Foundation pit construction method

A construction method and foundation pit technology, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of site and long construction period, large equipment, surrounding environmental pollution, etc., achieve simple construction, reduce construction land, occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

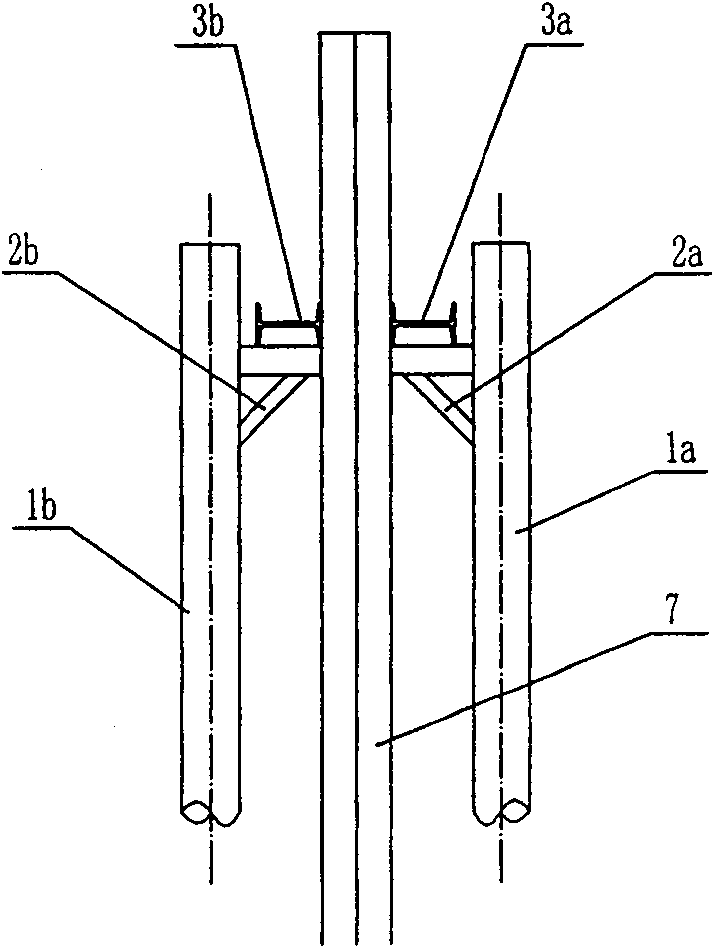

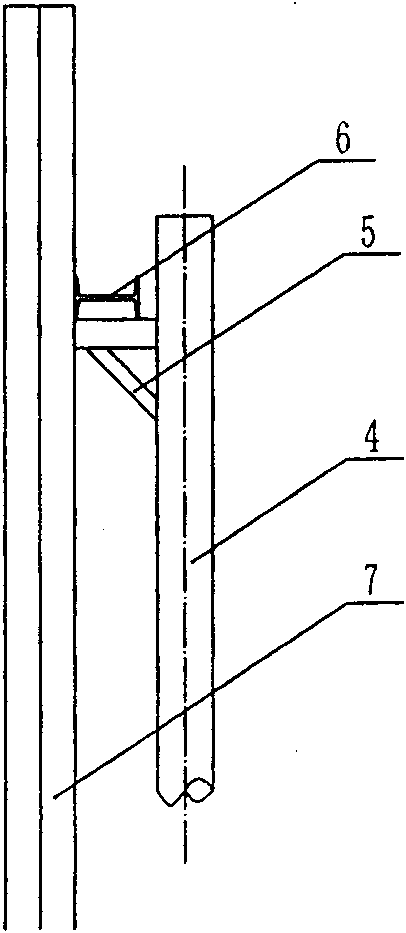

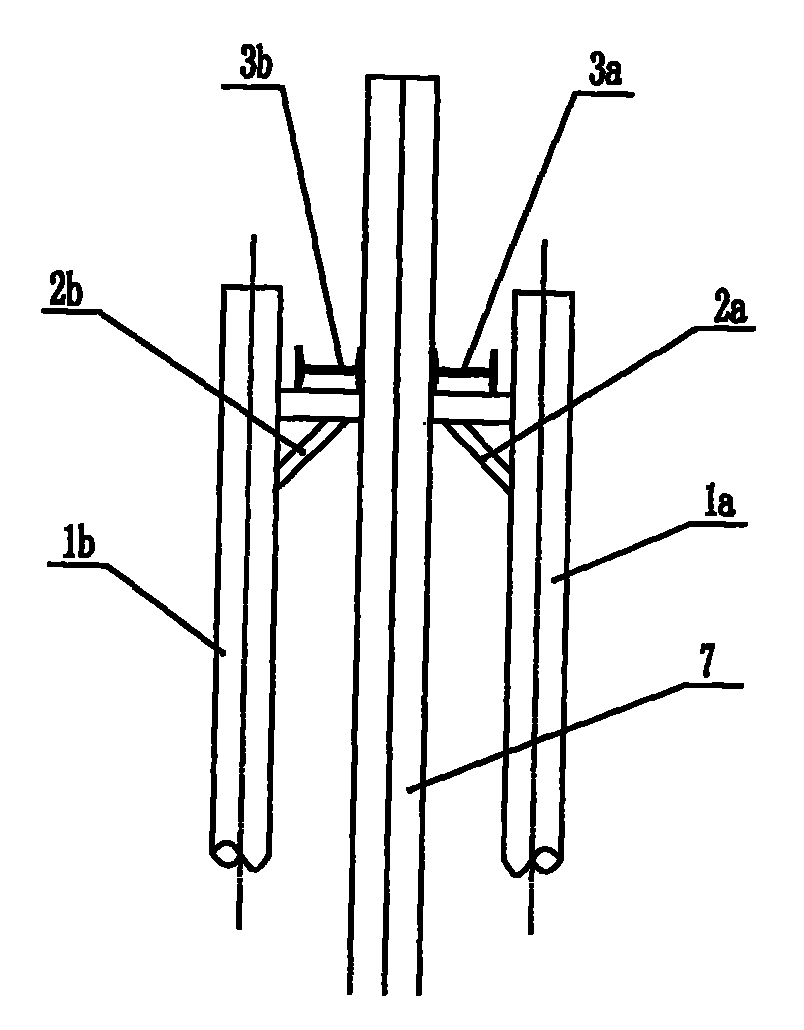

[0027] This embodiment is the foundation pit of an underground circular three-dimensional garage, using steel sheet piles as the supporting structure, the outer diameter of the foundation pit is 2143cm, and the net inner diameter is 2059cm. 4 ring-shaped internal supports are arranged on the inside of the steel sheet piles in the foundation pit, and the outer edge of the ring-shaped internal supports touches the steel sheet piles to support the steel sheet piles. After excavating 17m in the foundation pit, pour 3.5m of bottom-sealing concrete, and then pour 1m thick reinforced concrete floor.

[0028] The specific implementation steps of the above-mentioned underground circular three-dimensional garage foundation pit are as follows:

[0029] A. Measure the inner diameter of the center line of the steel sheet pile required for stakeout;

[0030] B. Insert and drive positioning piles inside the center line of the steel sheet pile, and install the above-mentioned steel sheet pil...

Embodiment 2

[0039] This embodiment is the same construction process for the foundation pit of the underground three-dimensional garage as in Embodiment 1, the only difference is that the soil layer is almost impermeable or poorly permeable. Therefore, all other construction steps are the same, only steps E-H are different, and the specific differences are as follows: Excavate the soil layer of the cofferdam to the place where groundwater seeps, and use a small pump to drain water outward, as long as the foundation in the cofferdam is not There is standing water. This construction method is relatively simple, as long as the internal support is added while pumping water; then other work such as back sealing can be performed according to conventional ground operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com