Lattice type combined steel sheet pile cemented soil composite pile and construction method thereof

A technology combining steel sheet piles and construction methods, which is applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of increased steel cost, increased construction difficulty, and enlarged pile section, and achieves low cost and high construction methods. Fast, good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

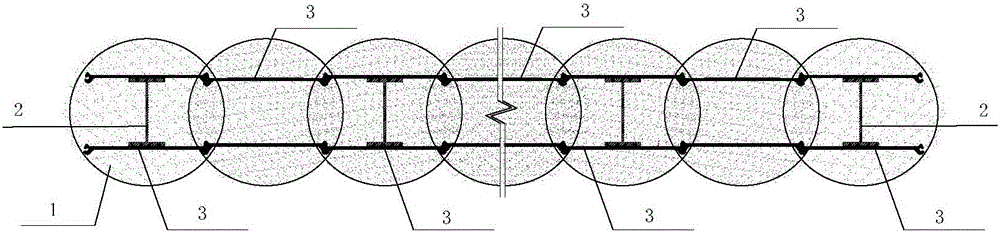

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0023] The first step: construction of cement-soil deep mixing pile;

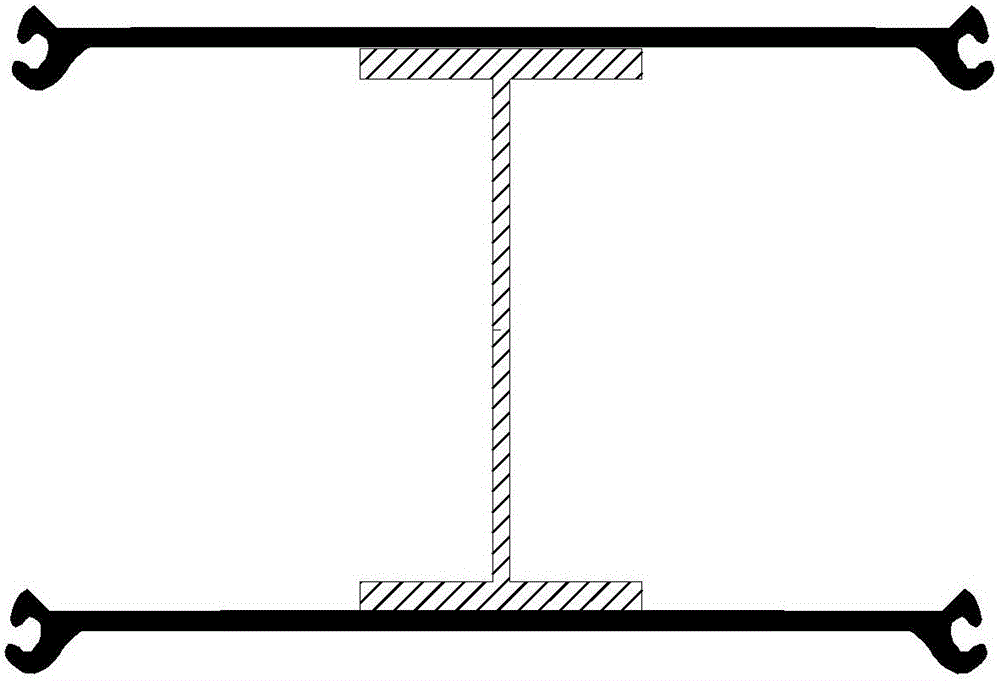

[0024] Step 2: Apply release agent to the outer side of the narrow-wing I-beam and straight steel sheet piles; the narrow-wing I-beam is 300*150mm narrow-wing I-beam;

[0025] Step 3: Set the guide frame and suspension beam for the composite steel sheet pile insertion;

[0026] Step 4: before the cement soil is hardened, the narrow-wing I-beam is vertically inserted into the cement-soil mixing pile through theodolite measurement and deviation correction control, and then the linear steel sheet pile is inserted outside the upper and lower flanges to complete a combined unit body; The steel sheet pile is YSP-FL linear steel sheet pile;

[0027] Step 5: Continue to complete another adjacent combined unit body, and the locks of the adjacent linear steel sheet piles are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com