Calcium aluminate cement-combined corundum castable and preparation method thereof

A technology of calcium aluminate cement and corundum, applied in the field of refractory materials, can solve the problems of low strength, achieve low cost, improve performance, increase strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a calcium aluminate cement-bonded corundum castable, comprising the following steps: 70-88 parts by weight of platy corundum particles, 0.1-10 parts by weight of platy corundum fine powder, 5-10 parts by weight Active alumina micropowder in parts by weight, calcium aluminate cement in 0.5-8 parts by weight, microsilica powder in 1 part by weight, titanium dioxide / calcium carbonate / magnesia composite micropowder additive in 0.1-10 parts by weight, water reducing agent and water are mixed, Vibration molding after stirring, curing for 20-30 hours at a temperature of 20-50°C and a relative humidity of 80-100%, then raising the temperature to 100-150°C for 12-36 hours to obtain calcium aluminate cement bonded corundum casting material.

[0026] In the above preparation process, the present invention uses calcium aluminate cement as a binder, tabular alumina and activated alumina as main components, and uses titanium dioxide / calci...

Embodiment 1

[0059] Preparation of Titanium Dioxide / Calcium Carbonate / Magnesium Oxide Composite Micropowder Additive

[0060] Mix titanium dioxide, calcium carbonate and magnesium oxide with a weight ratio of 40:50:10, and grind to a particle size ≦10 μm, and the average particle size d 50 =2.4 μm, to obtain titanium oxide / calcium carbonate / magnesia composite micropowder additive.

Embodiment 2

[0062] Prepare the above-mentioned platy corundum particles, 6.8 parts by weight of platy corundum fine powder, 7 parts by weight of activated alumina micropowder, 3.7 parts by weight of calcium aluminate cement, 1 part by weight of silica micropowder, and 2.5 parts by weight of Example 1 Titanium dioxide / calcium carbonate / magnesia composite micropowder additive, 0.2 parts by weight of water reducer and 4.3 parts by weight of water are mixed, stirred evenly, formed by vibration, and cured for 24 hours at a temperature of 25°C and a relative humidity of 100%. , the temperature was raised to 110° C. and kept for 24 hours to obtain a calcium aluminate cement bonded corundum castable.

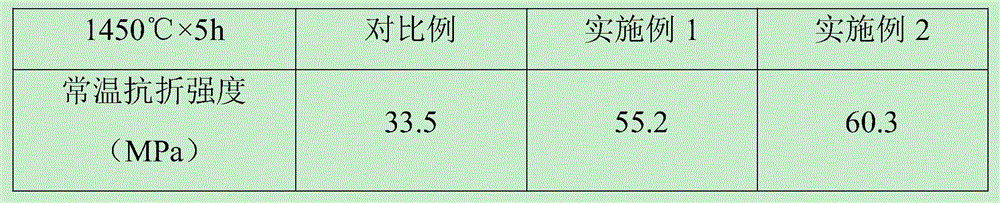

[0063] The calcium aluminate cement bonded corundum castable prepared in this example was treated at 1450° C. for 5 hours, and its flexural strength at room temperature was tested, as shown in Table 1.

[0064] Example 2:

[0065] Prepare the above-mentioned platy corundum particles, 6.6 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Room temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com