Construction method for exchanging shield ventral brush

A construction method, shield tail brush technology, applied in the direction of earth cube drilling, mining equipment, tunnels, etc., can solve the problems of limited types of strata, segments back together, difficult to meet and other problems, to achieve safe and reliable construction conditions, environmental adaptability Strong, good operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments.

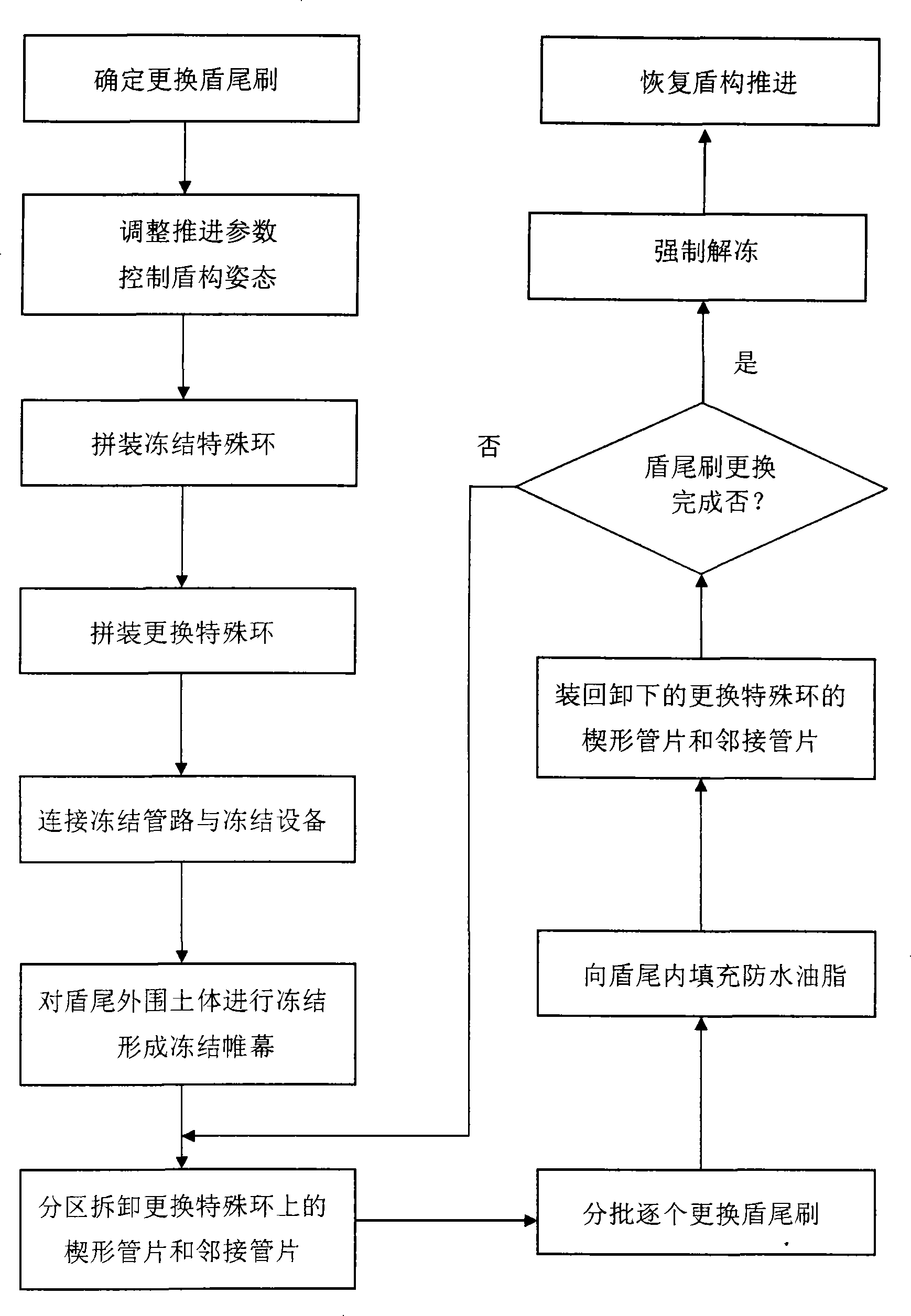

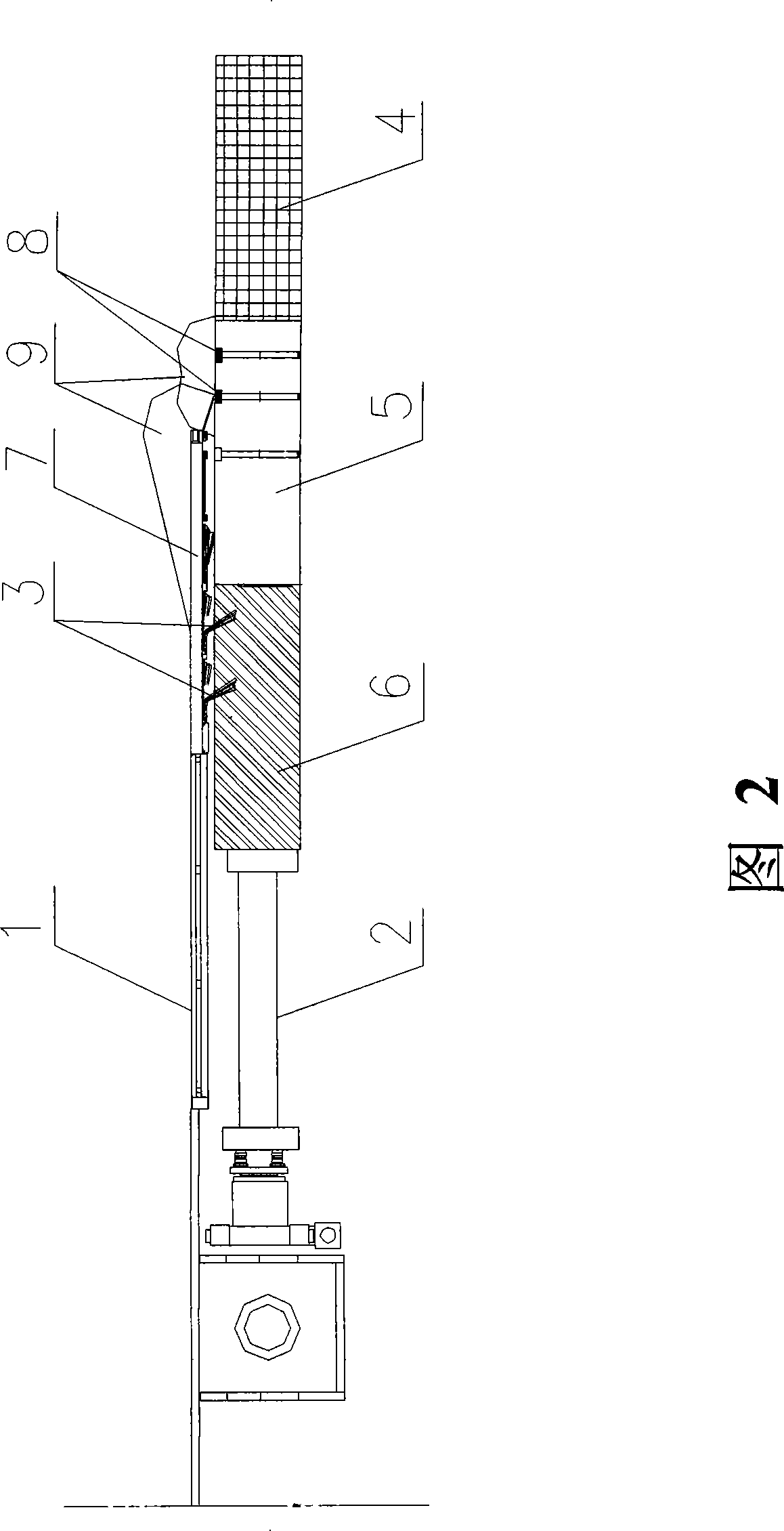

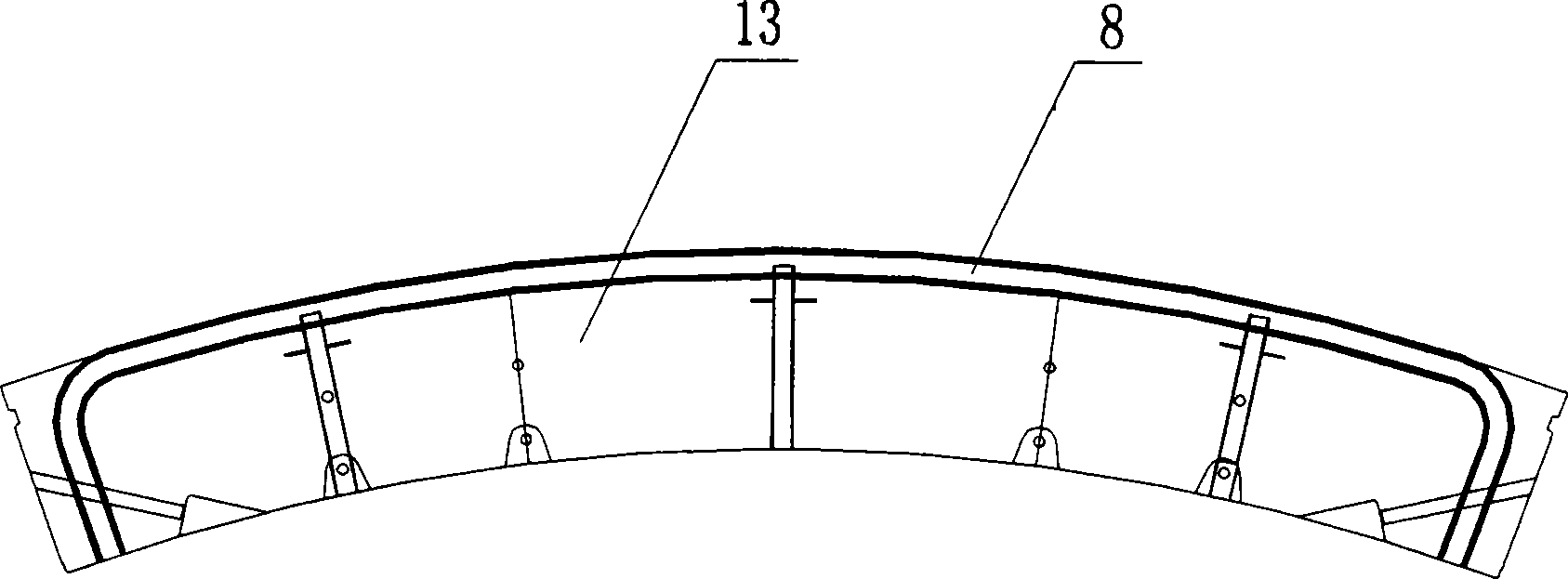

[0024] The construction method for the replacement of the shield tail brush in the present invention adopts the water-stopping method of the freezing method, which is based on active prevention. Therefore, the possible replacement of the shield tail brush has been considered when the shield machine is manufactured. The tail part 1 of the shield machine is pre-installed with a preset freezing pipe 7 (see FIG. 2 ). Applying the construction method of the present invention to replace the shield tail brush includes the following steps in sequence:

[0025] (1) Make sure to replace the shield tail brush.

[0026] First please also see figure 1 The flow chart of the method and the structural schematic diagram of the shield tail in FIG. 2 . Before the shield tail brush 3 is replaced, the wear condition of the shield tail brush 3, the soil condition around the tunnel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com