Treatment method of plugging water stop construction for foundation pit dewatering well to penetrate through concrete base plate of basement

A technology for concrete floor and basement floor, which is applied in earthwork drilling, infrastructure engineering, sealing/isolation, etc. It can solve problems such as corrosion of pipe fittings, many water-stopping links, and difficult construction, and achieve simple structure and water-stopping effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

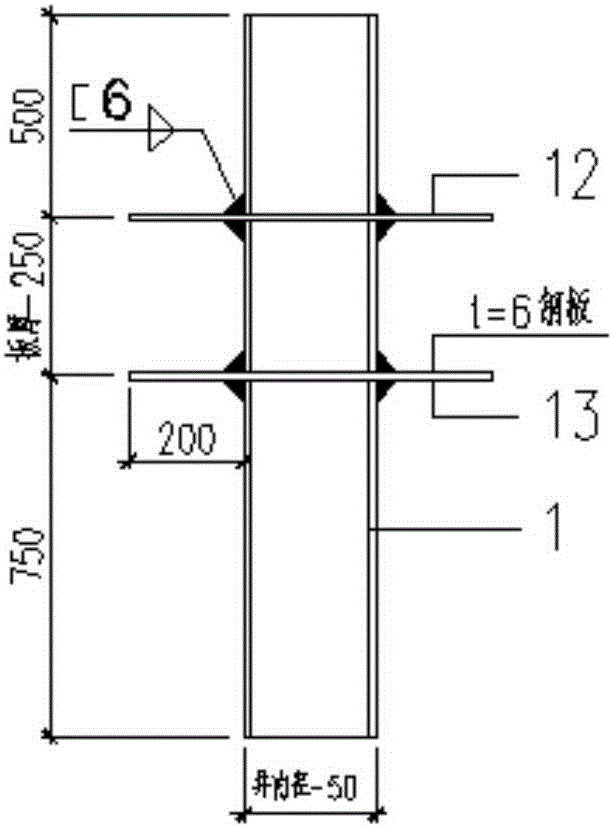

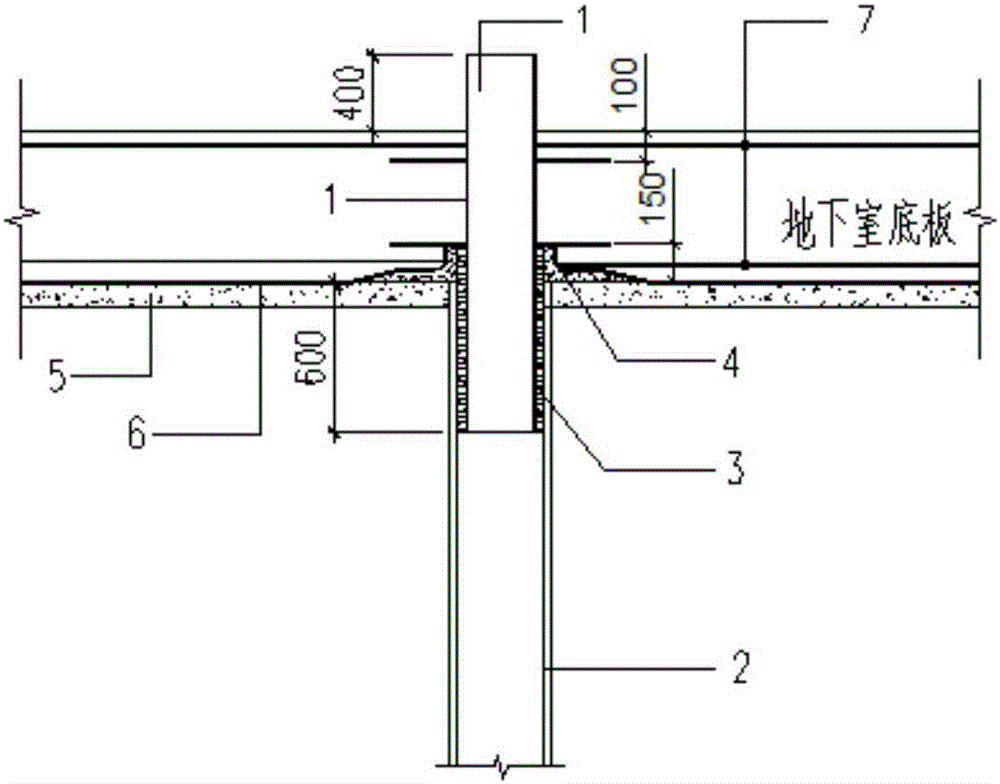

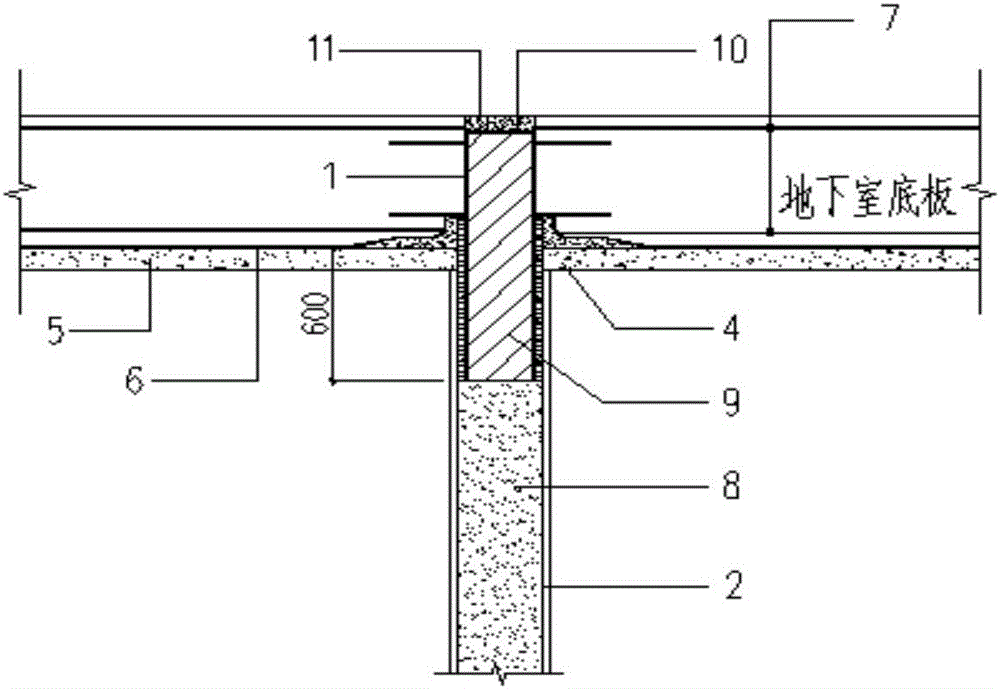

[0031] According to the present invention, the foundation pit dewatering well penetrates the concrete floor of the basement to block and stop the water. The construction processing method includes the following steps: making a water-stop steel casing 1 → pouring the basement floor cushion concrete → cutting the cushion surface dewatering well filter pipe 2, The lower end of the water-stop steel casing 1 is wrapped with asphalt hemp silk 3, and then inserted into the drainage well filter pipe 2, and sealed with cement mortar 4 → waterproof layer 6 construction of the basement floor cushion surface → binding concrete floor reinforcement 7, continuous precipitation → pouring Basement floor concrete, continuous precipitation → precipitation wells stop precipitation one by one → block precipitation wells.

[0032] The specific workflow is as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com