Iron ore waste rock self-compaction concrete

A self-compacting concrete and concrete technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., to achieve the effect of reducing production costs, reducing mining energy consumption, and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

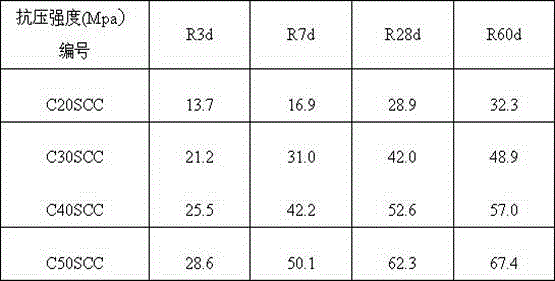

[0027] A kind of iron ore waste rock self-compacting concrete, described concrete is prepared by mixing and stirring the components of the mass fractions in Table 1:

[0028] Table 1 Self-compacting concrete benchmark mix ratio (parts)

[0029] Numbering

water-binder ratio

water

sand rate

Iron ore waste rock

Additives (percentage to the sum of cement and admixture mass)

C20SCC

0.60

185

220

40

50

45

1020

1.9%

C30SCC

0.48

180

240

65

70

42

1050

2.0%

C40SCC

0.41

175

250

80

95

39

1070

2.2%

C50SCC

0.33

165

270

120

105

37

1080

2.3%

[0030] The iron ore waste rock is the ore-free surrounding rock and interlayer stones under iron ore mining, which are mechanically crushed and screened into crushed stones with a particle size of 5-20mm and continuous grading, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com