Combined type steel tube intermediate jacking station equipment for jacking pipe construction and construction method

A combined, steel pipe technology, applied in the direction of mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

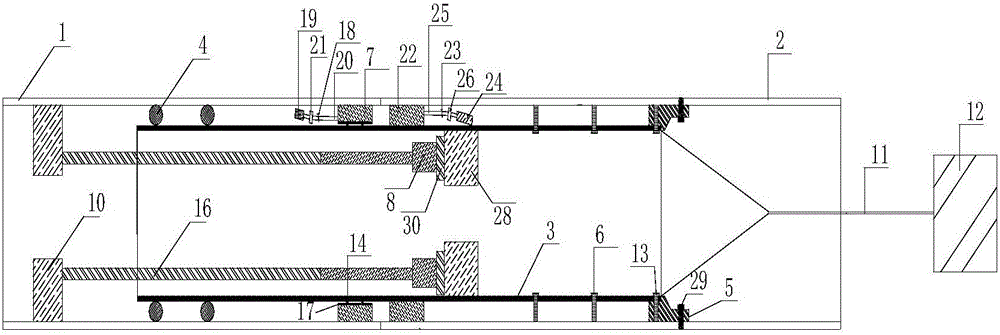

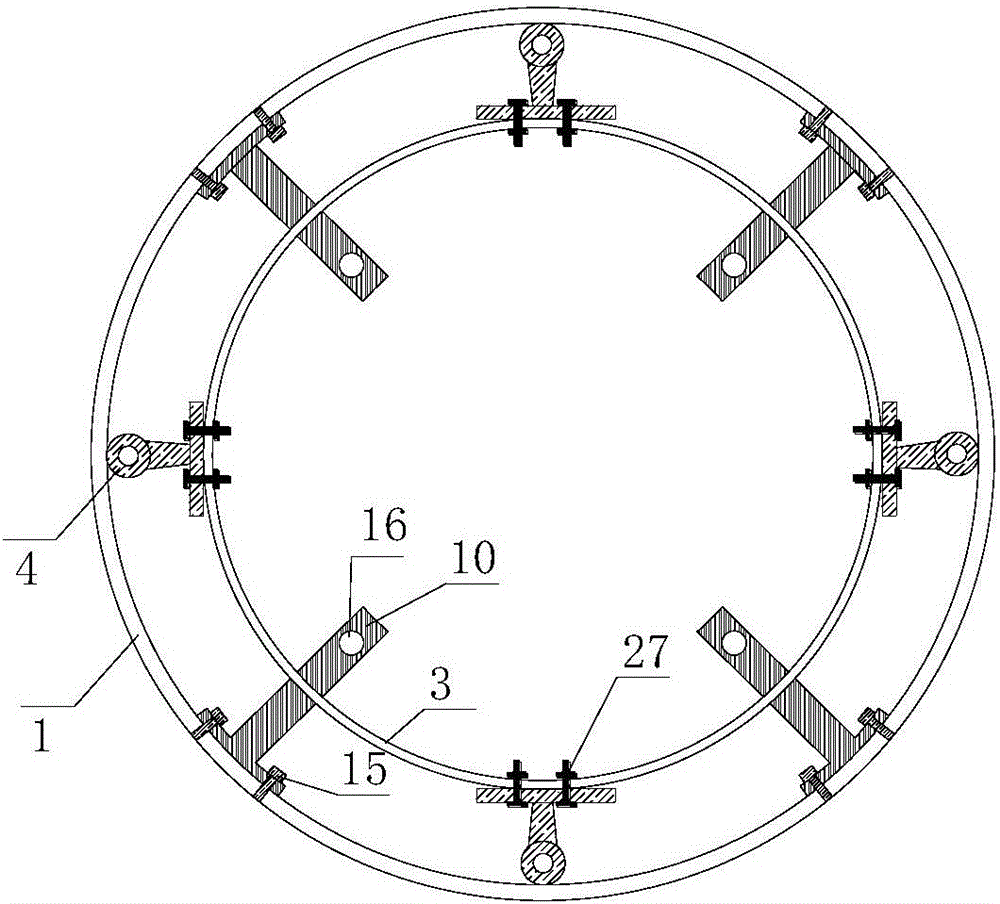

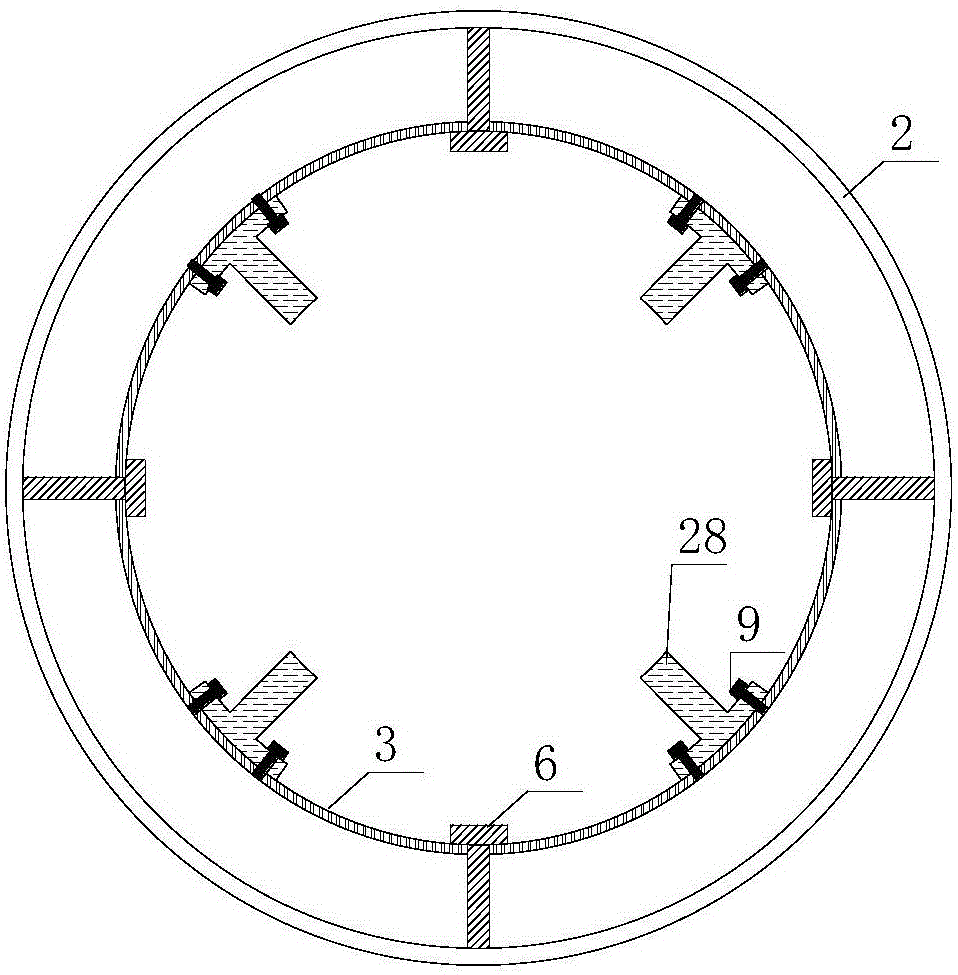

[0063] The present invention will be described in further detail below according to accompanying drawing:

[0064] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a reusable combined steel pipe relay room device consists of front jacking pipe 1, rear jacking pipe 2, round steel pipe 3 in the relay room, and heavy-duty universal casters (model: B10-01-075-10-2) 4. Fixed pedestal 5, fixed screw 6, first A sealed inflatable bag 7, jack 8, jack pedestal fixing bolt 9, jack receiving seat 10, traction rope 11, hoist 12, round steel pipe fixing bolt 13 between relays, ring Sealing ring 14, jack socket bolt 15, jack dowel rod 16, steel ring 17, A valve 18, A inflatable booster pump 19, A pressurized inflatable tube 20, A pressure gauge 21, second B sealed inflatable bag 22, B valve 23, B inflatable booster pump 24, B pressurized gas tube 25, B pressure gauge 26, caster bolt 27, jack pedestal...

Embodiment 2

[0089] A construction method for a reusable combined steel pipe relay room device for pipe jacking construction, the steps of which are:

[0090] 1) Installation:

[0091] a) First assemble the steel ring 17 and the first A sealed inflatable bag 7 into one body, set them on the outer wall of the round steel pipe 3 in the relay room, and at the same time put the second B sealed inflatable bag 22 on the outer wall of the round steel pipe 3 in the relay room Above, the assembly of the steel ring 17 and the first A-sealed air bag 7 is in front, and the second B-sealed air bag 22 is behind.

[0092] b) Use the caster bolts 27 to fix the heavy-duty universal caster 4 at a predetermined position on the outer wall of the round steel pipe 3 in the relay room.

[0093] c) Fix the fixed pedestal 5 on the predetermined position on the inner wall of the rear jacking pipe 2 with the pedestal fixing bolt 29 .

[0094] d) Place the front jacking pipe 1 and the rear jacking pipe 2 in sequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com