I-shaped steel joint structure for underground continuous wall and construction method for I-shaped steel joint structure

A technology of underground diaphragm wall and joint structure, which is applied to underwater structures, infrastructure engineering, artificial islands, etc. The effect of retaining sand, improving the overall impermeability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

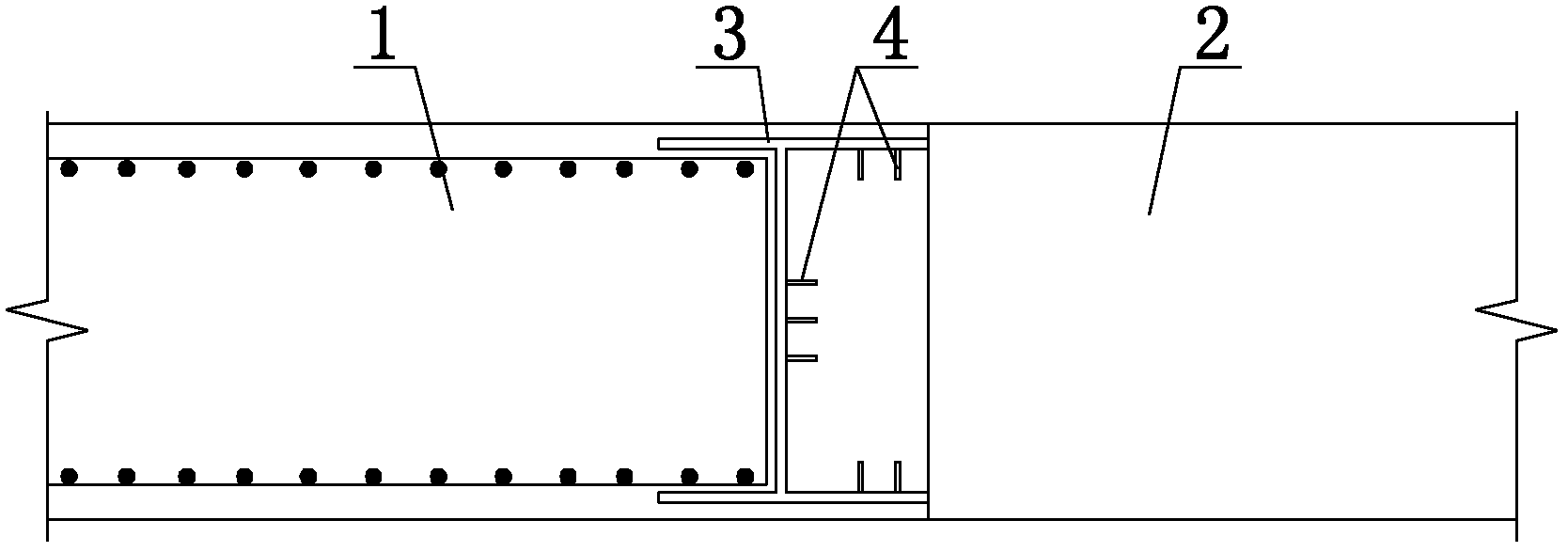

Examples

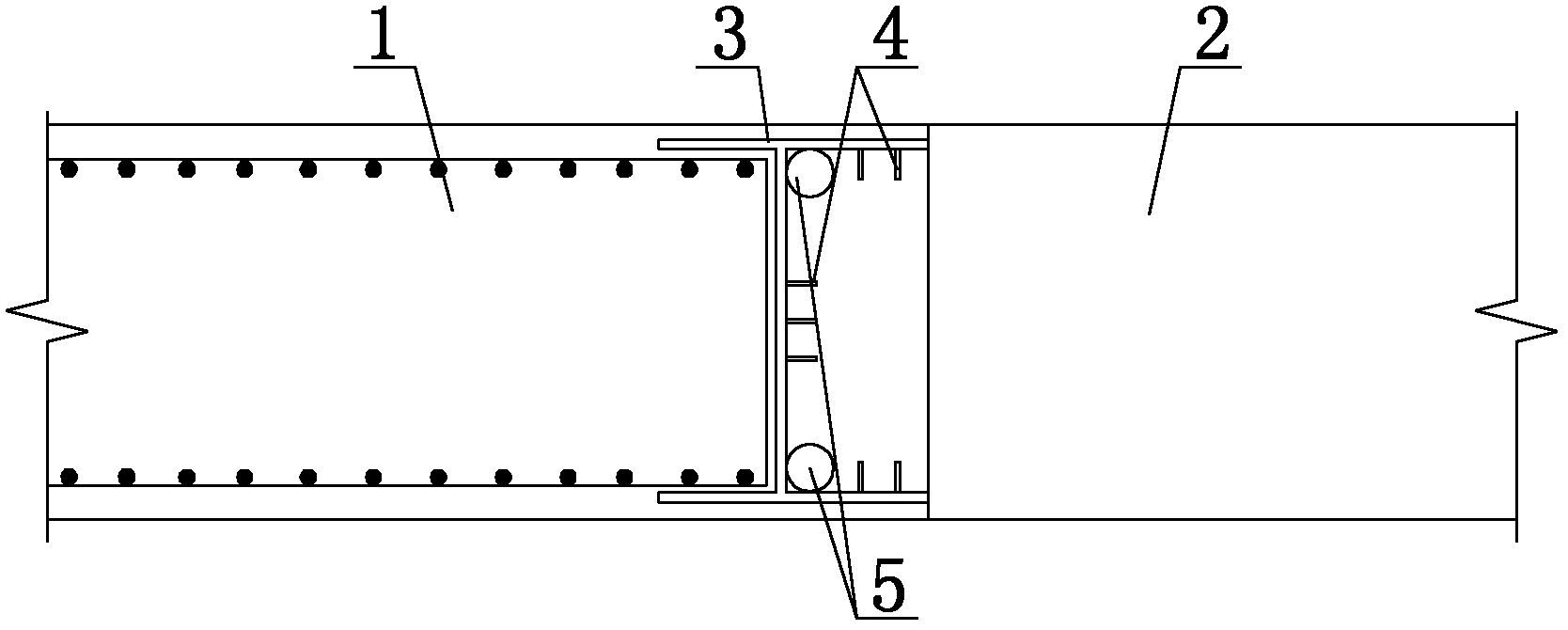

Embodiment 2

[0027] refer to figure 2 As shown, another underground diaphragm wall I-steel joint structure of the present invention is basically the same as Embodiment 1, the difference is that the inner wall of the I-steel 3 and the rear adjacent wall 2 side is provided with two spray nozzles. The grouting cleaning pipe 5 of the hole is used for cleaning the anchor bar 4 with high-pressure water and grouting with high-pressure grout in the later stage of wall formation, which is convenient for construction and anti-seepage treatment of joints in the later stage of wall formation.

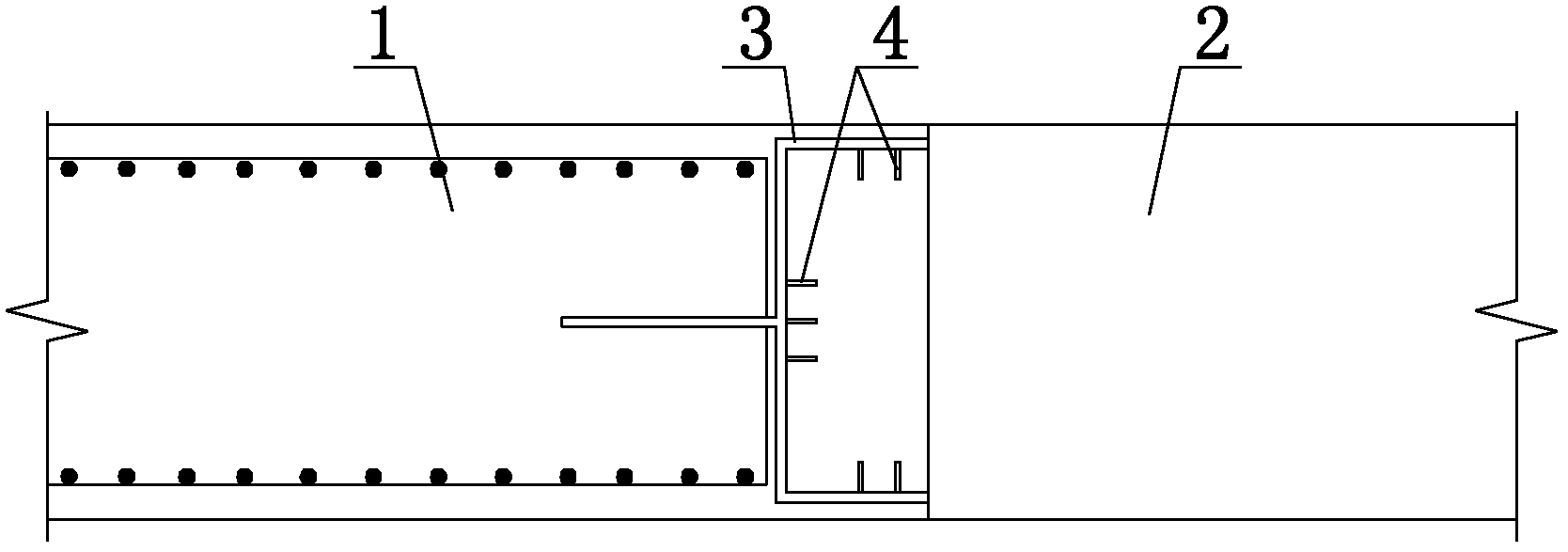

Embodiment 3

[0029] refer to image 3 As shown, it is another I-beam joint structure of the underground diaphragm wall according to the present invention, which is basically the same as that of Embodiment 1, except that the I-beam 3 connecting the preceding wall panel 1 and the rear adjacent wall panel 2 is a special-shaped joint , its implementation effect is basically the same as in Example 1.

Embodiment 4

[0031] refer to Figure 4 Shown, be one of concrete construction mode of the present invention, specifically comprise the following steps:

[0032] (1) Excavate the ground groove of the preceding wall width 1;

[0033] (2) Make the reinforcement cage of the preceding wall width, and set the I-shaped steel 3 joint at the end of the reinforcement cage of the preceding wall width 1;

[0034] (3) Weld and distribute the anchor bars 4 inside the I-beam 3;

[0035] (4) Hang the reinforcement cage of the leading wall width 1 in the ground groove of the leading wall width 1, and set the mud retaining joint pipe 6 between the outer side of the anchor bar 4 and the inner side of the I-beam 3, and the mud retaining joint pipe 6 is longitudinal Set of three circular tubes;

[0036] (5) Concrete pouring of the preceding wall width 1;

[0037] (6) Excavate the ground groove adjacent to the wall panel 2 on the outside of the joint pipe 6, and make a reinforcement cage adjacent to the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com