Steel caisson enclosure structure at island-tunnel combination part

A technology of enclosure structure and internal steel, applied in caisson, foundation structure engineering, construction, etc., can solve the problems of long procurement cycle, limited number of uses, and long construction period of steel sheet piles, so as to ensure construction safety and project quality, reduce The effect of schedule pressure and construction schedule advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

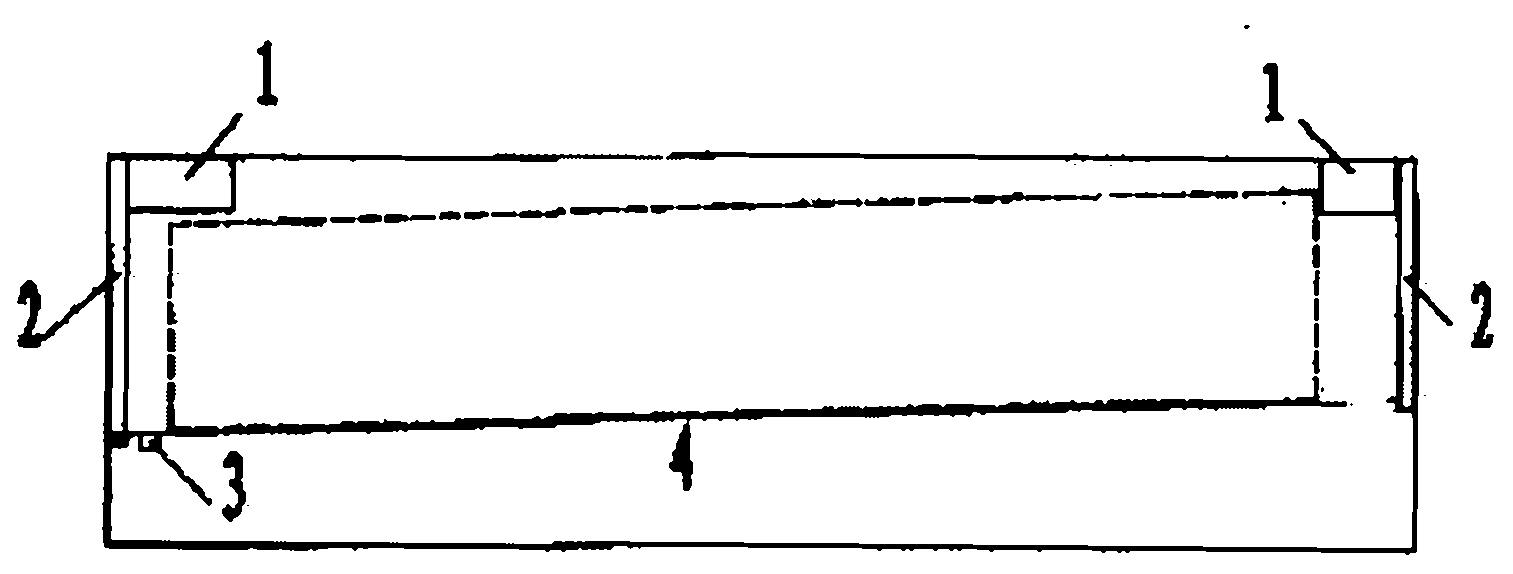

[0048] 1 In the island-sui junction of the Hong Kong-Zhuhai-Macao Bridge (the junction of the tunnel and the artificial island), it is proposed to design the construction enclosure structure of the 163m buried tunnel as three steel caissons. The main dimensions of the steel caisson are shown in Table 1.

[0049] List of main dimensions of steel caisson in buried section (163m) Table 1

[0050]

[0051]

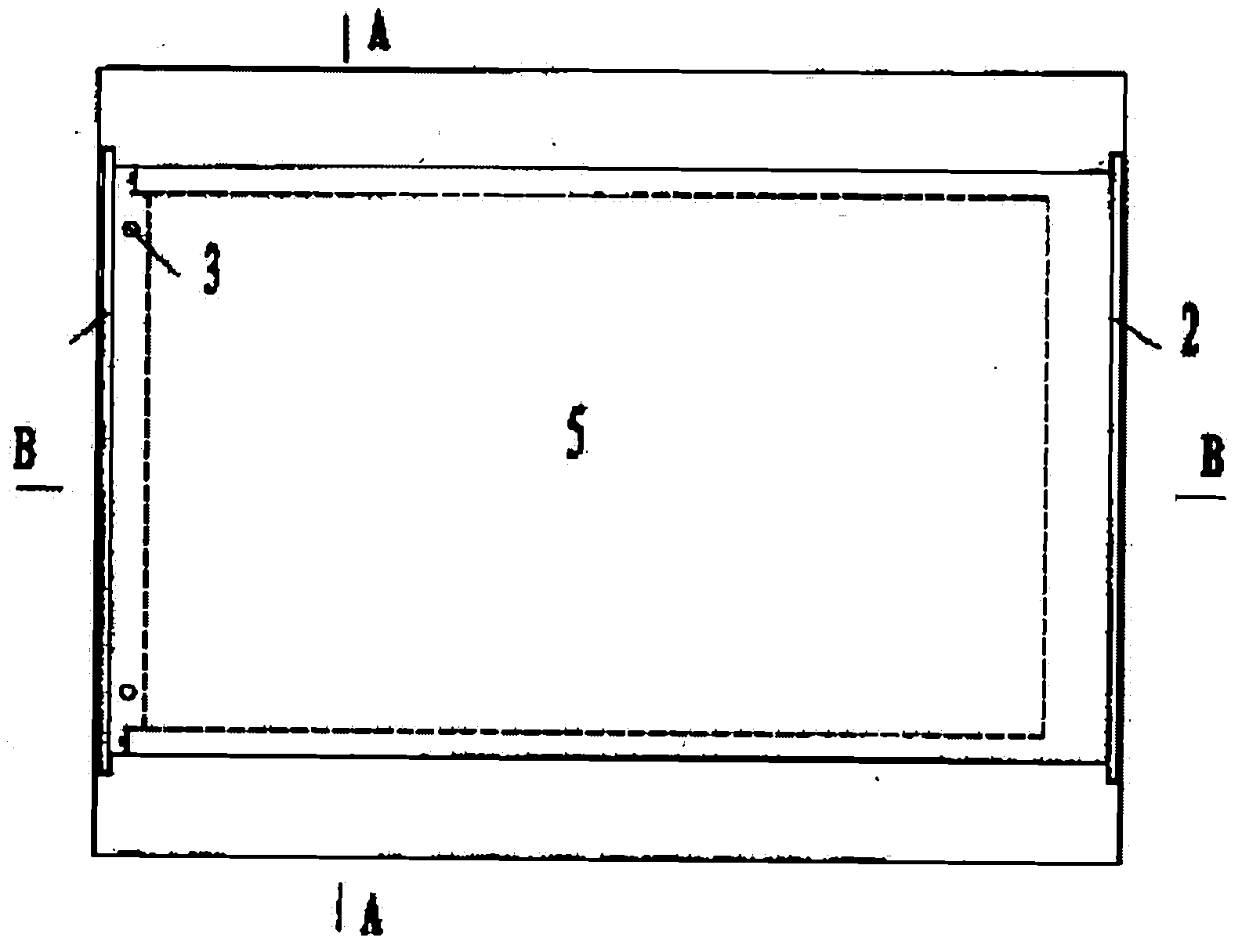

[0052] Both ends of the steel caisson are closed with steel gates, and D-type rubber is used to stop water. The top of the steel gate is supported by a steel box girder with sections of 6m×3m and 4.5m×3m.

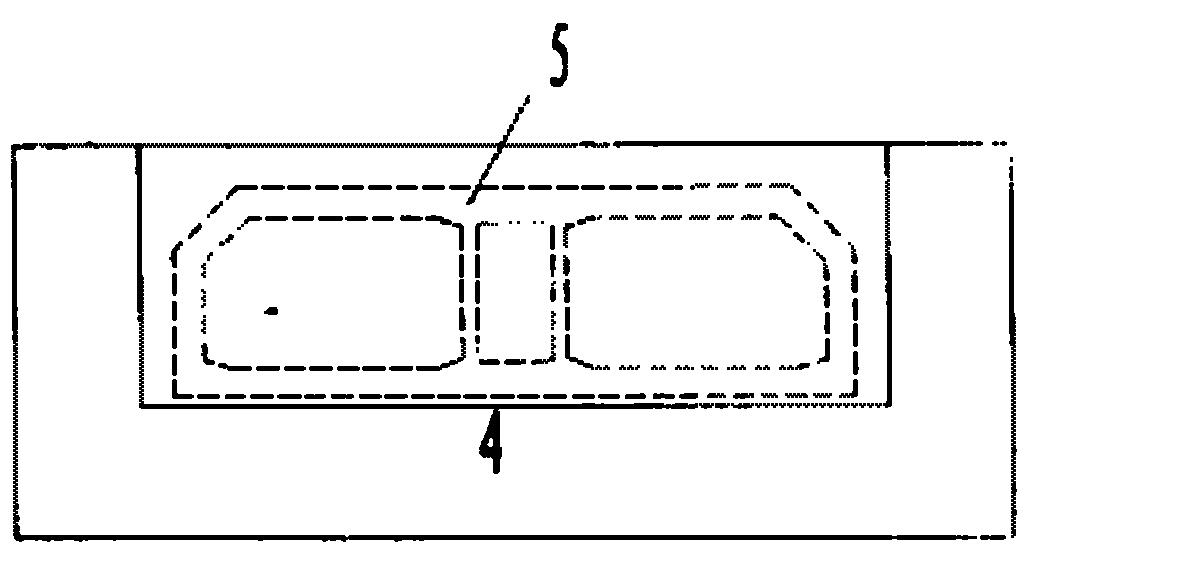

[0053] Inside the steel caisson there is a steel sleeve for the construction of the tunnel foundation cast-in-place pile, with a diameter of 1.8m and the top is 1.0m higher than the side wall. Realize the separation of steel caissons and tunnel foundation piles to ensure that the load borne by cast-in-situ piles remains unchanged.

[0054] At the same time, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com