High-temperature-resistant wallpaper basic film and preparation method thereof

A technology of high temperature resistance and wallpaper, applied in the direction of adhesive types, coatings, acid copolymer adhesives, etc., can solve the problems affecting the use effect and service life of wall coverings, warping, bulging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high temperature resistant wallpaper base film, the raw material formula is: 160kg of acrylic acid, 10kg of butyl acrylate, 15kg of ethyl acrylate, 8kg of methyl acrylate, 35kg of methyl methacrylate, 70kg of acrylonitrile, 3kg of sodium lauryl sulfate, emulsified Agent MS-1 4kg, emulsifier OP-10 5kg, sodium acetate 2kg, potassium persulfate 1.2kg, ammonium persulfate 0.8kg, divinylbenzene 1.5kg, sodium hydroxide 5kg, fungicide 1.8kg.

[0028] 1) Ingredients:

[0029] Dissolve 1.2kg of potassium persulfate and 0.8kg of ammonium persulfate with 50kg of deionized water to obtain an initiator solution. The total volume of the initiator solution is recorded as 100%, and the system is added in batches during the reaction to avoid the phenomenon of too violent reaction and the phenomenon of cascading;

[0030] Dissolve 3kg sodium lauryl sulfate with 20kg deionized water to obtain sodium lauryl sulfate solution;

[0031] Dissolve and dilute 5kg of sodium hydroxide with 8kg ...

Embodiment 2

[0039] A high temperature resistant wallpaper base film, the raw material formula is: 165kg of acrylic acid, 10kg of butyl acrylate, 16kg of ethyl acrylate, 8kg of methyl acrylate, 37kg of methyl methacrylate, 75kg of acrylonitrile, 3.5kg of sodium lauryl sulfate, Emulsifier MS-1 5kg, emulsifier OP-10 5kg, sodium acetate 2.4kg, potassium persulfate 1.4kg, ammonium persulfate 0.9kg, divinylbenzene 1.6kg, sodium hydroxide 7kg, fungicide 1.9kg. The preparation method is the same as in Example 1.

Embodiment 3

[0041] A high temperature resistant wallpaper base film, the raw material formula is: acrylic acid 160kg, butyl acrylate 9kg, ethyl acrylate 15kg, methyl acrylate 9kg, methyl methacrylate 35kg, acrylonitrile 70kg, sodium lauryl sulfate 3kg, emulsified Agent MS-1 4kg, emulsifier OP-10 5kg, sodium acetate 2kg, potassium persulfate 1.2kg, ammonium persulfate 0.8kg, divinylbenzene 1.5kg, sodium hydroxide 5kg, fungicide 1.8kg. The preparation method is the same as in Example 1.

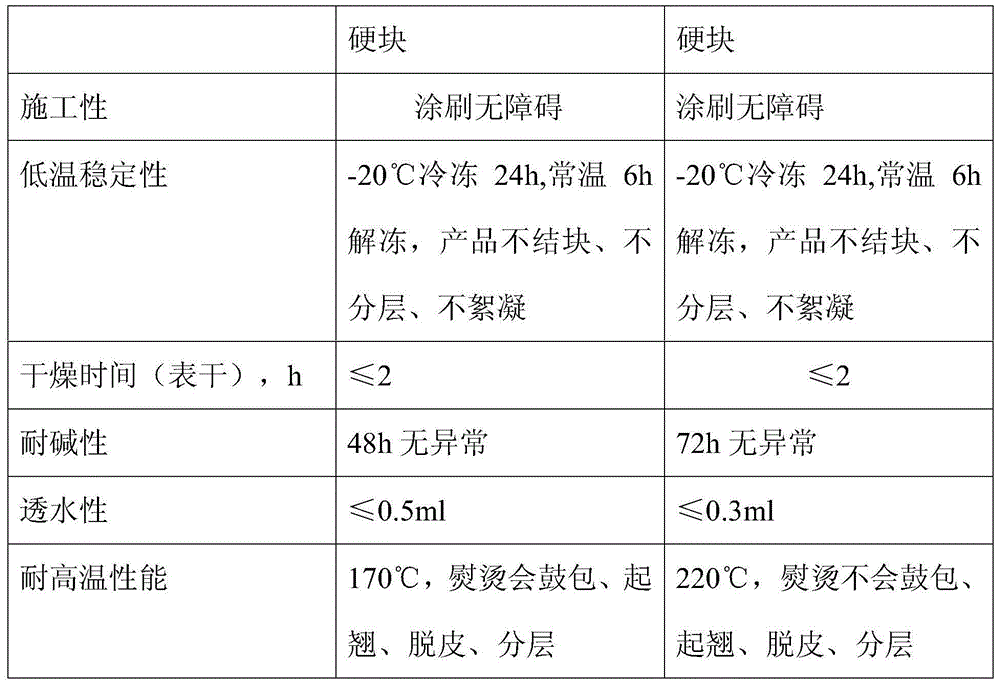

[0042] The wallpaper base film obtained in each embodiment of the present invention is compared with other common base films in performance comparison test Table 1.

[0043] Table 1

[0044]

[0045]

[0046]The specific method of using the base film of high temperature resistant wallpaper is as follows: 1. First apply the base film (direct brushing, spraying, rolling) to the wall, and then paste the wall cloth after it is completely dry; 2. When pasting , cut according to the pasting area of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com