Corundum-spinel casting material for dip pipe of RH refining furnace

A corundum spinel and refining furnace technology is applied in the field of refractory materials, which can solve the problems of poor corrosion resistance, slag penetration resistance and thermal shock resistance, poor thermal shock resistance of castables, and prone to crack structures. Effects of reduced porosity, increased density, improved thermal shock resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

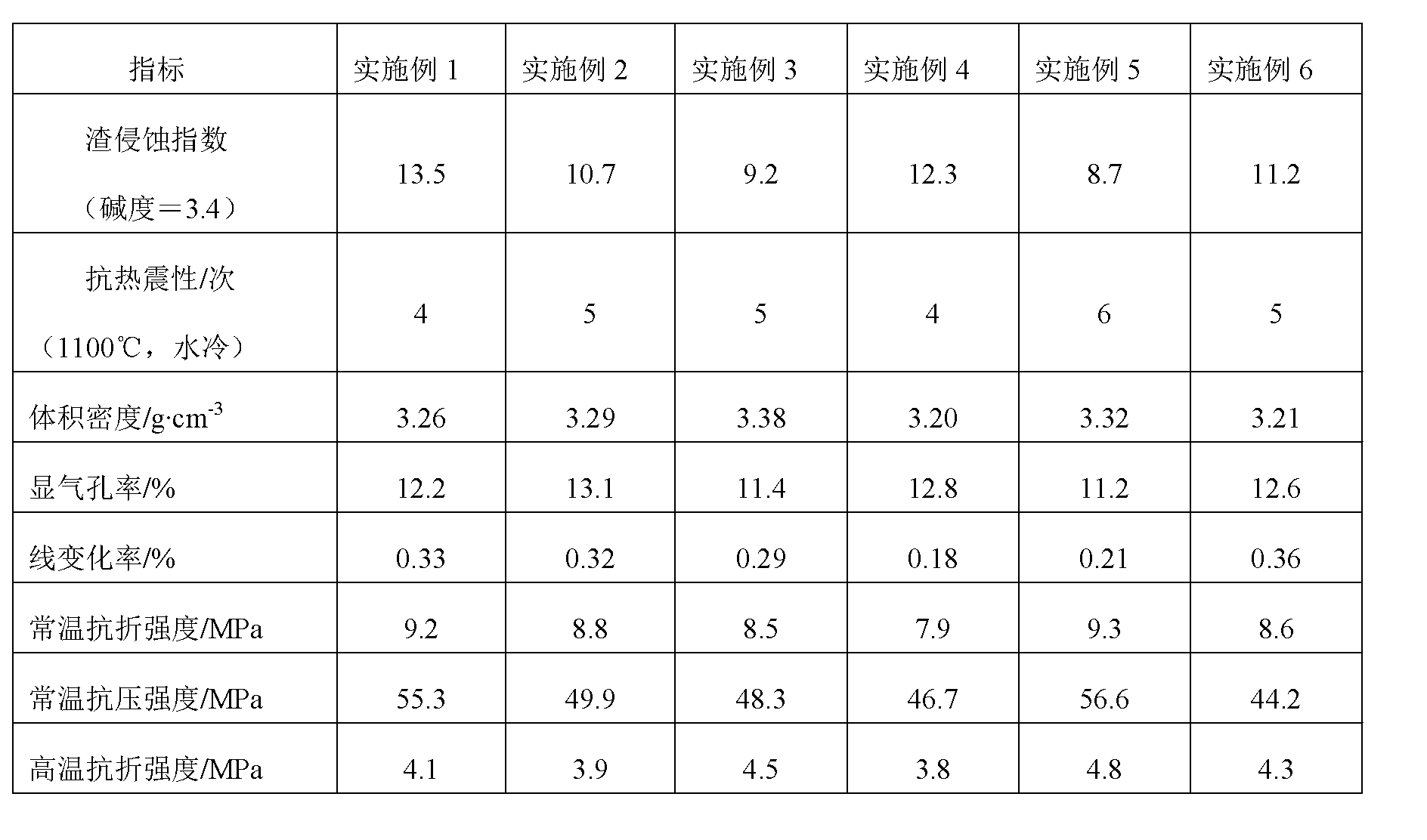

Examples

Embodiment 1

[0025] A corundum-spinel castable for dipping pipes of a RH refining furnace is composed of a main material and an admixture, and the components of the main material by weight percentage are:

[0026] Fused white corundum accounts for 60%,

[0027] Fused dense corundum accounts for 10%,

[0028] Fused magnesia powder accounts for 6%,

[0029] Ultrafine spinel powder accounts for 8%,

[0030] Activated alumina powder accounts for 5%,

[0031] Calcium aluminate cement group accounted for 6%,

[0032] Zirconia sol accounts for 5%;

[0033] The admixtures are FDN water reducing agent equal to 1% of the weight of the main material and explosion-proof organic fiber equal to 0.15% of the weight of the main material, wherein: the particle size of fused magnesia is ≤ 0.1mm, the particle size of spinel micropowder is ≤ 25μm, and the active The particle size of alumina powder is ≤0.1mm, and the explosion-proof organic fiber is polypropylene fiber; the size of various particles in fu...

Embodiment 2

[0035] A corundum-spinel castable for dipping pipes of a RH refining furnace is composed of a main material and an admixture, and the components of the main material by weight percentage are:

[0036] Fused white corundum accounts for 45%,

[0037] Fused dense corundum accounts for 25%,

[0038] Fused magnesia powder accounts for 6%,

[0039] Ultrafine spinel powder accounts for 10%,

[0040] Activated alumina powder accounts for 5%,

[0041] Calcium aluminate cement group accounted for 5%,

[0042] Zirconia sol accounts for 4%;

[0043] The admixtures are FDN water reducing agent equal to 1% of the weight of the main material and explosion-proof organic fiber equal to 0.1% of the weight of the main material, wherein: the particle size of fused magnesia is ≤ 0.1mm, the particle size of spinel micropowder is ≤ 25μm, and the active The particle size of alumina powder is ≤0.1mm, and the explosion-proof organic fiber is polyethylene fiber; the size of various particles in fus...

Embodiment 3

[0045] A corundum-spinel castable for dipping pipes of a RH refining furnace is composed of a main material and an admixture, and the components of the main material by weight percentage are:

[0046] Fused white corundum accounts for 50%,

[0047] Fused dense corundum accounts for 15%,

[0048] Fused magnesia powder accounts for 10%,

[0049] Spinel powder accounts for 10%,

[0050] Activated alumina powder accounts for 6%,

[0051] Calcium aluminate cement group accounted for 4%,

[0052] Zirconia sol accounts for 5%,

[0053]The admixtures are FDN water reducing agent equal to 0.8% of the weight of the main material and explosion-proof organic fiber equal to 0.1% of the weight of the main material, wherein: the particle size of fused magnesia is ≤ 0.1mm, the particle size of spinel micropowder is ≤ 25μm, active The particle size of alumina powder is less than or equal to 0.1mm, and the explosion-proof organic fiber is made of polypropylene fiber and polyethylene fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com