] Add modifier to the nano-montmorillonite aqueous solution to obtain a mixed solution, the modifier includes allyltrimethylammonium bromide and triethanolamine, and the mass ratio of the modifier to nano-montmorillonite is 1 :4-6;

[0030] The pH value of the mixed solution is adjusted to 2-3, stirred to obtain an aqueous solution containing modified nano-montmorillonite, and the modified nano-montmorillonite can be obtained after drying.

[0031] The silicone monomer is γ-methacryloxypropyltrimethoxysilane (KH-570), vinyltrimethoxysilane (A-171) or vinyltriethoxysilane (A-151) One or more mixtures of these.

[0032] The initiator is potassium persulfate or ammonium persulfate.

[0033] The water-based composite resin of the present invention uses organic modifiers containing polyhydroxy fun...

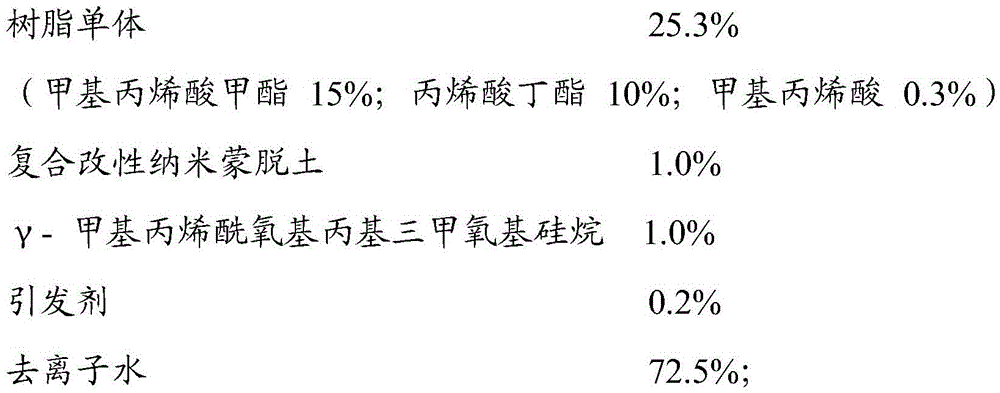

Embodiment 1

[0054] The composite resin of the embodiment of the present invention comprises the following components by weight percentage:

[0055]

[0056] The composite resin preparation method of this embodiment comprises the following steps:

[0057] 1. Prepare an aqueous solution containing modified nano-montmorillonite:

[0058] The preparation mass fraction is the nano-montmorillonite aqueous solution of 2%;

[0059] Add modifier to the nano-montmorillonite aqueous solution to obtain a mixed solution, the modifier includes allyltrimethylammonium bromide and triethanolamine, and the mass ratio of the modifier to nano-montmorillonite is 1 :4;

[0060] Adjust the pH value of the mixed solution to 2, stir to obtain an aqueous solution containing modified nano-montmorillonite,

[0061] 2. Preparation of composite resin:

[0062] Add composite modified nano-montmorillonite water dispersion and a certain amount of deionized water into the reactor equipped with thermometer, reflux c...

Embodiment 2

[0064] The composite resin of the embodiment of the present invention comprises the following components by weight percentage:

[0065]

[0066] The composite resin preparation method of this embodiment comprises the following steps:

[0067] 1. Prepare an aqueous solution containing modified nano-montmorillonite:

[0068] The preparation mass fraction is the nanometer montmorillonite aqueous solution of 3.5%;

[0069] Add modifier to the nano-montmorillonite aqueous solution to obtain a mixed solution, the modifier includes allyltrimethylammonium bromide and triethanolamine, and the mass ratio of the modifier to nano-montmorillonite is 1 :5;

[0070] The pH value of the mixed solution was adjusted to 2.5, and stirred to obtain an aqueous solution containing modified nano-montmorillonite,

[0071] 2. Preparation of composite resin:

[0072] Add composite modified nano-montmorillonite water dispersion and a certain amount of deionized water into the reactor equipped with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com