Patents

Literature

222 results about "DIN rail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A DIN rail is a metal rail of a standard type widely used for mounting circuit breakers and industrial control equipment inside equipment racks. These products are typically made from cold rolled carbon steel sheet with a zinc-plated or chromated bright surface finish. Although metallic, they are meant only for mechanical support, and are not used as a busbar to conduct electric current, although they may provide a chassis grounding connection.

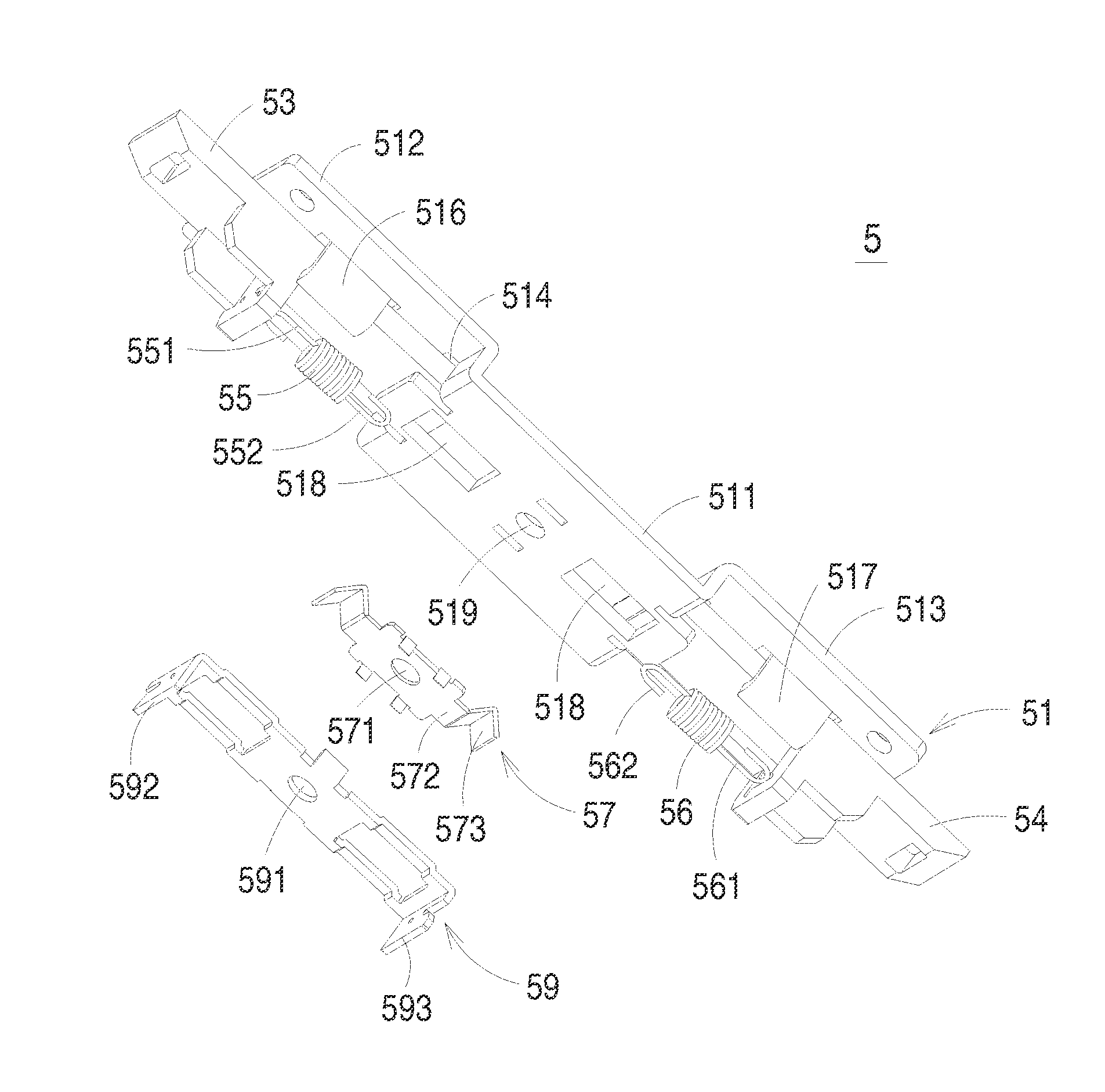

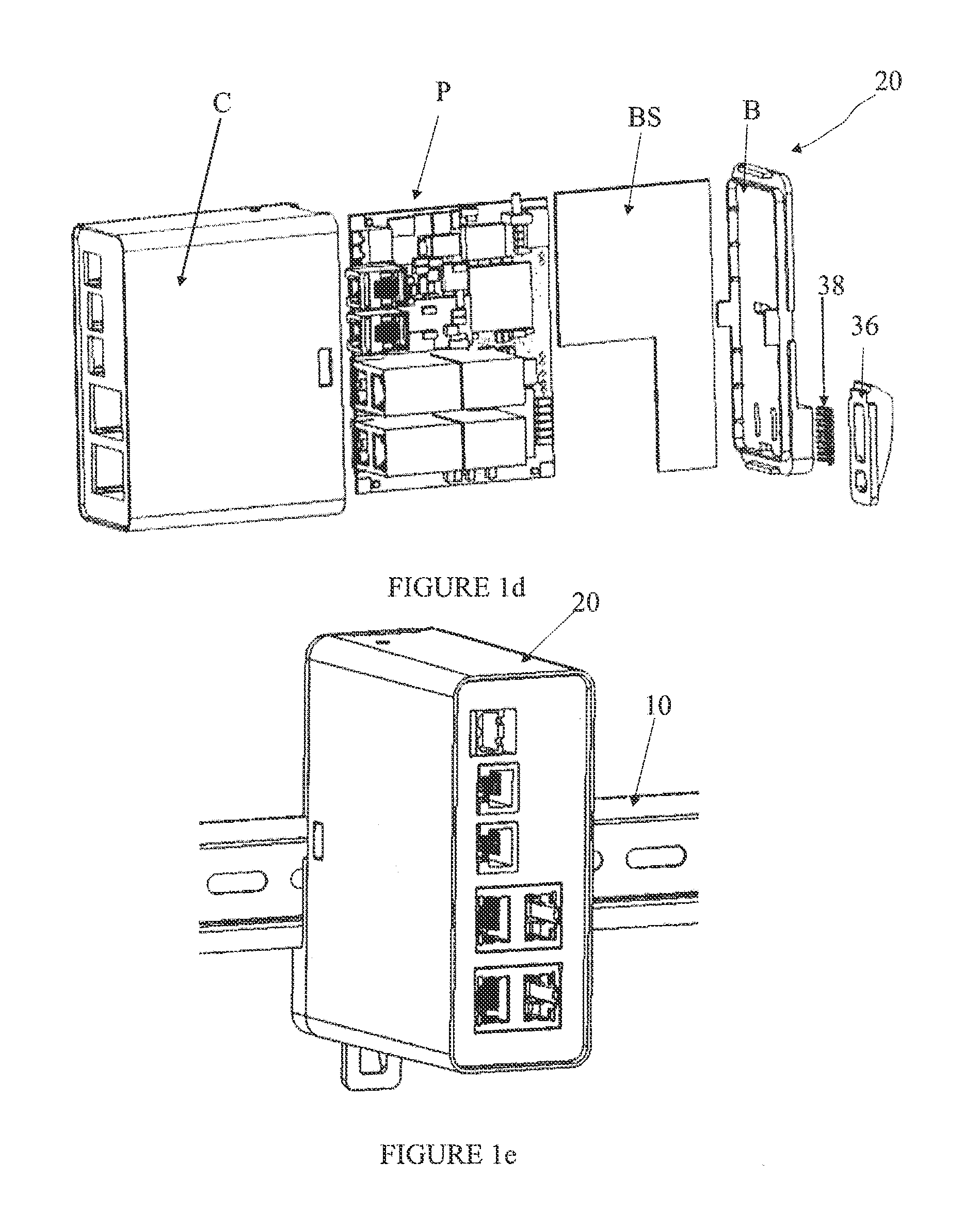

Mechanism of fastening detachable electronic device to din rail

ActiveUS20080108248A1Engagement/disengagement of coupling partsSubstation/switching arrangement detailsEngineeringMaterial Perforation

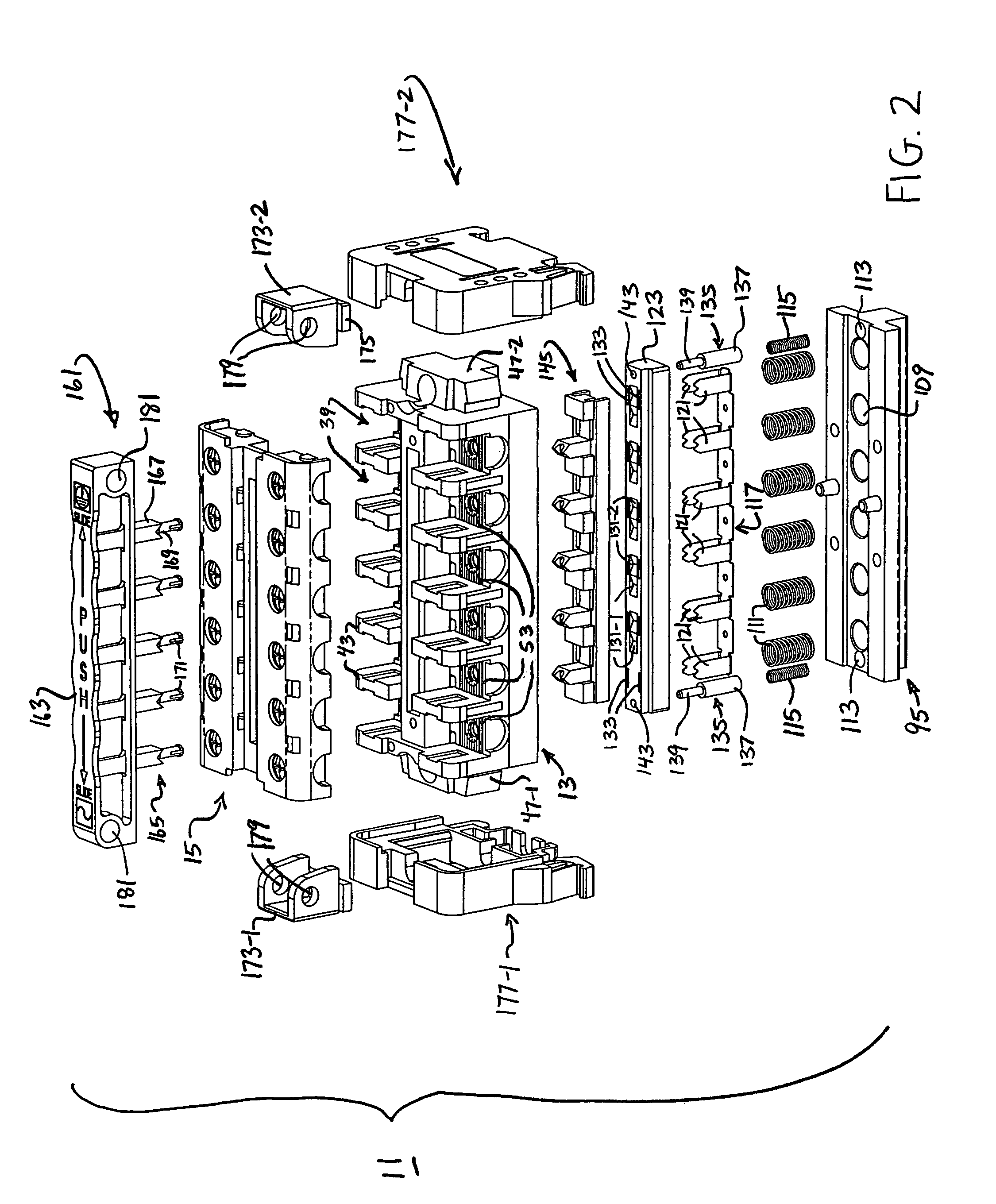

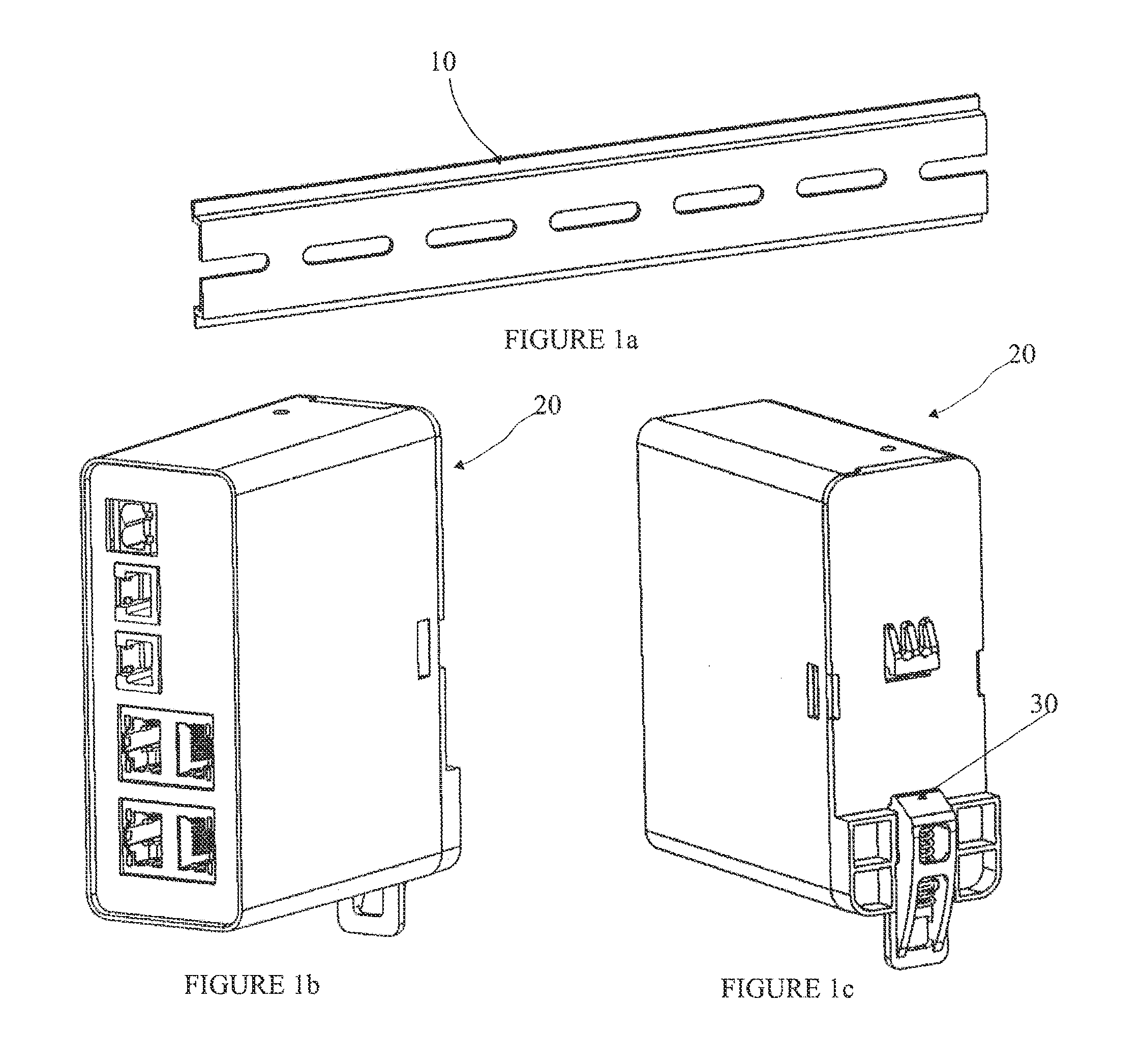

A fastening mechanism for fastening a detachable electronic device onto a DIN rail includes a frame, a first slab member and a first resilient element. The frame includes a base, a first extension part and a second extension part. The first extension part and the second extension part are arranged at bilateral sides of the base. A first perforation is formed between the first extension part and the base. The first slab member is movable along the bottom surface of the first extension part and has an end penetrating through the first perforation to be disposed over the base. The first resilient element is coupled to the first slab member and exerts a clamping force for claming a first extending edge of the DIN rail between the first slab member and the base.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

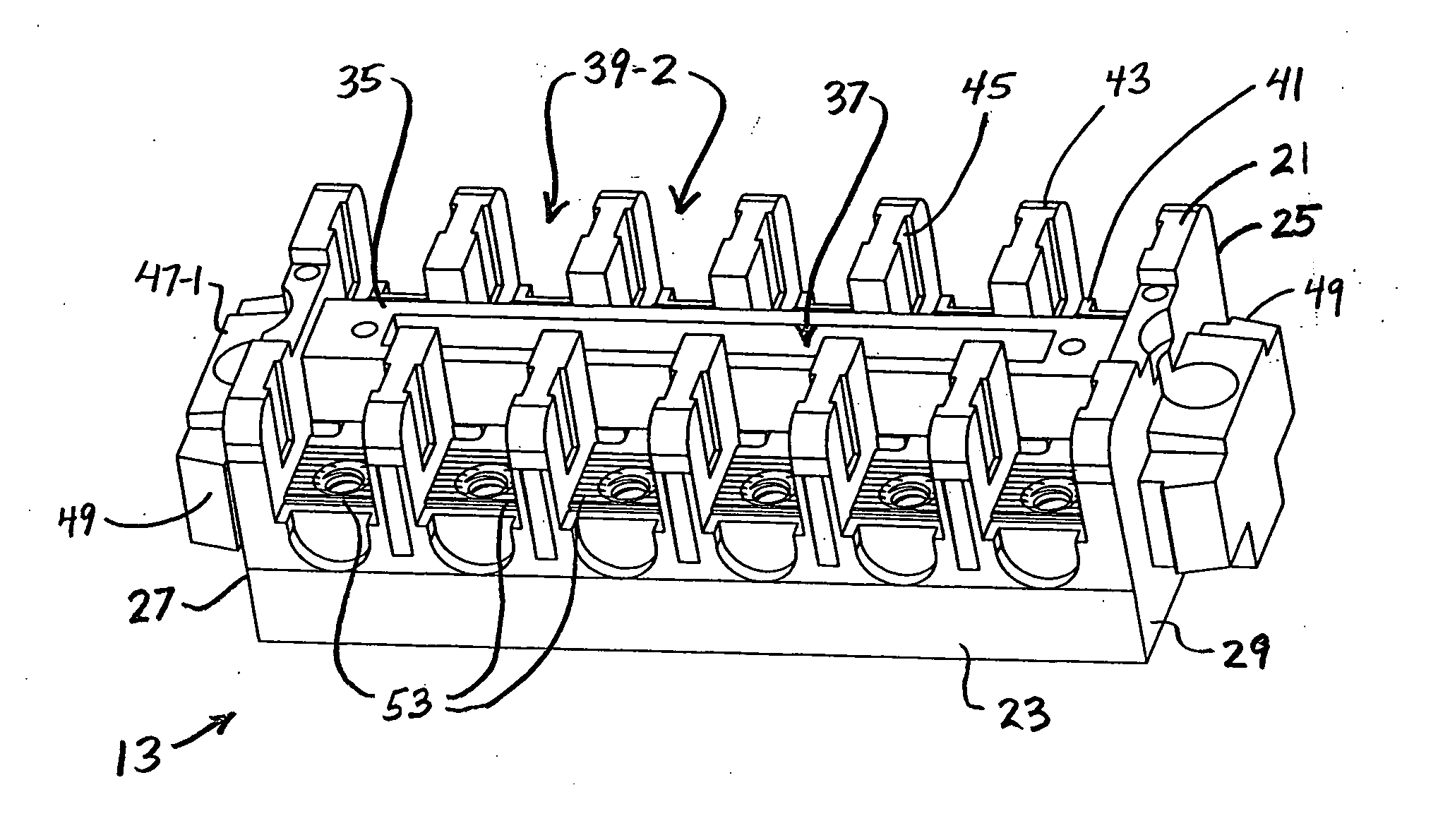

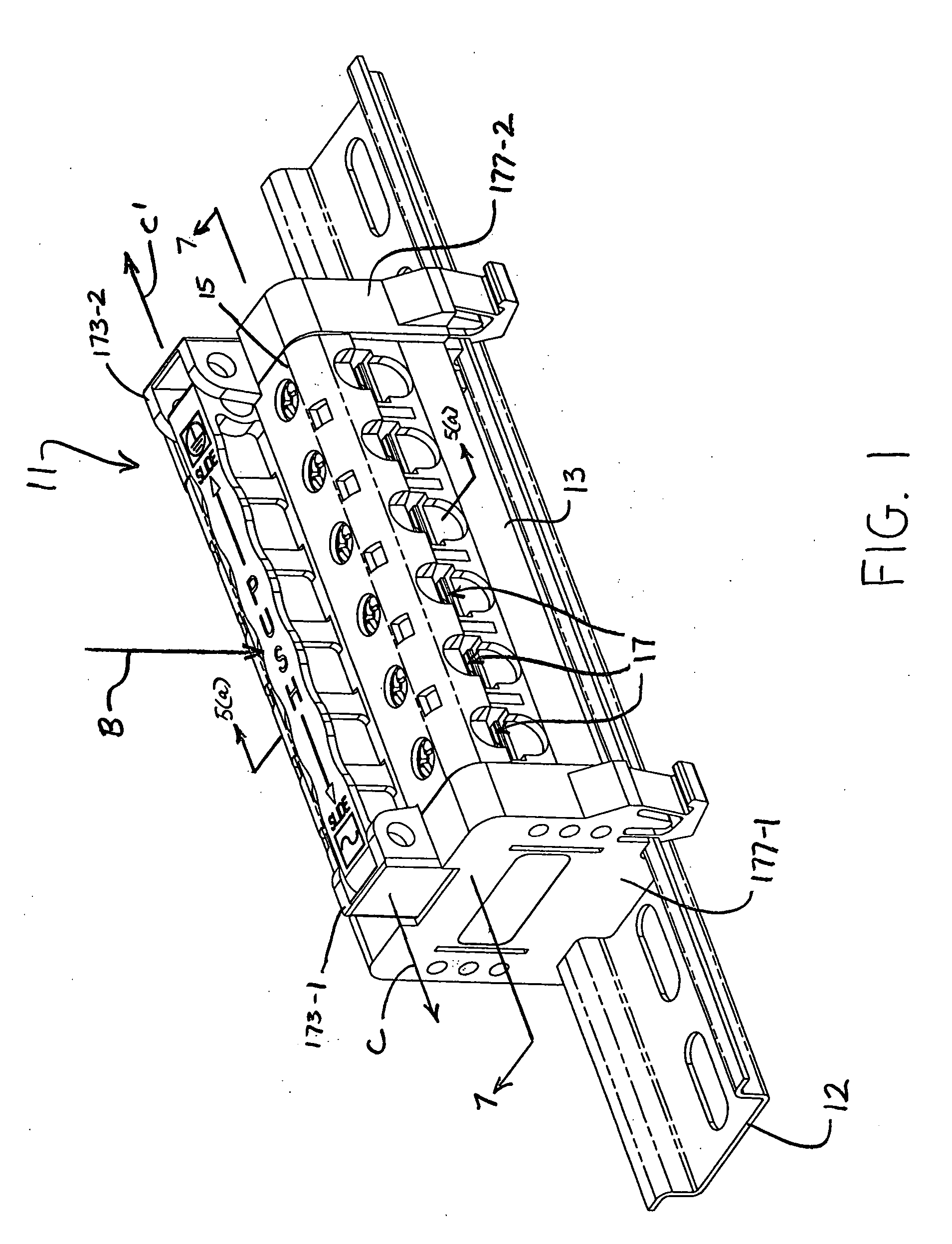

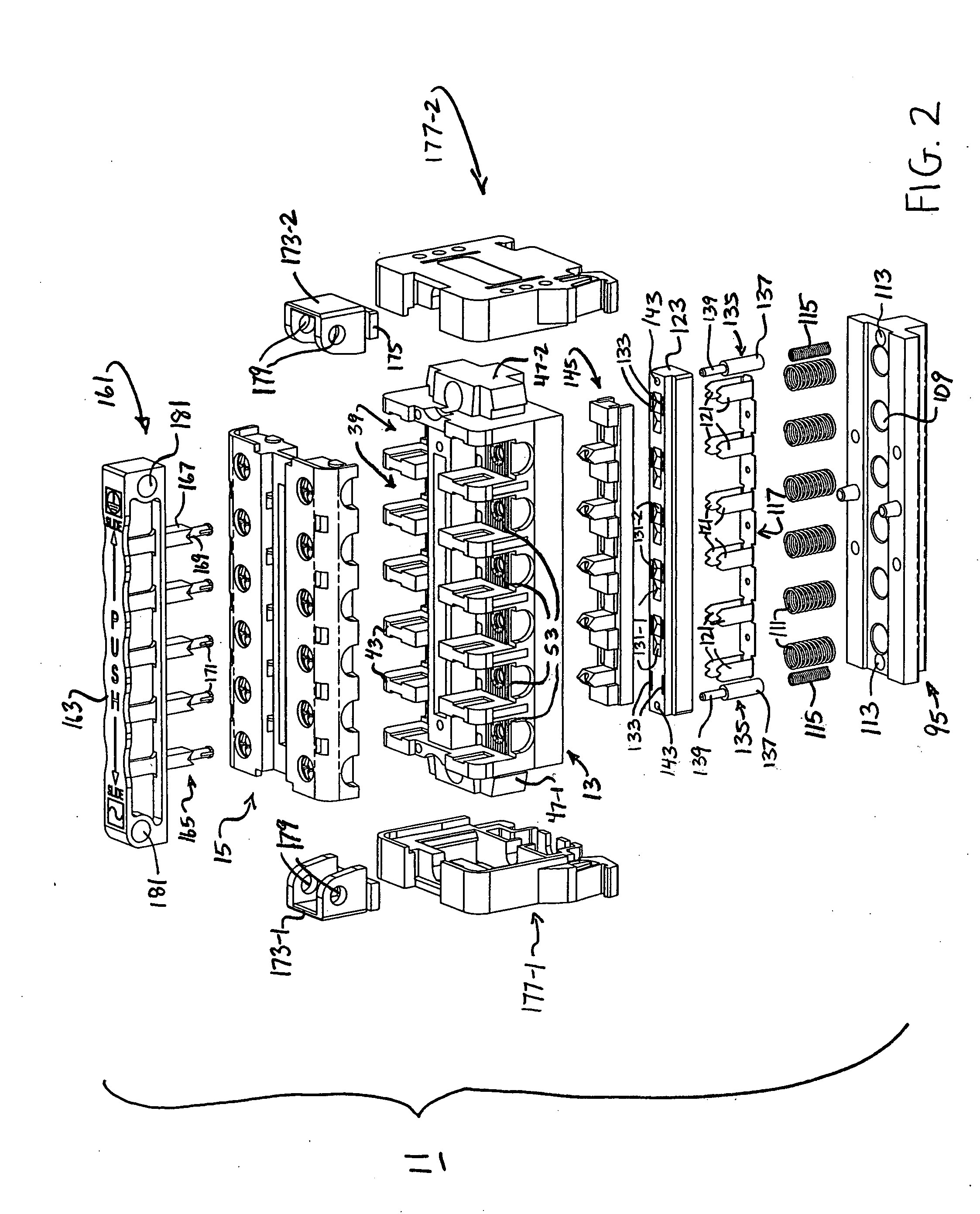

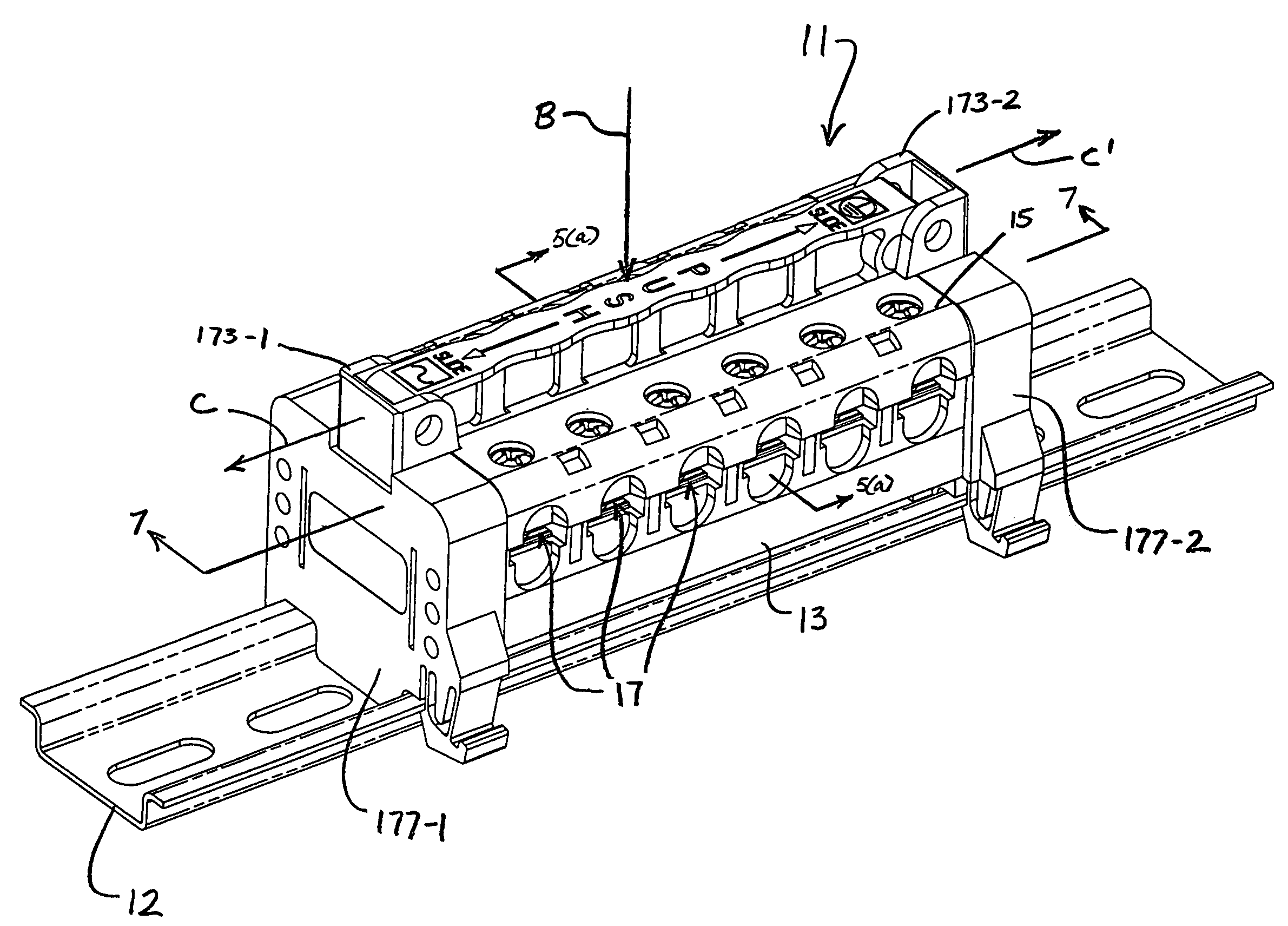

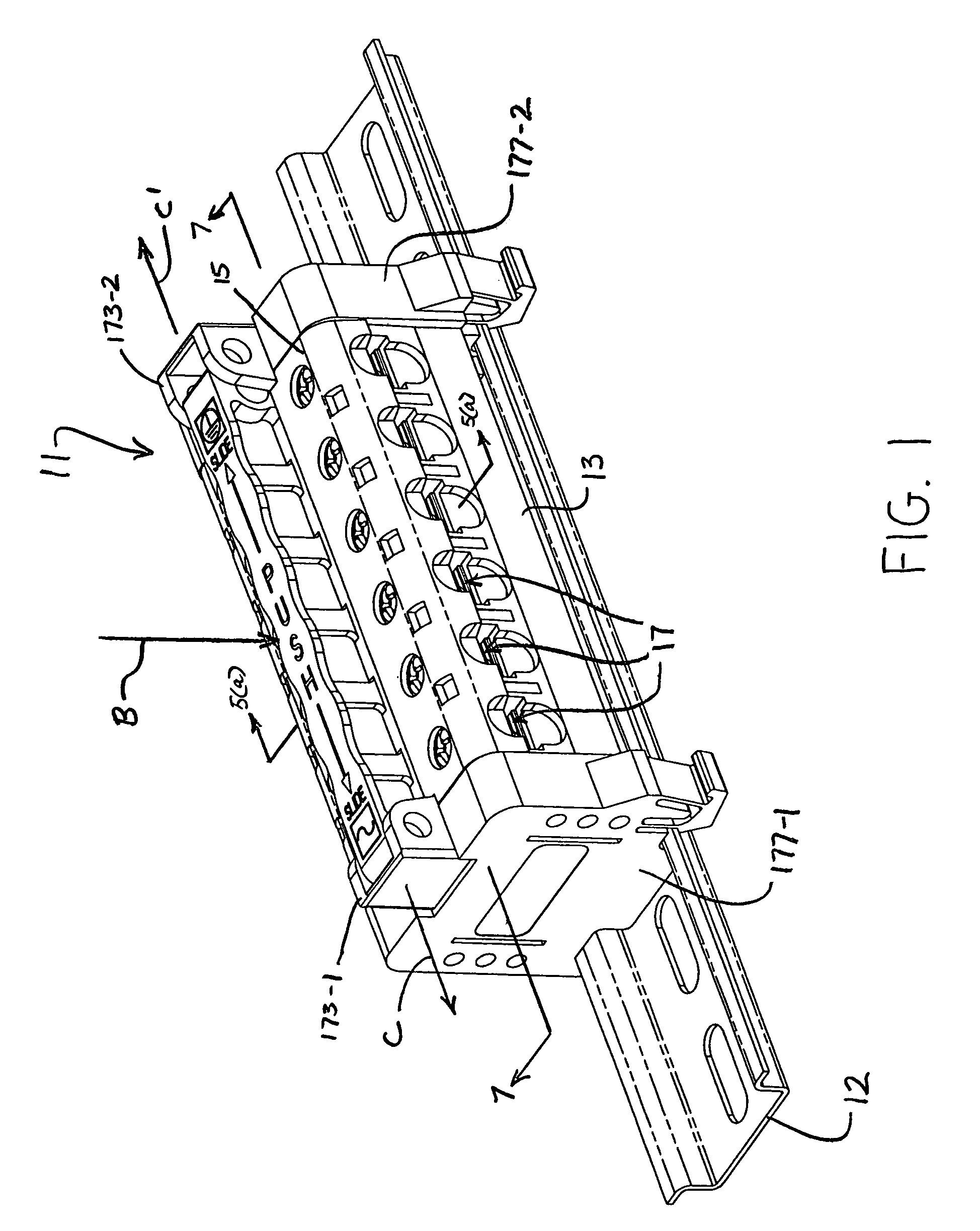

Electrical terminal block

ActiveUS20050250389A1Easily and safely conductively coupledElectric shock preventionElectric connection structural associationsDIN rail

A terminal block for conductively coupling multiple pairs of electrical wires includes a deadfront cover mounted onto a non-conductive base so as to define multiple pairs of wire receiving receptacles, each pair of wire receiving receptacles being electrically connected together via a conductive bus bar. As one feature of the present invention, a conductive shunt can be disposed by means of a manually operable shunt switch to selectively contact all of the bus bars in order to discharge any current present thereon. As another feature of the present invention, a plurality of finger-safe captive screw assemblies are retained within the cover, each captive screw assembly including a screw which can be driven into a threaded bore formed in one end of a corresponding bus bar. As yet another feature of the present invention, multiple pairs of interchangeable end caps can be removably snap-fit mounted on the base to enable the terminal block to be retained onto a wide variety of different surfaces. As yet still another feature of the present invention, a DIN rail lock is retained between each end cap and the base and includes one or more sharpened teeth which can be driven into the surface of the DIN rail to lock the terminal block in place.

Owner:CONCENTRIC DEVICES INC

Electrical terminal block

ActiveUS7011551B2Easily and safely conductively coupledMinimum number of partElectric connection structural associationsEngineeringElectric wire

A terminal block for conductively coupling multiple pairs of electrical wires includes a deadfront cover mounted onto a non-conductive base so as to define multiple pairs of wire receiving receptacles, each pair of wire receiving receptacles being electrically connected together via a conductive bus bar. As one feature of the present invention, a conductive shunt can be disposed by means of a manually operable shunt switch to selectively contact all of the bus bars in order to discharge any current present thereon. As another feature of the present invention, a plurality of finger-safe captive screw assemblies are retained within the cover, each captive screw assembly including a screw which can be driven into a threaded bore formed in one end of a corresponding bus bar. As yet another feature of the present invention, multiple pairs of interchangeable end caps can be removably snap-fit mounted on the base to enable the terminal block to be retained onto a wide variety of different surfaces. As yet still another feature of the present invention, a DIN rail lock is retained between each end cap and the base and includes one or more sharpened teeth which can be driven into the surface of the DIN rail to lock the terminal block in place.

Owner:CONCENTRIC DEVICES INC

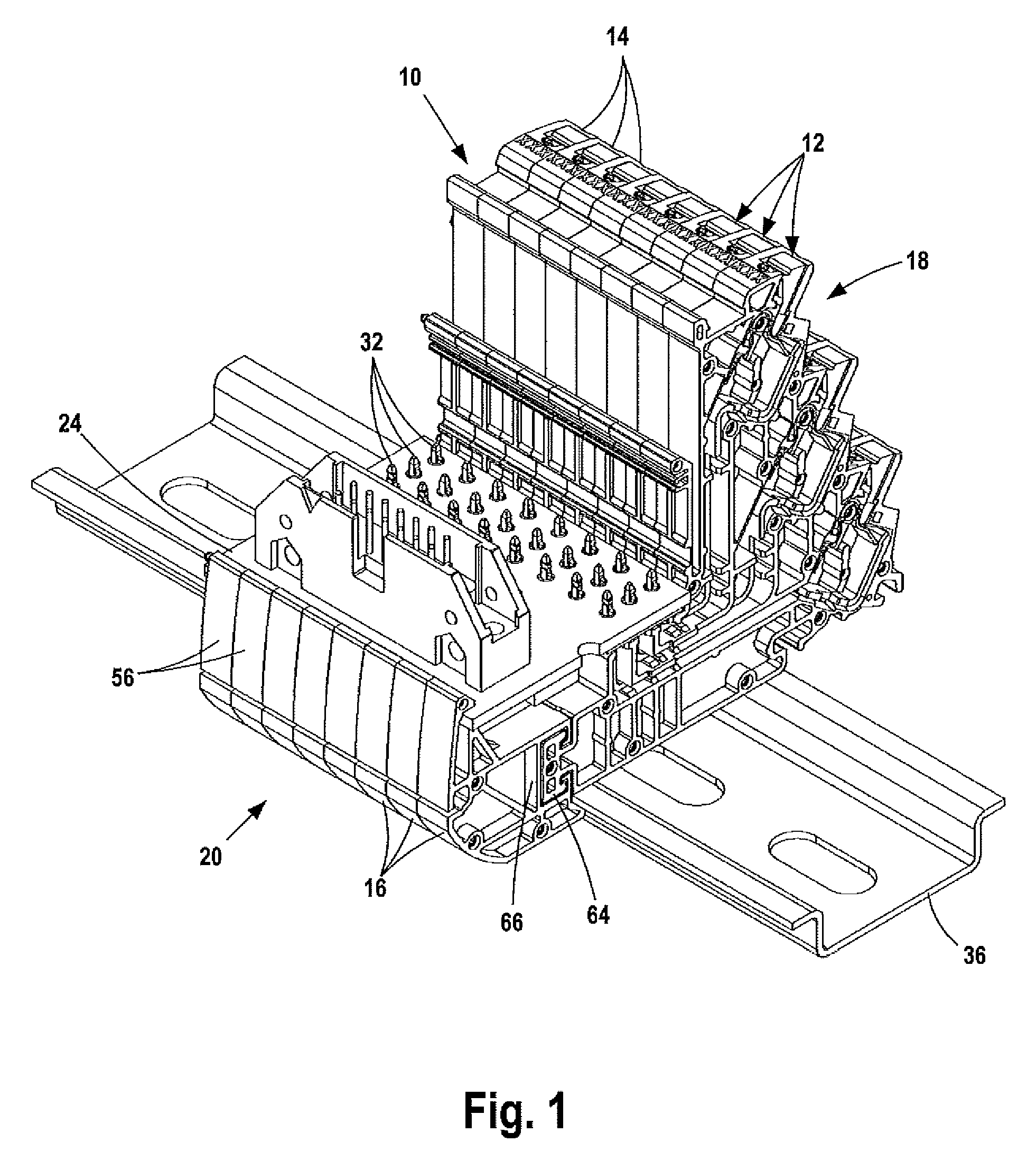

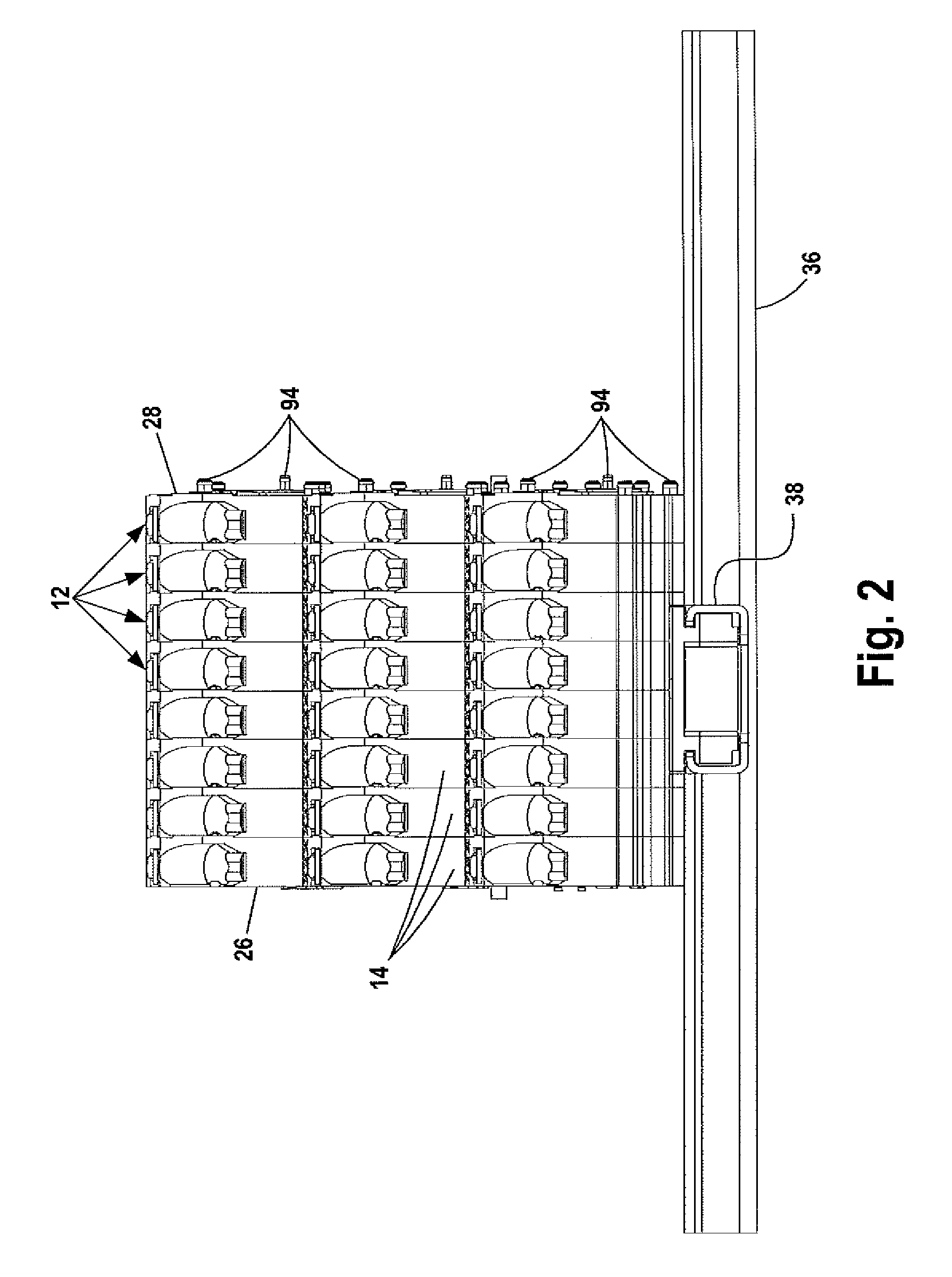

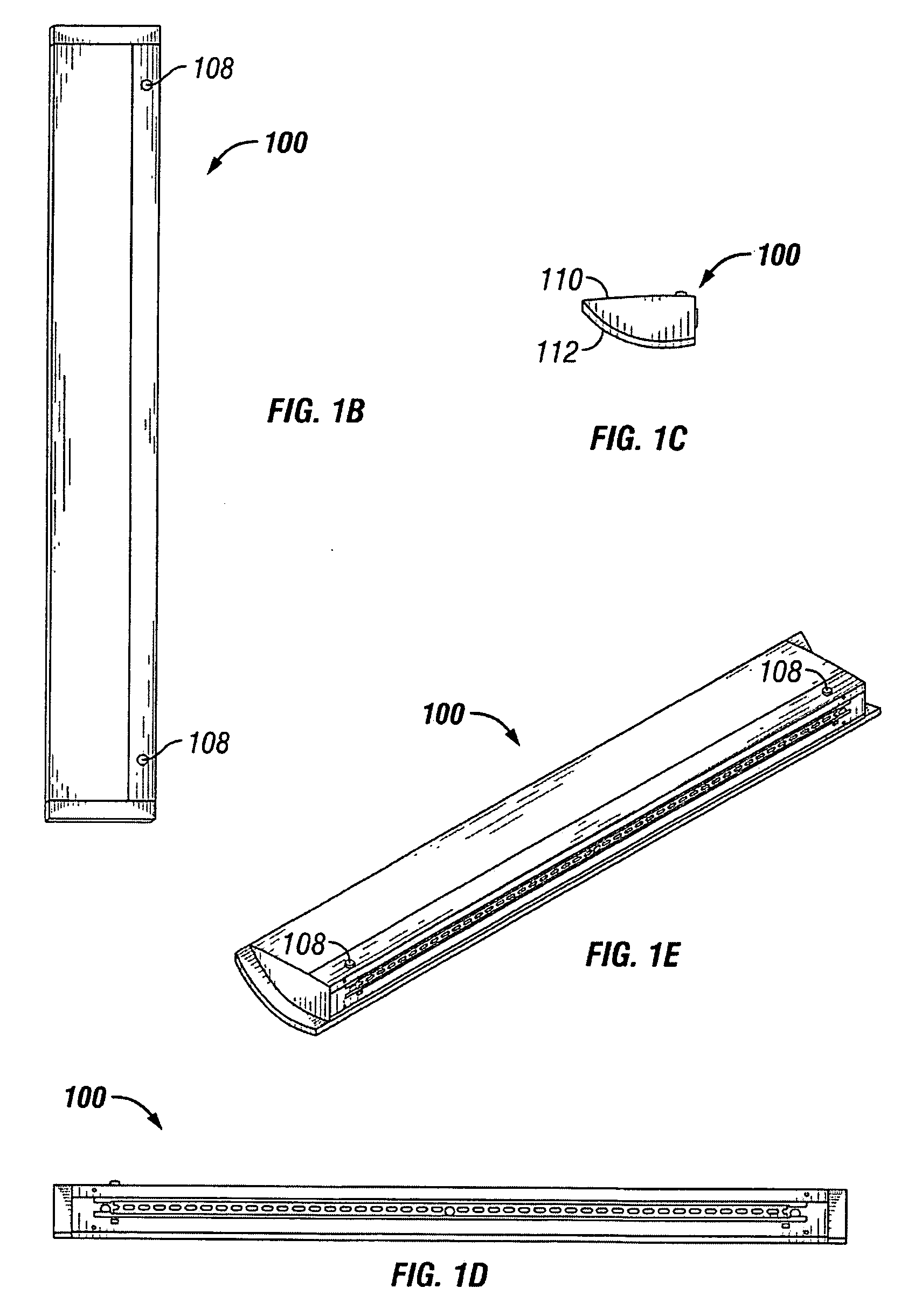

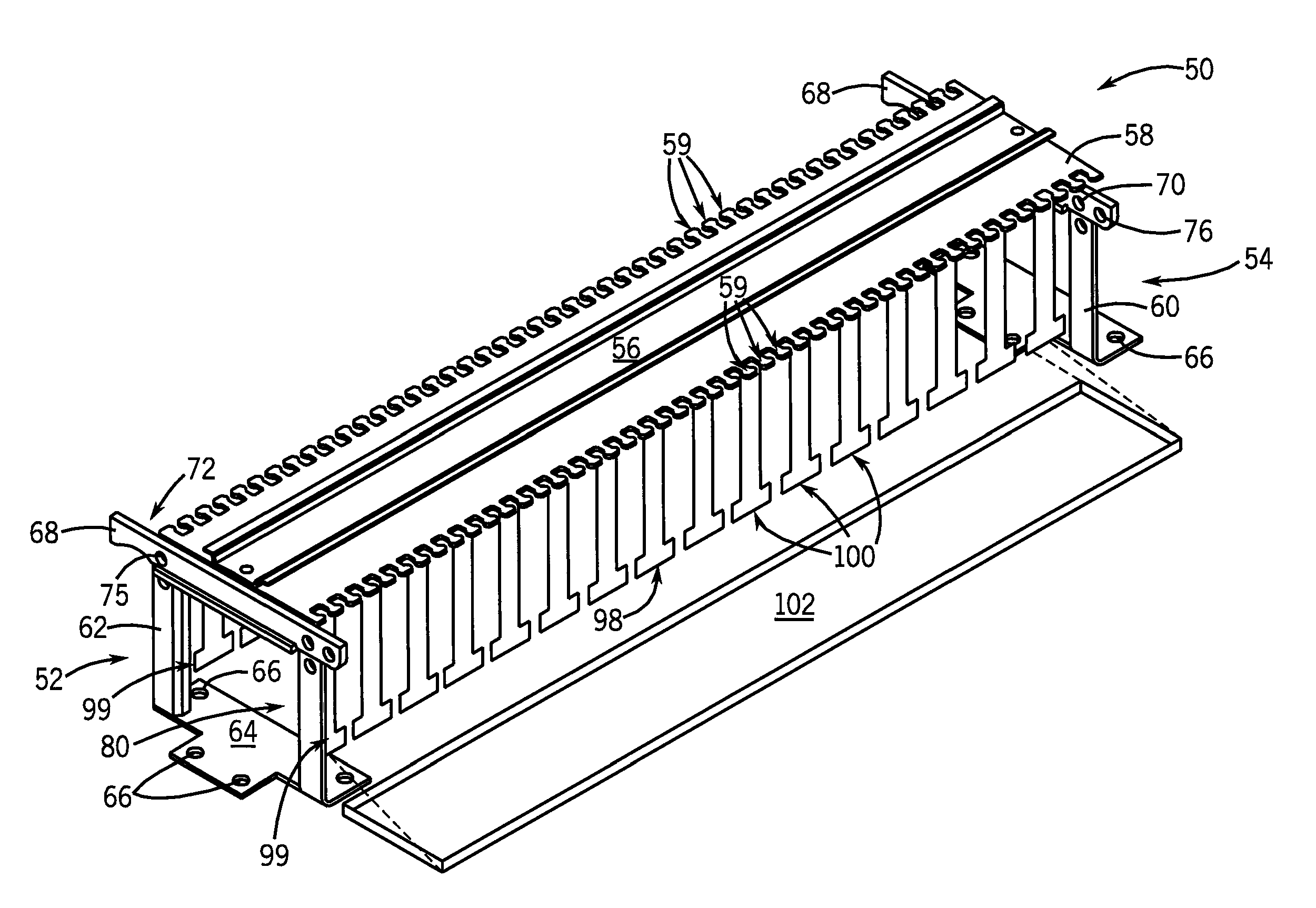

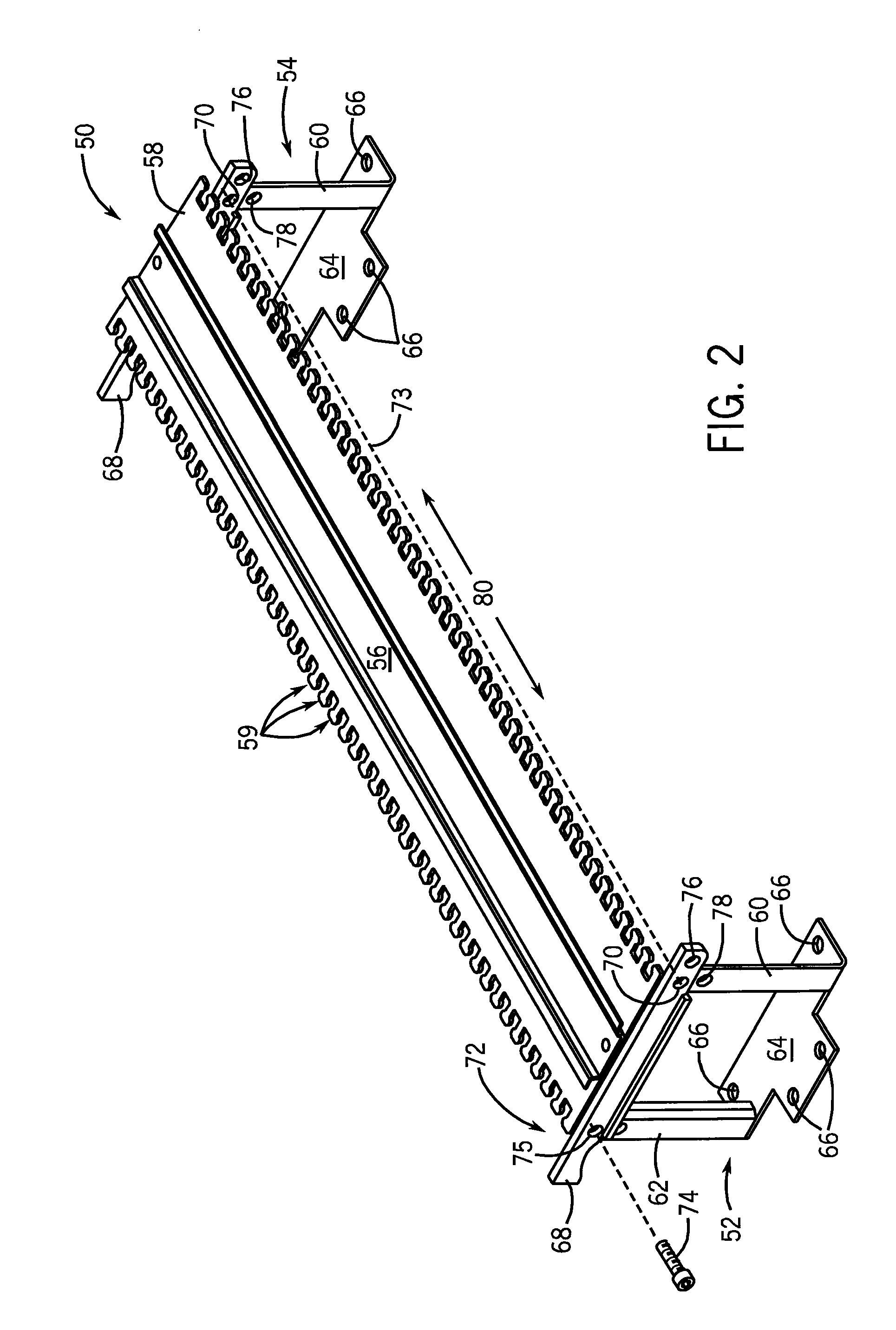

Rail Wiring Duct

Certain embodiments of the present invention provide a DIN rail wiring duct. The DIN rail wiring duct has a top, a bottom, and a side. The DIN rail wiring duct includes a base. The base has a top wall, a bottom wall, a sidewall, and a divider wall, which define a channel and a channel opening for accessing the channel. The DIN rail wiring duct also includes a cover for the channel opening. The cover has a top wall and a sidewall substantially perpendicular to the top wall. The top wall of the cover is removably connected to the top wall of the base and the sidewall of the cover is rotatably connected to the sidewall of the base such that the channels are accessible through the channel openings from the top and the side of the DIN rail wiring duct when the cover is rotated from a closed position to an open position.

Owner:PANDUIT

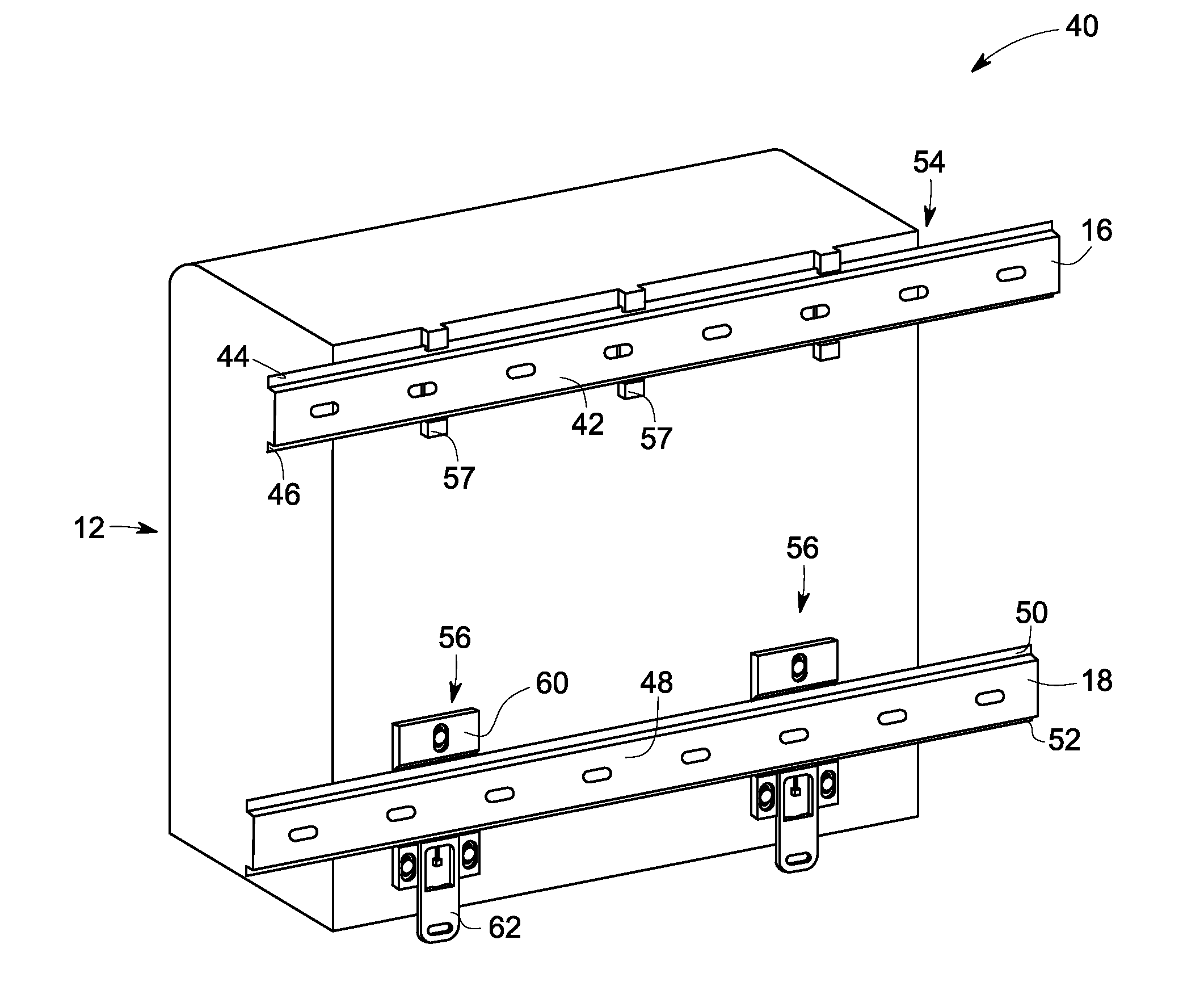

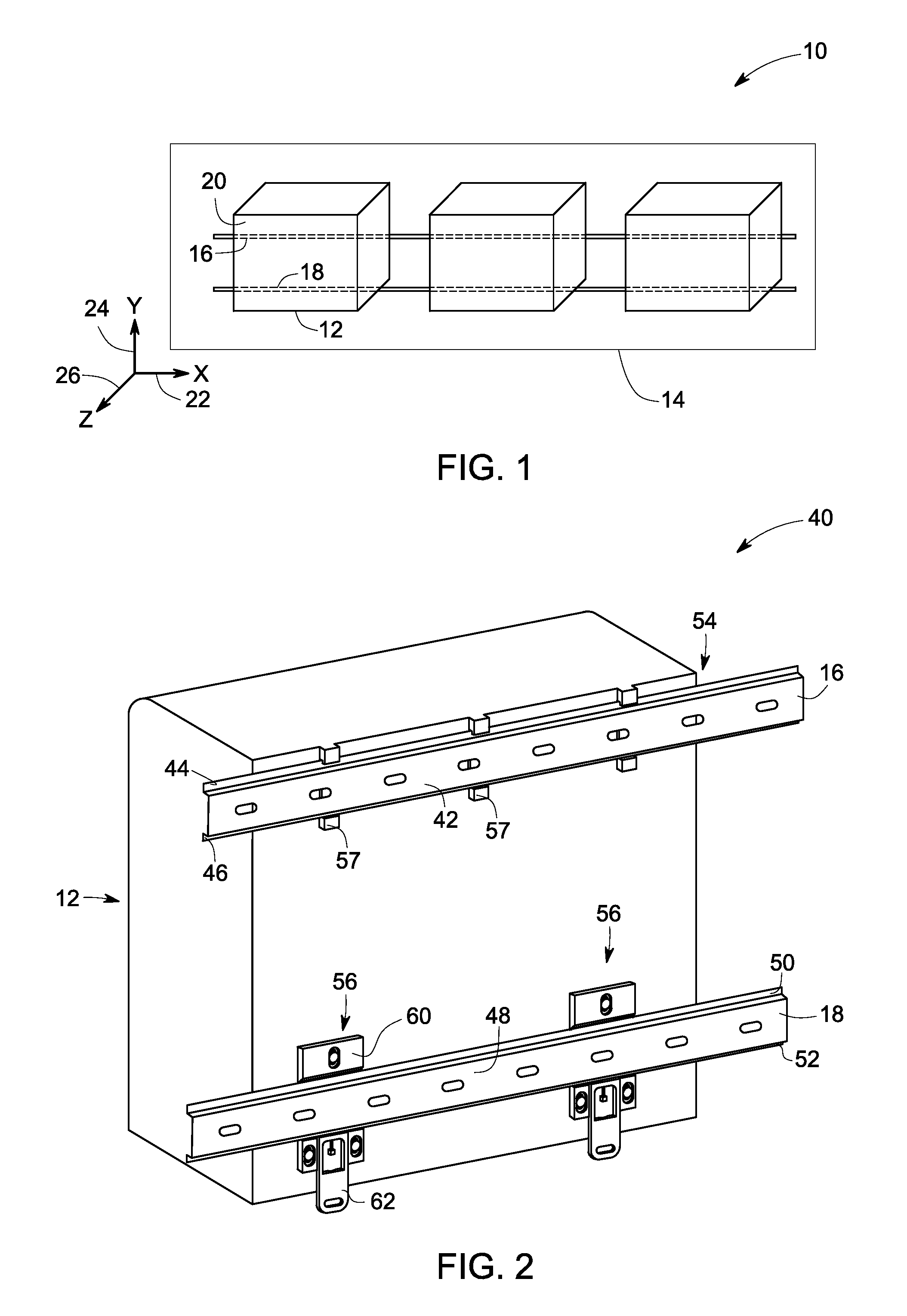

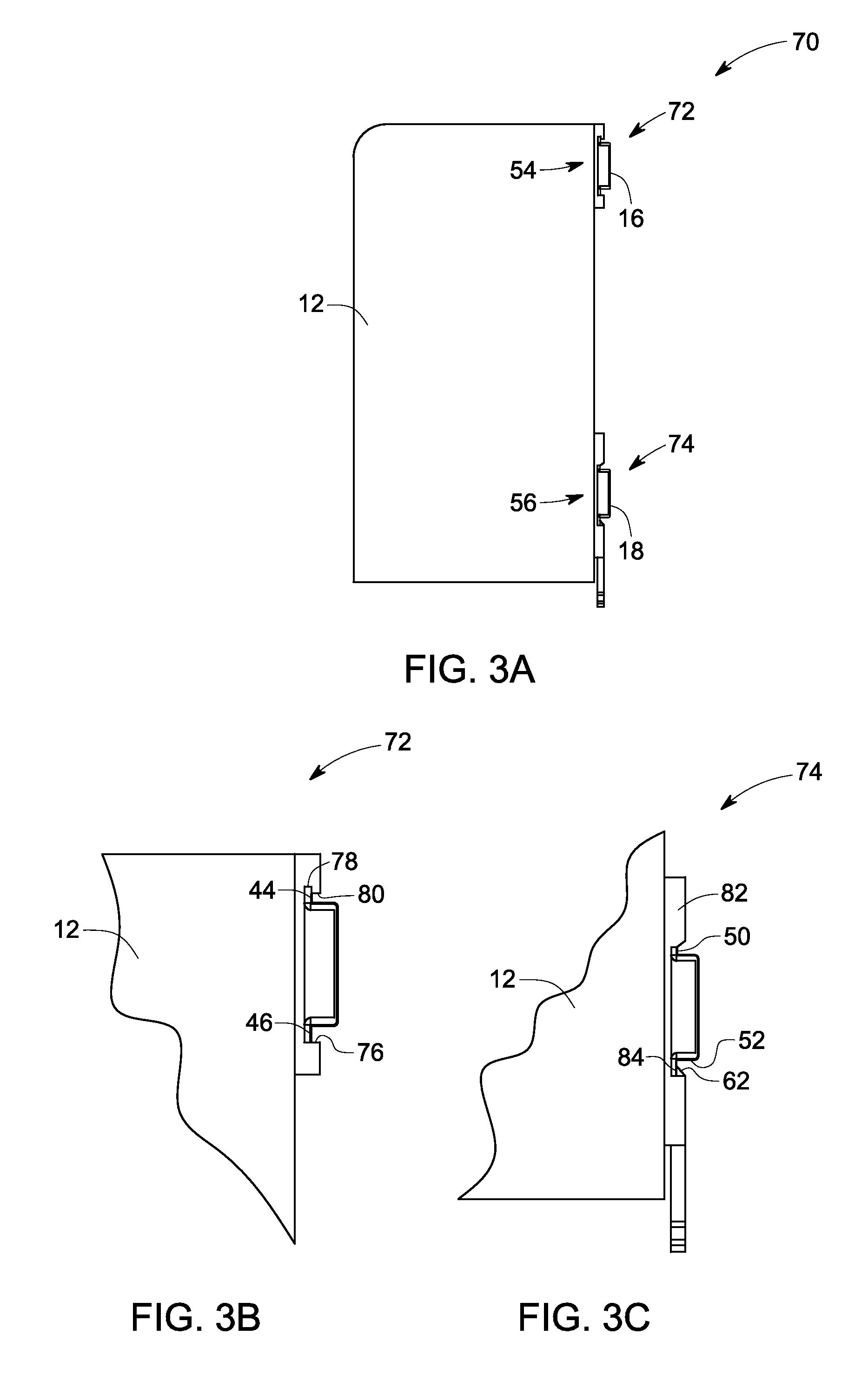

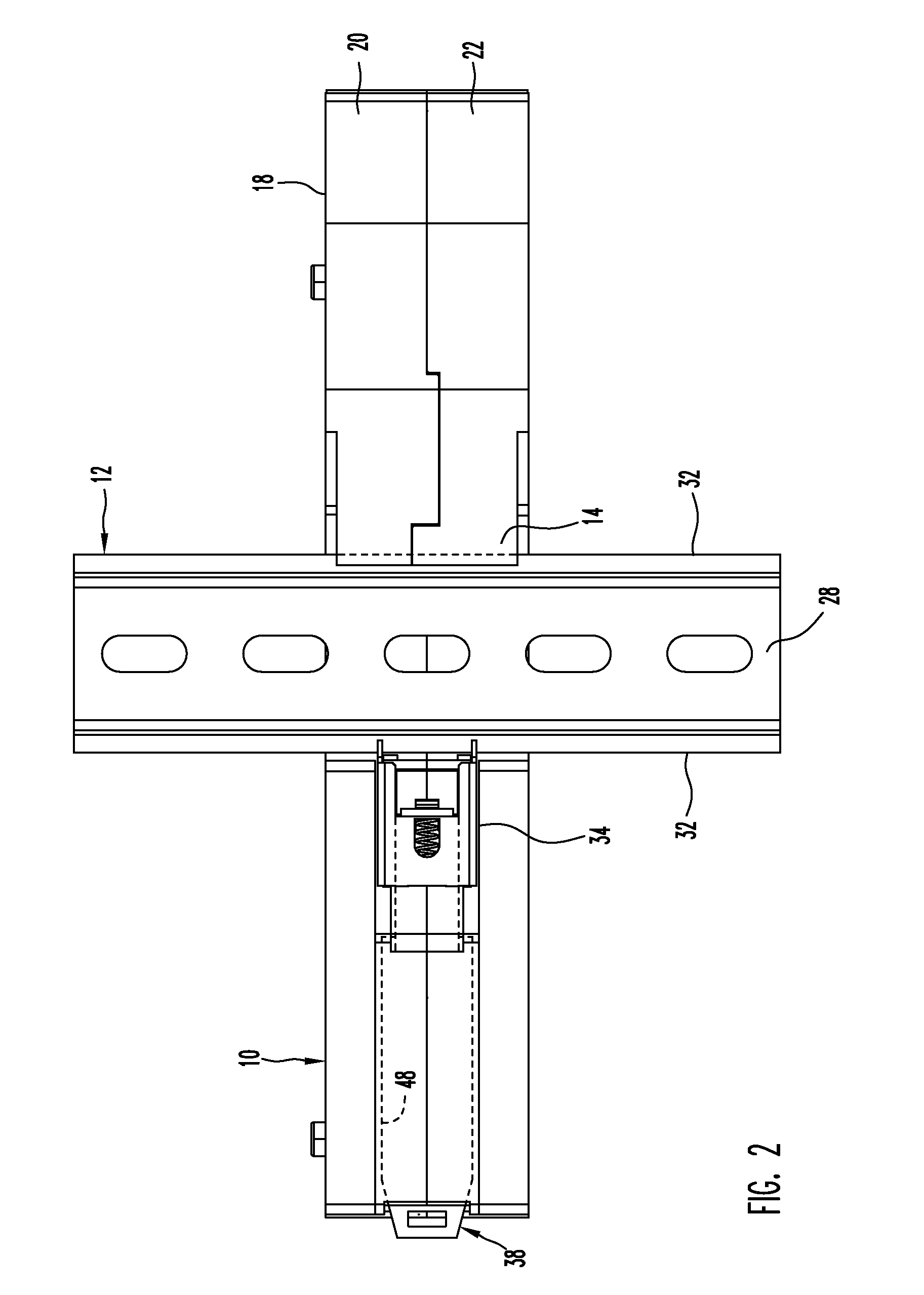

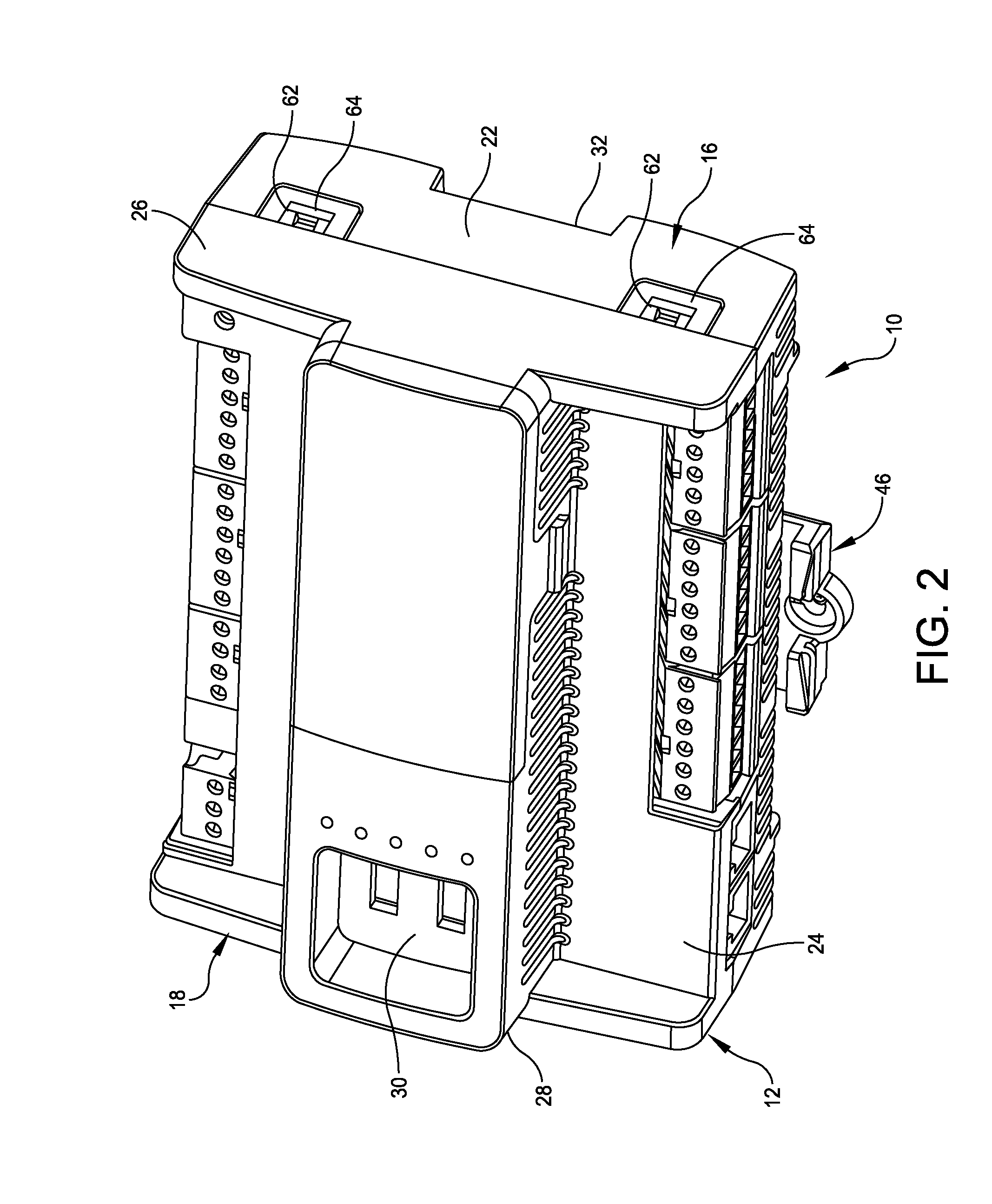

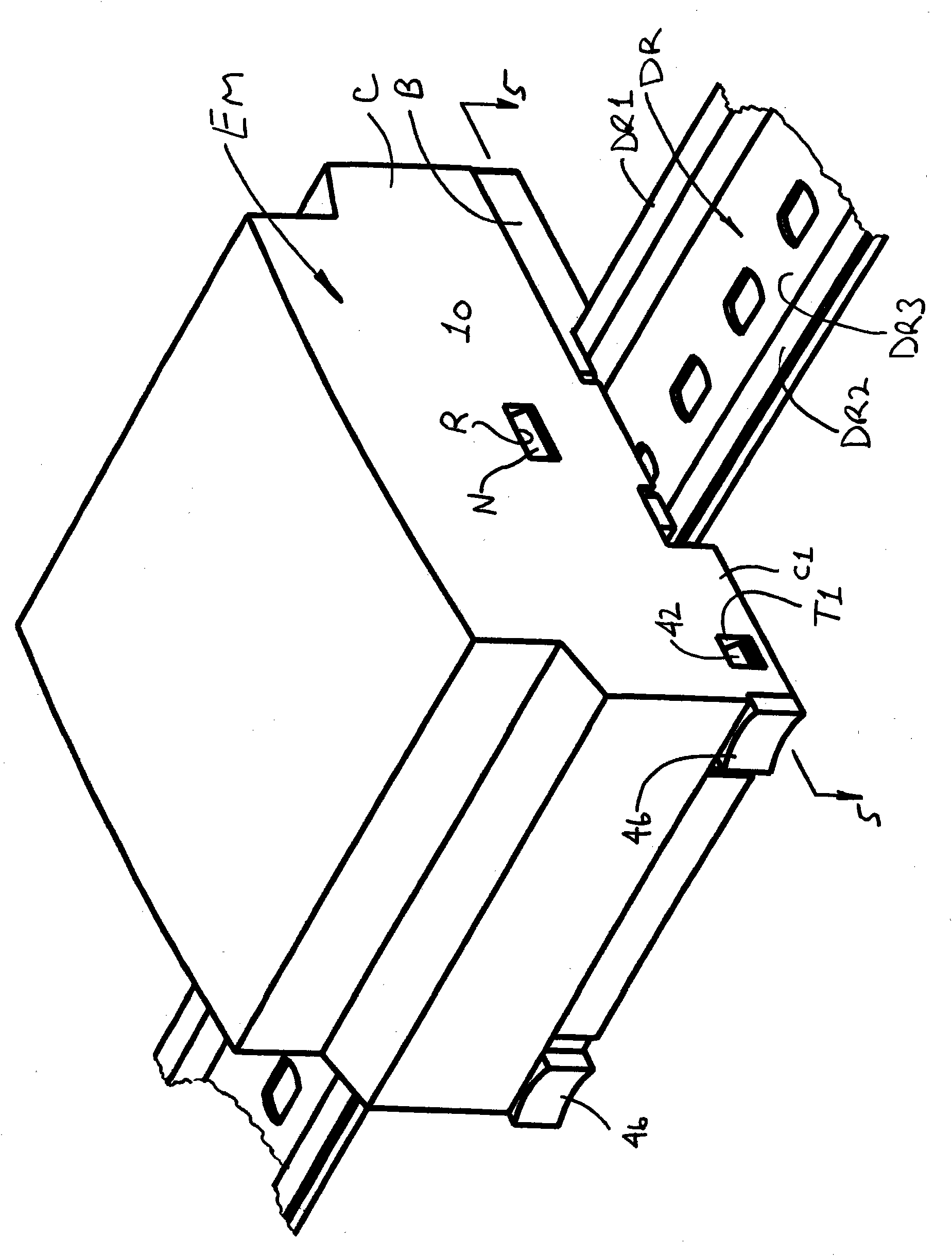

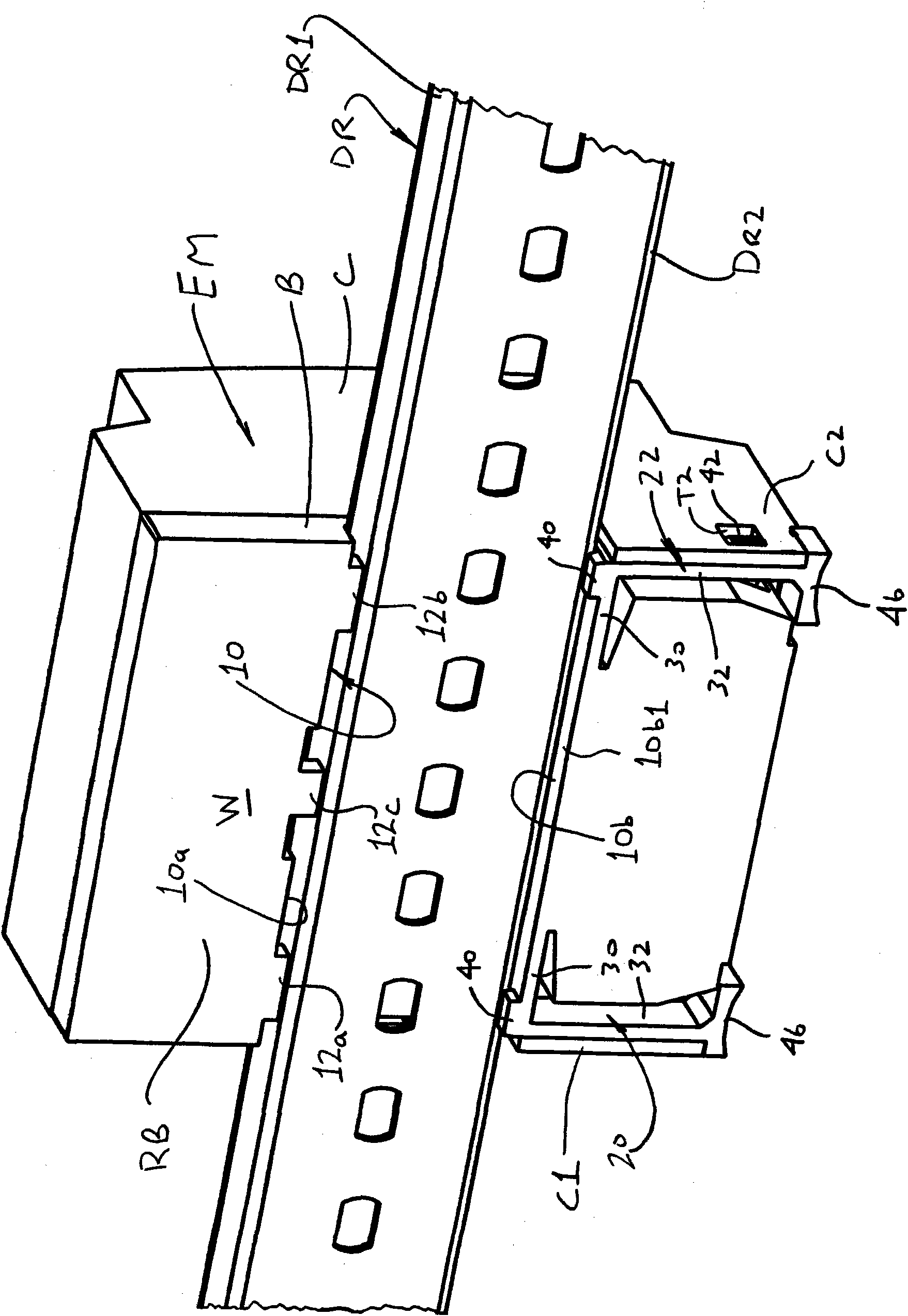

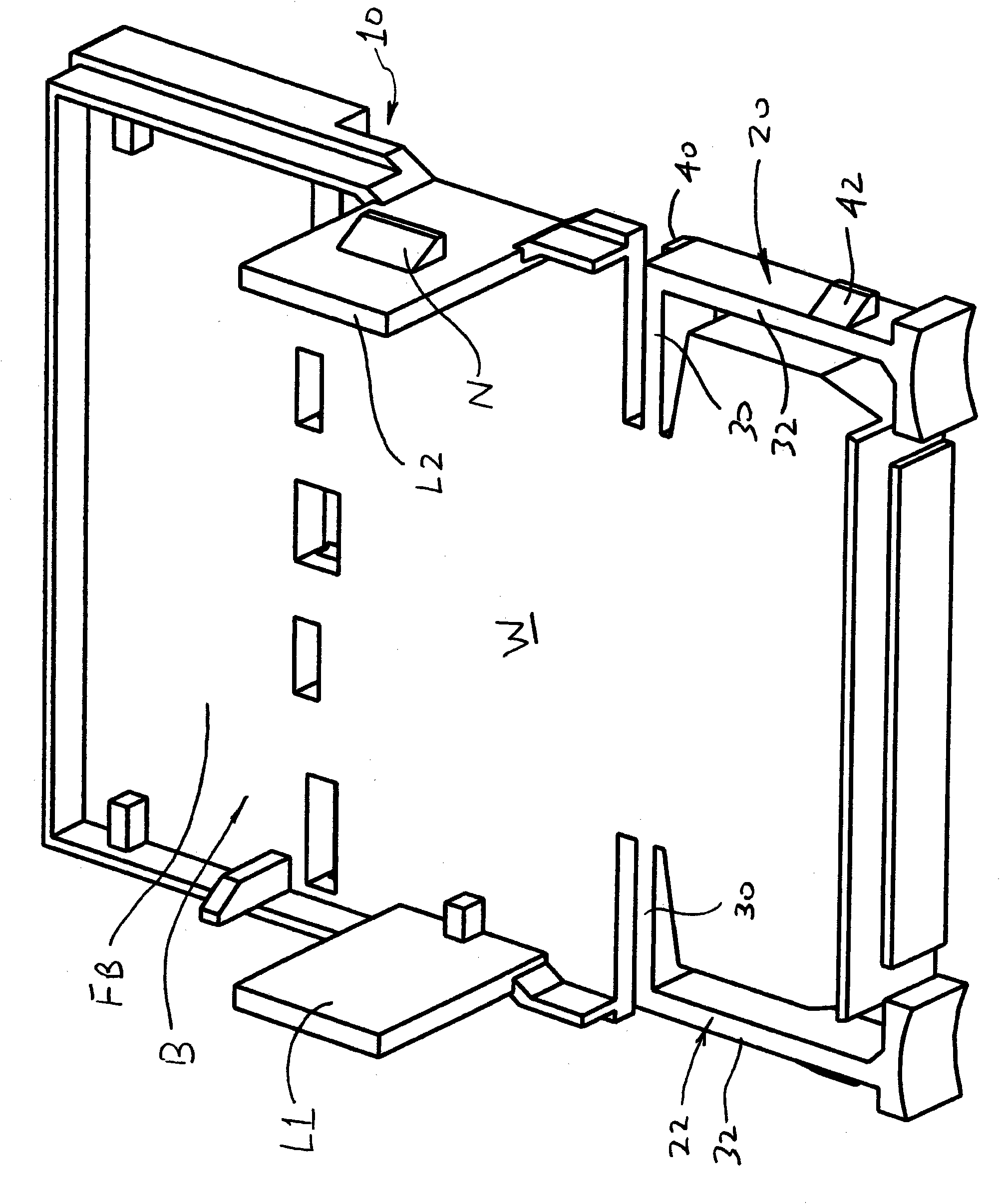

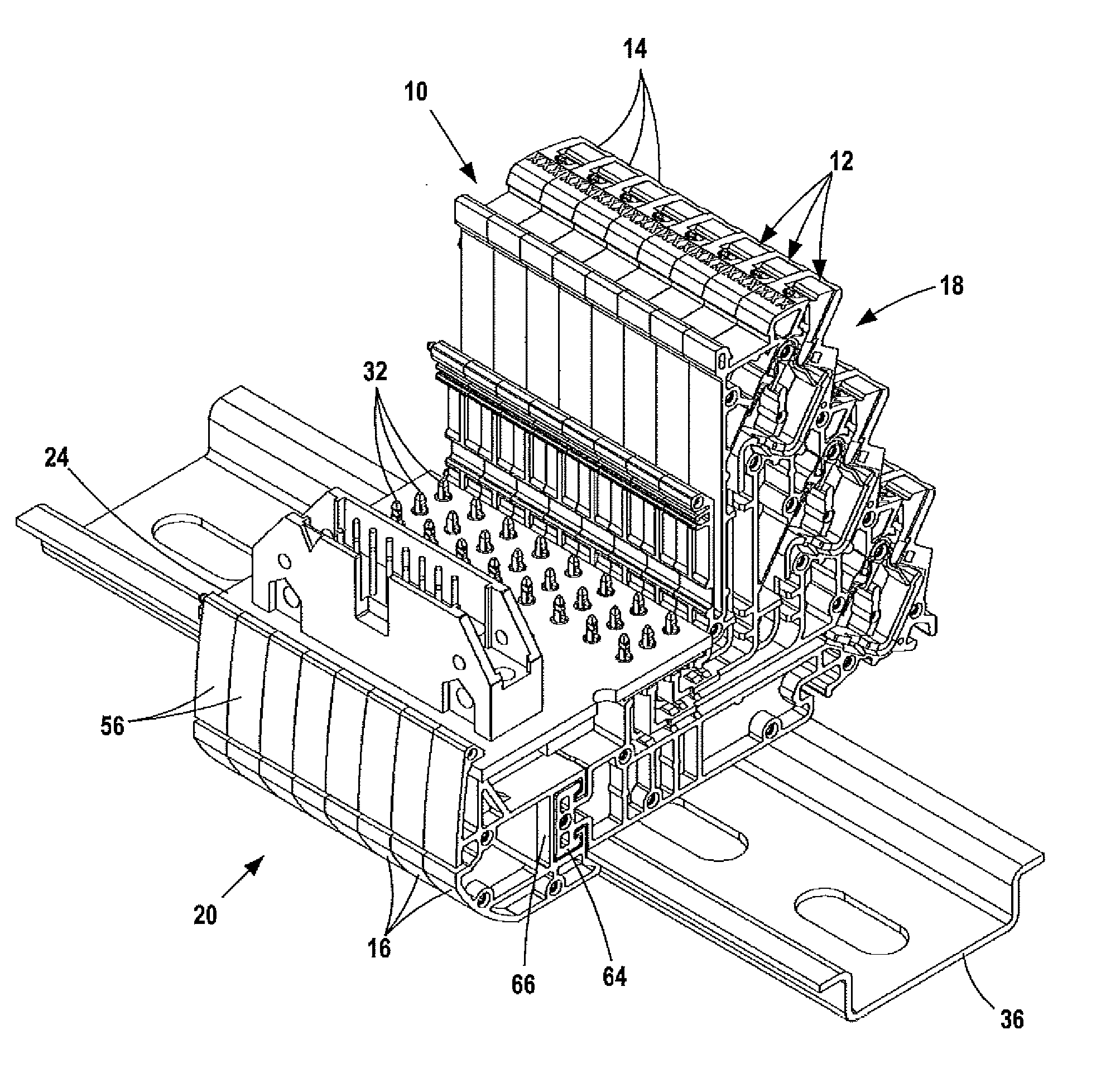

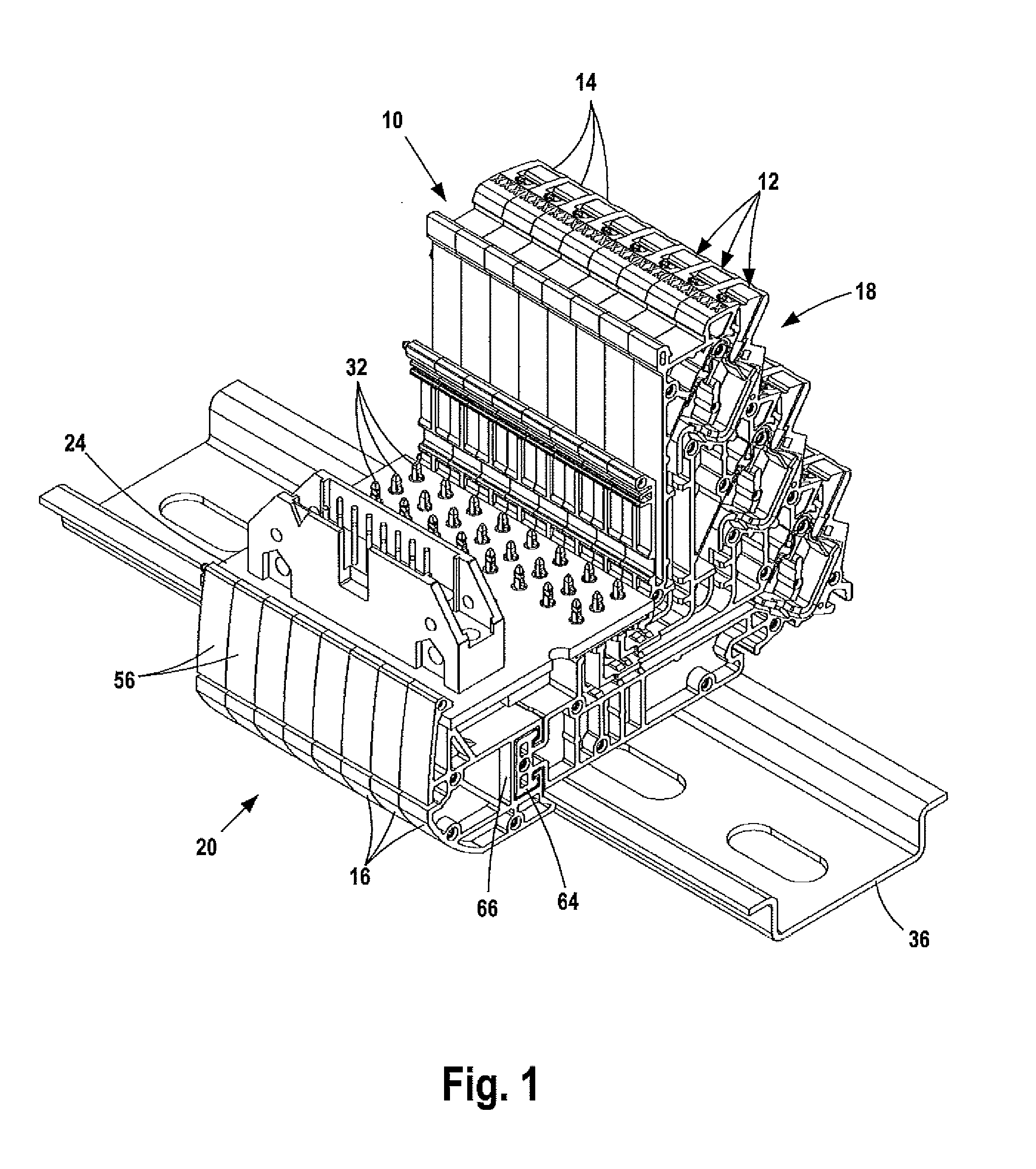

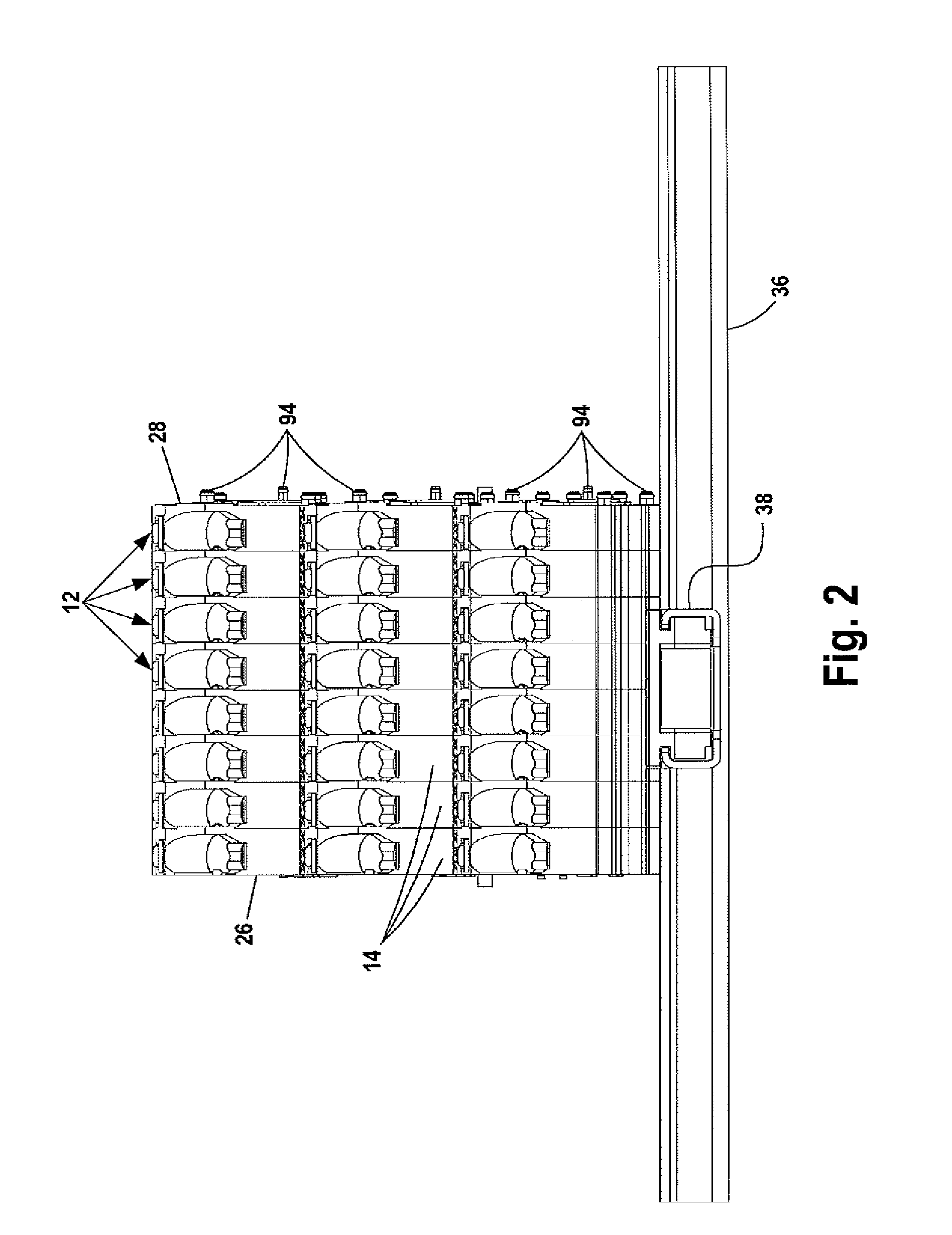

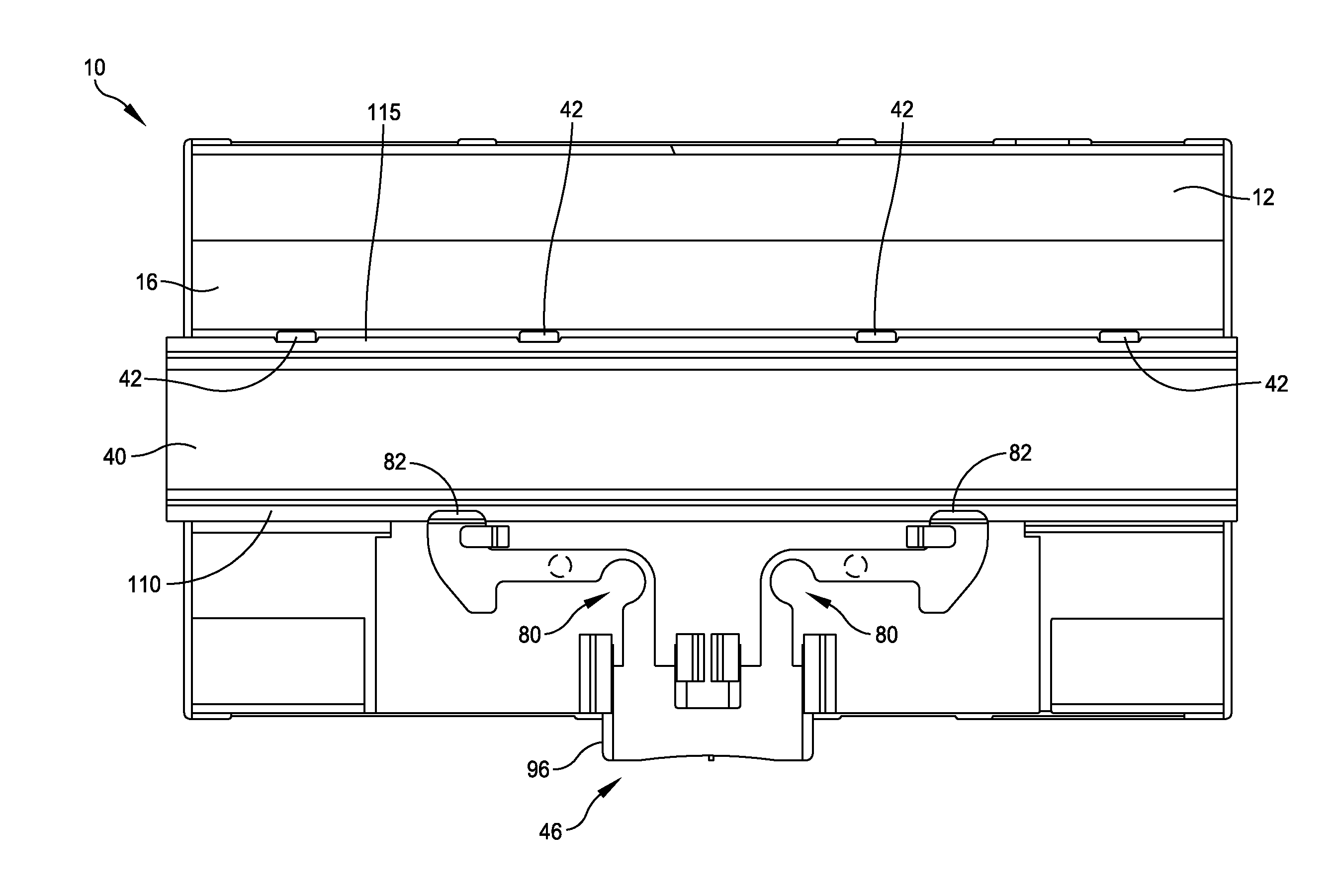

System for securing a device using two din rails

InactiveUS20110269339A1Coupling device detailsElectrical apparatus contructional detailsDevices fixationDIN rail

A system for securing a device to first and second DIN rails is provided. The system includes a static attachment structure configured to secure the device to the first DIN rail and a movable attachment structure configured to secure the device to the second DIN rail. The movable attachment structure includes a carrier secured to the device and a latch secured to the carrier and configured to engage the device to the second DIN rail in a latched position.

Owner:ROCKWELL AUTOMATION TECH

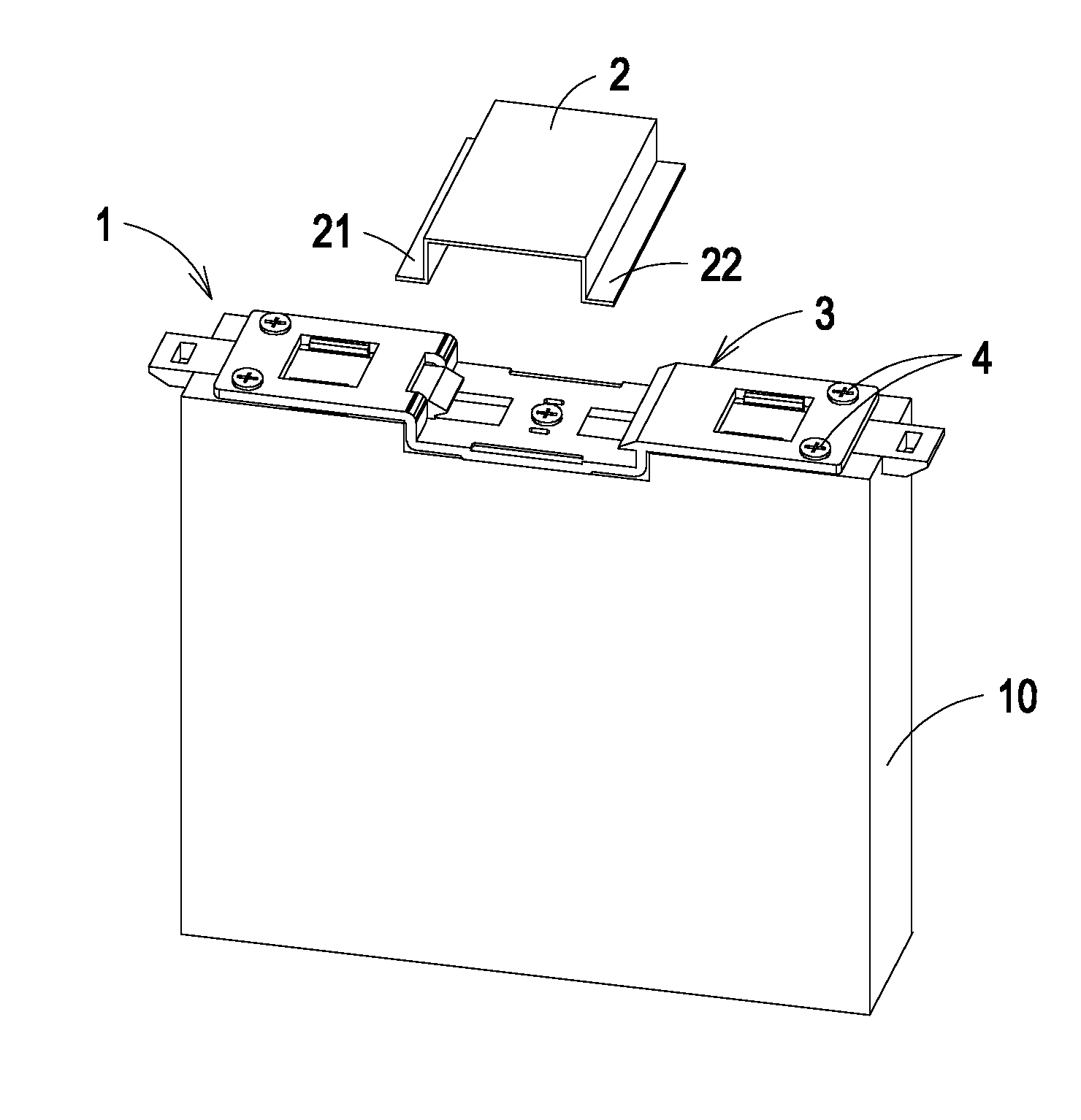

Mechanism of fastening detachable electronic device to DIN rail

ActiveUS8062061B2Substation/switching arrangement detailsElectrically conductive connectionsEngineeringMaterial Perforation

A fastening mechanism for fastening a detachable electronic device onto a DIN rail includes a frame, a first slab member and a first resilient element. The frame includes a base, a first extension part and a second extension part. The first extension part and the second extension part are arranged at bilateral sides of the base. A first perforation is formed between the first extension part and the base. The first slab member is movable along the bottom surface of the first extension part and has an end penetrating through the first perforation to be disposed over the base. The first resilient element is coupled to the first slab member and exerts a clamping force for claming a first extending edge of the DIN rail between the first slab member and the base.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

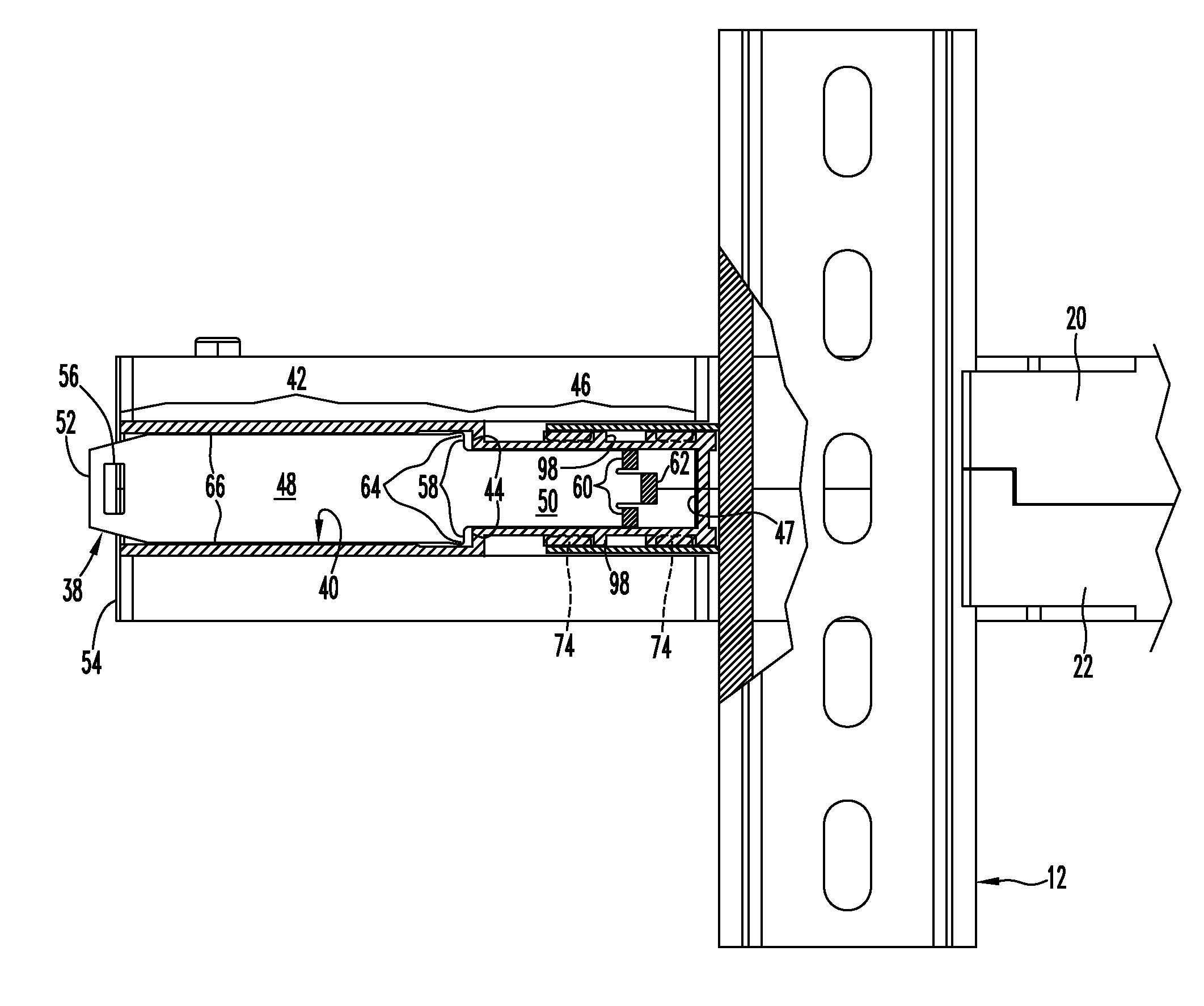

Latch assembly for mounting power supply base for a process fieldbus on a DIN rail and method

InactiveUS8226433B1Easy to manufactureEasy transferElectrically conductive connectionsCoupling device detailsEngineeringActuator

A base for mounting on a DIN rail includes a body and a latch assembly on the bottom of the body. The latch assembly has an elongate actuator extending to one side of the base and a latch member attached to the actuator for engaging the DIN rail. The release member is held on the base in an assembly position to facilitate mounting of the attachment member on the release member and the base, and is then shifted to an operative position.

Owner:PHOENIX CONTACT DEVMENT & MFG

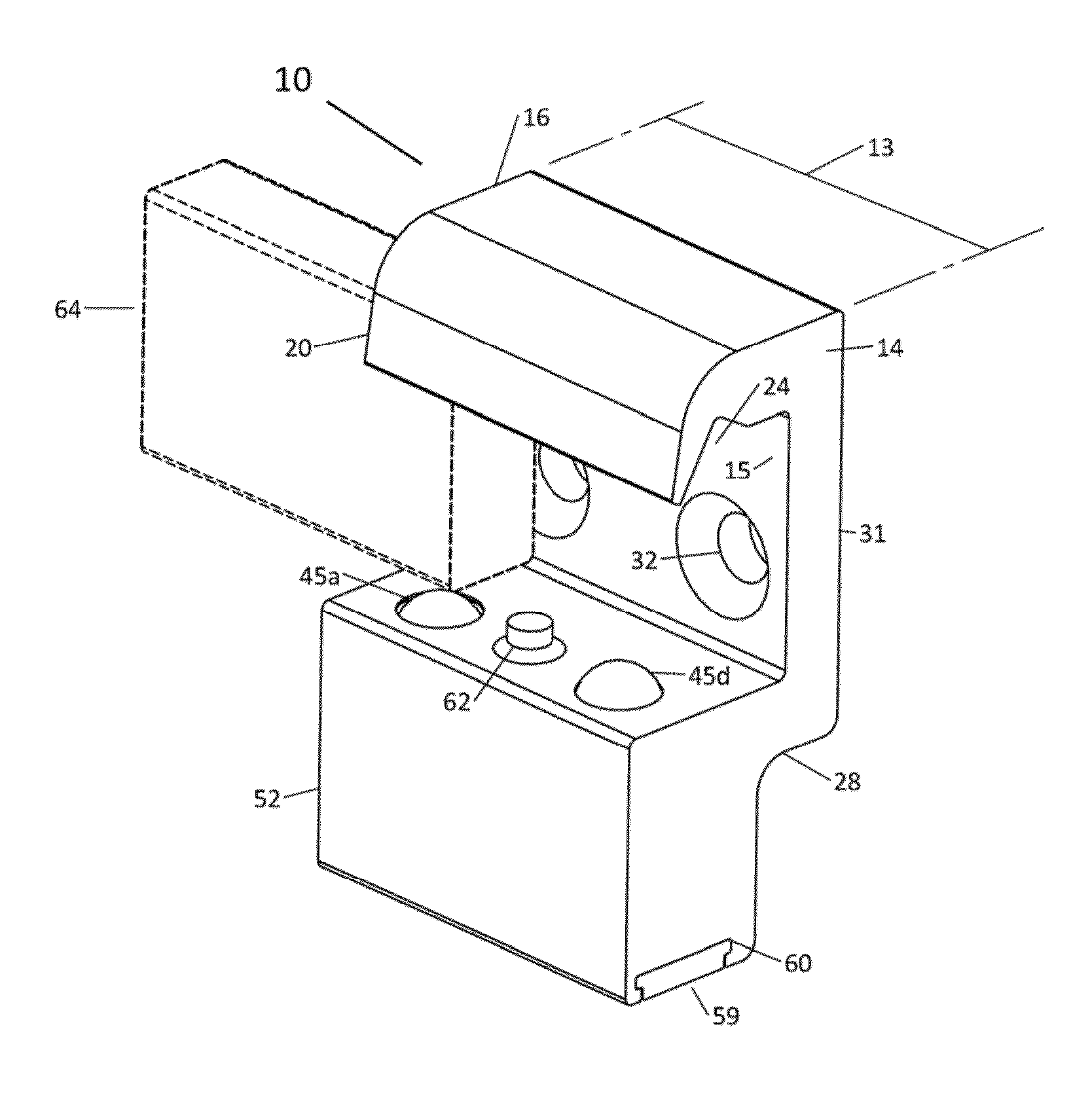

Modular rail adapter system

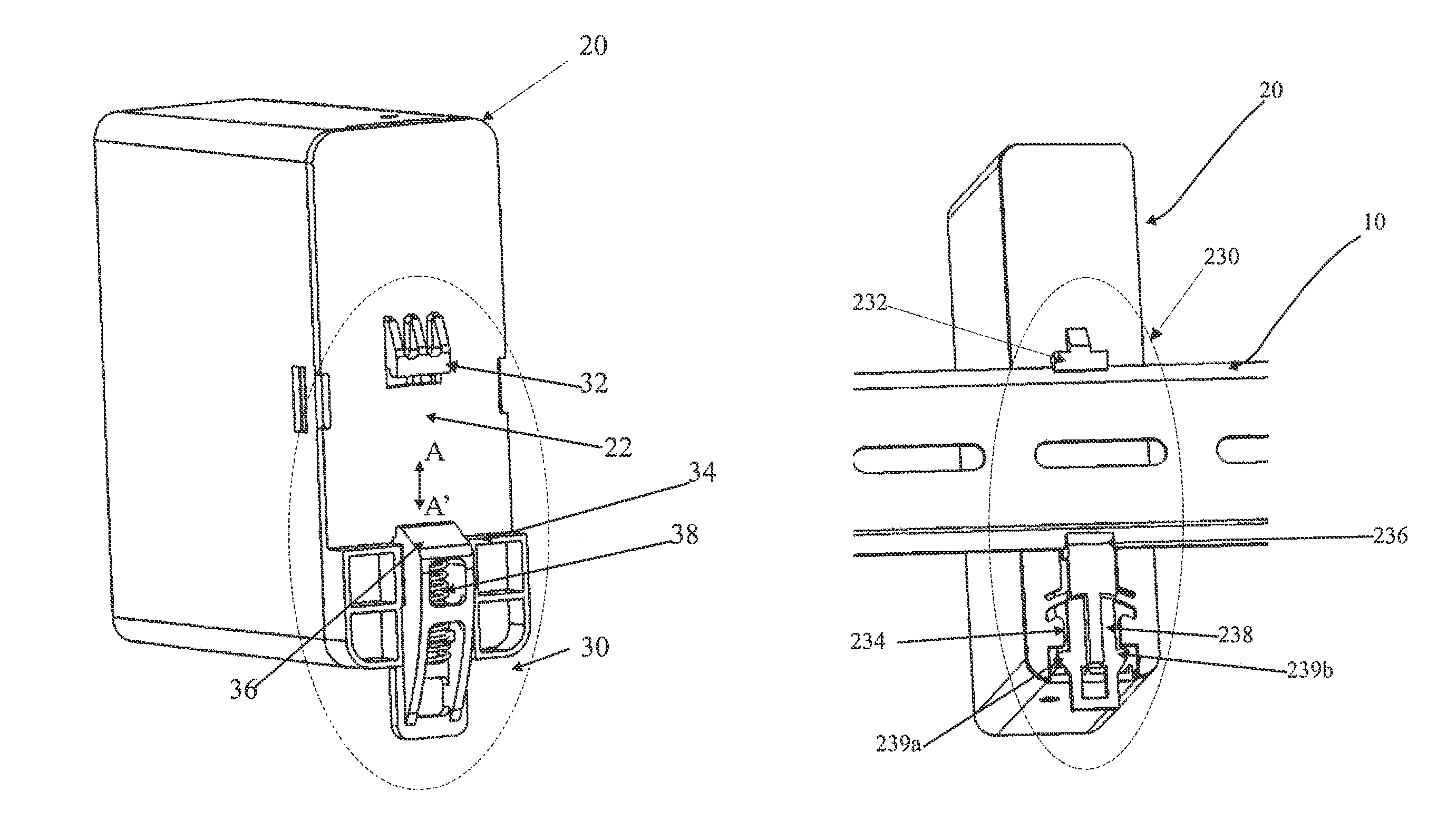

InactiveUS20140205371A1Simple, safe, cost effective and user-friendlyReduce gapControlling membersDiagnosticsModularityEngineering

A modular rail adapter that automates latching an adapter to a DIN rail without the need for users to manually latch adapter to a rail. Users simply snap the adapter to the DIN rail in one, continuous movement using a built-in, self-latching catch mechanism. The present adapter eliminates, or greatly reduces the adapter clearance gap to enable a simple, safe, cost effective and user-friendly snap-on mechanism that doesn't require users to remember to latch the accessory being attached to a DIN rail.

Owner:BALLY ALEXANDER

DIN Rail Latching Arrangement

ActiveUS20140199864A1Strict requirementsEasy to pullCoupling device connectionsElectrically conductive connectionsEngineeringDIN rail

A latching arrangement for detachably mounting a device on a DIN rail. A support member configured to be mounted on the DIN rail. A guiding slot configured on a same side of the device on which the support member is configured. An engaging lug received in the guiding slot and adapted to move between an engaging, extended configuration and a retracted, disengaging configuration. An urging element cooperating with the engaging lug and the device, the urging element adapted to be configured between a first operative configuration in which the urging element urges the engagement lug towards the support member and a second operative configuration in which said urging element is moved to facilitate moving of the engaging lug away from said support member.

Owner:ASCO POWER TECH LP

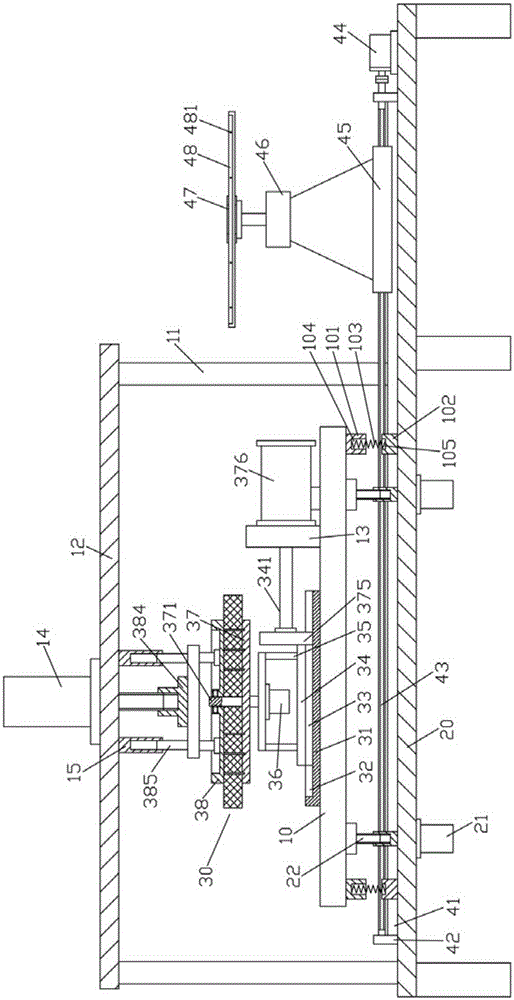

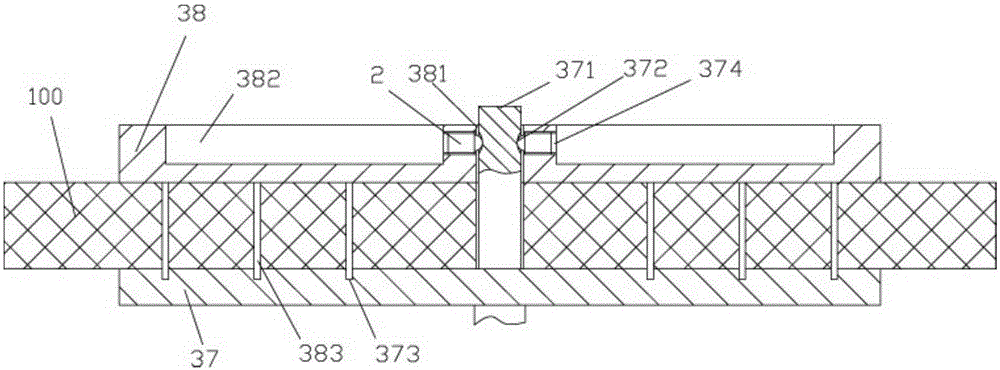

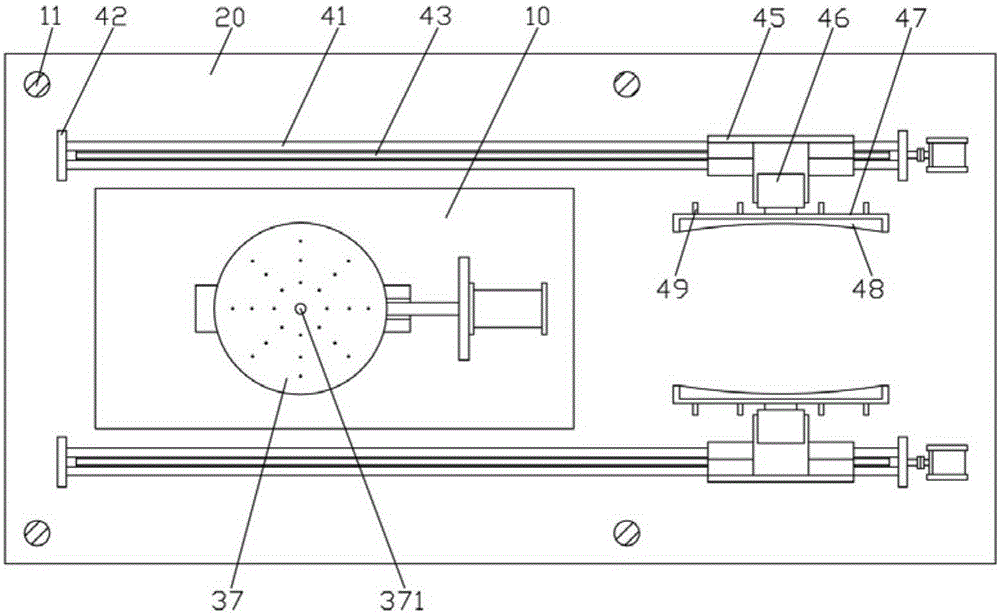

Automatic feeding and clamping device applied to sponge cutting mechanism

The invention discloses an automatic feeding and clamping device applied to a sponge cutting mechanism. The automatic feeding and clamping device applied to the sponge cutting mechanism comprises a rack, wherein a plurality of lifting motors are fixed on a top plate of the rack; output shafts of the lifting motors stretch upwards out of the top plate and are screwed with lifting screws; the lifting screws are fixed at the bottom surface of a bottom lifting plate; a sliding rail is fixed on the top surface of the bottom lifting plate; support pillars and two feeding rails are fixed on the side parts of the top plate of the rack; the feeding rails are arranged at the front side and the back side of each lifting motor; vertical supporting and adjusting plates are fixed at the two ends of each feeding rail; two ends of a feeding screw are hinged onto the two vertical supporting and adjusting plates; a feeding motor is fixed at the right end of the top plate of the rack. The automatic feeding and clamping device applied to the sponge cutting mechanism can be mounted at the position of a resistance wire cutting device, is capable of automatically conveying and fixing sponge blocks, lifting and descending the sponge blocks, enabling the height of the sponge blocks to correspond to the resistance wire cutting position and conveniently cutting the sponge blocks; and the effect is excellent.

Owner:东莞明睿新材料有限公司

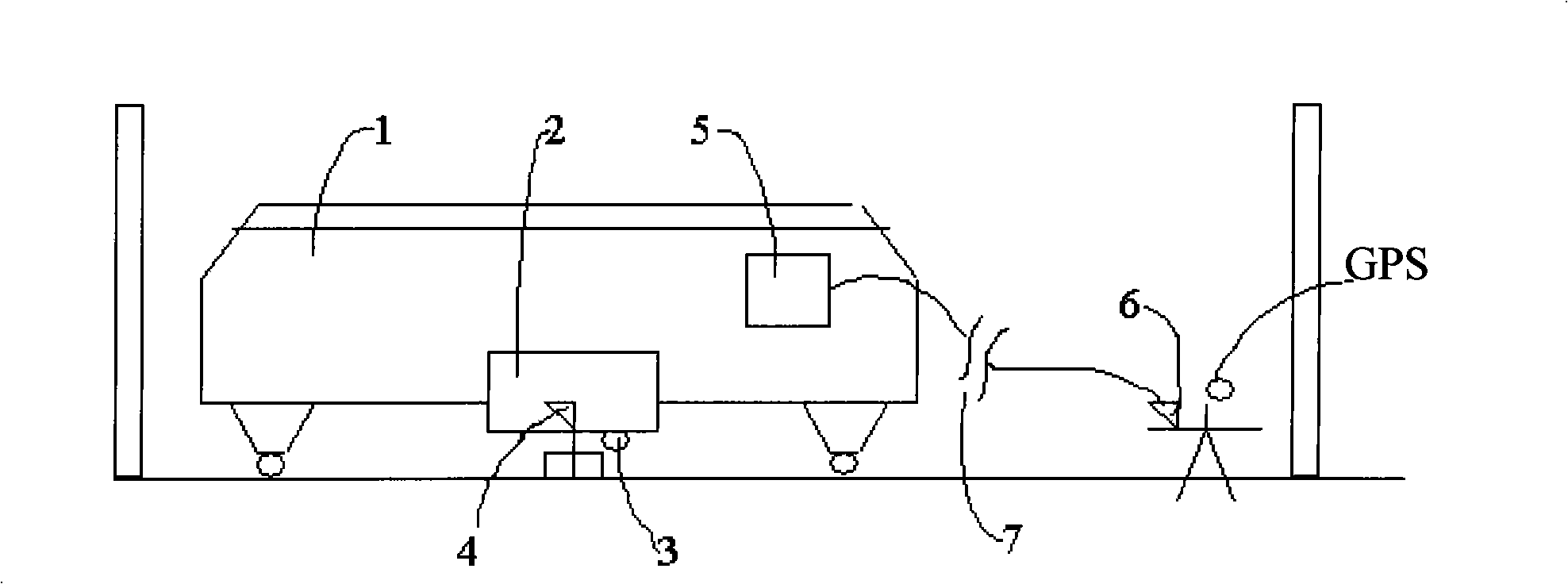

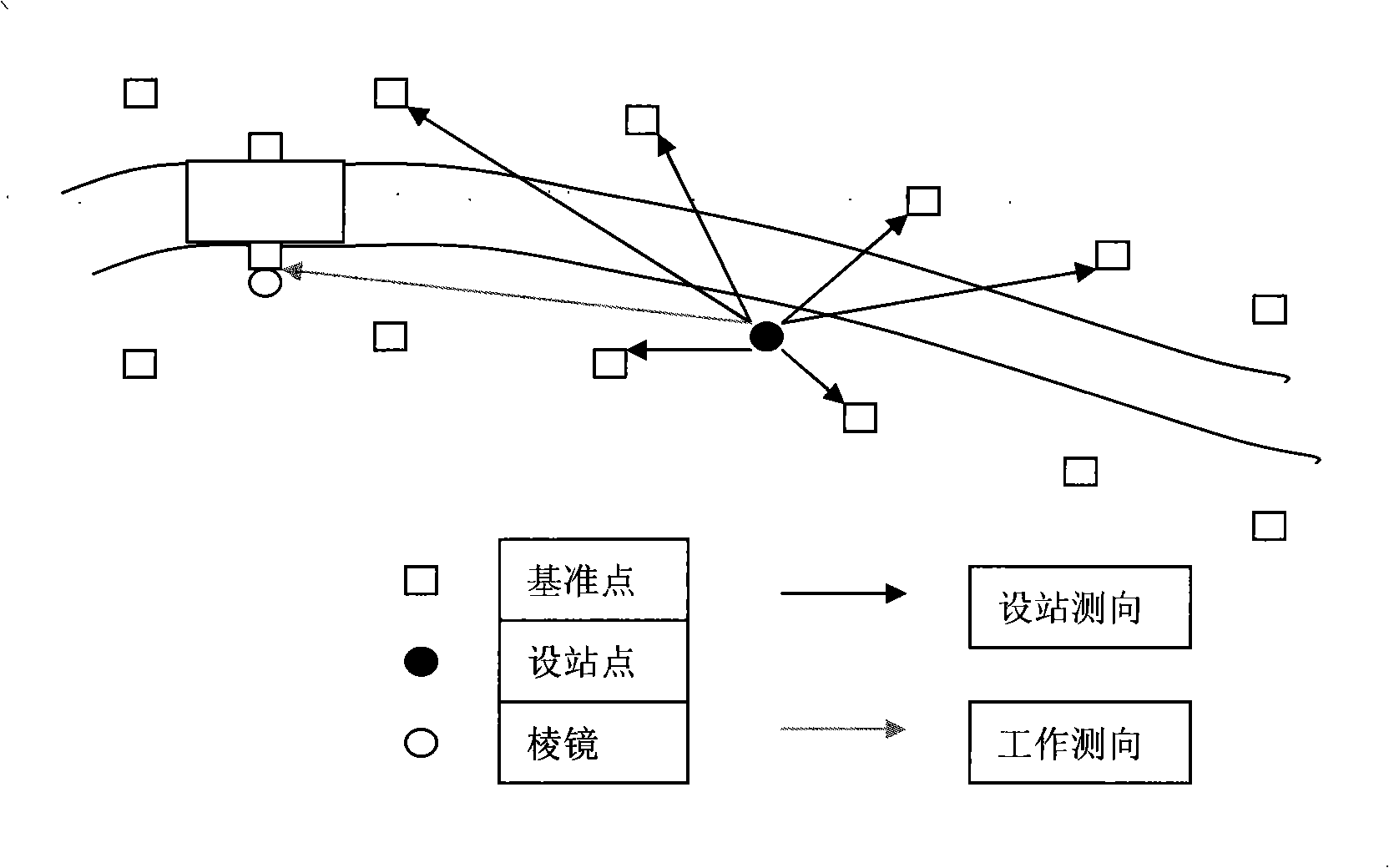

Track correction measurement and control method

InactiveCN101307584AReduce error rateEliminate errorsAngle measurementBeacon systems using radio wavesData connectionEngineering

The invention provides a device for measuring and controlling the track correction. The device comprises a track parameter measurement cart arranged along with a shift vehicle, an inclination sensor, a vehicle-mounted computer and a reflector total station, wherein a data link for bi-directional flow of data is established among the inclination sensor, the vehicle-mounted computer and the reflector total station; the method is as follows: a construction section is selected, and geodetical coordinates of the total station are measured; the total station locks a reflector, and a data connection channel is established, and the vehicle-mounted computer receives data from the total station and the inclination sensor and calculates the present curve parameters of the iron rail, which are compared with pre-stored static curve values of the iron rail which are recorded under the normal working conditions by taking geodetical coordinates as parameters, and control parameters controlling the track raising and lining clamp operation are generated and outputted, thereby forming a closed control process; such a circulation completes the construction of a section. The device has the advantages of eliminating errors of vibration and gravity-down due to the original use of steel chords, simplifying the measuring system, lowering the error probability of the complicated system and reducing the maintenance worklaod.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

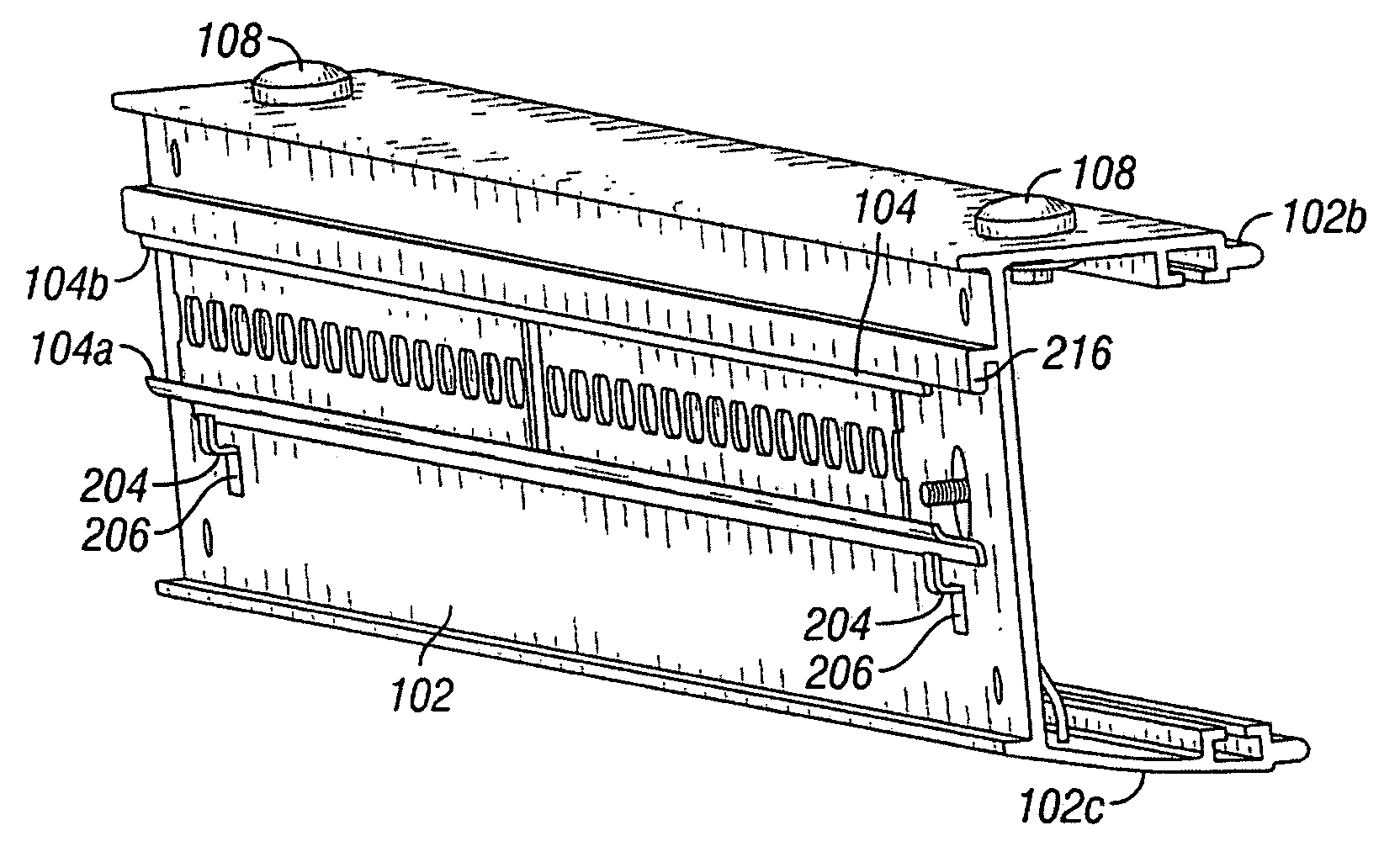

Terminal block having an extender body fitted to a contact body

ActiveUS8715017B1Low costElectrically conductive connectionsCoupling device detailsComputer moduleElectronic component

A terminal block for mounting on a DIN rail includes a plurality of stacked modules with each module having a contact body and an extender body mounted on the contact body. A circuit board or electronic component is mounted on the contact body and the extender body. Different size extender bodies may be mounted on a common contact body to accommodate mounting different size circuit boards or components on the block.

Owner:PHOENIX CONTACT DEVMENT & MFG

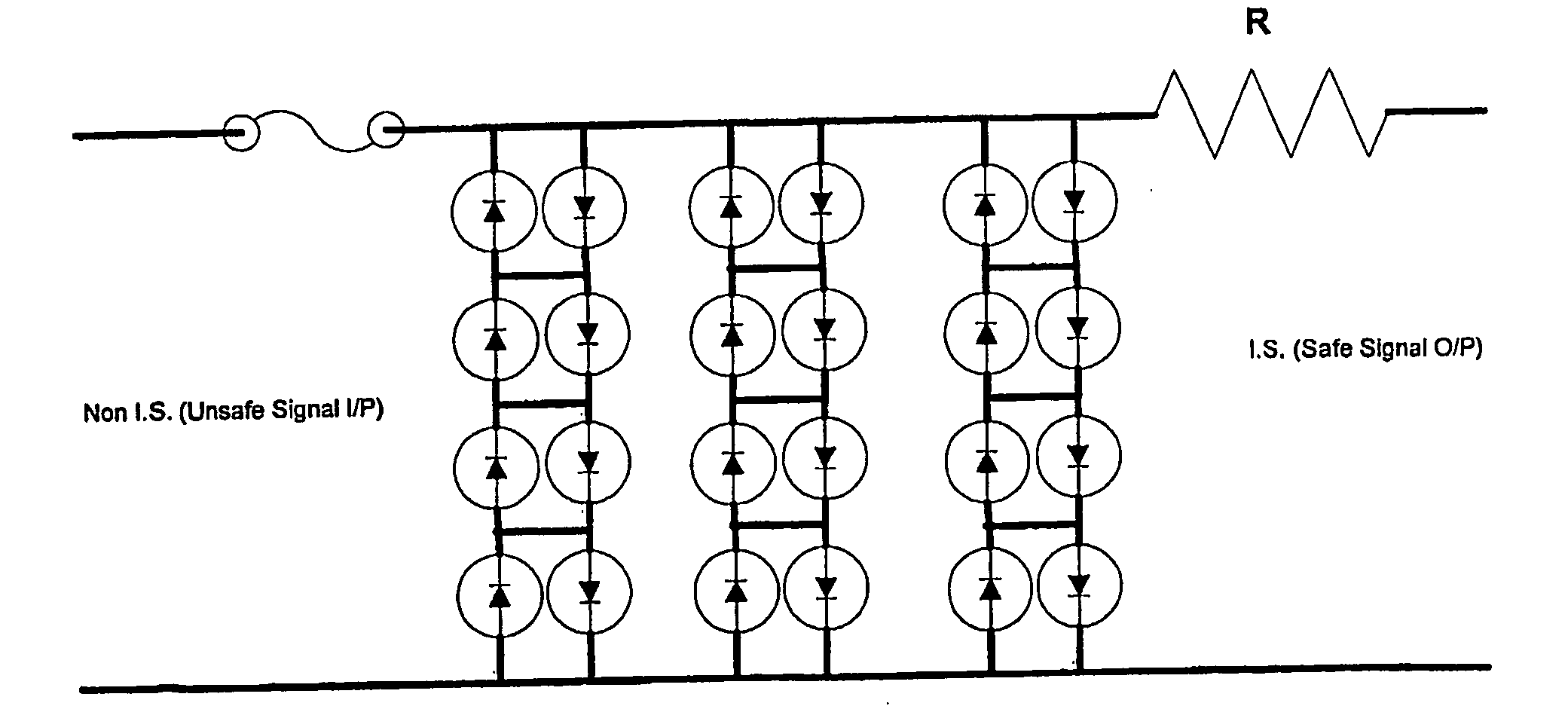

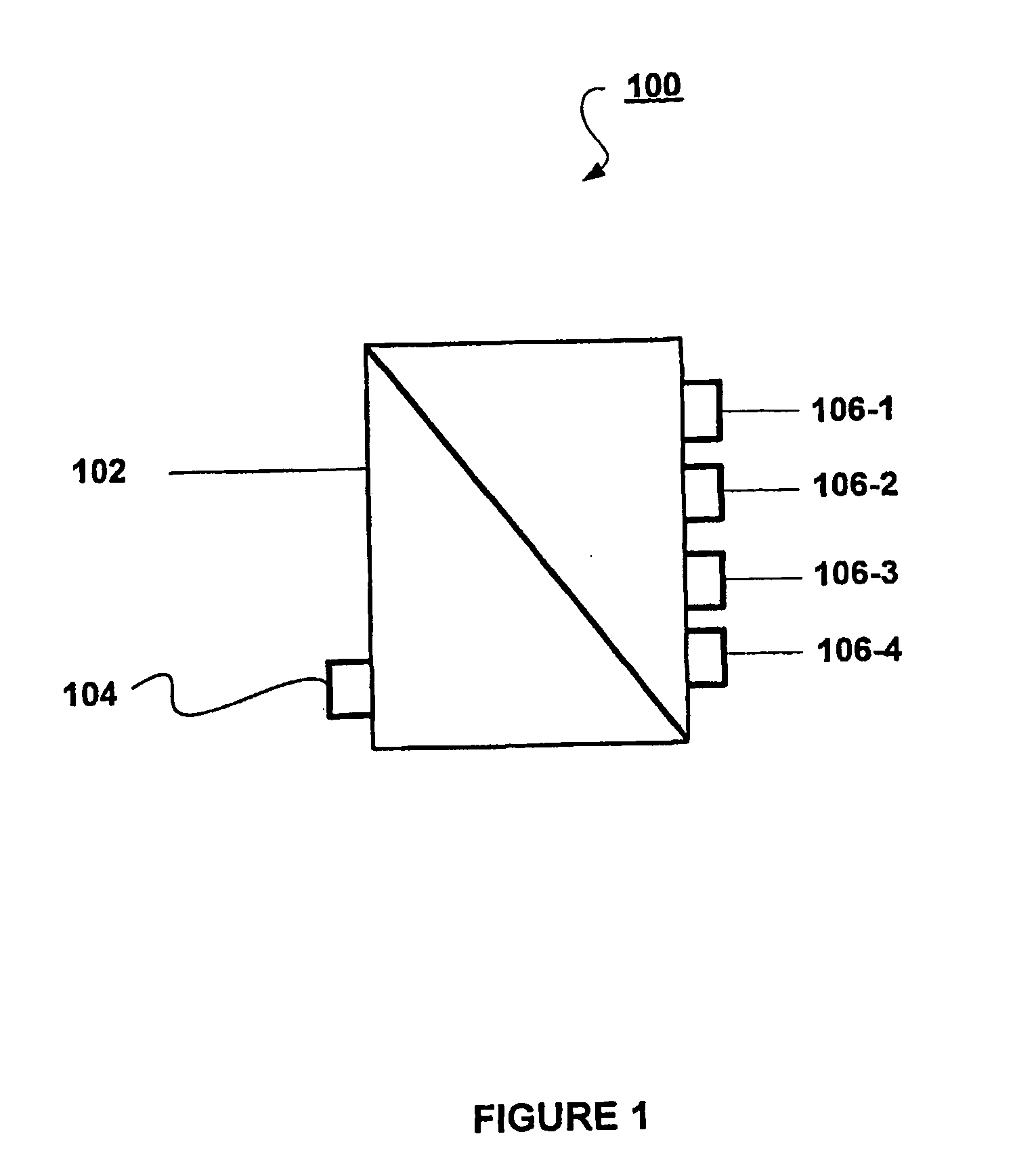

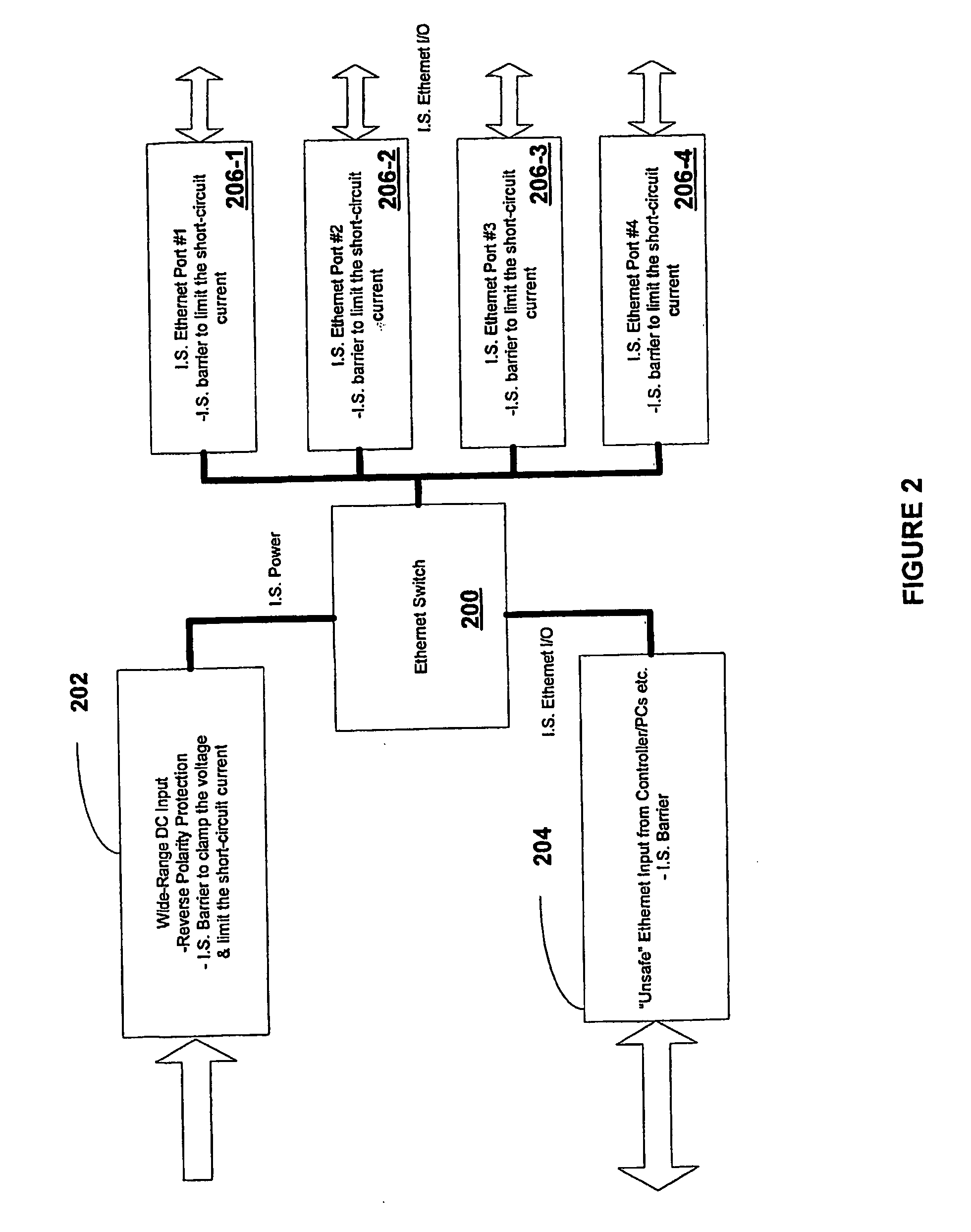

Intrinsically Safe Ethernet-Based Communication

ActiveUS20080285186A1Current be limitedProgramme controlPower network operation systems integrationHigh integrityNetwork switch

An intrinsically safe network switch (200) includes five electronically isolated ports, four for connections in hazardous areas (206-1, 206-2, 206-3, 206-4) and one for receiving an unsafe Ethernet input (204). The device may use 10 / 100 mbps Ethernet cables and connectors and provides speed and activity LED indicators for each port. The device may be din rail-mountable, wall mountable, or desk mountable, and includes an integral heat sink for cool operation. The device incorporates internal barriers and isolated circuitry to guarantee safety and high-integrity signals with resistance to ambient EMI / RFI radiation. This network switch (200) could be any Ethernet communication devices such as hub, managed or unmanaged switch etc. Also, it could have total “n” number of ports (isolated or un-isolated) with 1 port for safe area and “n−1” port of hazardous area. The number of ports for safe and hazardous area can be varied to meet specific application requirements.

Owner:EATON INTELLIGENT POWER LIMITED

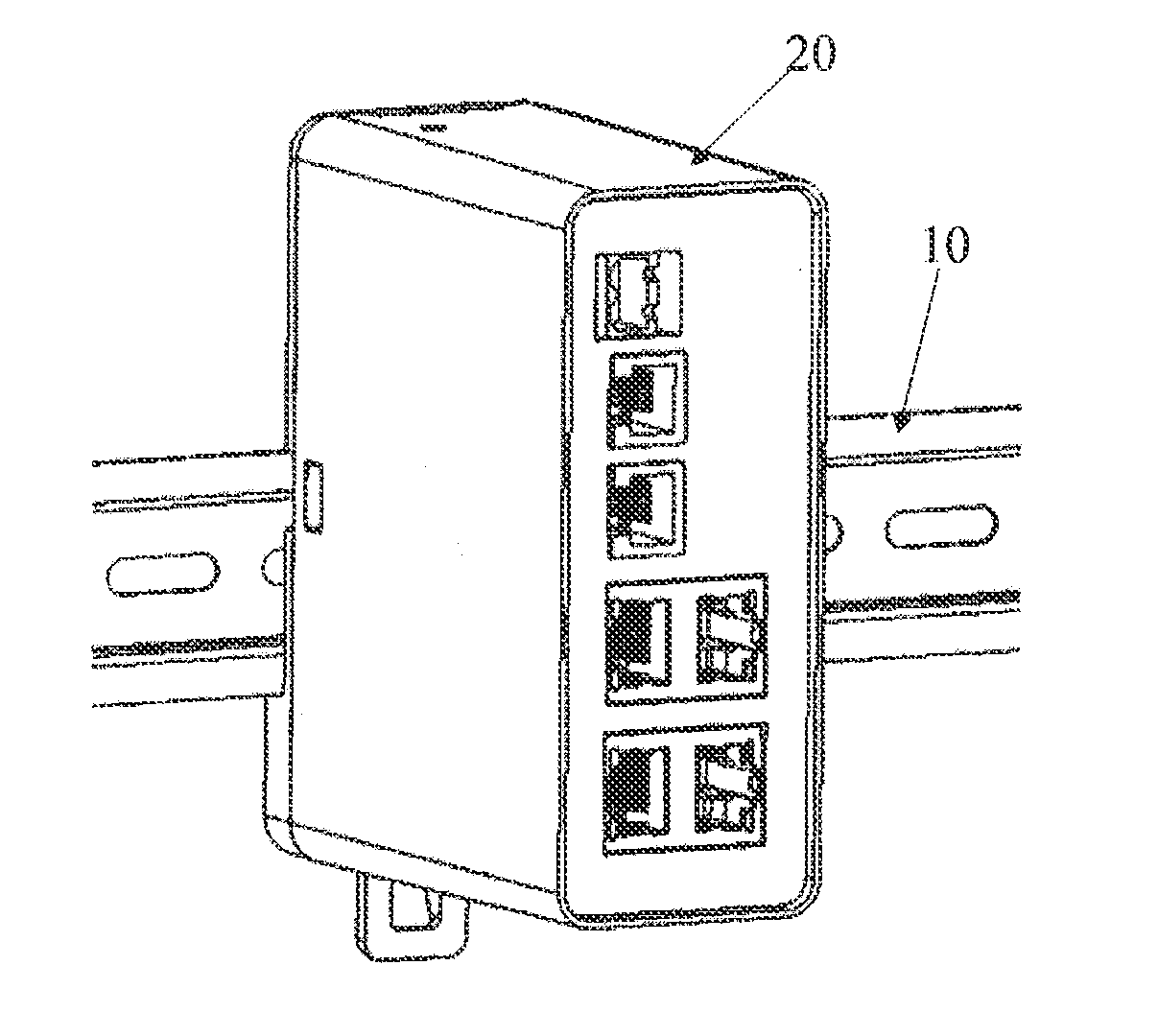

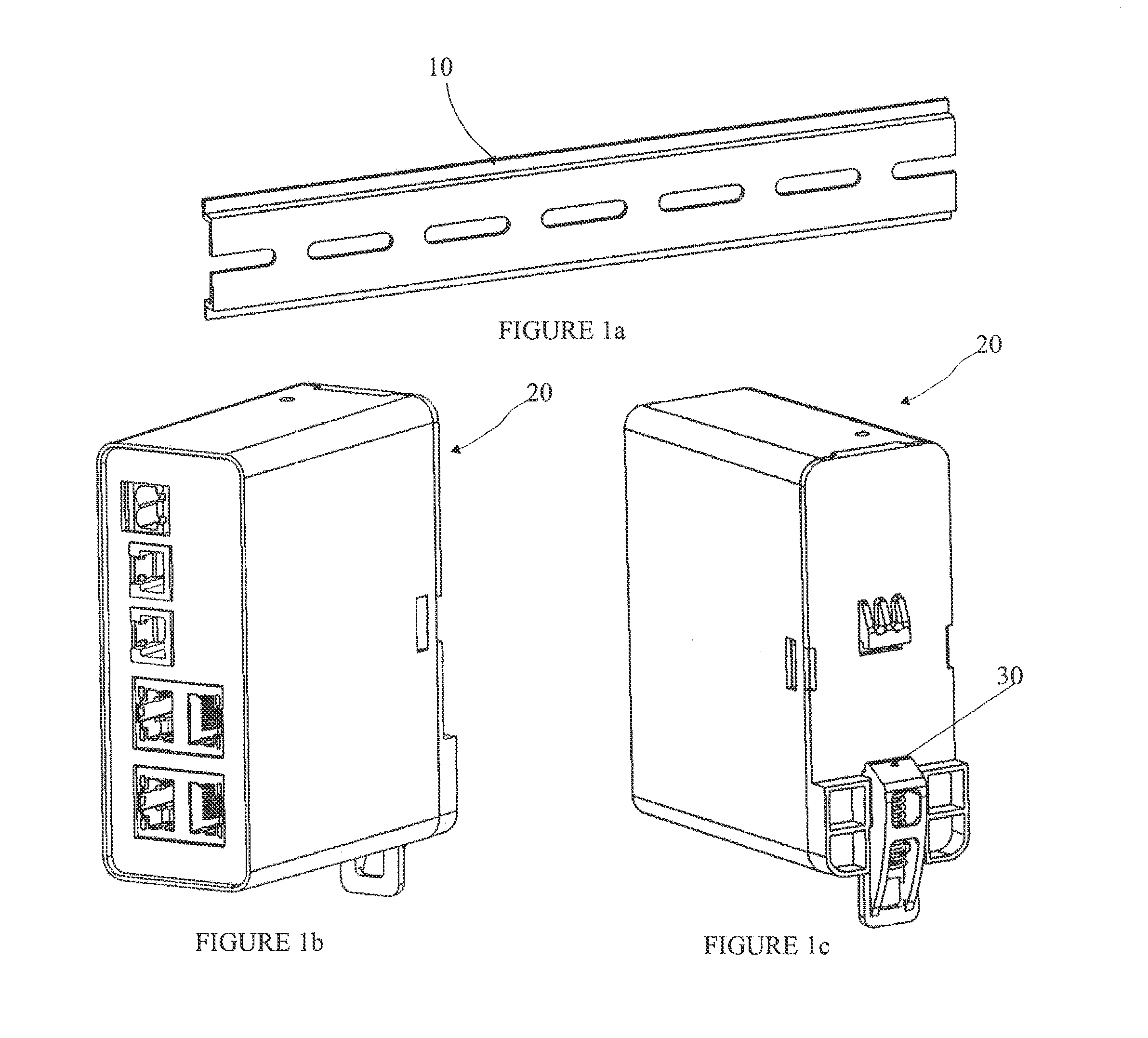

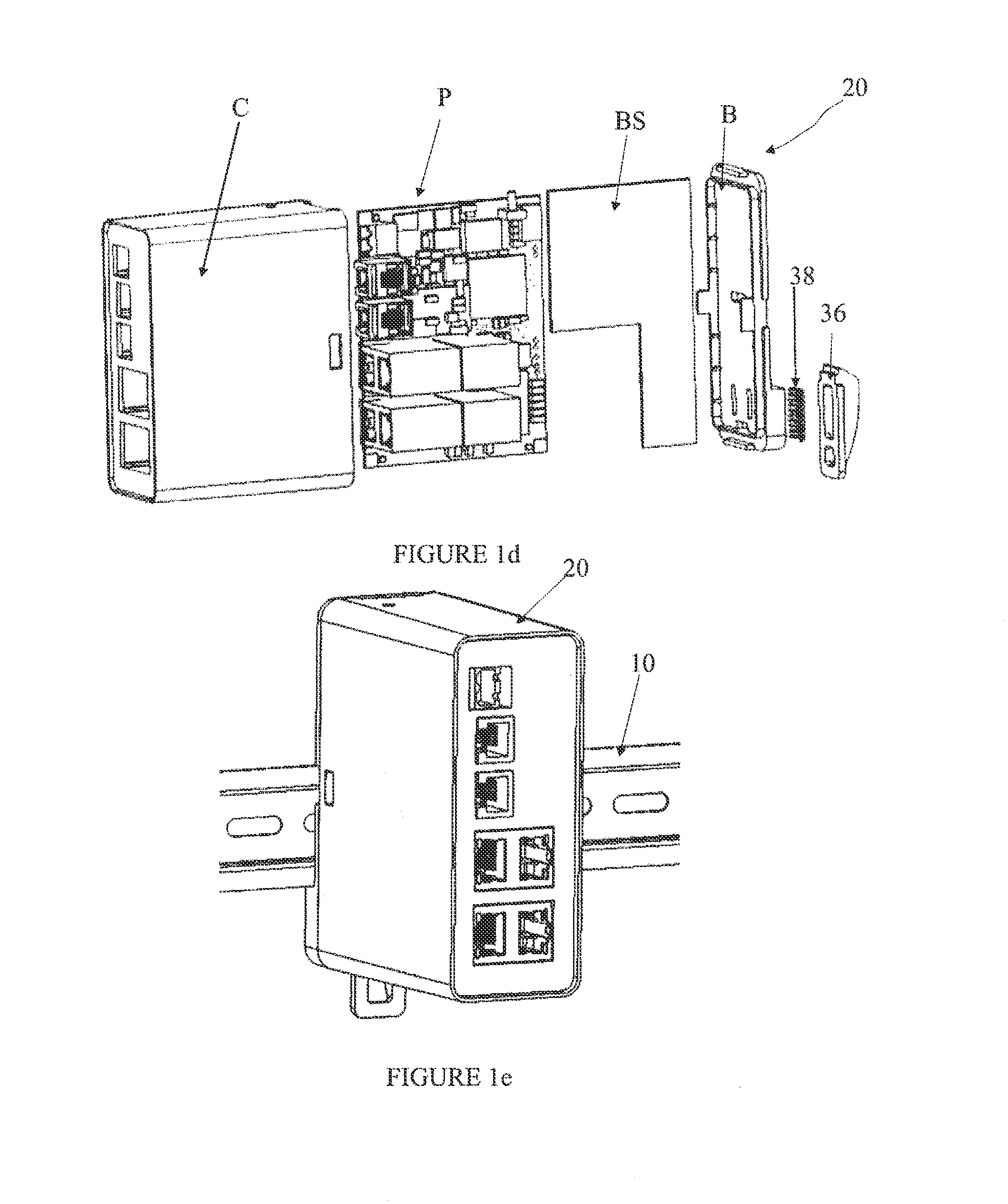

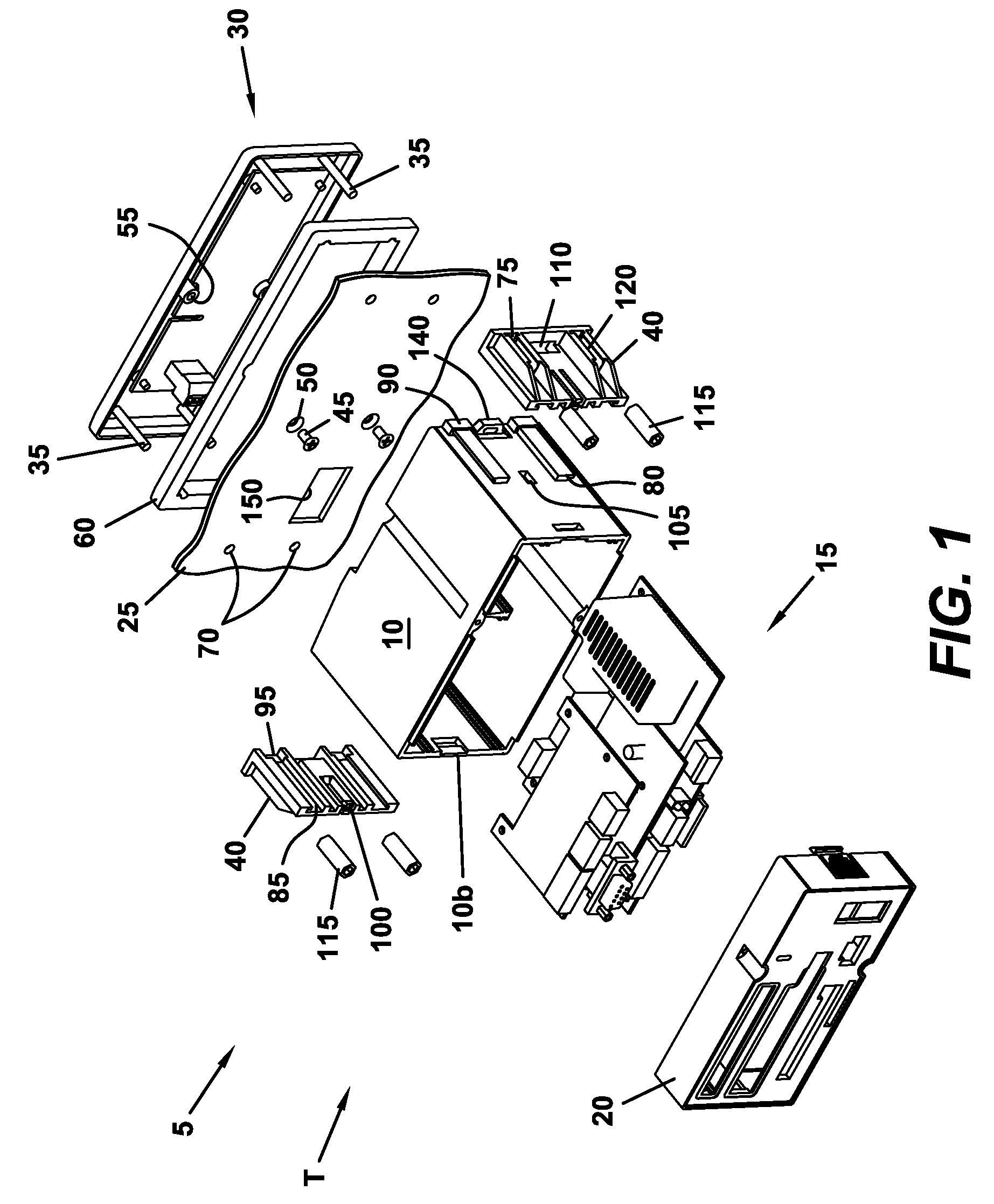

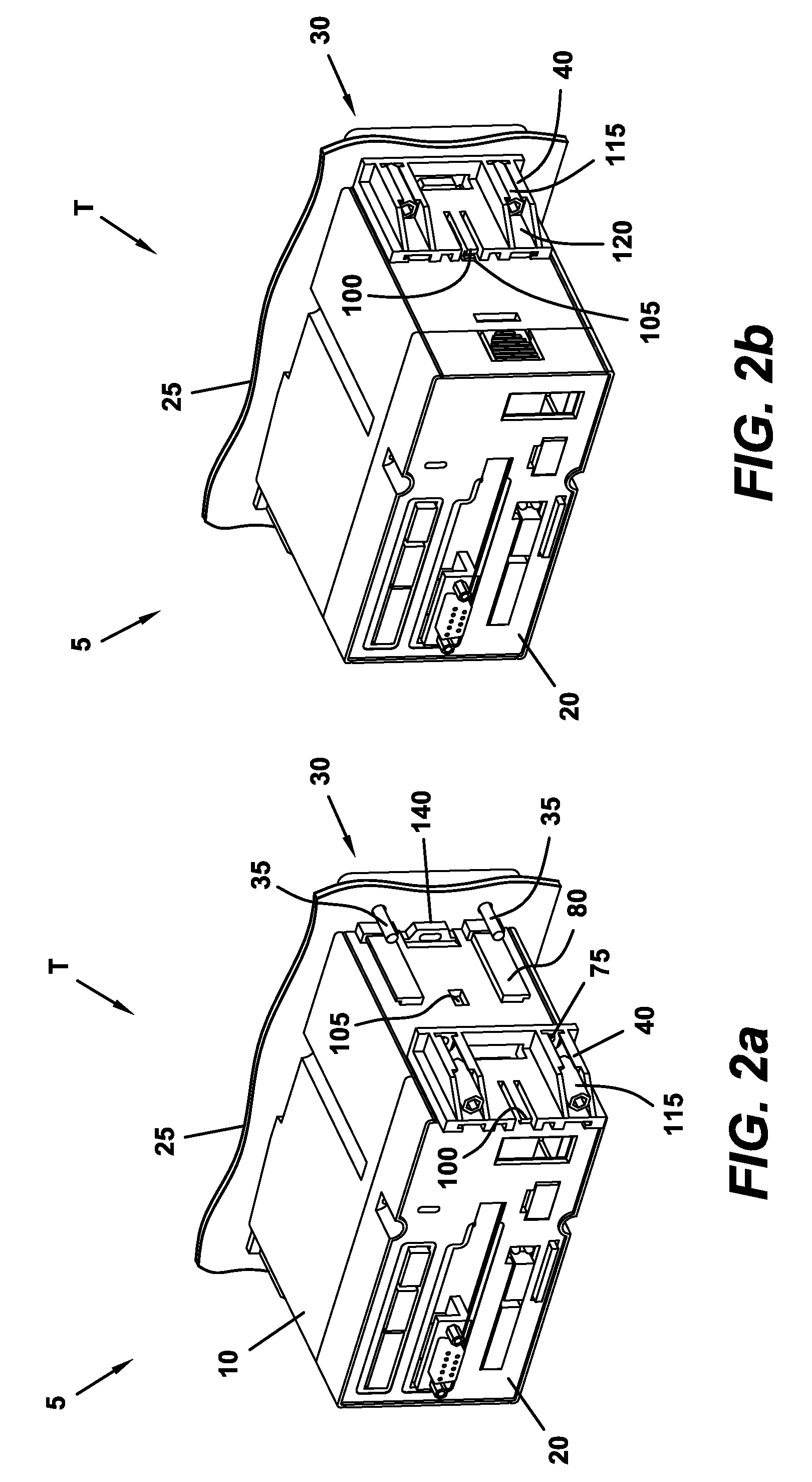

Din rail mounted enclosure assembly and method of use

A mounting enclosure assembly configured to mount an electronic component onto a DIN rail. The mounting enclosure assembly includes a mounting bracket having a slot configured to receive the DIN rail therein. The mounting enclosure assembly further includes a locking mechanism configured to selectively engage the DIN rail. The locking mechanism includes a release button and a protrusion positioned proximate the slot and configured to releasably engage a first flange of the DIN rail. The locking mechanism further includes a first hinged armature connected to the release button and the first protrusion, wherein the first protrusion is configured to disengage the first flange of the DIN rail when the release button is depressed. Other embodiments of the mounting enclosure assembly, as well as methods directed to the mounting enclosure assembly, are further disclosed.

Owner:SCHNEIDER ELECTRIC BUILDINGS AMERICAS INC

Method and apparatus for increasing heat dissipation capacity of a din rail mounted enclosure

ActiveUS20160330869A1Support structure mountingCooling/ventilation/heating modificationsElectronic componentThermal bonding

A mounting enclosure assembly is configured to mount electronic components onto a DIN rail. The mounting enclosure assembly includes a mounting bracket including a body having at least one elongate slot configured to receive an edge of the electronic component therein. The mounting enclosure assembly further includes a heat sink secured to the mounting bracket. The heat sink includes a mounting configuration configured to secure the heat sink and the mounting bracket to the DIN rail. The mounting enclosure assembly further includes a thermal bonding material disposed within the slot to secure the electronic component to the body of the mounting bracket within the slot. Other embodiments of the mounting enclosure assembly are further disclosed.

Owner:SCHNEIDER ELECTRIC USA INC

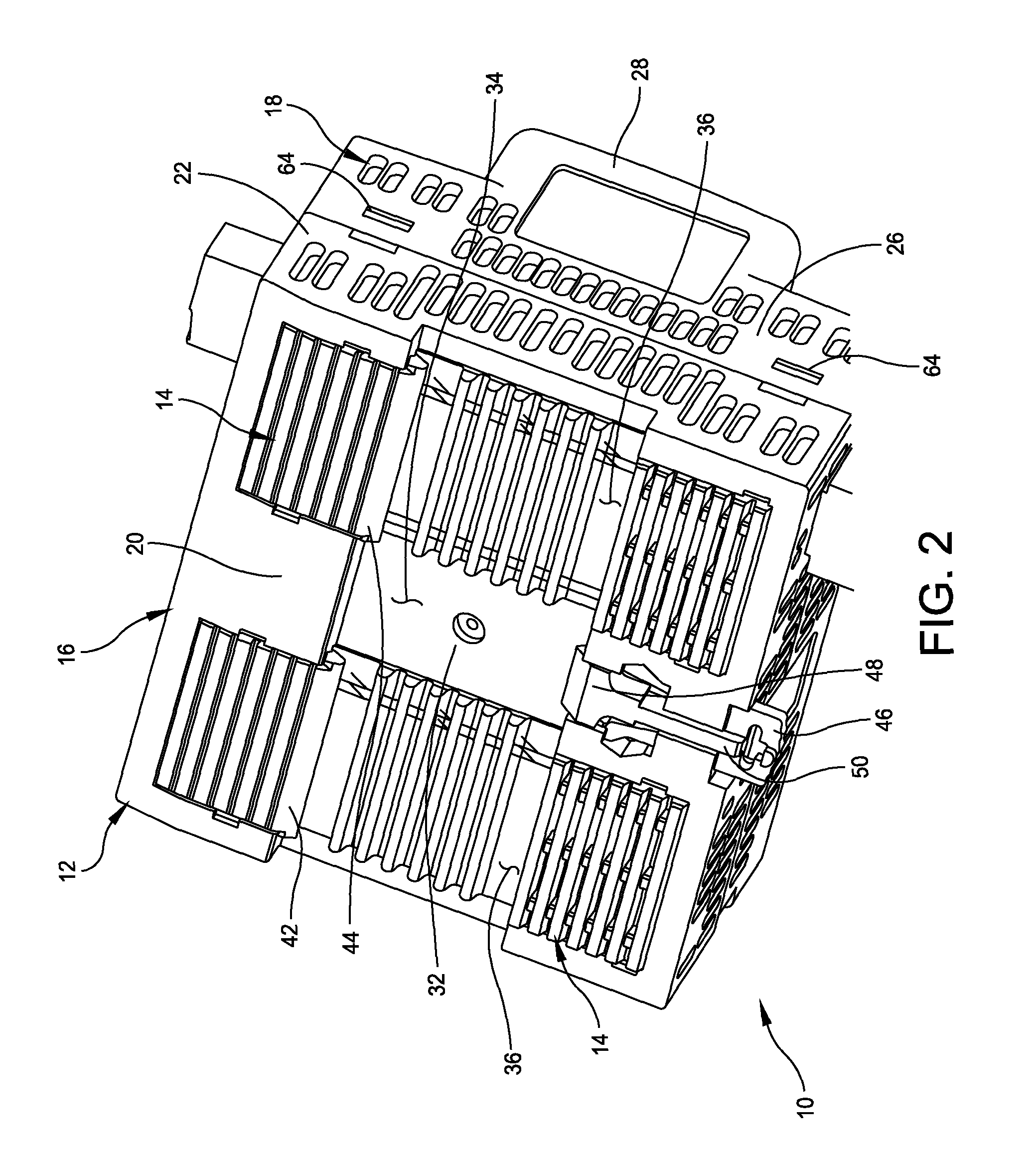

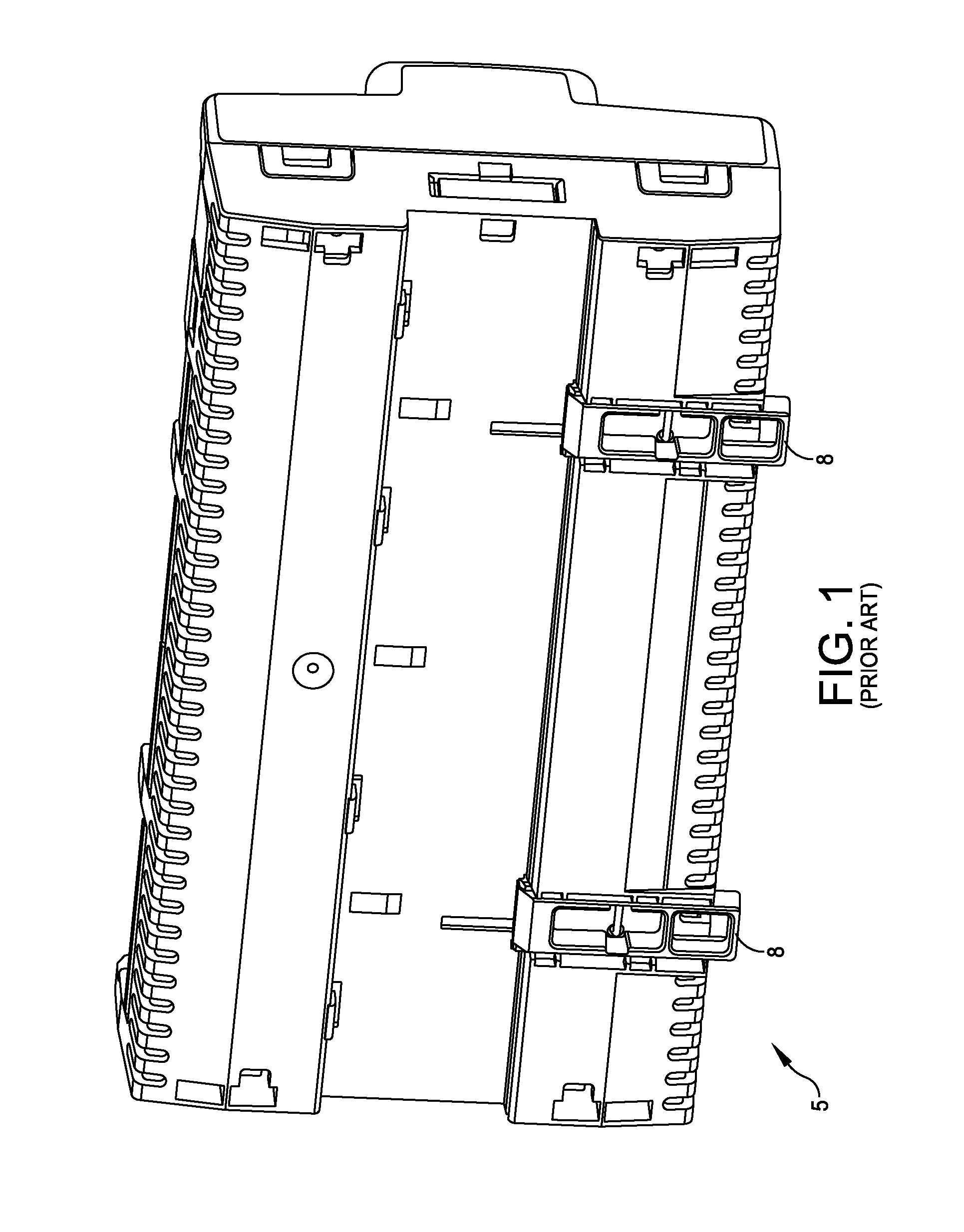

Integrated DIN rail attachment feature for superior attachment

InactiveCN101925281ASubstation/switching arrangement detailsRack/frame constructionEngineeringDIN rail

An electronics module includes a base and a cover connected to the base. The base includes a recess adapted to receive an associated mounting rail. At least one fixed rail constraining tab is located adjacent a first edge of the recess and is adapted to engage a first flange of the associated mounting rail. First and / or second latch arms are located adjacent a second edge of the recess that is opposite the first edge of the recess. The first and second latch arms are connected to a fixed portion of the second edge and project outwardly relative to opposite lateral sides of the fixed portion. Each of the first and second latch arms includes a rail capture tab. The first and second latch arms are selectively movable resiliently to and from latched and unlatched positions, wherein the rail capture tabs of the first and second latch arms project beyond the fixed portion of the second edge and into the recess when the first and second latch arms are located in their respective latched positions, and wherein the rail capture tabs of the first and second latch arms are withdrawn relative to the fixed portion of the second edge when the first and second latch arms are located in their respective unlatched positions. The cover or other portion of the module defines first and second receiving locations that receive and retain portions of the first and second latch arms when the first and second latch arms are located in their respective latched positions.

Owner:ROCKWELL AUTOMATION TECH

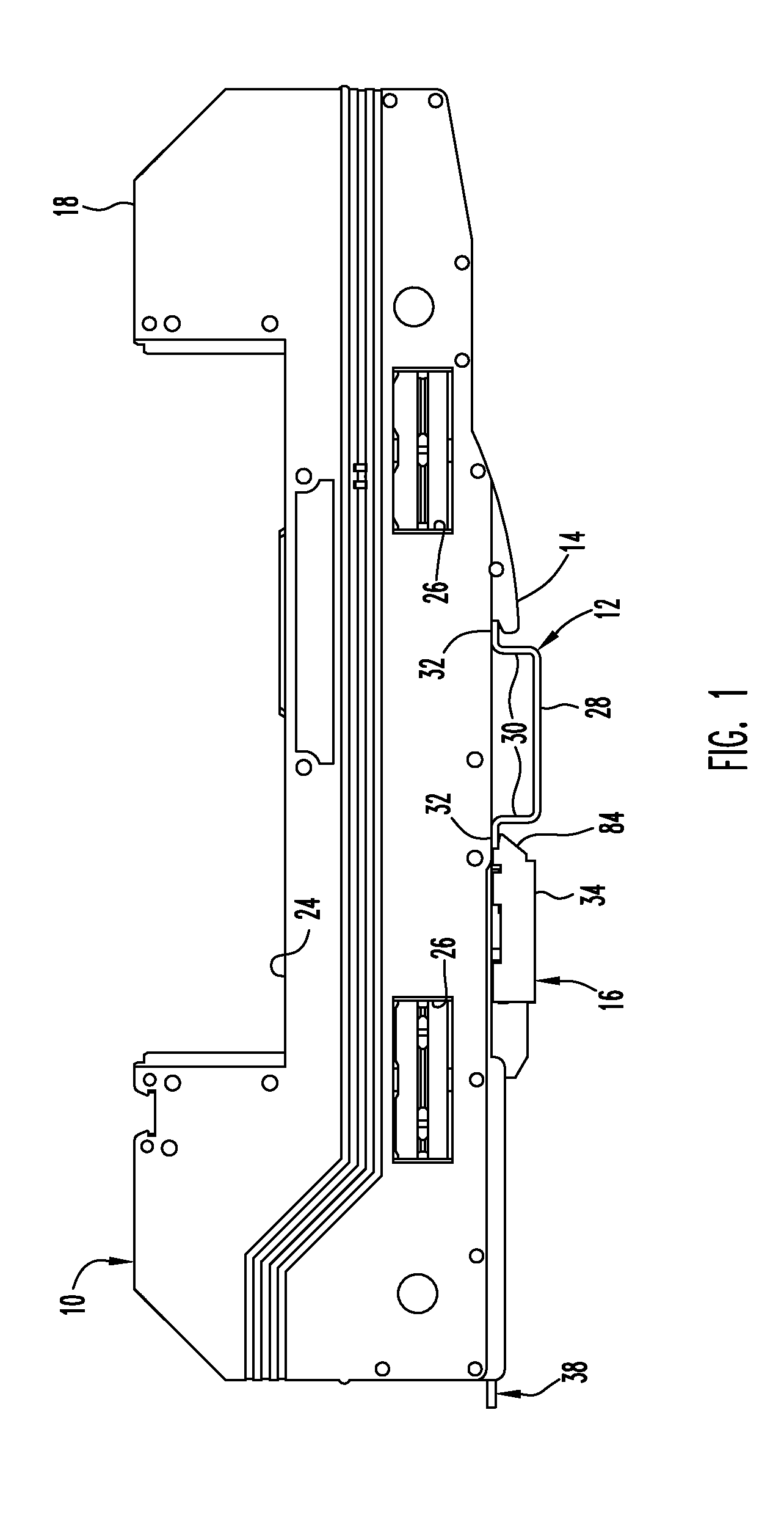

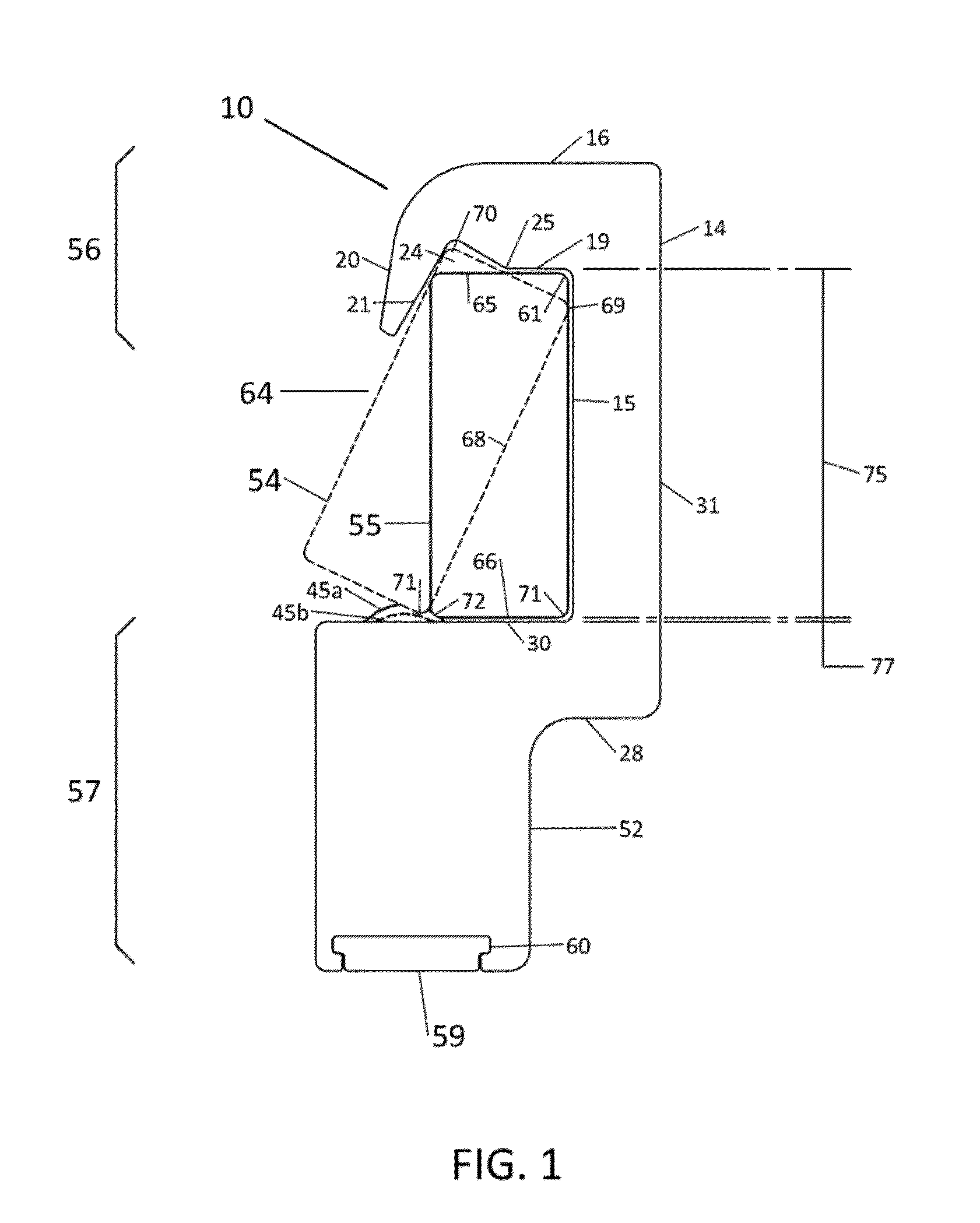

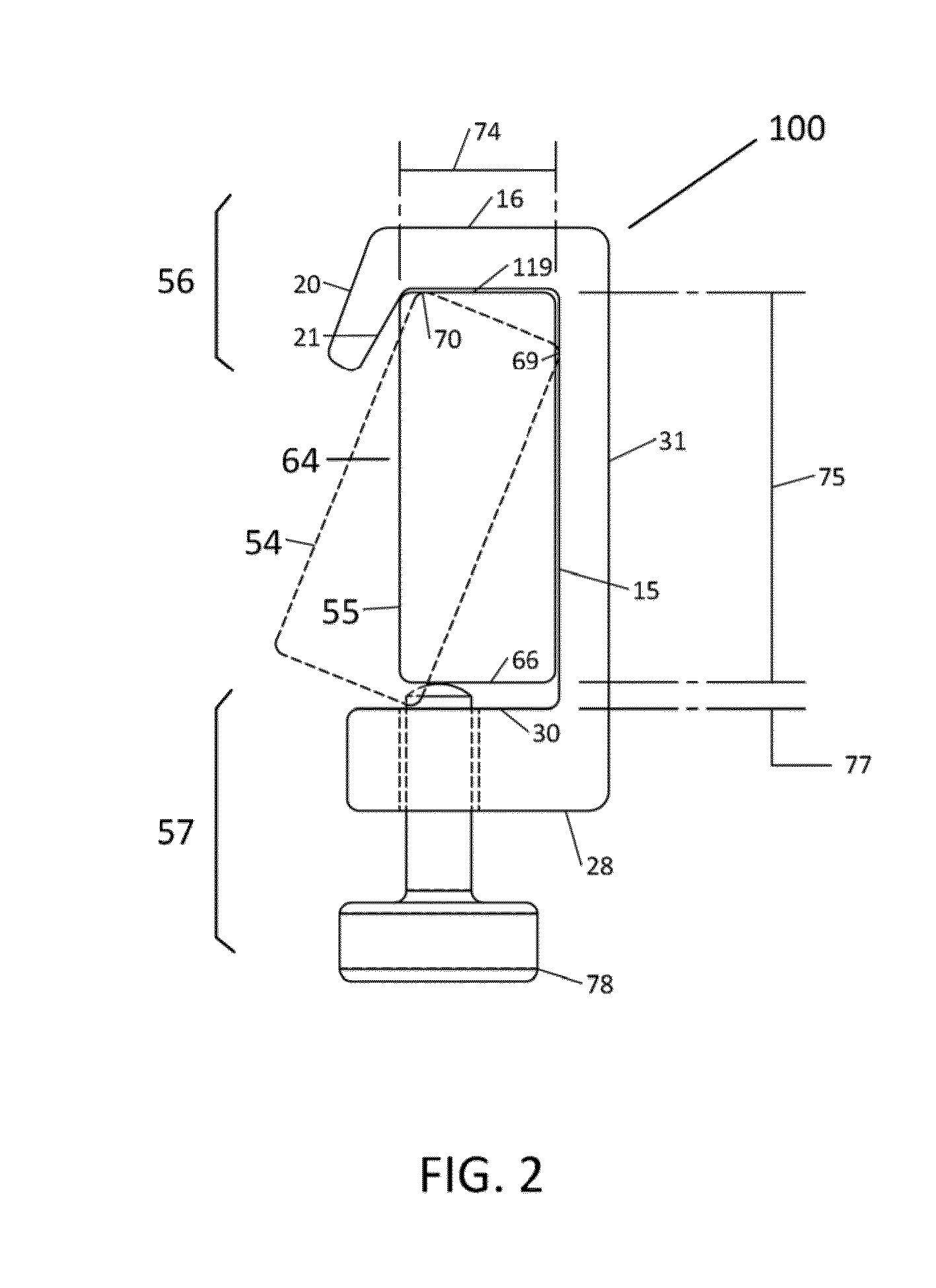

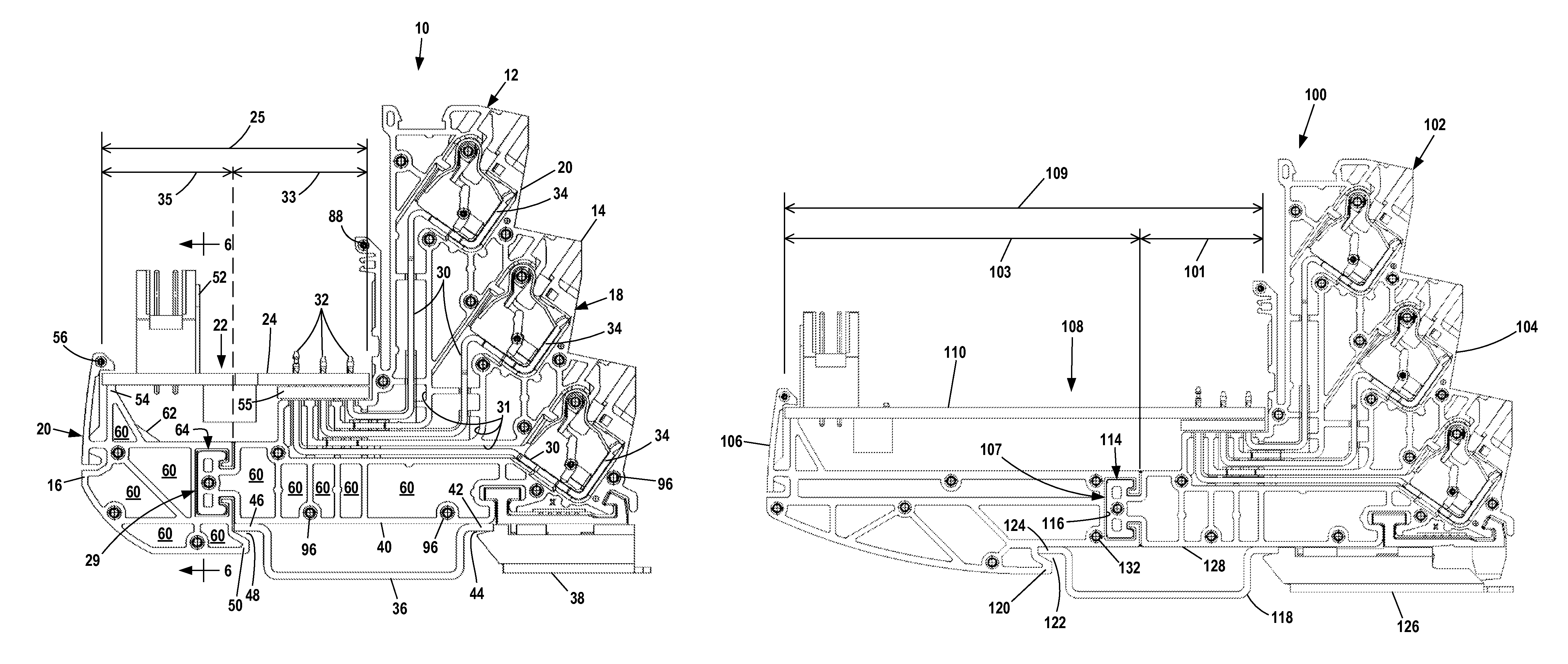

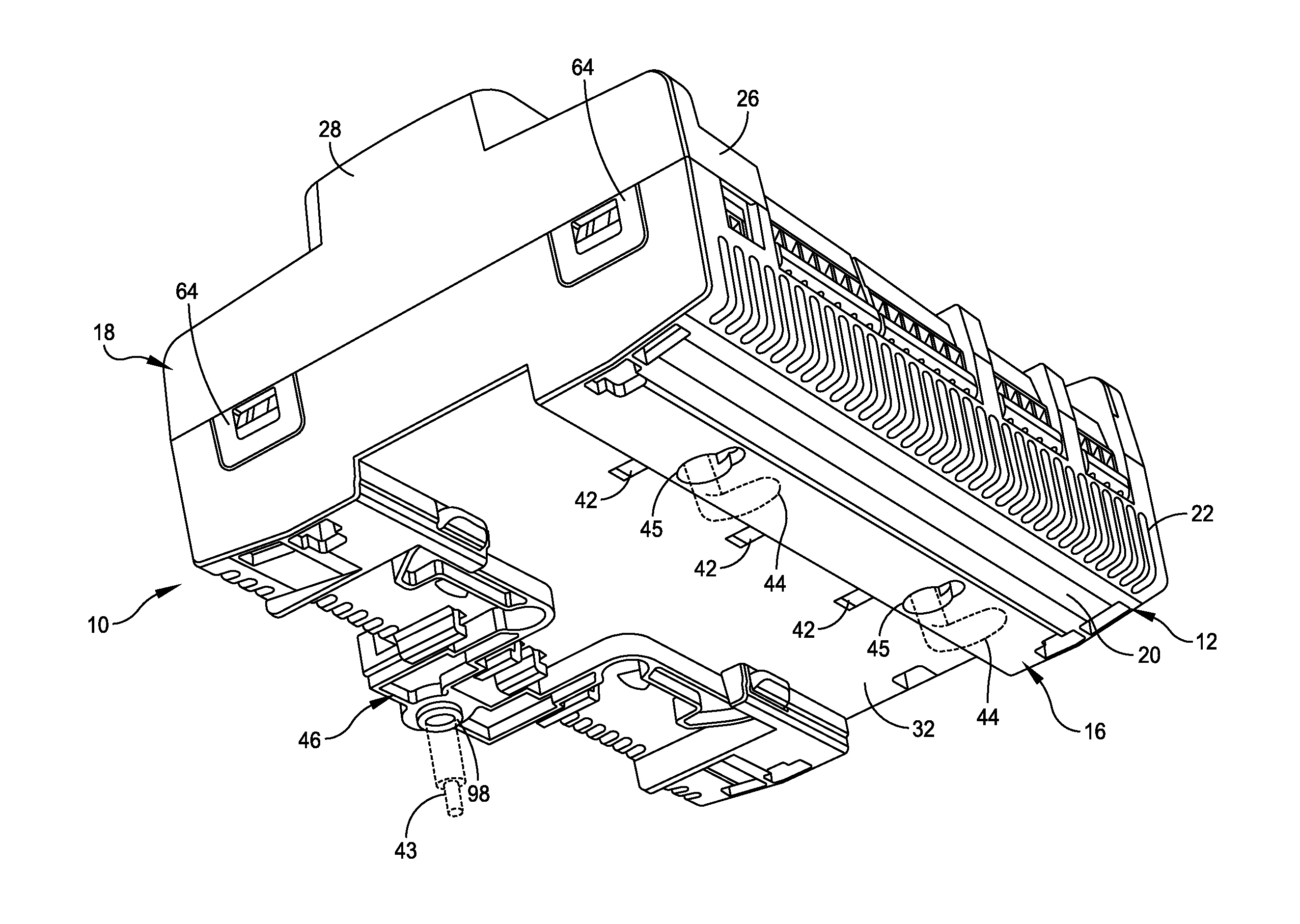

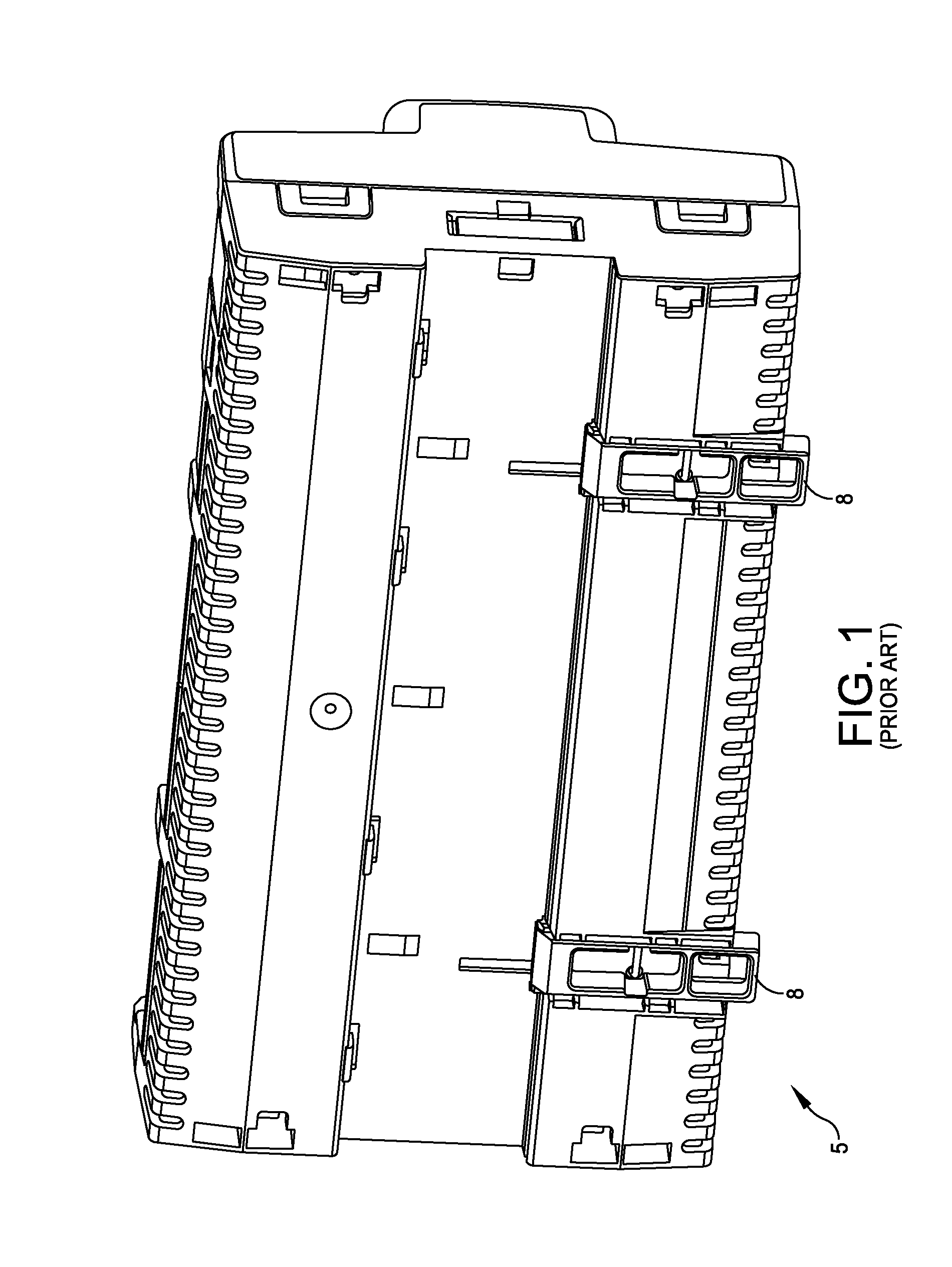

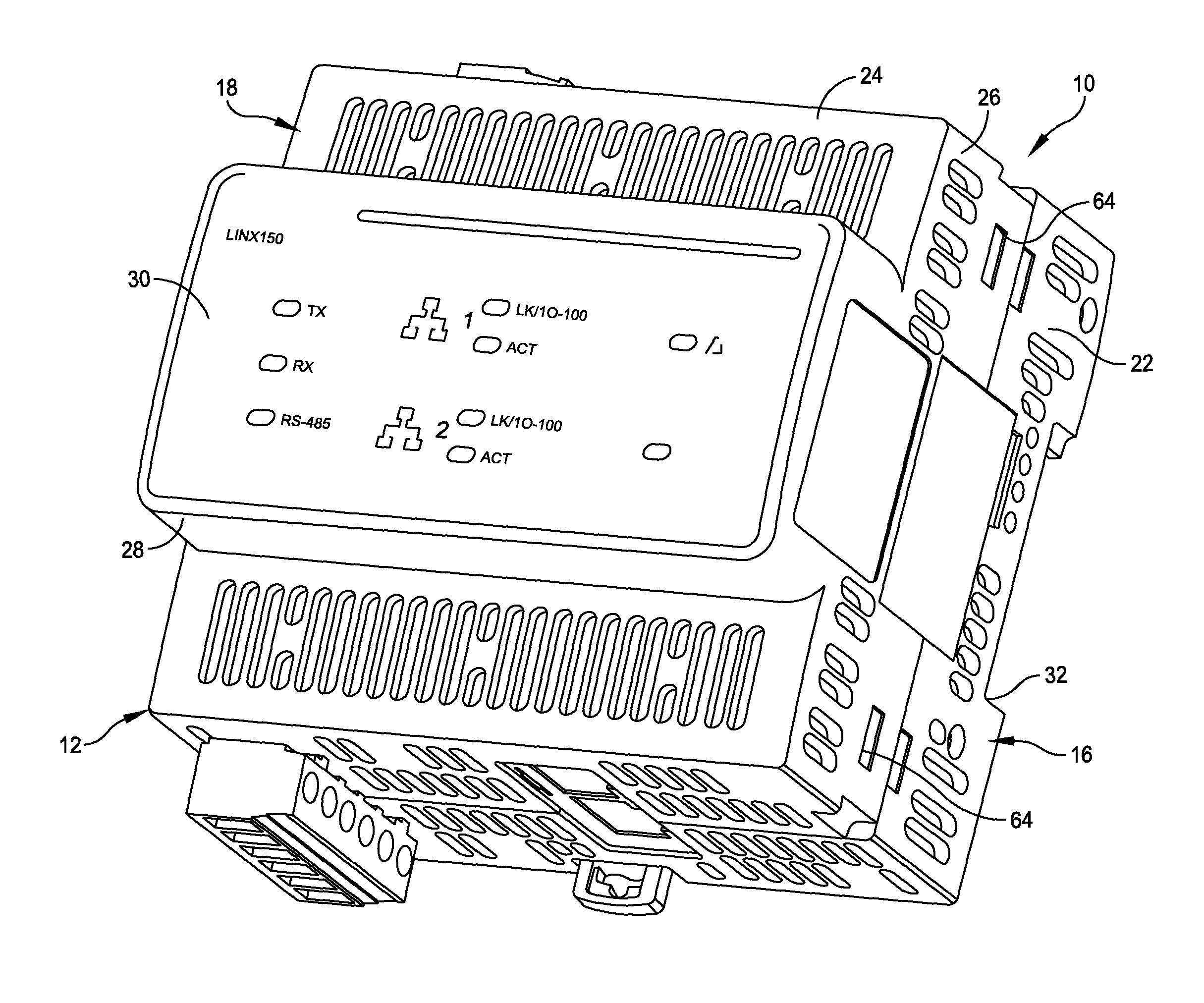

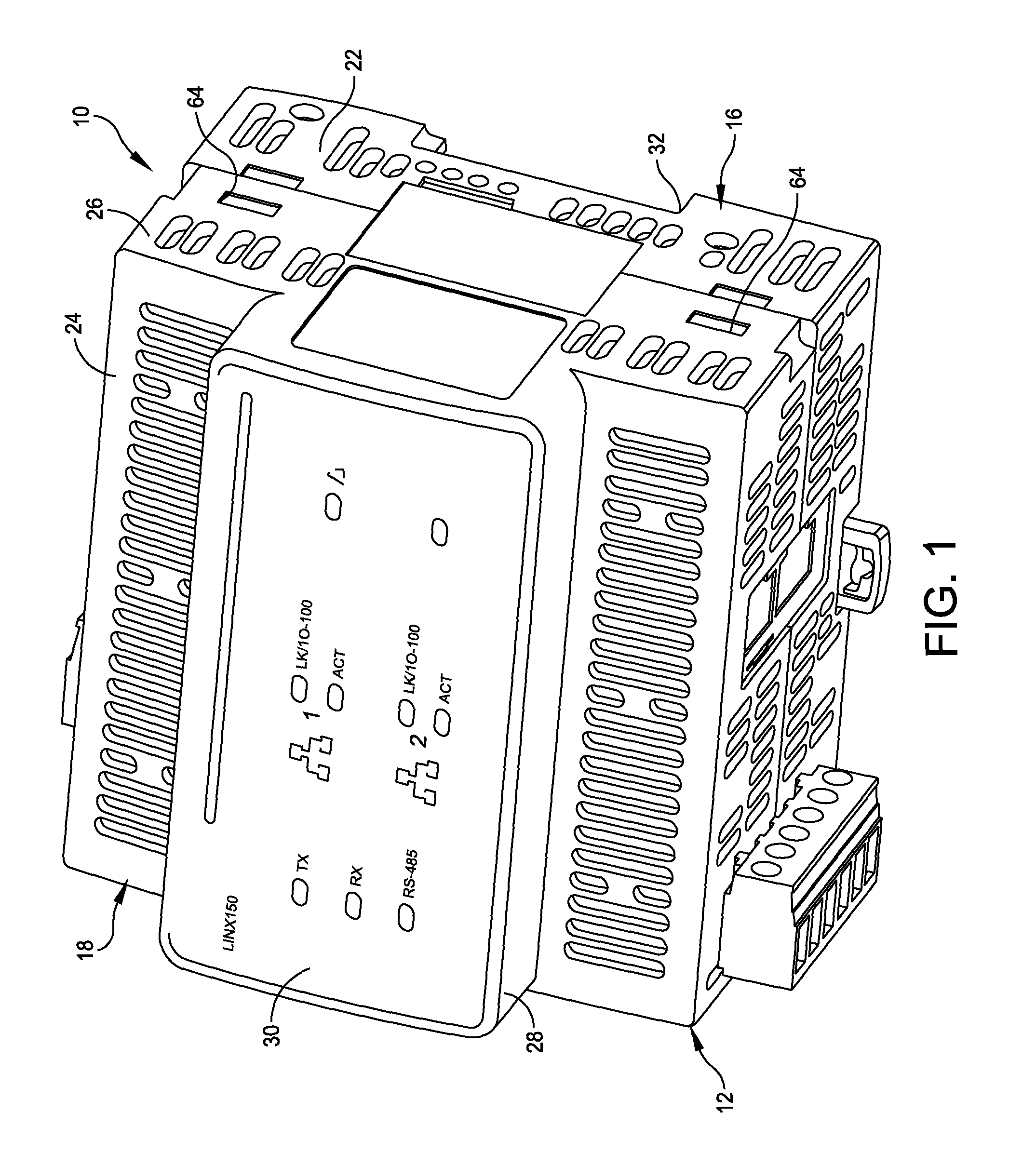

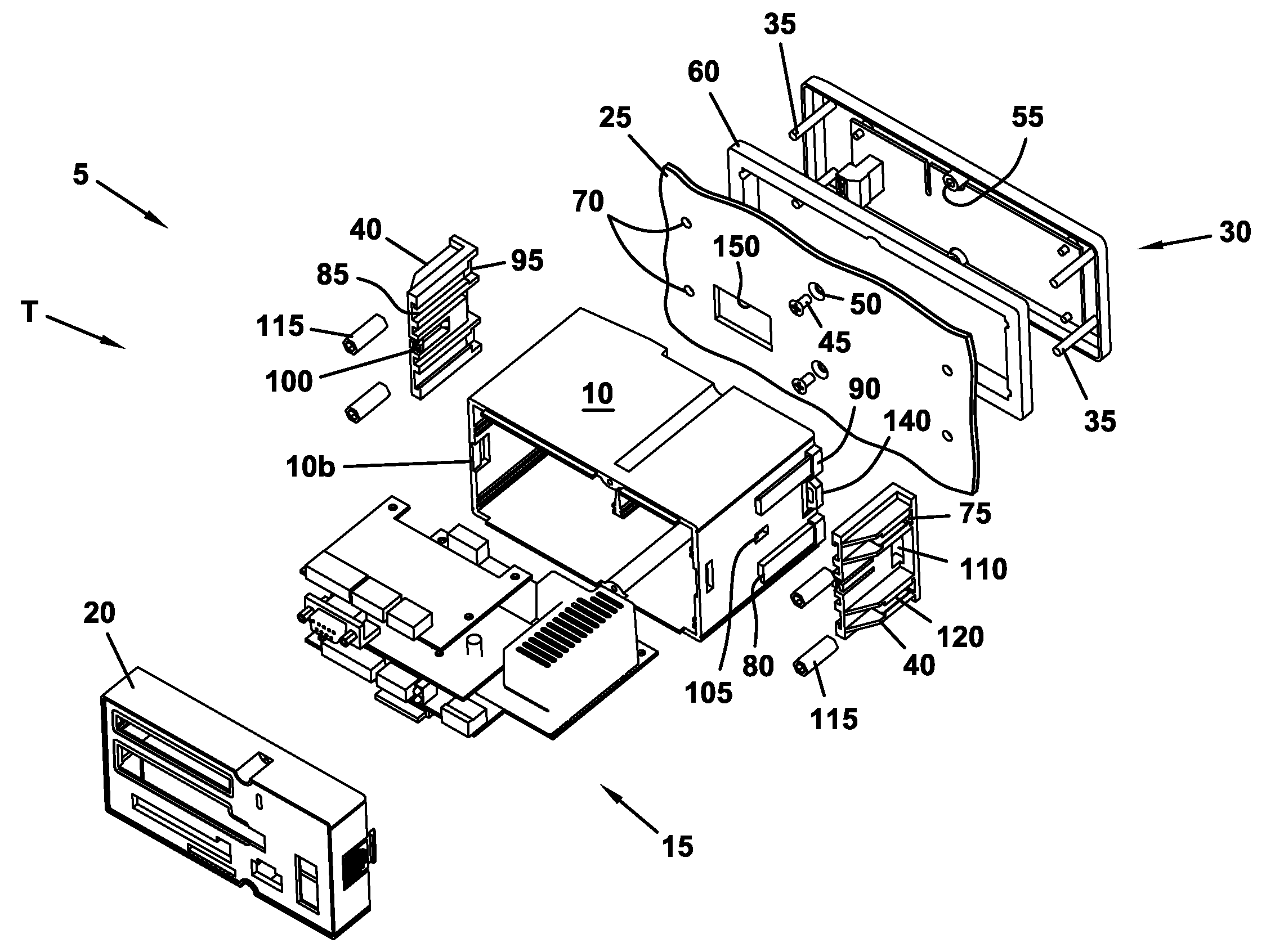

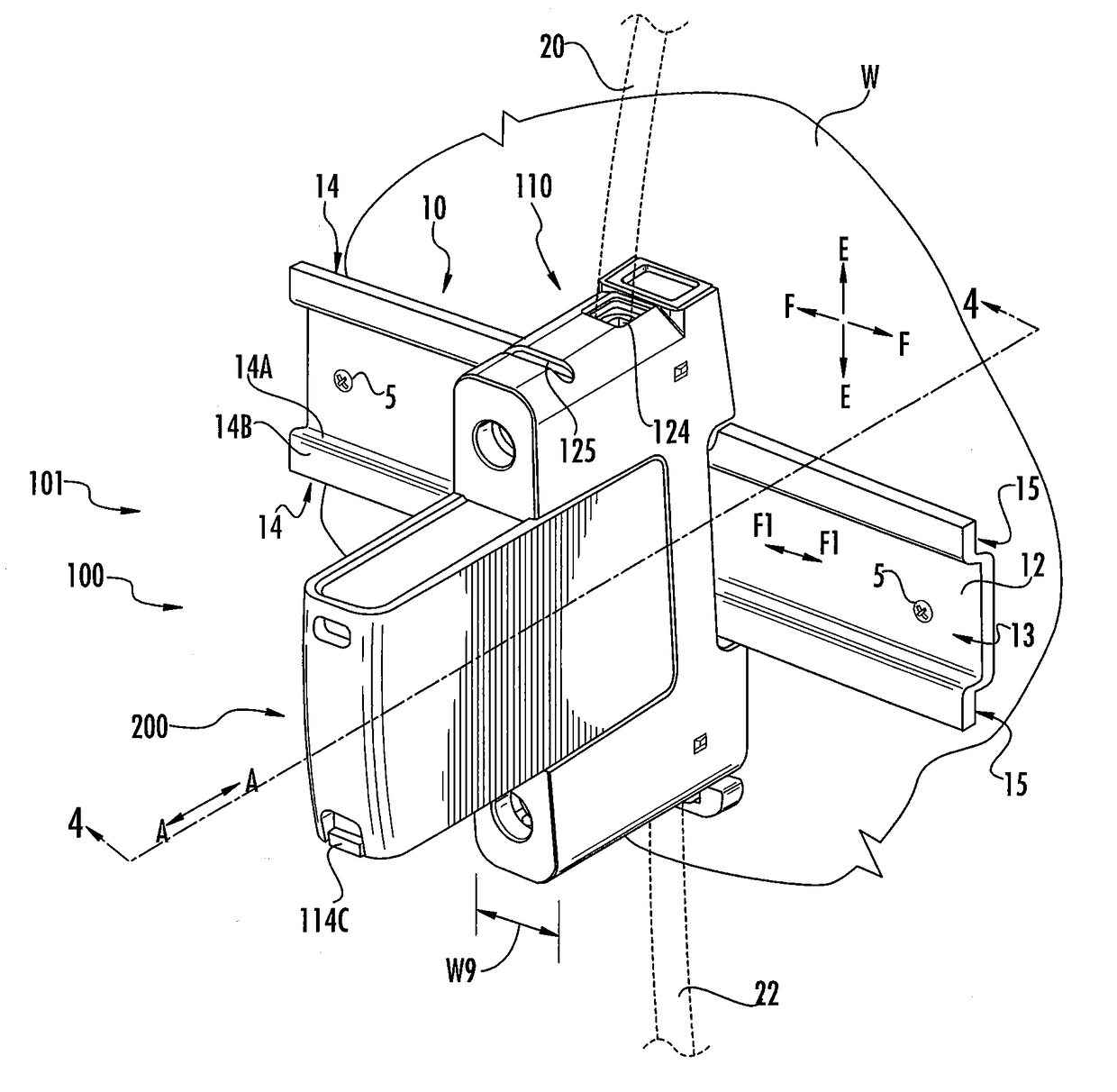

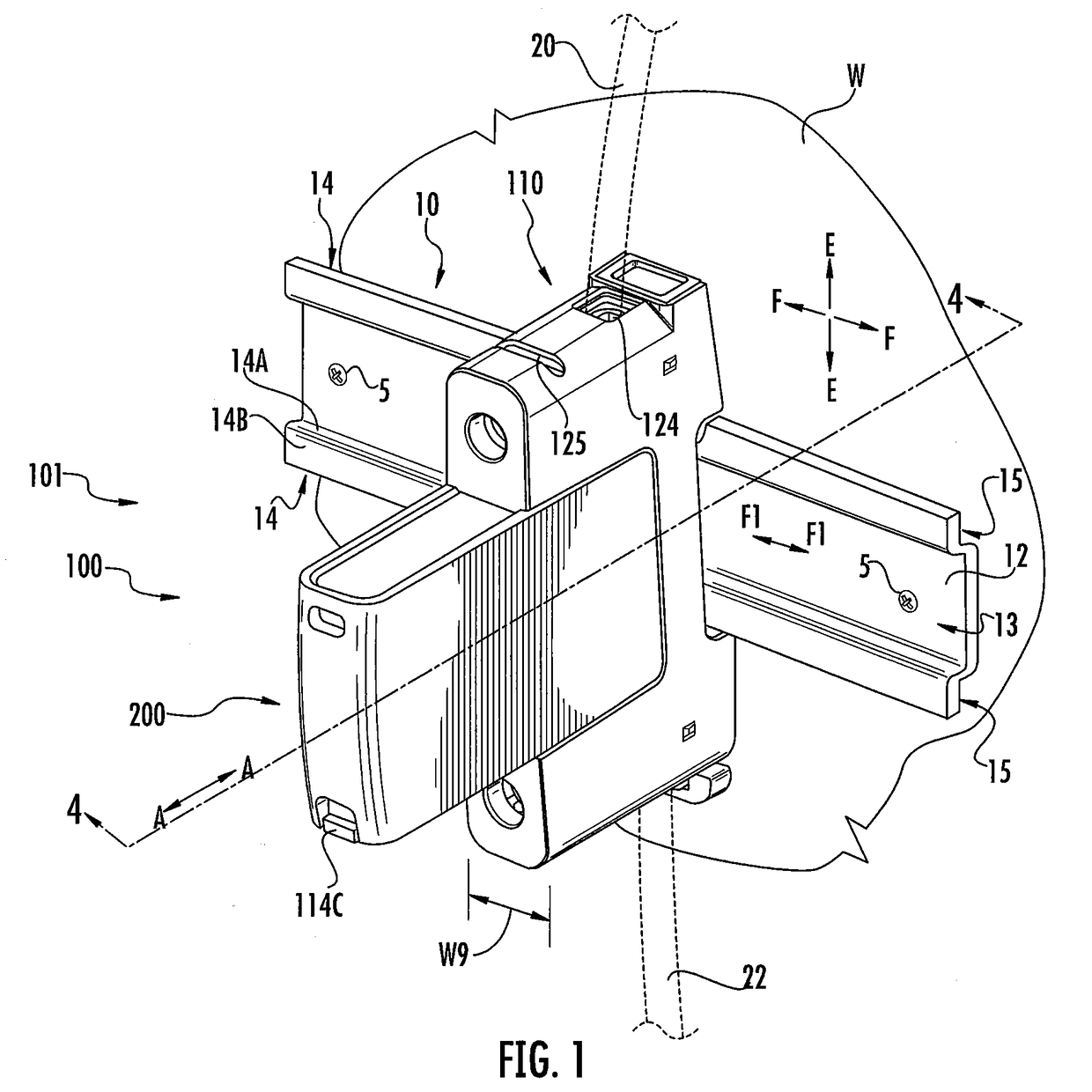

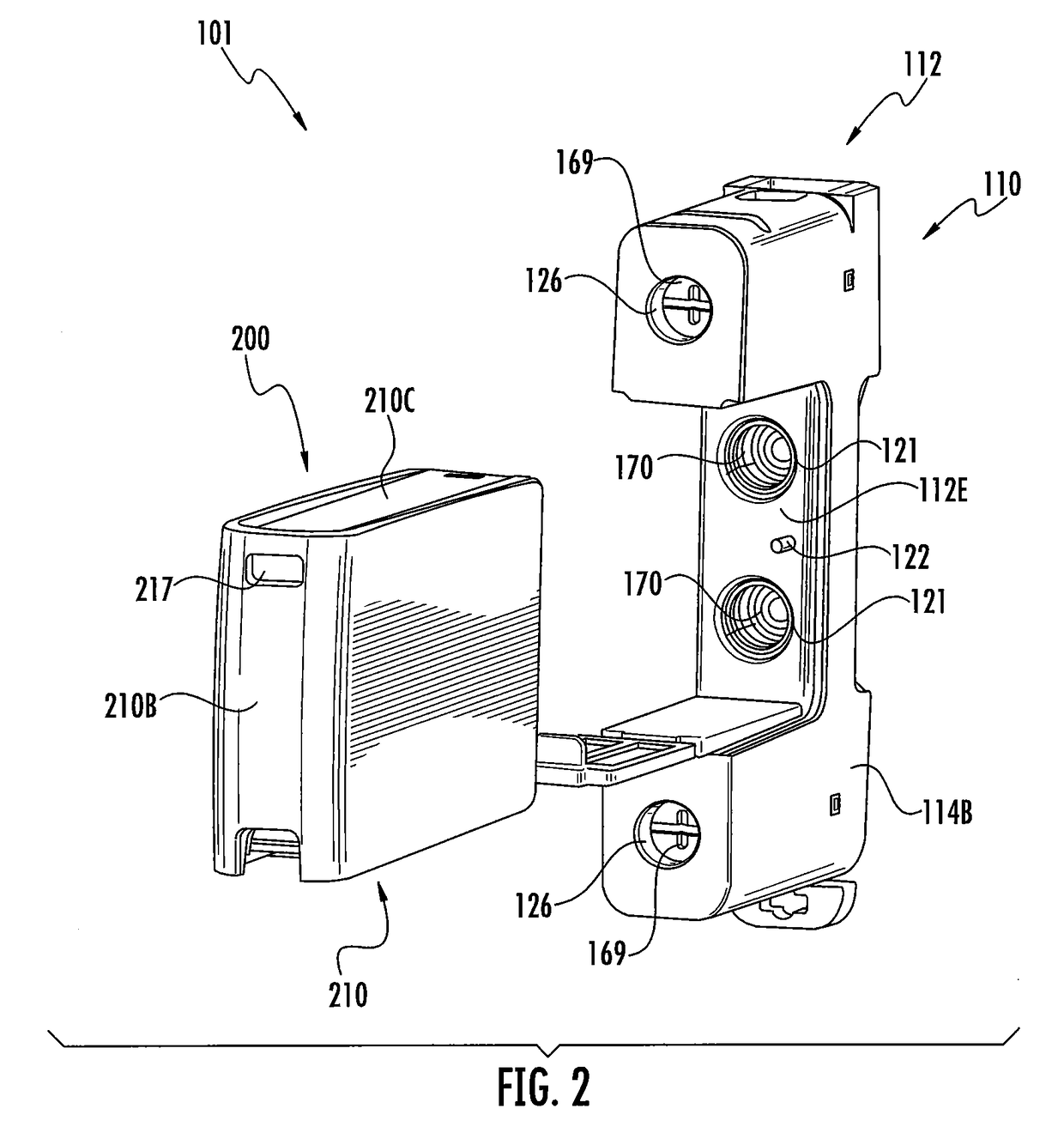

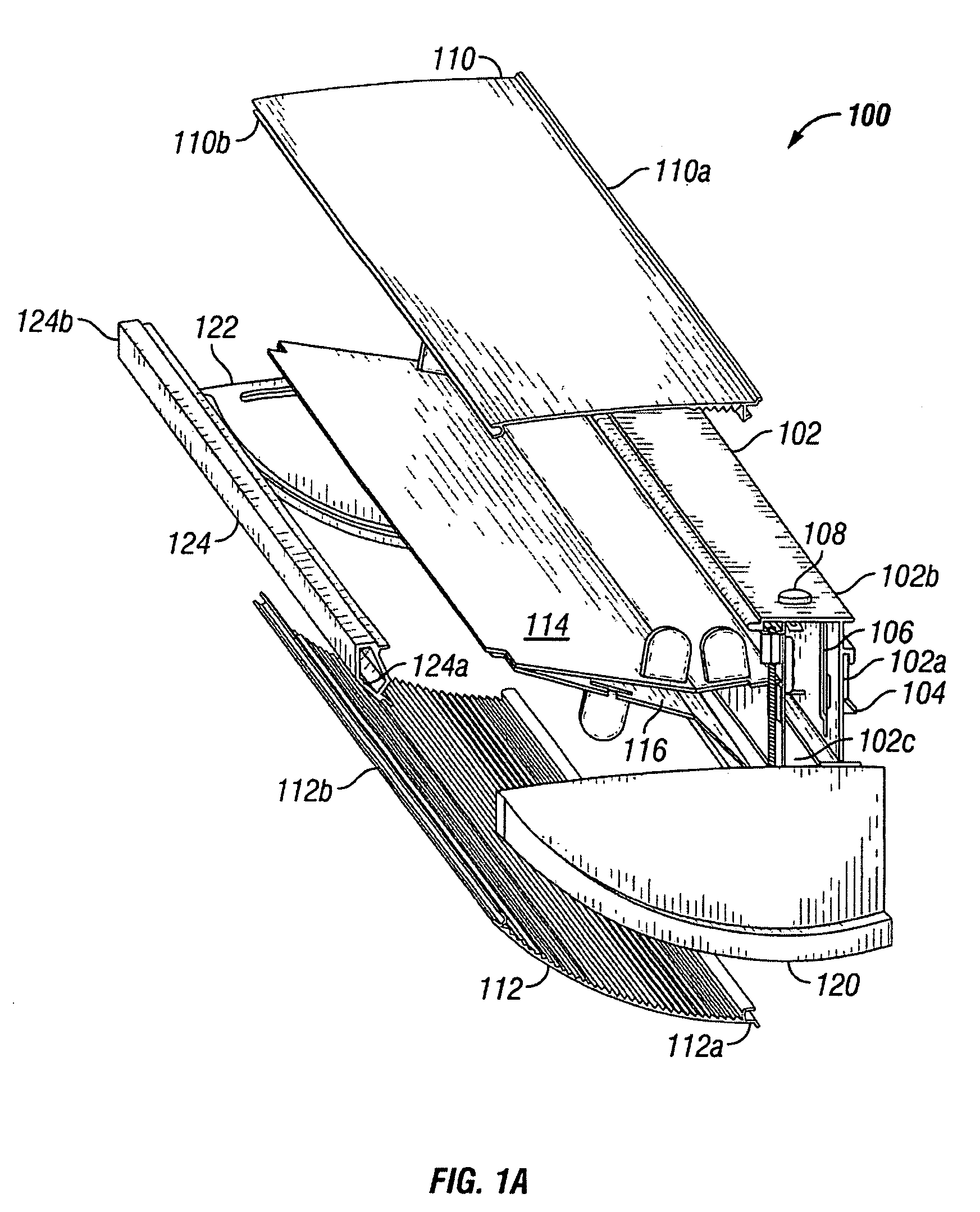

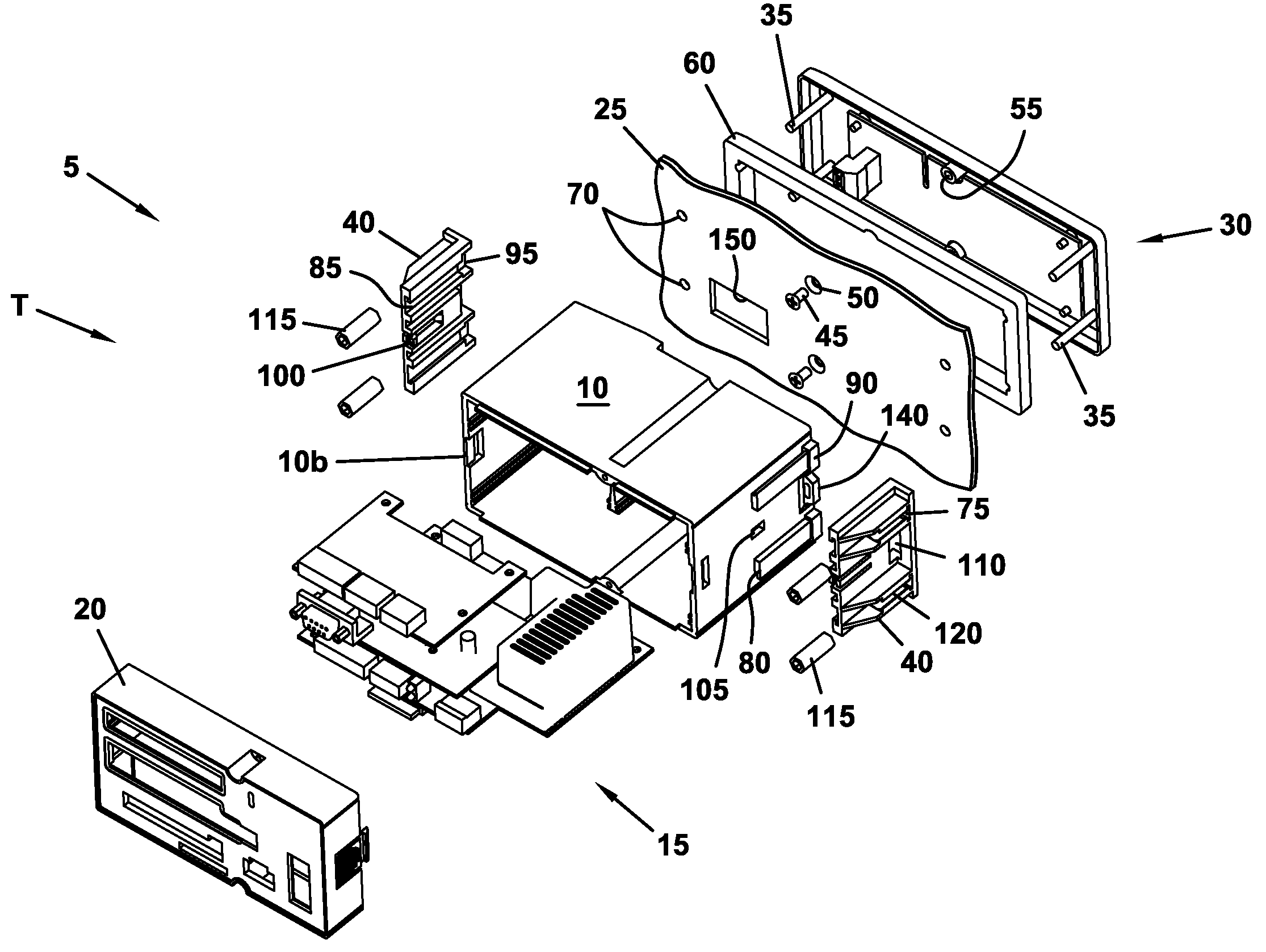

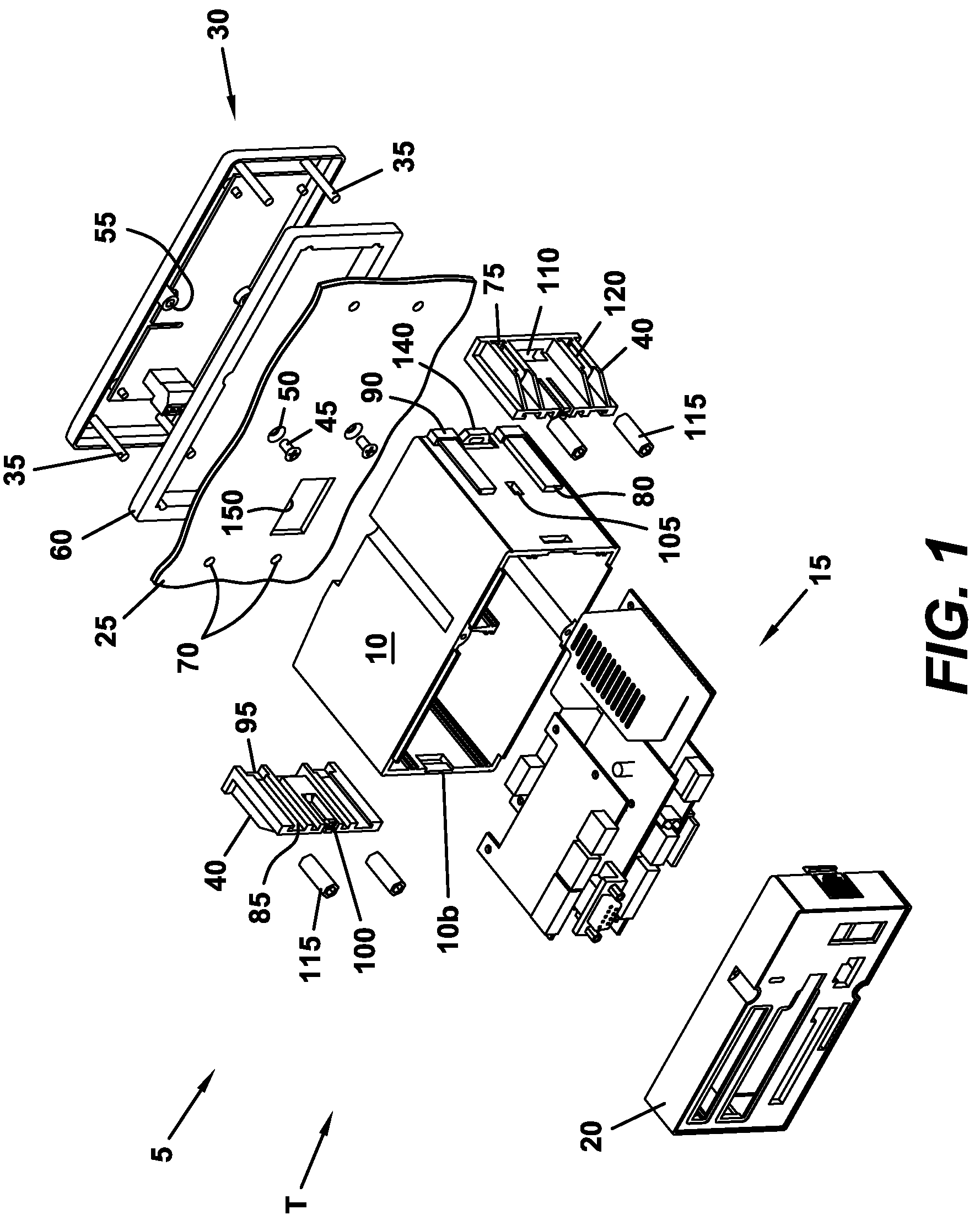

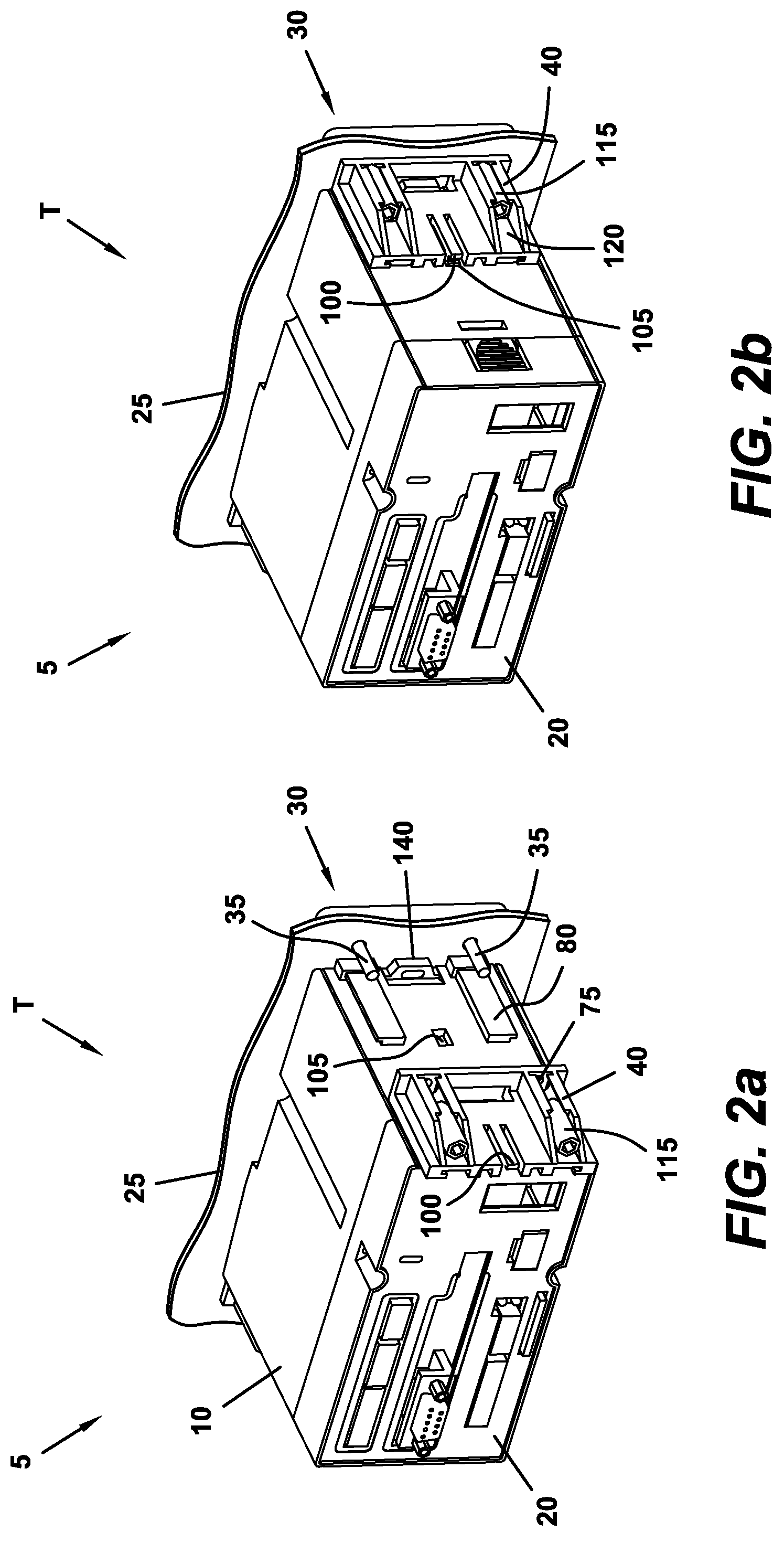

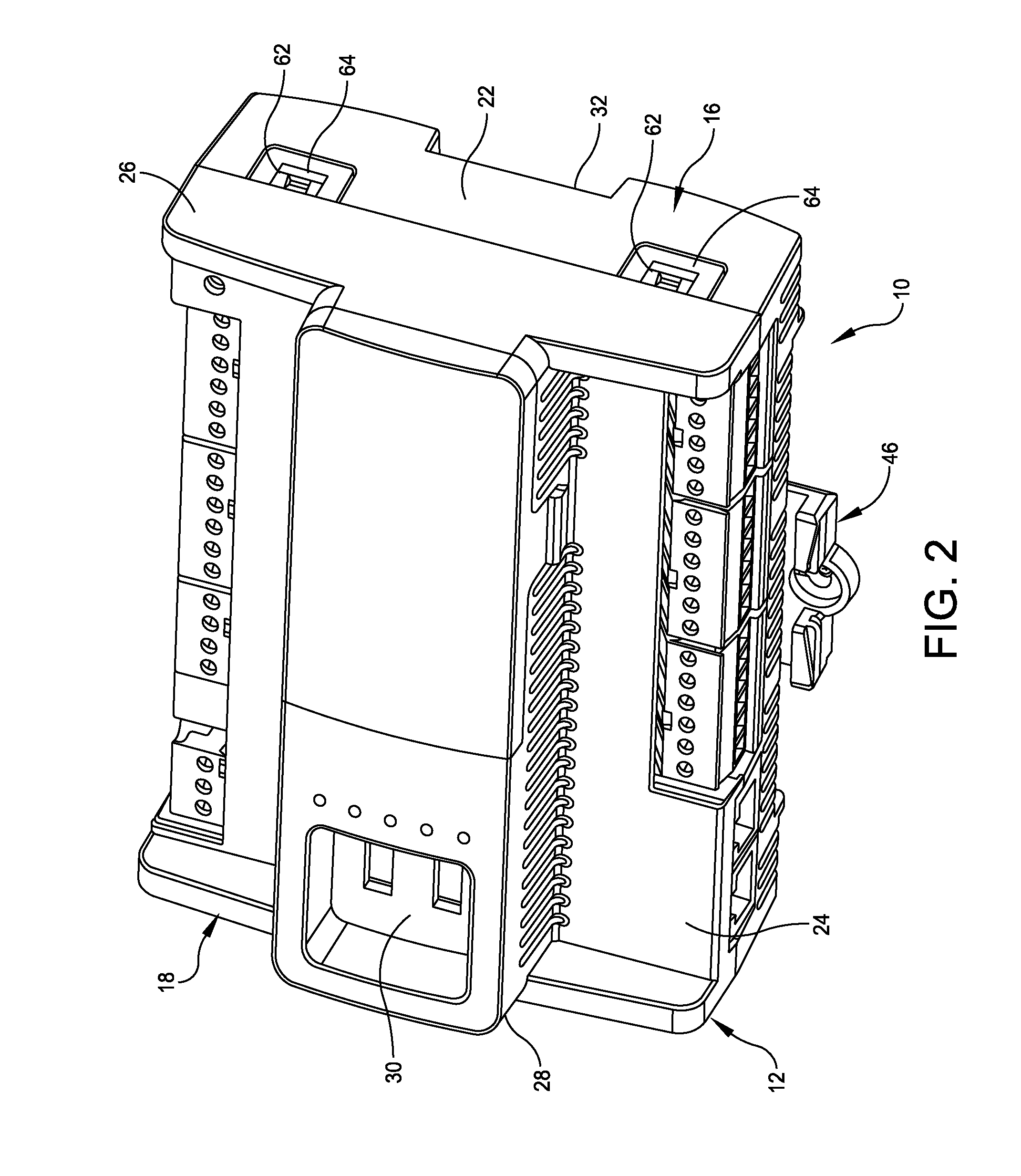

Mounting for industrial instrumentation

ActiveUS20100128448A1Facilitate manufacturing simplicityFacilitate cost-effectivenessSubstation/switching arrangement detailsCoupling device detailsModularityElectronic component

A flexible, modular mounting system for an industrial process terminal or similar instrumentation. The instrumentation may be panel mounted or DIN rail mounted using an enclosure having only a minimum number of unique components. An instrument housing is included for containing various electronic components of such a terminal. The housing is adapted to mate with a DIN rail, and can easily be fitted with mounting brackets that allow the housing to be used in a panel mounted arrangement. In the latter case, a user interface module is located on an opposite side of a panel wall and connected to the appropriate electronic components of the instrumentation through an opening provided therein.

Owner:METTLER TOLEDO INC

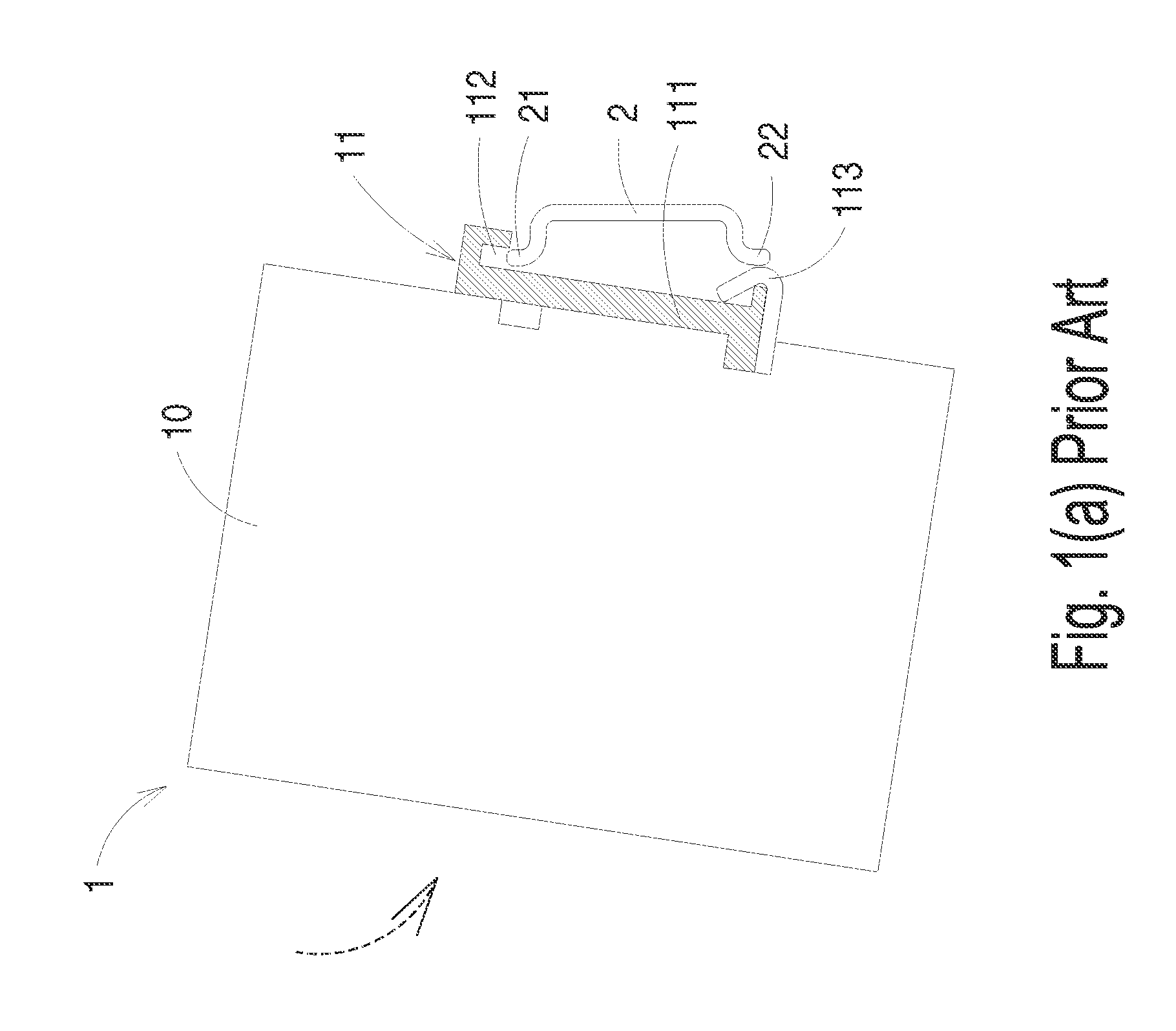

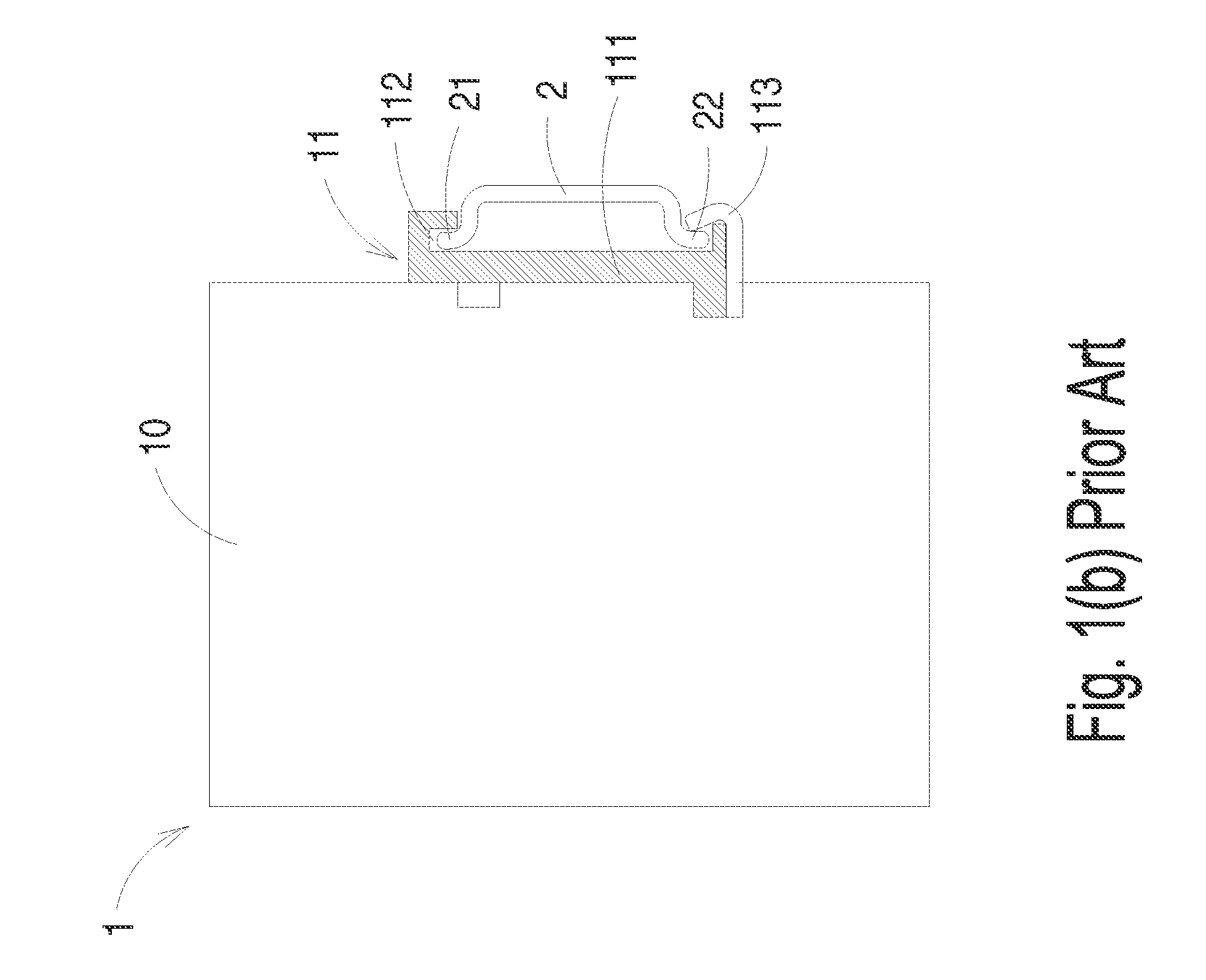

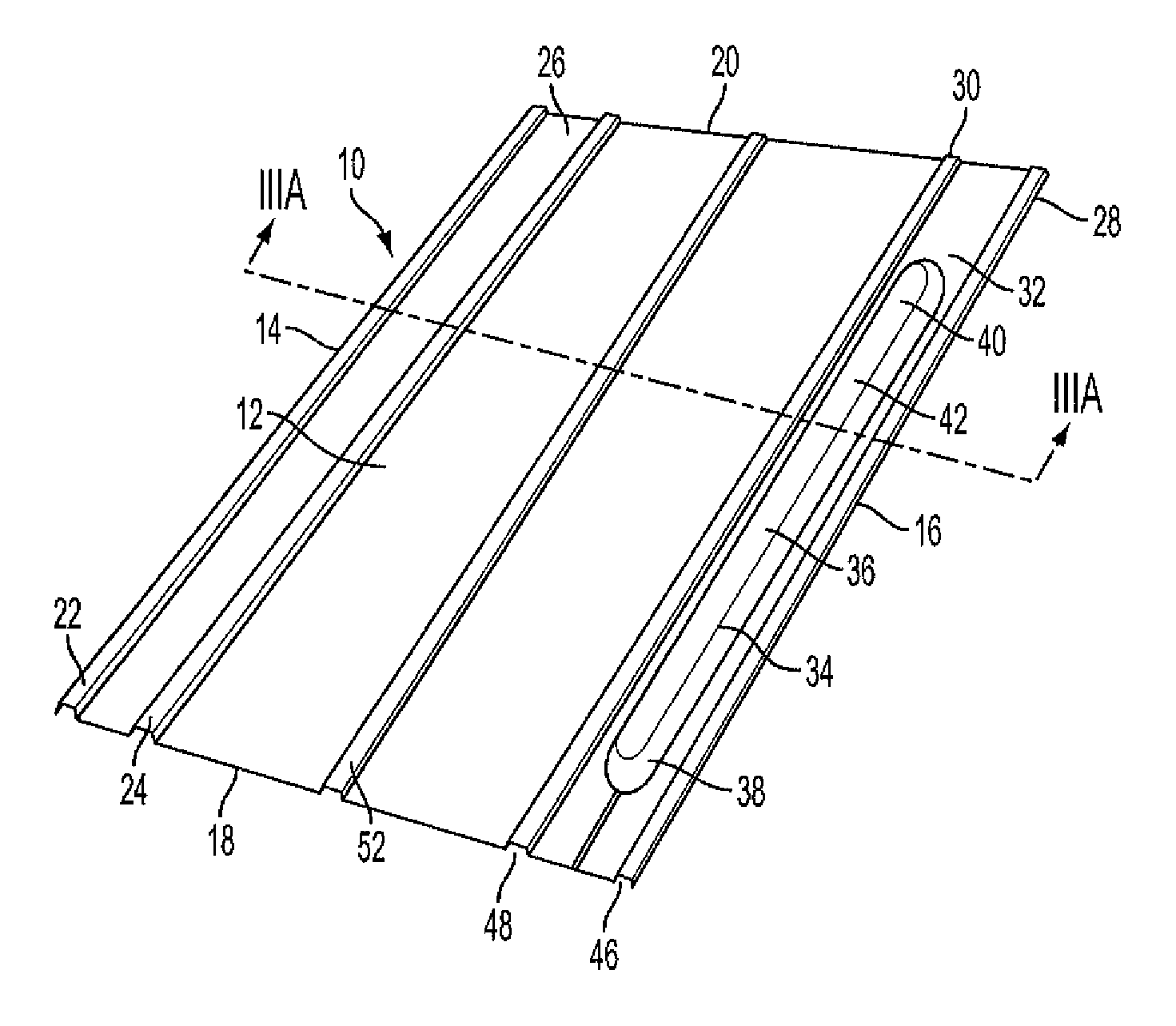

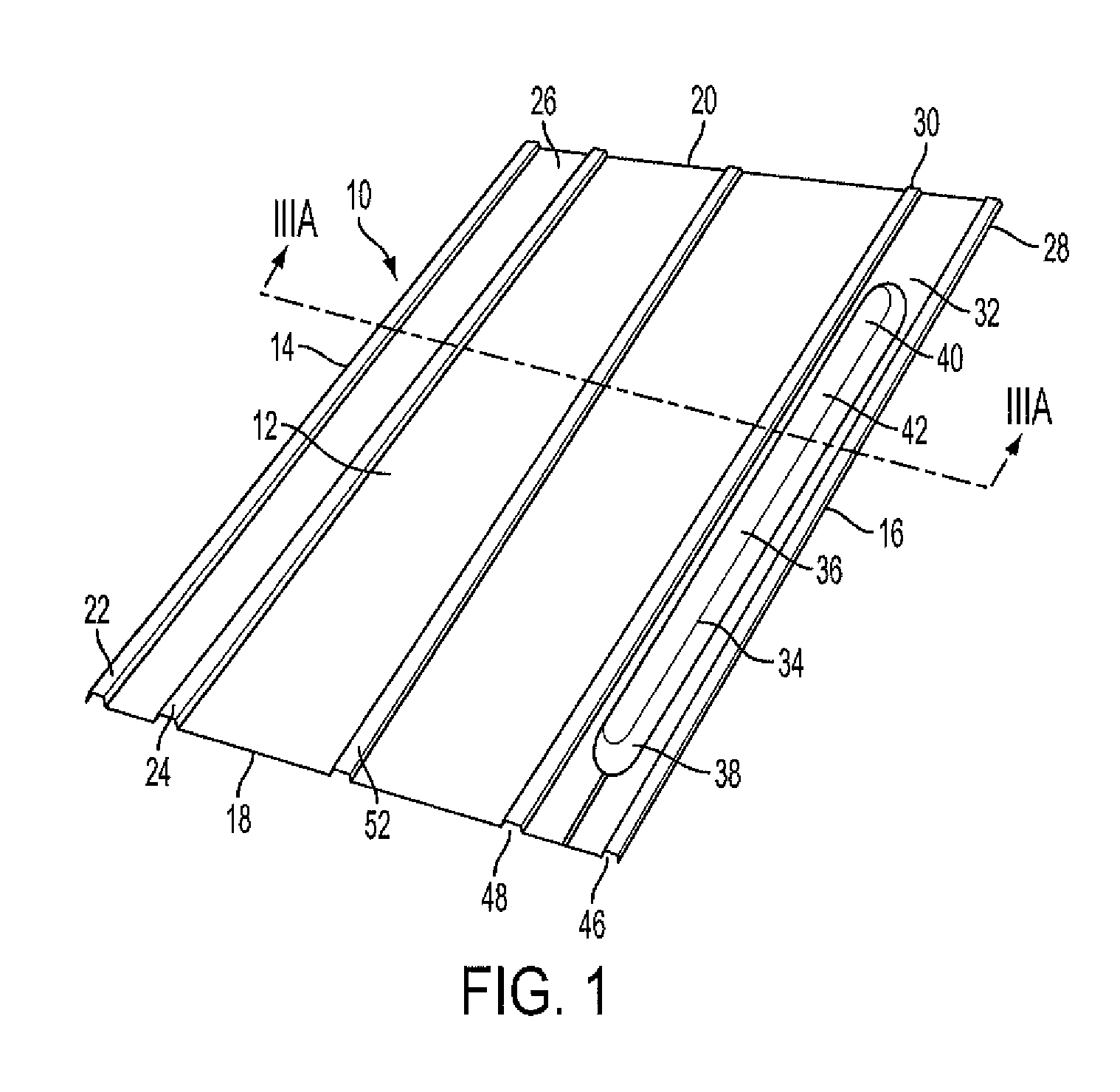

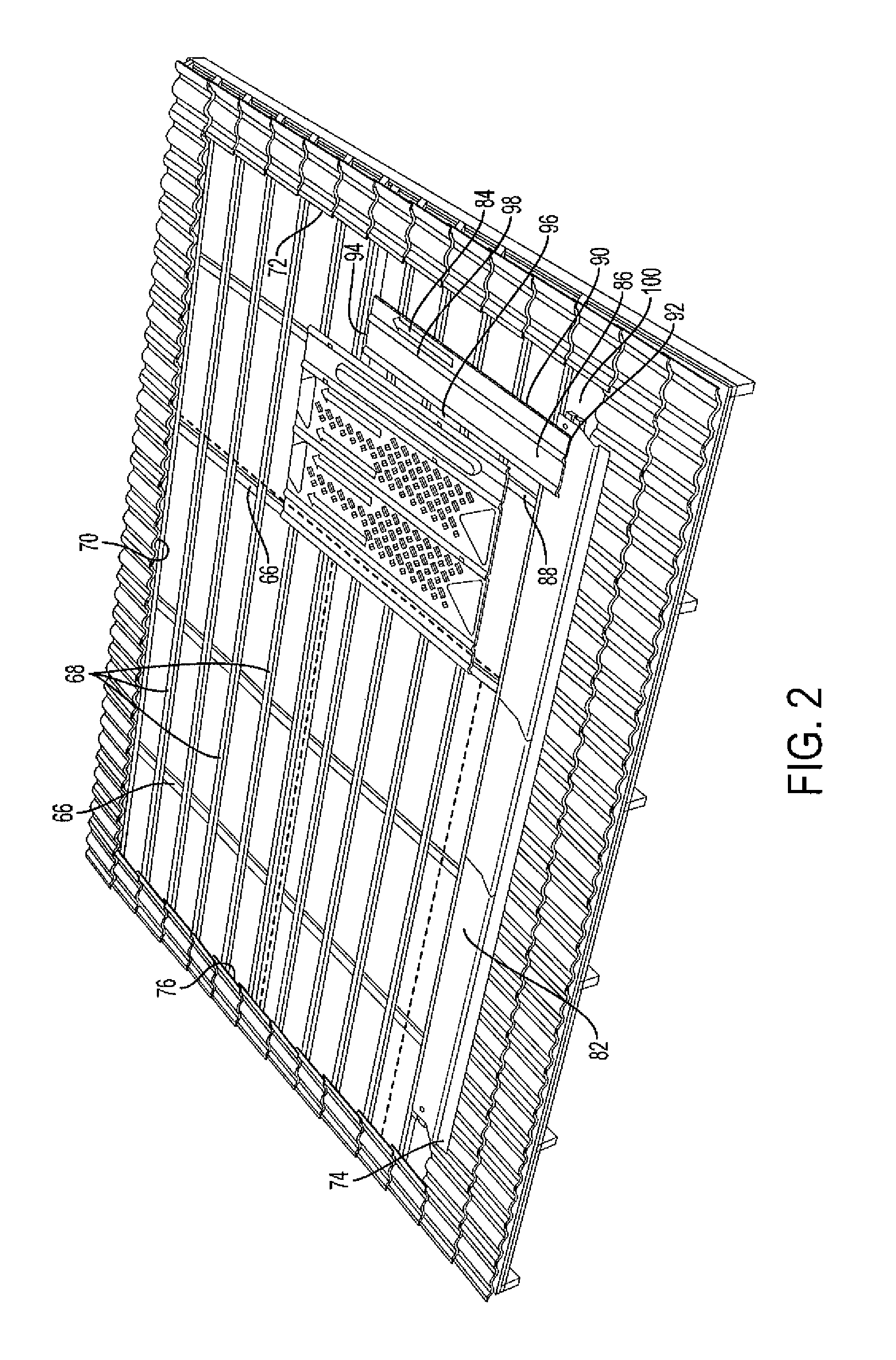

Roof panel for supporting PV modules

ActiveUS8904718B2Improve aestheticsReduce the overall heightPhotovoltaic supportsSolar heating energyEngineeringDIN rail

A panel (10) that is a roof cover for a sloped roof and that also is a mounting system for an array of PV modules (132). The panels (10) define rails (22, 24, 28, 30) that interlock with grooves (46, 48, 124, 126) to secure adjacent panels in each row of the array. The modules (132) are supported by bosses (34, 120) that determine the height of the module array and avoid the interlocking structure between the modules.

Owner:SUNPOWER CORPORATION

Surge protective device modules and din rail device systems including same

ActiveUS20180151318A1Coupling device connectionsElectrically conductive connectionsElectricityComputer module

A surge protective device (SPD) module includes a module housing, first and second module electrical terminals mounted on the module housing, a gas discharge tube (GDT) mounted in the module housing, and a fail-safe mechanism mounted in the module housing. The GDT includes a first GDT terminal electrically connected to the first module electrical terminal and a second GDT terminal electrically connected to the second module electrical terminal. The fail-safe mechanism includes: an electrically conductive shorting bar positioned in a ready position and repositionable to a shorting position; a biasing member applying a biasing load to the shorting bar to direct the shorting bar from the ready position to the shorting position; and a meltable member. The meltable member maintains the shorting bar in the ready position and melts in response to a prescribed temperature to permit the shorting bar to transition from the ready position to the shorting position under the biasing load of the biasing member. In the shorting position, the shorting bar forms an electrical short circuit between the first and second GDT terminals to bypass the GDT.

Owner:RAYCAP SURGE PROTECTIVE DEVICES LTD

Modular Terminal Block

ActiveUS20140113503A1Reduce inventory costsReduce manufacturing costElectrically conductive connectionsCoupling device detailsComputer moduleEngineering

A terminal block for mounting on a DIN rail includes a plurality of stacked modules with each module having a contact body and an extender body mounted on the contact body. A circuit board or electronic component is mounted on the contact body and the extender body. Different size extender bodies may be mounted on a common contact body to accommodate mounting different size circuit boards or components on the block.

Owner:PHOENIX CONTACT DEVMENT & MFG

Rail wiring duct

Certain embodiments of the present invention provide a DIN rail wiring duct. The DIN rail wiring duct has a top, a bottom, and a side. The DIN rail wiring duct includes a base. The base has a top wall, a bottom wall, a sidewall, and a divider wall, which define a channel and a channel opening for accessing the channel. The DIN rail wiring duct also includes a cover for the channel opening. The cover has a top wall and a sidewall substantially perpendicular to the top wall. The top wall of the cover is removably connected to the top wall of the base and the sidewall of the cover is rotatably connected to the sidewall of the base such that the channels are accessible through the channel openings from the top and the side of the DIN rail wiring duct when the cover is rotated from a closed position to an open position.

Owner:PANDUIT

Apparatus and Method for Tool Free Wall Mount Installation of a Luminaire

The wall mountable lighting fixture does not require tools to attach and remove the fixture from a wall surface. The wall mountable lighting fixture includes an attachment mechanism that can be manipulated from a first position to a second position by the push of a button. The button is pressed and the dimension of the attachment mechanism is increased and placed about the edges of a DIN rail attached to the wall. When the button is released, a biasing member returns the attachment mechanism to the first position, thereby reducing the dimension of the attachment mechanism. Once reduced, the dimension is smaller than the critical dimension of the DIN rail and either grips or rests within the DIN rail, thereby holding the fixture to the wall surface. Reversing the steps allows for the removal of the fixture from the wall for repair or replacement.

Owner:COOPER TECH CO

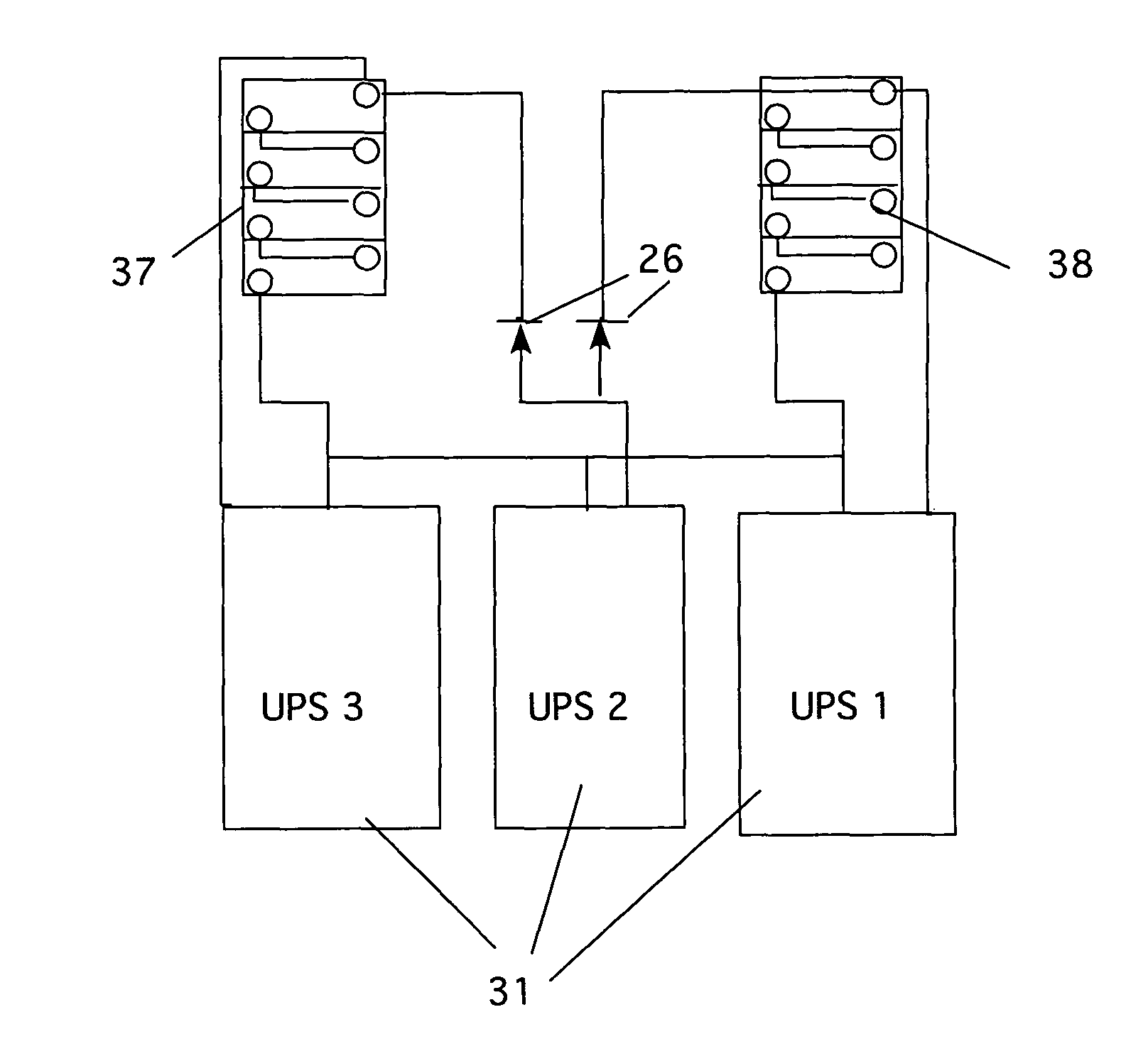

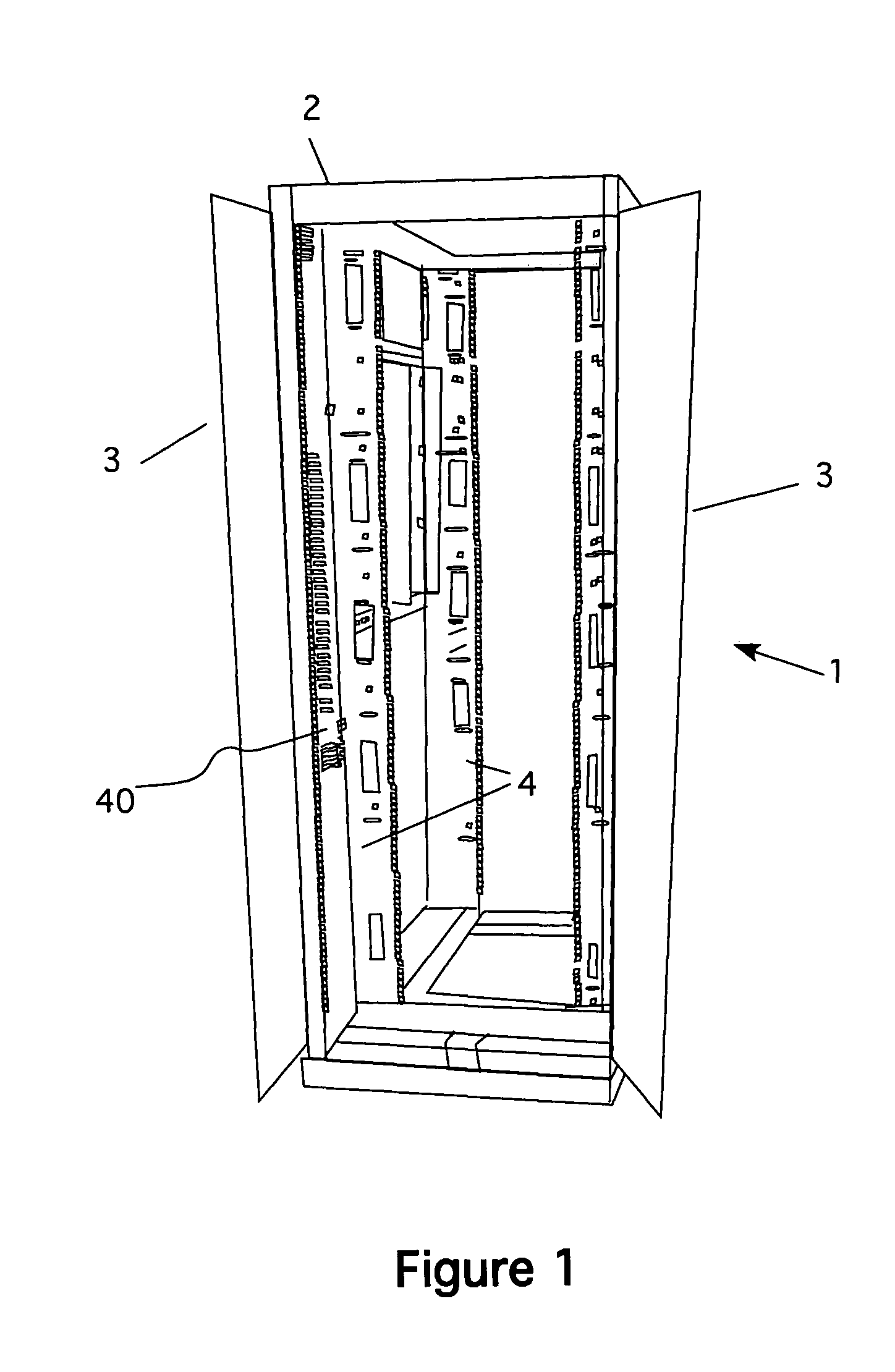

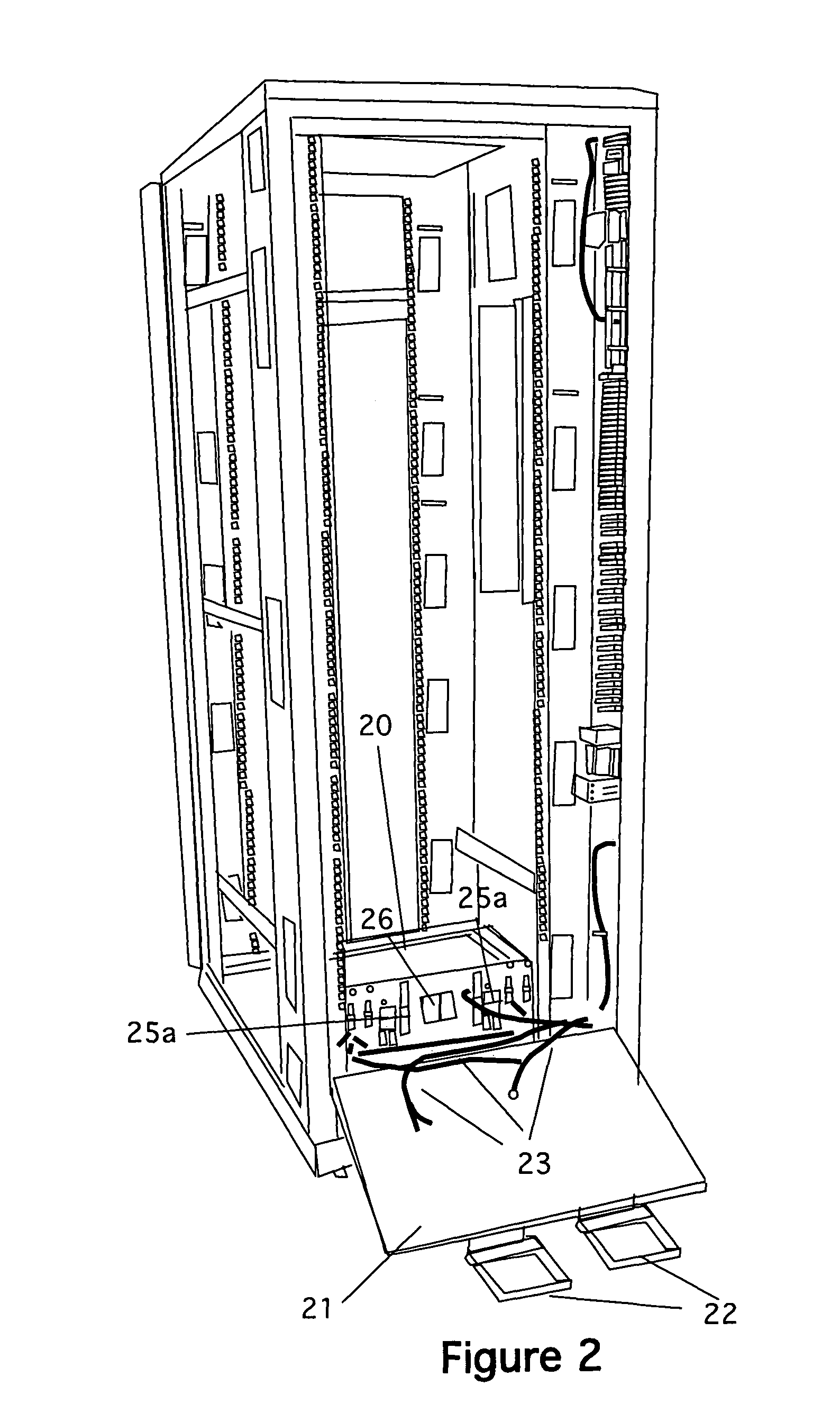

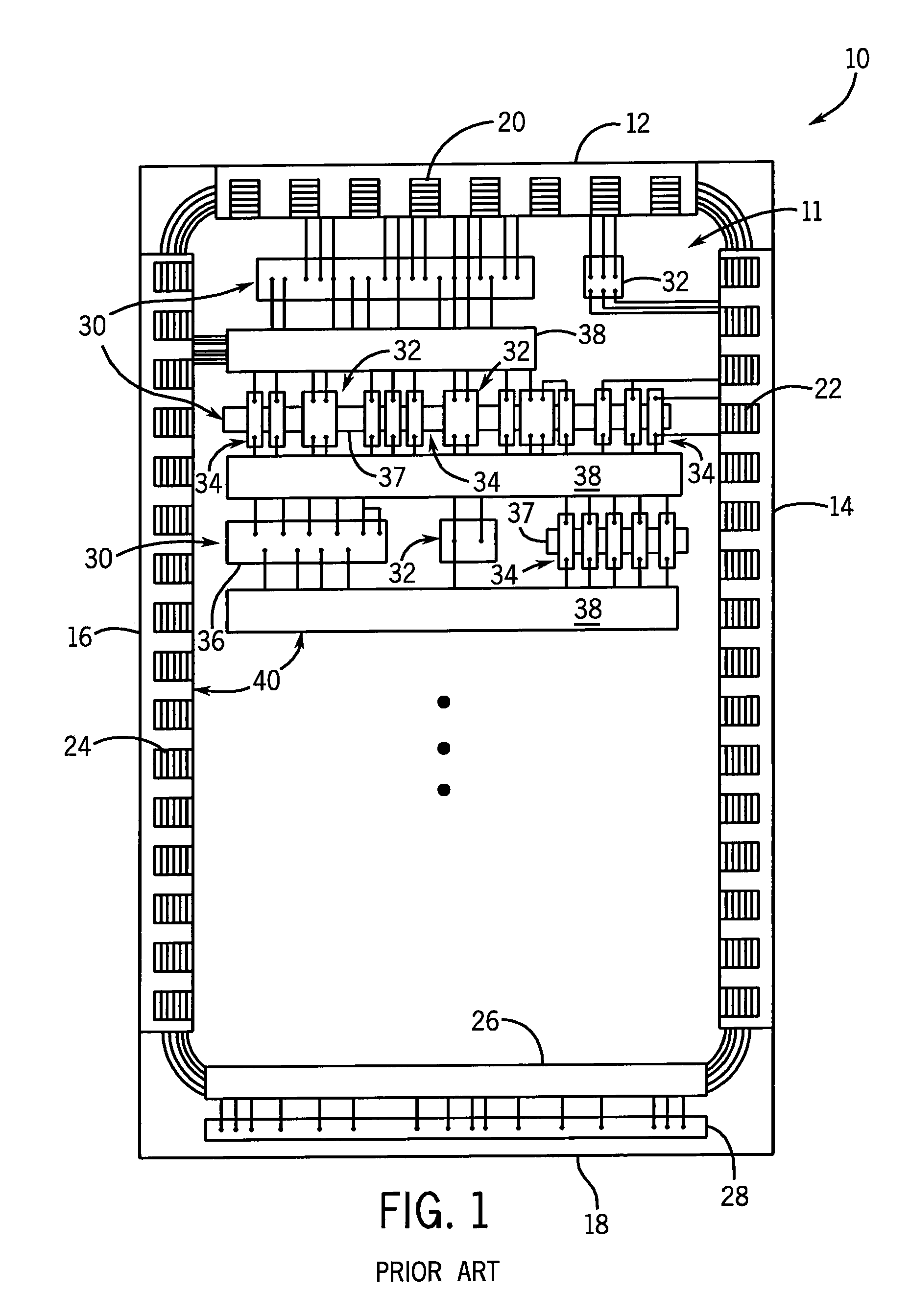

High density power supply cabinets

InactiveUS8415831B1Protection is in progressSmaller electrical feedServersBatteries circuit arrangementsHigh densityAC power

A High-Density Cabinet (HDC) that houses standard rack-mountable electronic equipment in a high-density configuration that also protects the equipment from transient electrical-supply problems. The standard HDC configuration provides up to 7,200 Watts of power at 110V or 220V AC with a backup supply lasting 30 minutes. The rack used for the HDC is approximately 2′5″ wide, 7′4″ high and approximately 3′2″ deep. The batteries in the HDC are located in the base of the HDC; the UPSs are located at the bottom of the HDC on a hinged-tray. This equipment takes up the bottom six RUs of the HDC; leaving 36 RUs available for production electronic equipment. The HDC also uses DIN-Rail blocks, which allow the safe, accessible, and unobtrusive connection of approximately 72 AC power cords into 36 sets of DIN-Rail blocks, in a space about 18″ high by 4″ wide and 2″ deep.

Owner:SEQUESTERED SOLUTIONS ALASKA

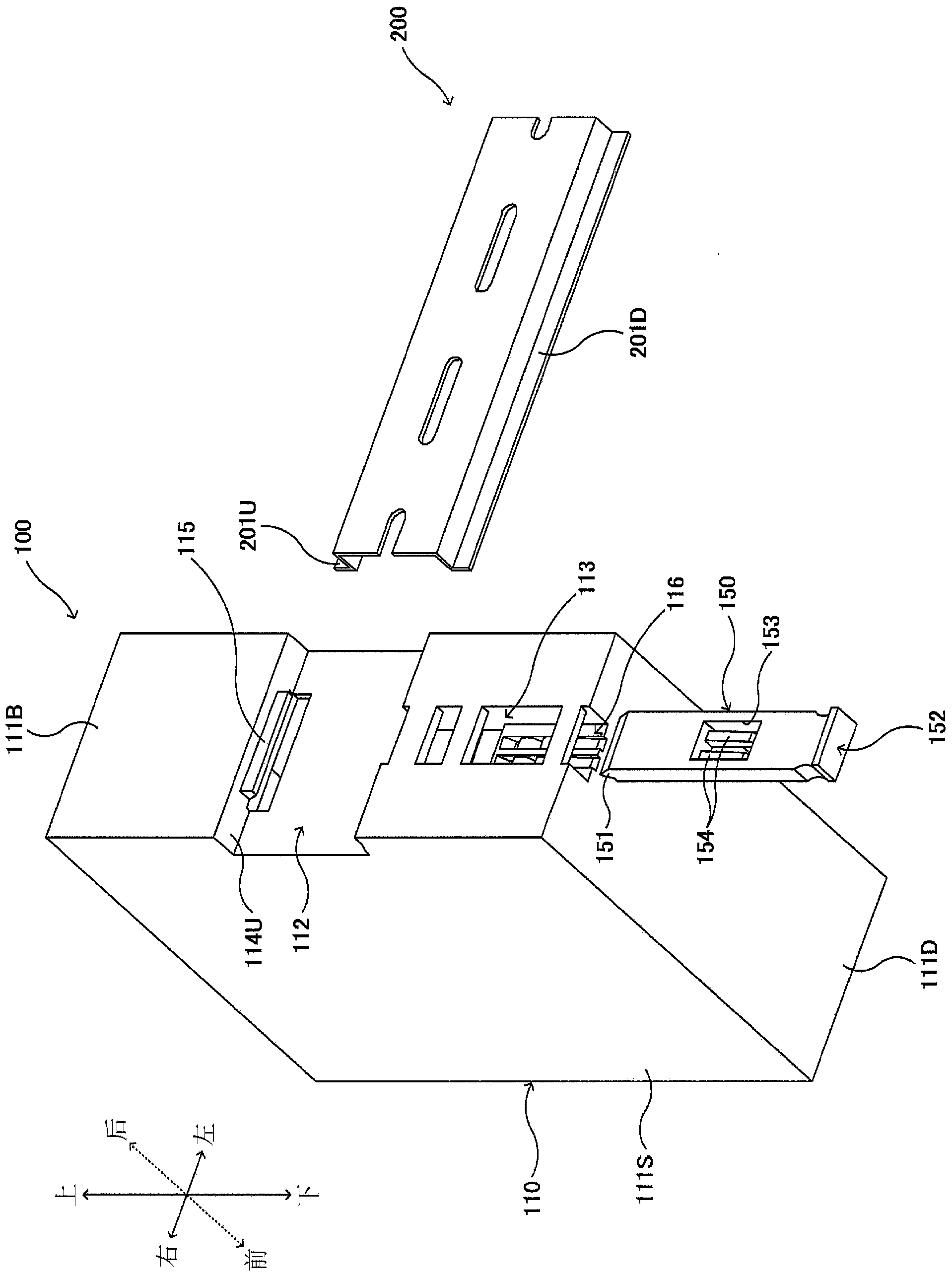

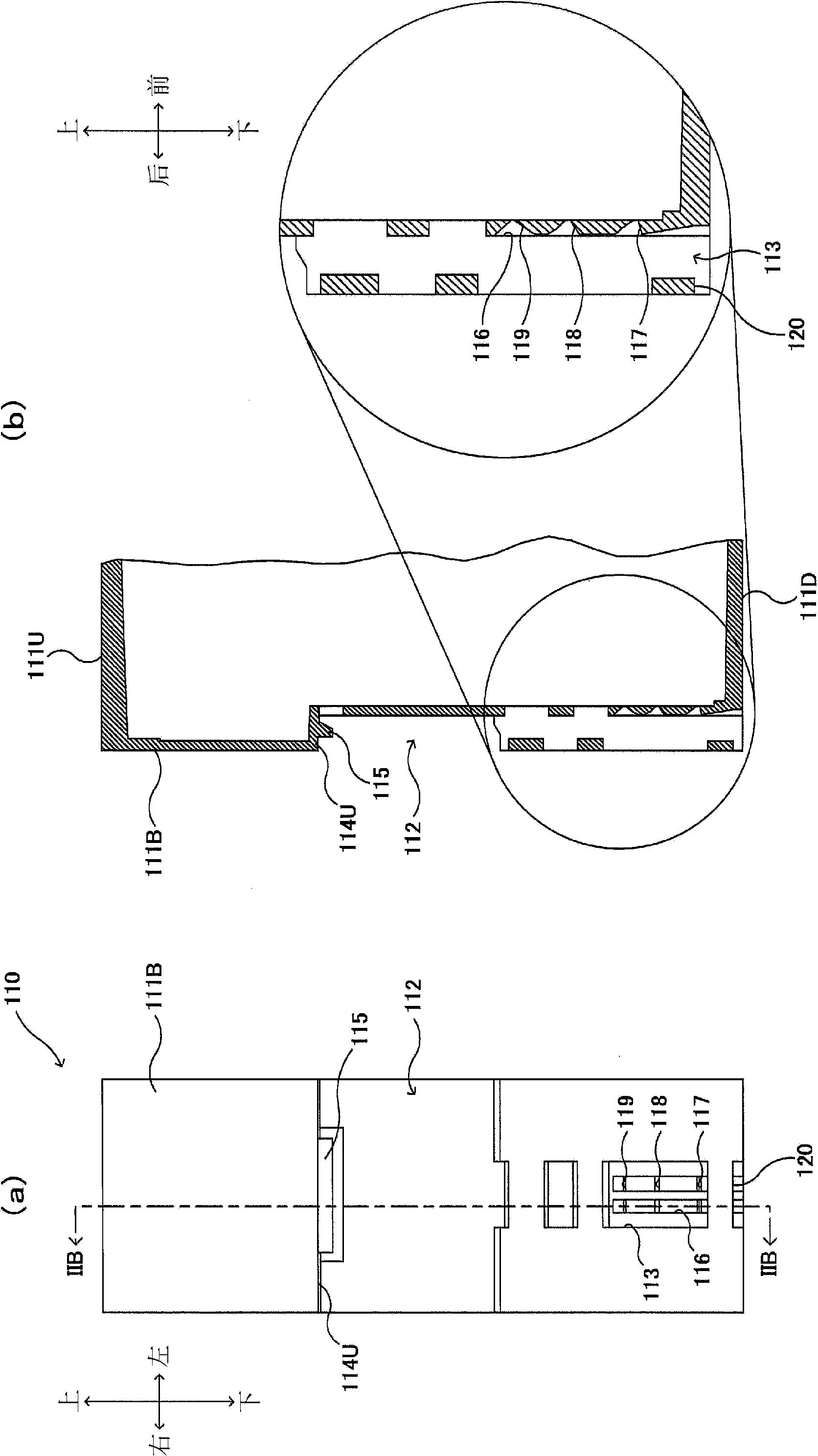

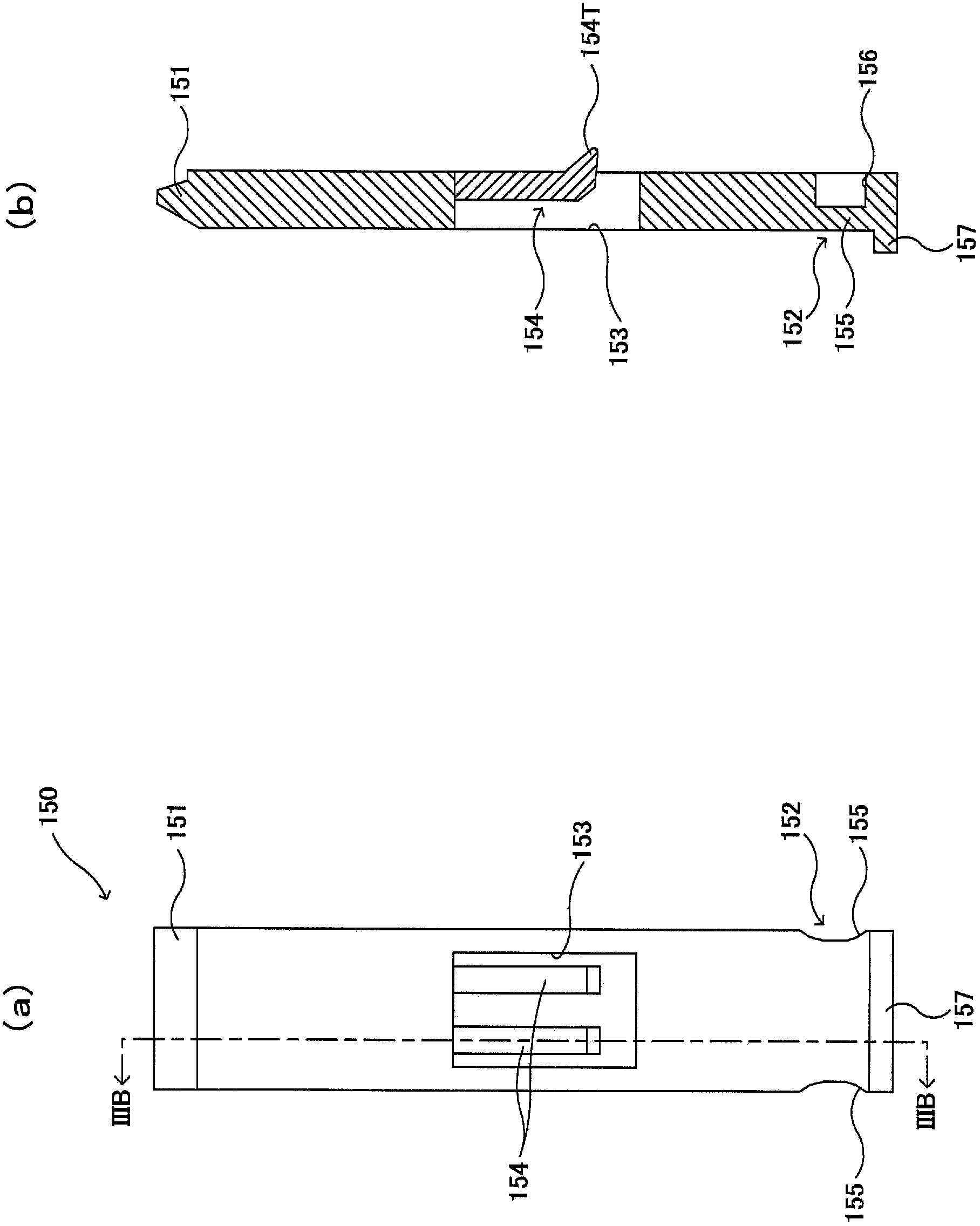

DIN-rail mount type device

ActiveCN103385041ASubstation/switching arrangement detailsResilient/clamping meansEngineeringDIN rail

In order to enable a locking member to be housed without protruding from a case, a DIN-rail mount type device (100) is equipped with a case (110), a rail groove (112) that can be fitted to a DIN rail (200), a slider groove (113), and a locking member (150). The locking member (150) is configured such that the locking member can be moved between a locked position at which the engagement-side end section (151) protrudes into the rail groove (112) from the slider groove (113) and the manipulation-side end section (152) protrudes from the case (110), and a housed position at which the engagement-side end section (151) protrudes into the rail groove (112) from the slider groove (113) and the manipulation-side end section (152) is housed inside the slider groove (113); the fitted state of the rail groove (112) and the DIN rail (110) can be maintained by letting the engagement-side end section (151) engage with the lower engagement piece section (201D) of the DIN rail (200) at the locked position; and the movement to the housed position is enabled only when the DIN rail (110) is not fitted to the rail groove (112).

Owner:YASKAWA DENKI KK

Mounting for industrial instrumentation

ActiveUS8003899B2Easy and convenientSubstation/switching arrangement detailsCoupling device detailsComputer moduleModularity

A flexible, modular mounting system for an industrial process terminal or similar instrumentation. The instrumentation may be panel mounted or DIN rail mounted using an enclosure having only a minimum number of unique components. An instrument housing is included for containing various electronic components of such a terminal. The housing is adapted to mate with a DIN rail, and can easily be fitted with mounting brackets that allow the housing to be used in a panel mounted arrangement. In the latter case, a user interface module is located on an opposite side of a panel wall and connected to the appropriate electronic components of the instrumentation through an opening provided therein.

Owner:METTLER TOLEDO INC

DIN rail latching arrangement

ActiveUS9331404B2Easy to pullCoupling device connectionsElectrically conductive connectionsEngineeringDIN rail

Owner:ASCO POWER TECH LP

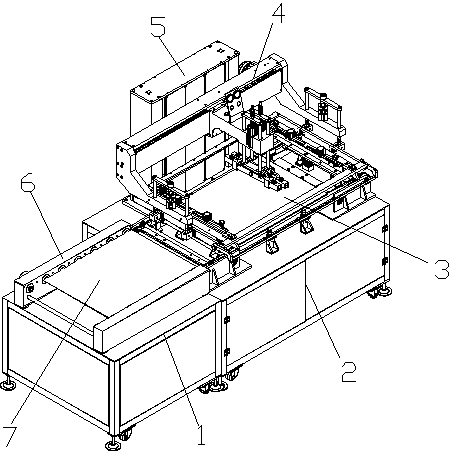

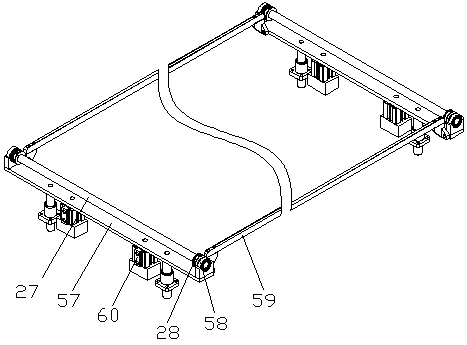

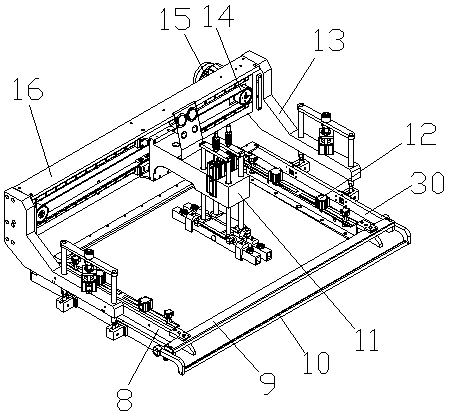

Full-automatic silk-screen printer

InactiveCN108274882AGuaranteed uptimeEasy maintenanceScreen printersPrinting press partsDistribution controlEngineering

The invention relates to the technical field of screen printing, in particular to a full-automatic silk-screen printer. The printer comprises a machine frame, a power distribution control cabinet, a feeding driving device and a feeding rail, wherein the feeding driving device and the feeding rail are arranged on the machine frame and are matched with each other; a printing mechanism is arranged onthe machine frame and on the right side of the feeding rail, and the printing mechanism comprises a lifting stand column set, a printing transmission device and a printing head arranged on the printing transmission device; and a carrier transmission device matched with the feeding rail is arranged on the machine frame and below the printing head. The full-automatic silk-screen printer is accuratein positioning, good in printing quality, stable in operation, easy to maintain and high in cost performance and accuracy.

Owner:邓君

DIN rail mounted enclosure assembly and method of use

A mounting enclosure assembly configured to mount an electronic component onto a DIN rail. The mounting enclosure assembly includes a mounting bracket having a slot configured to receive the DIN rail therein. The mounting enclosure assembly further includes a locking mechanism configured to selectively engage the DIN rail. The locking mechanism includes a release button and a protrusion positioned proximate the slot and configured to releasably engage a first flange of the DIN rail. The locking mechanism further includes a first hinged armature connected to the release button and the first protrusion, wherein the first protrusion is configured to disengage the first flange of the DIN rail when the release button is depressed. Other embodiments of the mounting enclosure assembly, as well as methods directed to the mounting enclosure assembly, are further disclosed.

Owner:SCHNEIDER ELECTRIC BUILDINGS AMERICAS INC

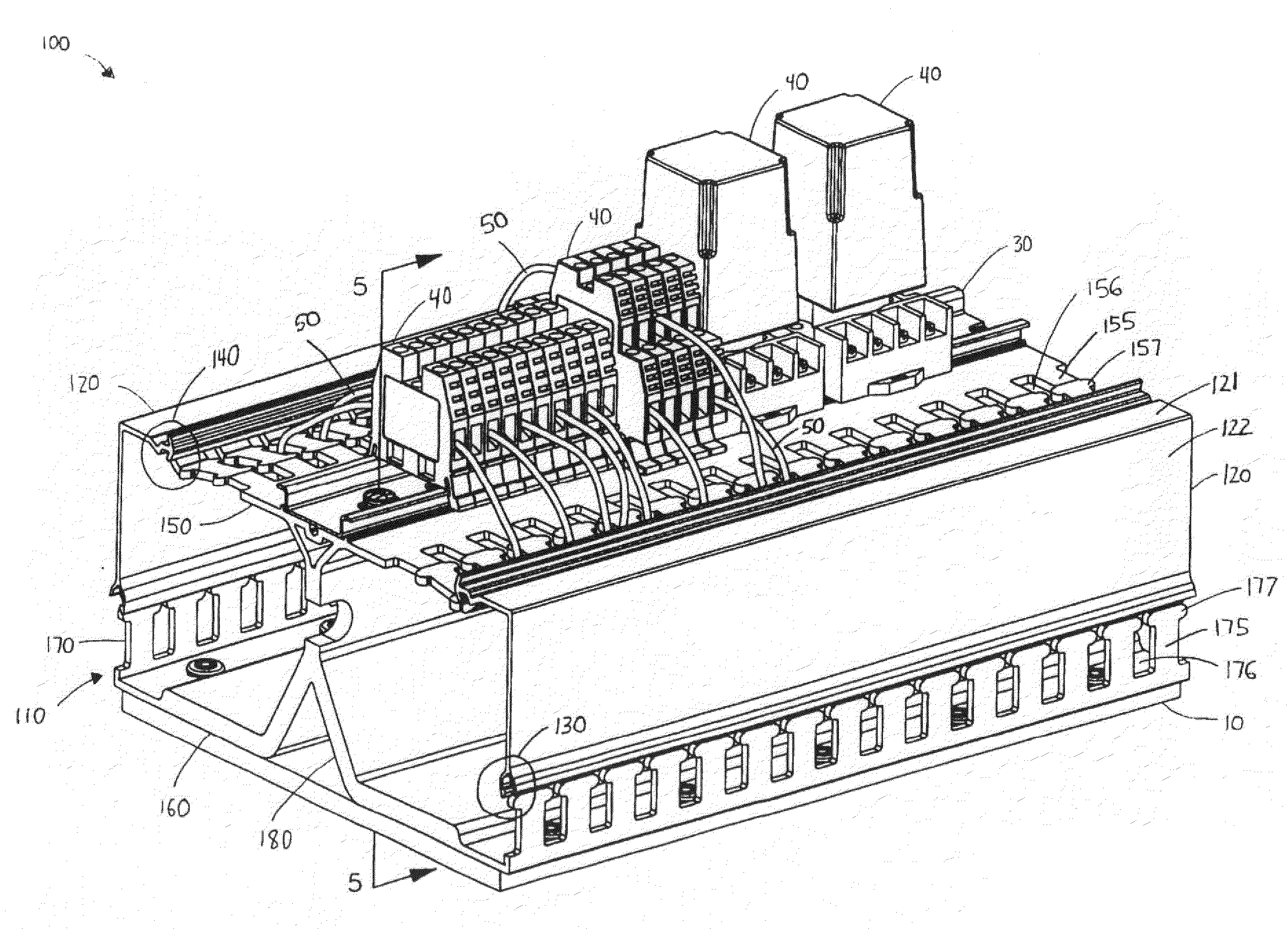

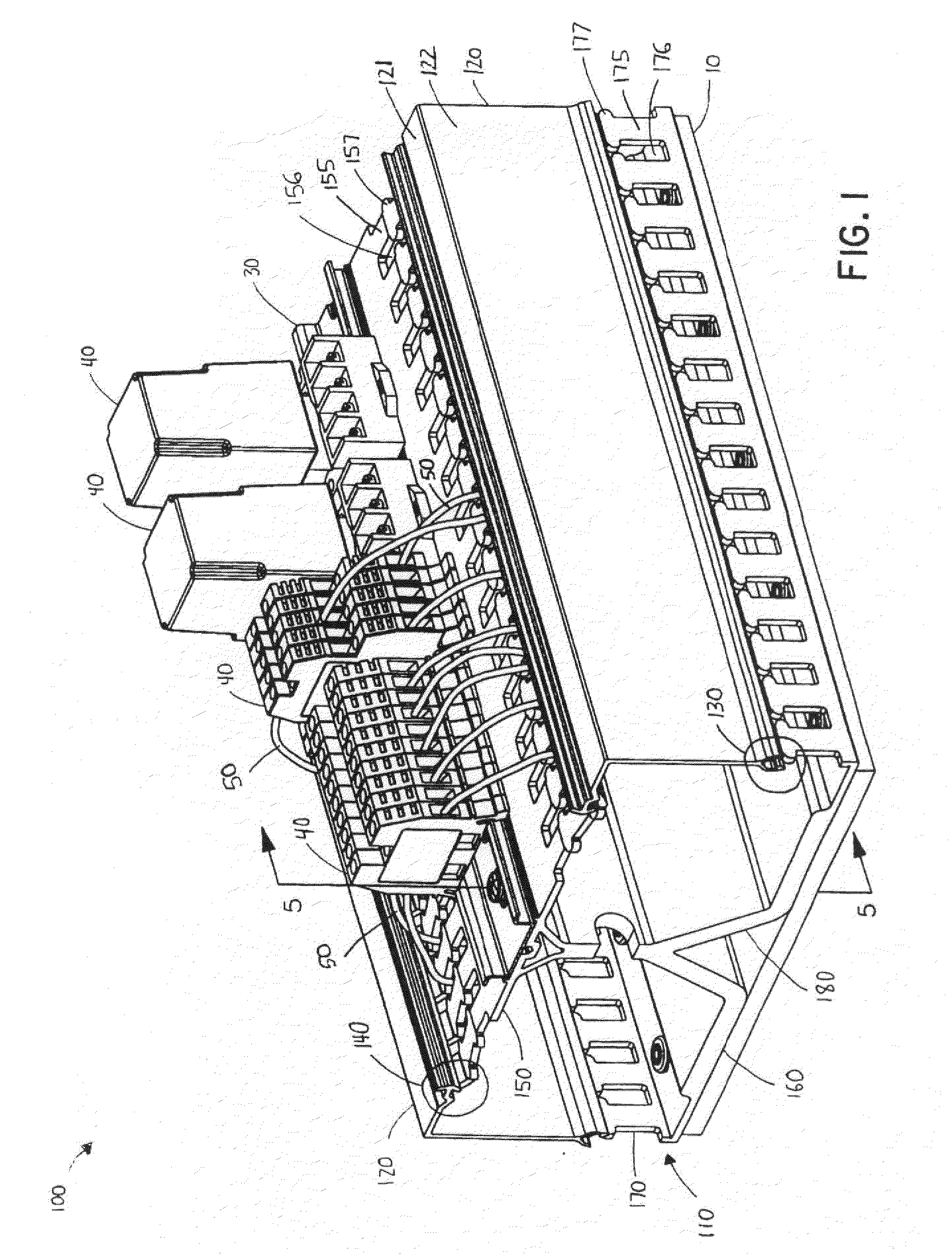

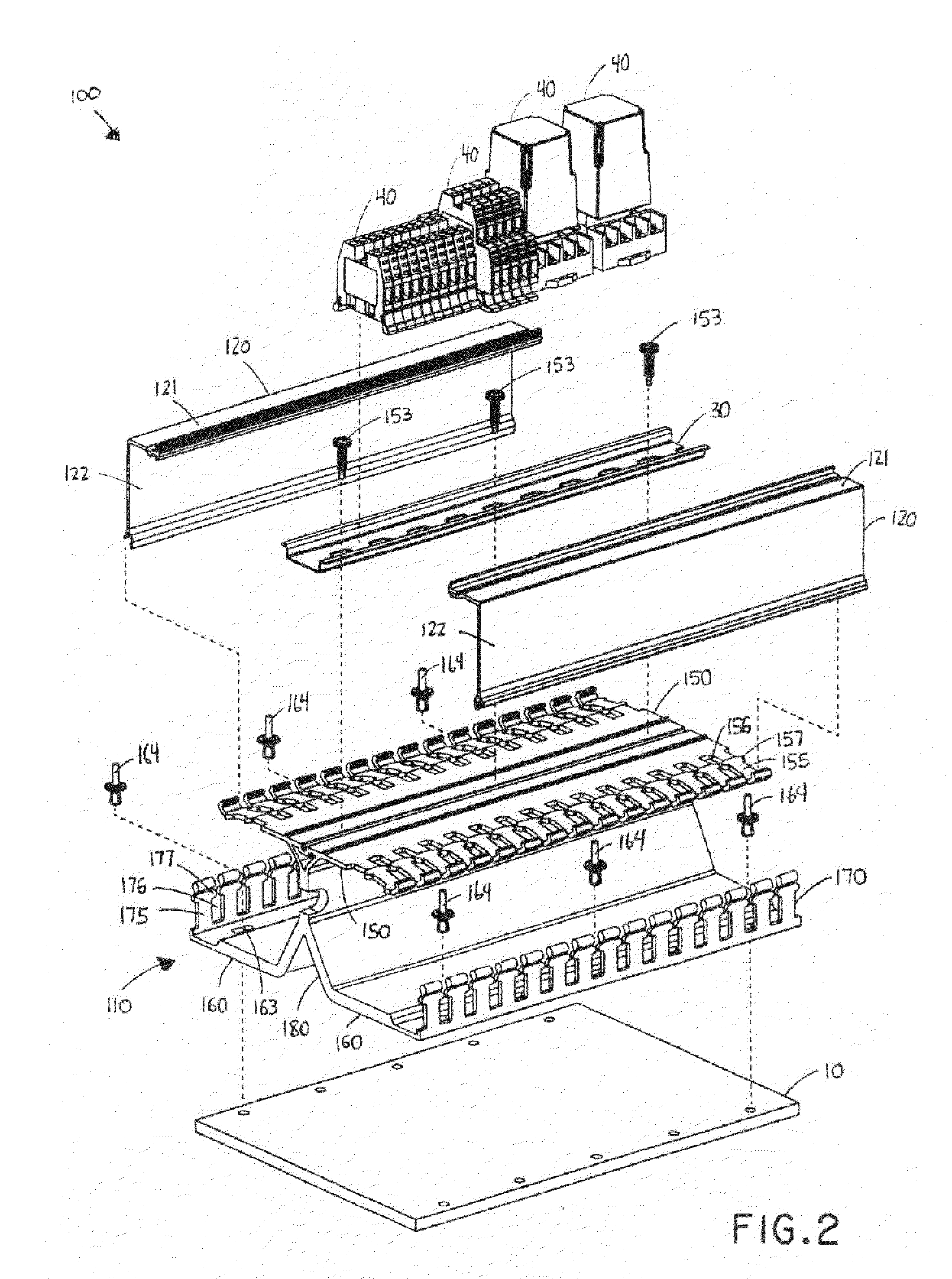

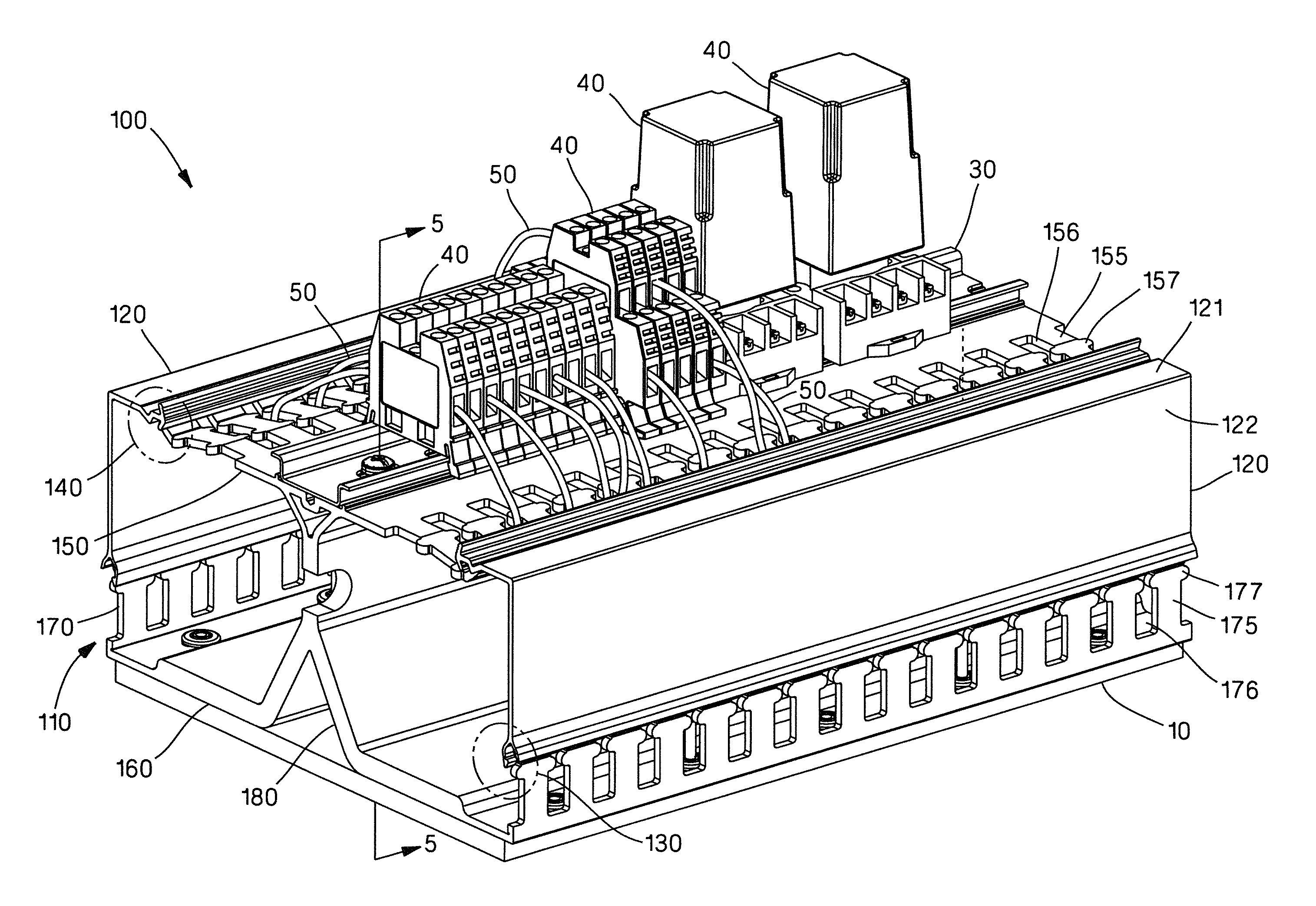

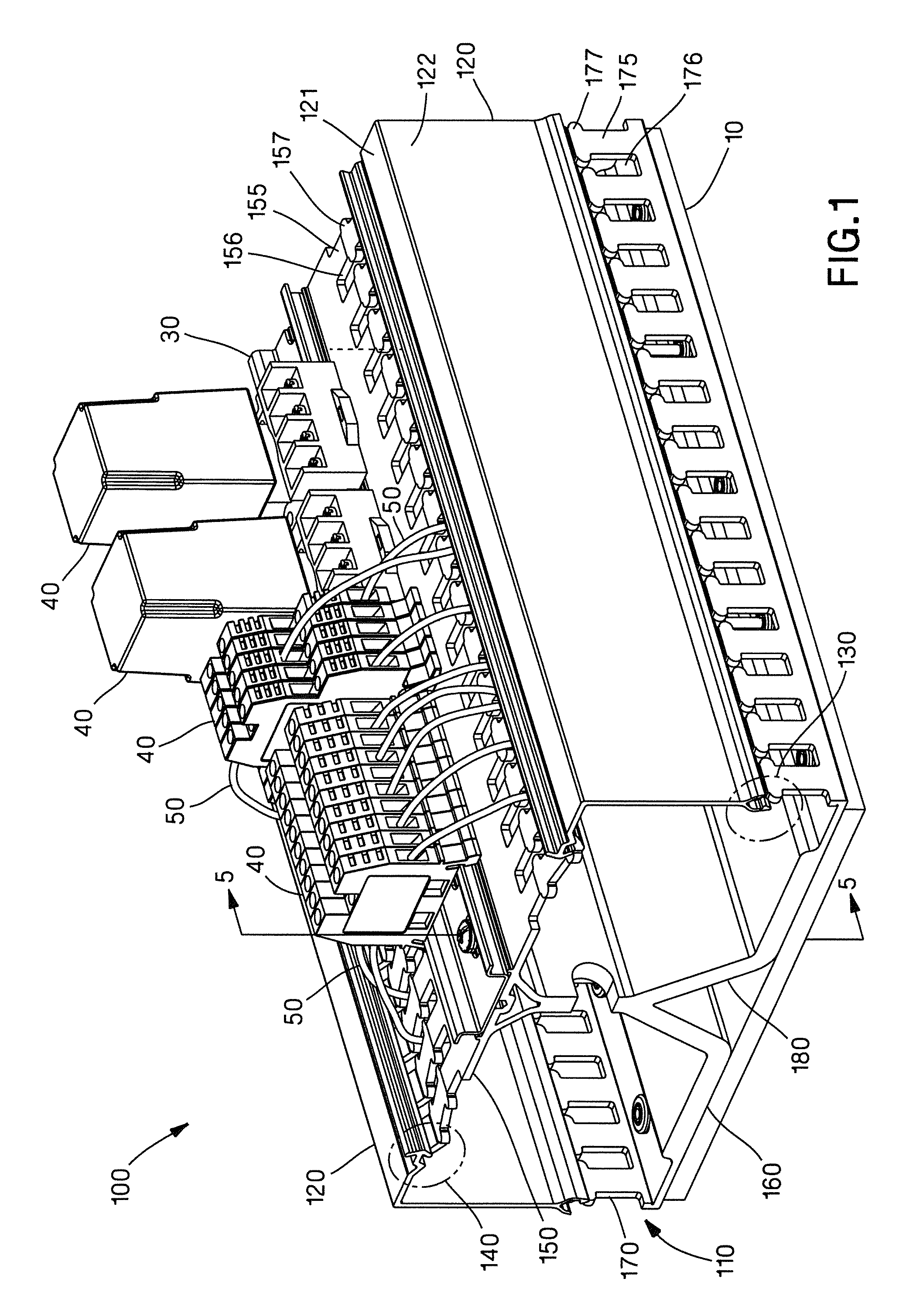

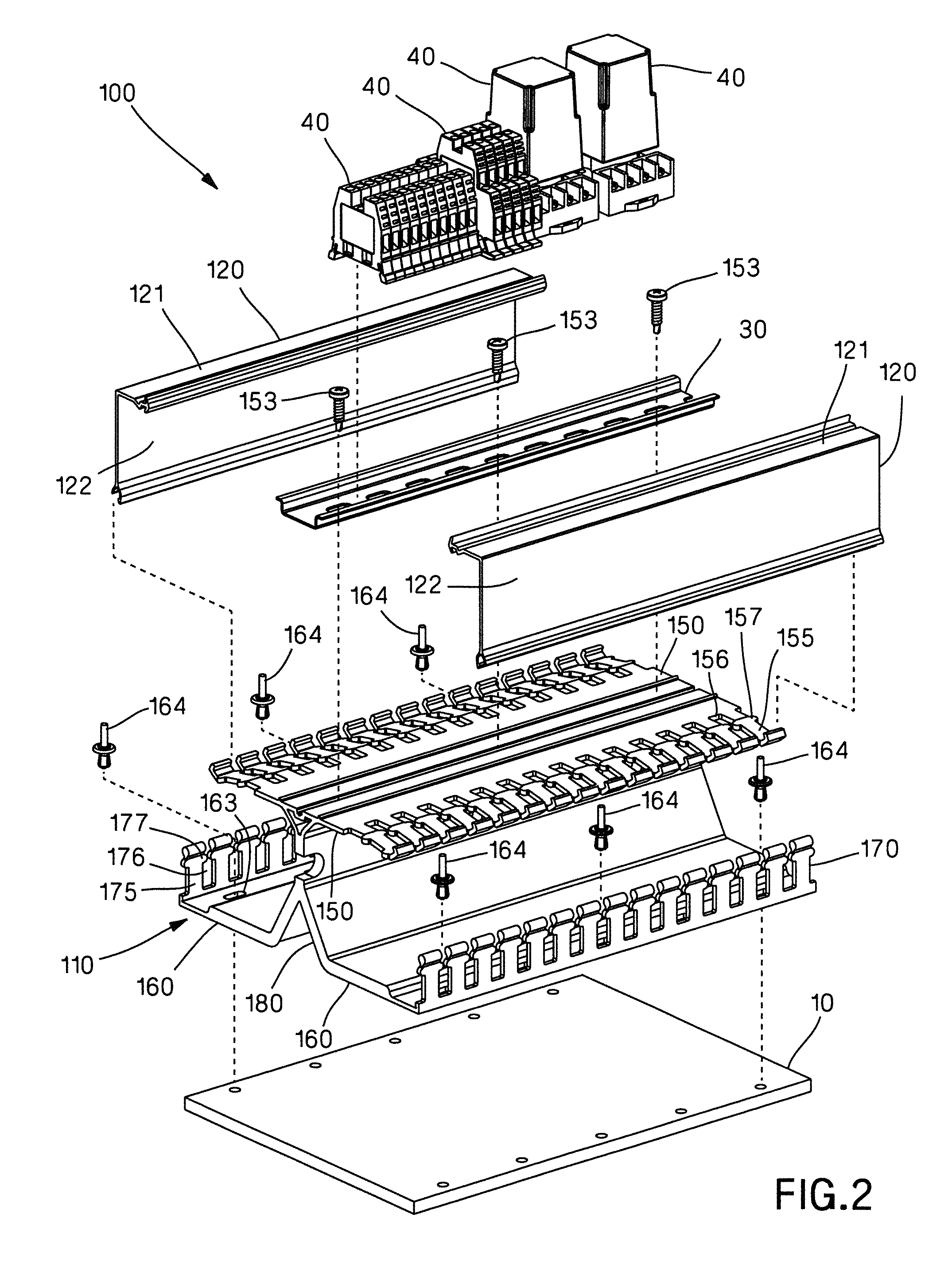

Wire management system with integrated din rail and selectively accessible wire

ActiveUS20090050345A1Overcomes drawbackExpand accessElectrically conductive connectionsSubstation/switching arrangement detailsEngineeringManagement system

A wiring system includes a first mounting bracket and a second mounting bracket having respective mounting flanges configured to secure the first and second mounting brackets to a mounting surface. The first and second mounting brackets extend away from the mounting surface to a distal end where a hinge is formed. The wiring system also includes a DIN rail supported above the mounting surface by the first and second mounting brackets through the respective hinges such that the DIN rail is rotatable about the hinges along an axis of rotation extending between the first and second mounting brackets to provide access to a wire passage extending parallel to the axis of rotation under the DIN rail and through the first and second mounting brackets.

Owner:ROCKWELL AUTOMATION TECH

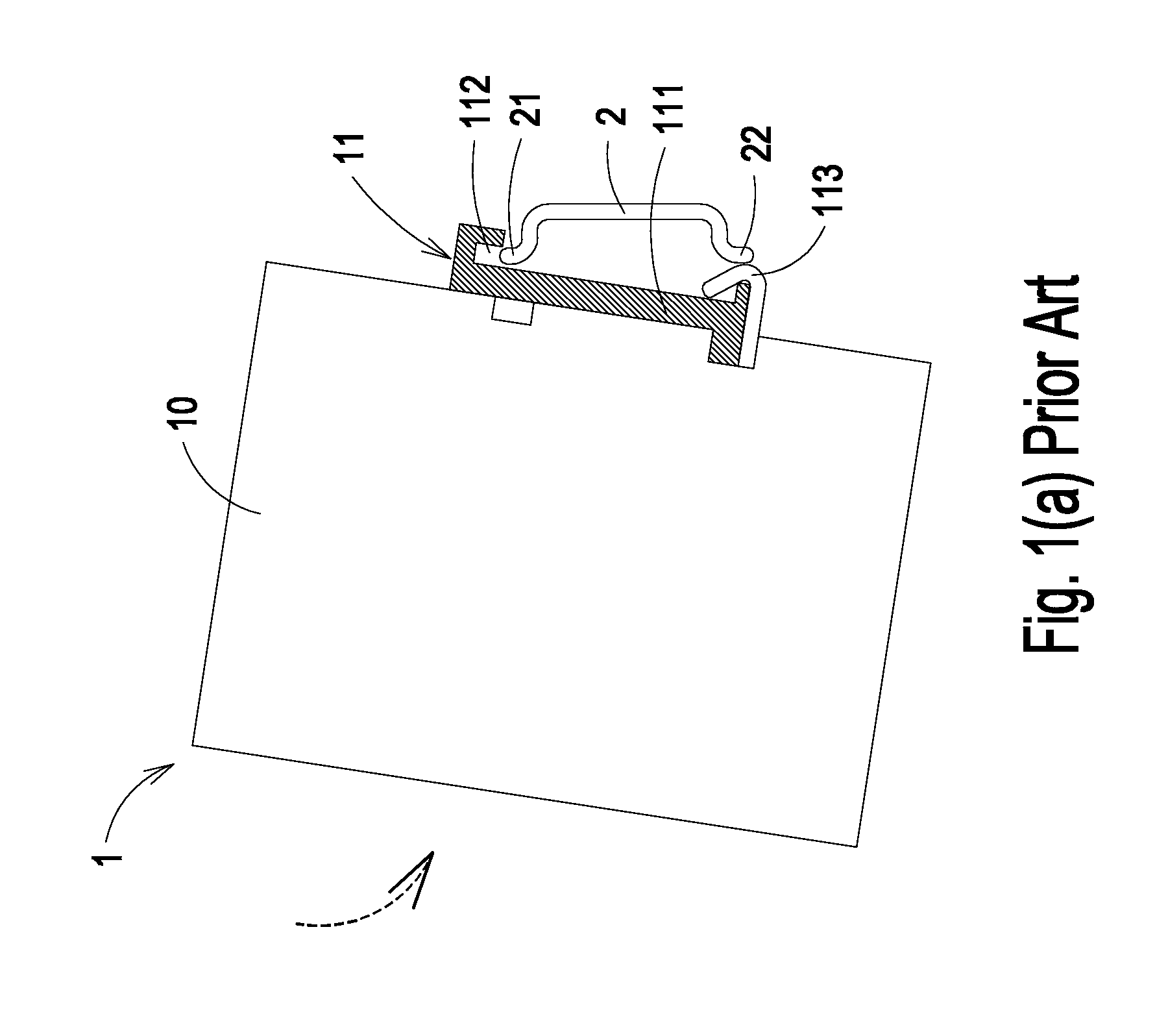

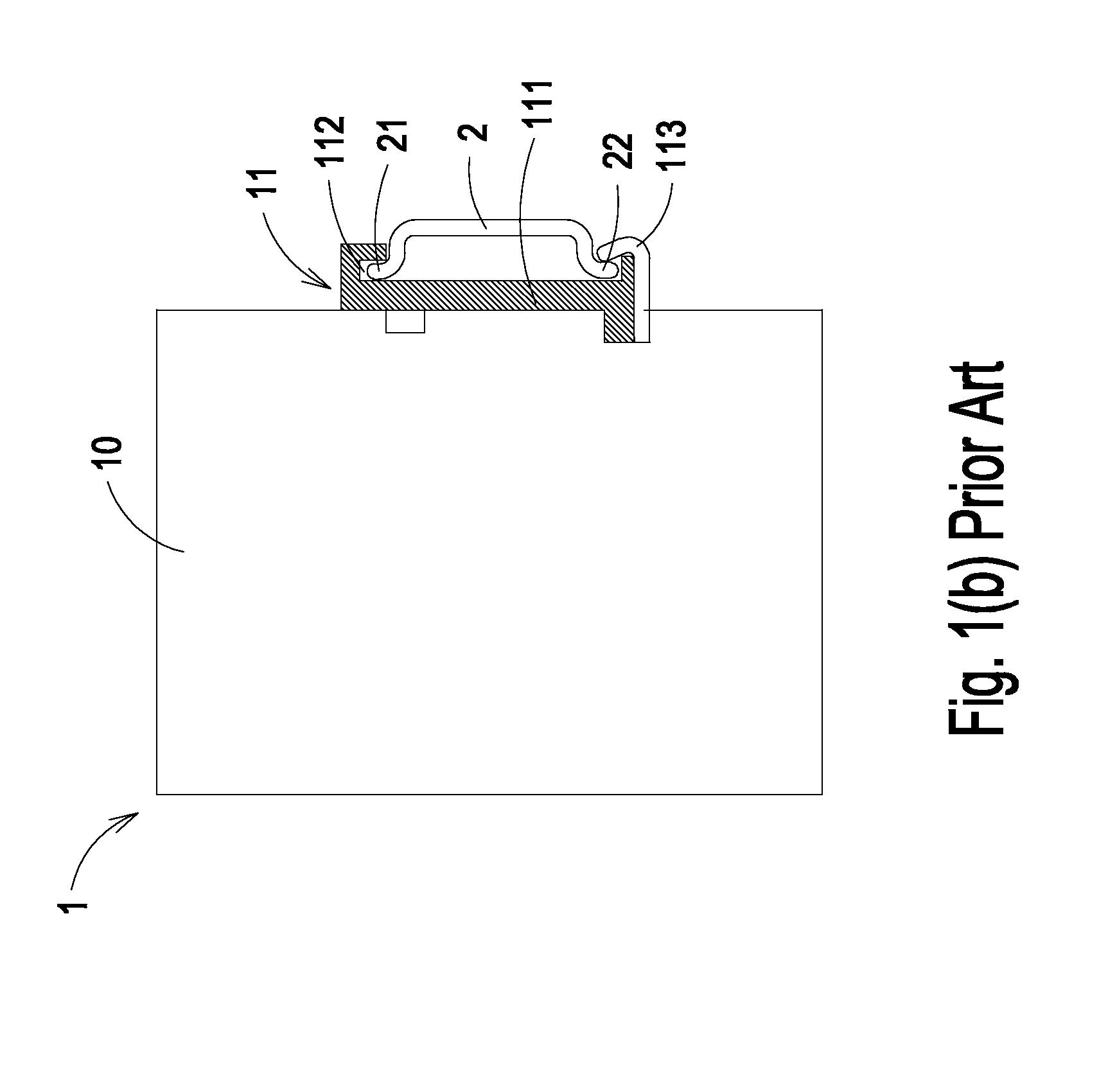

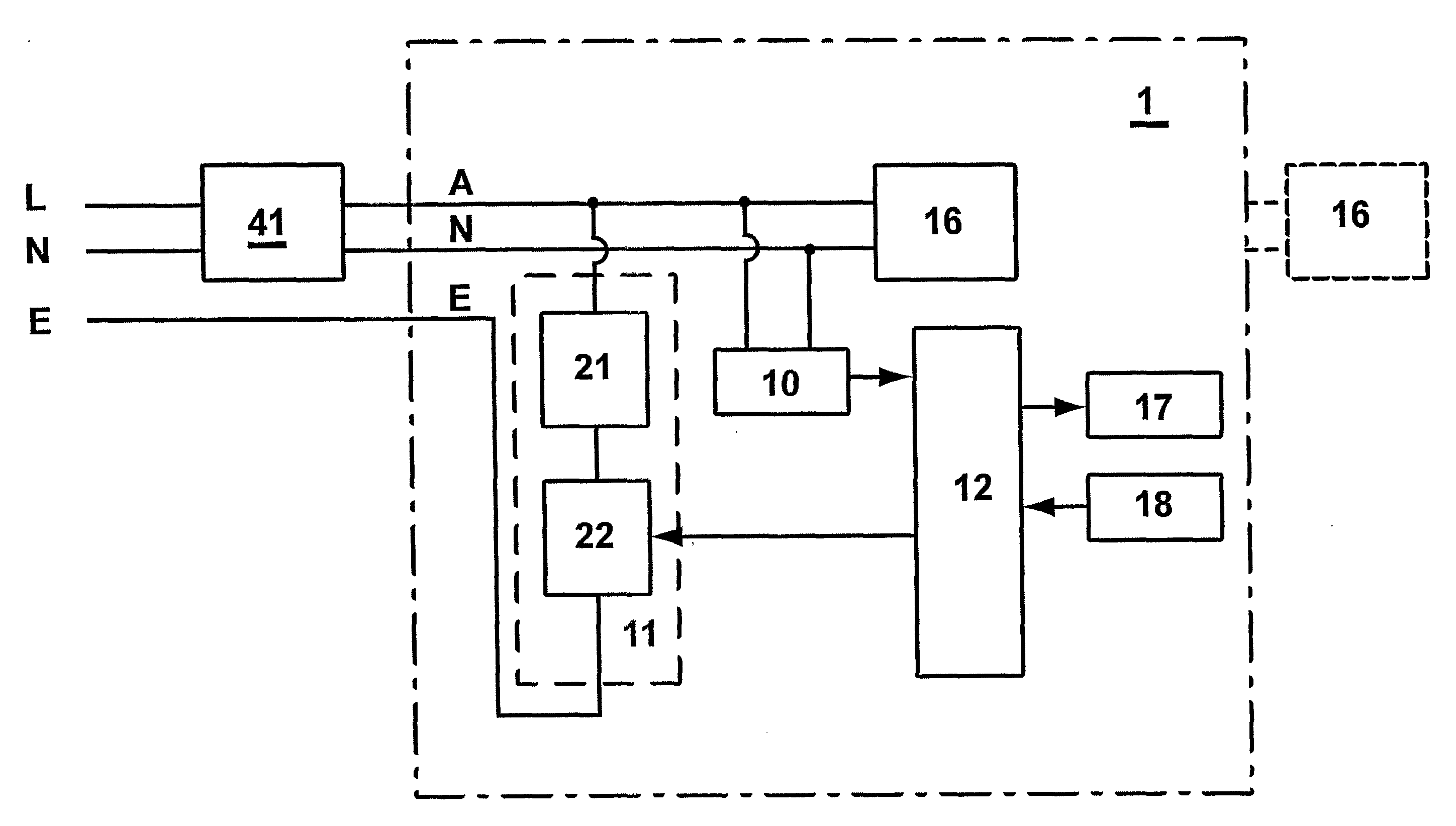

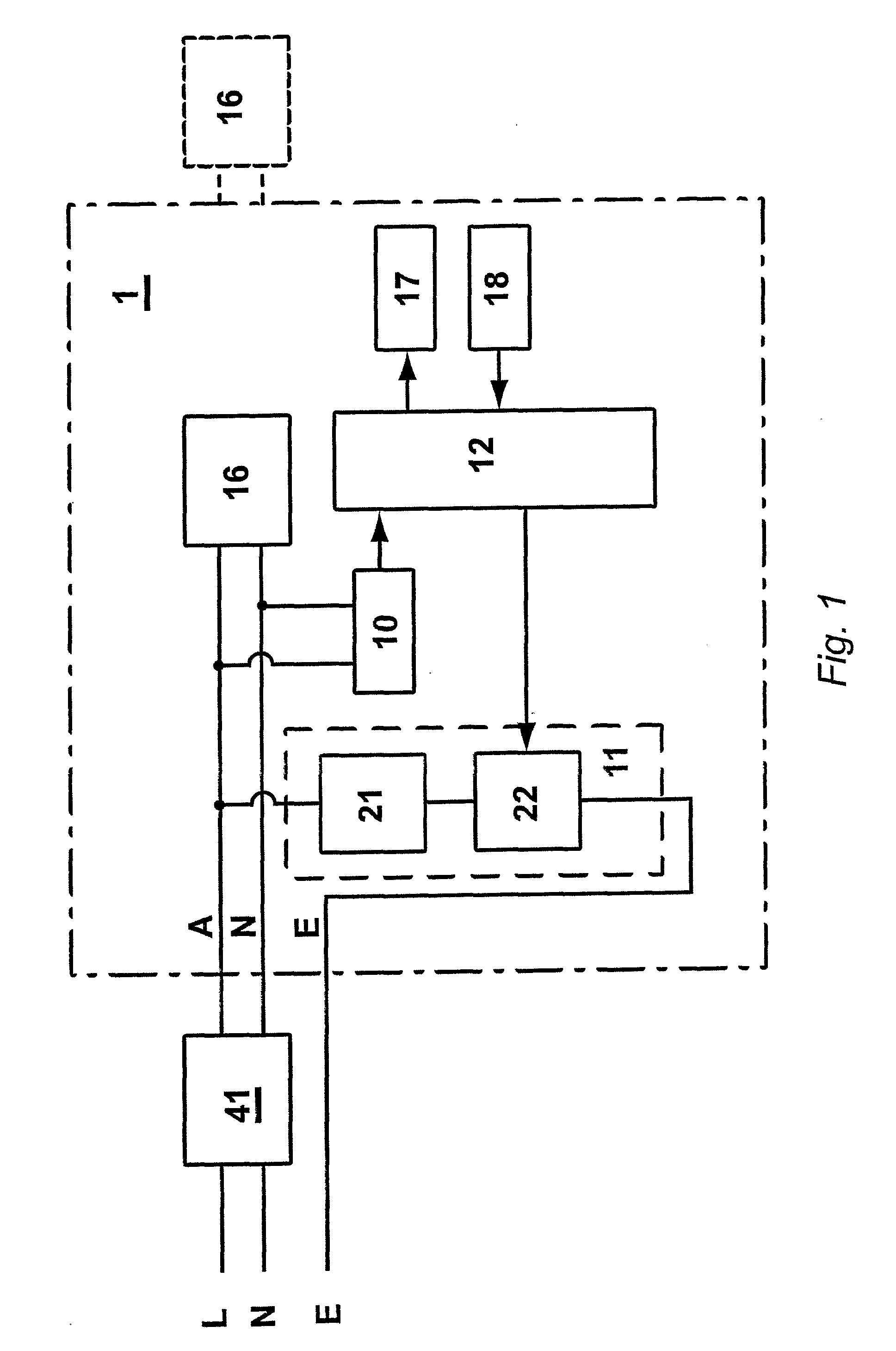

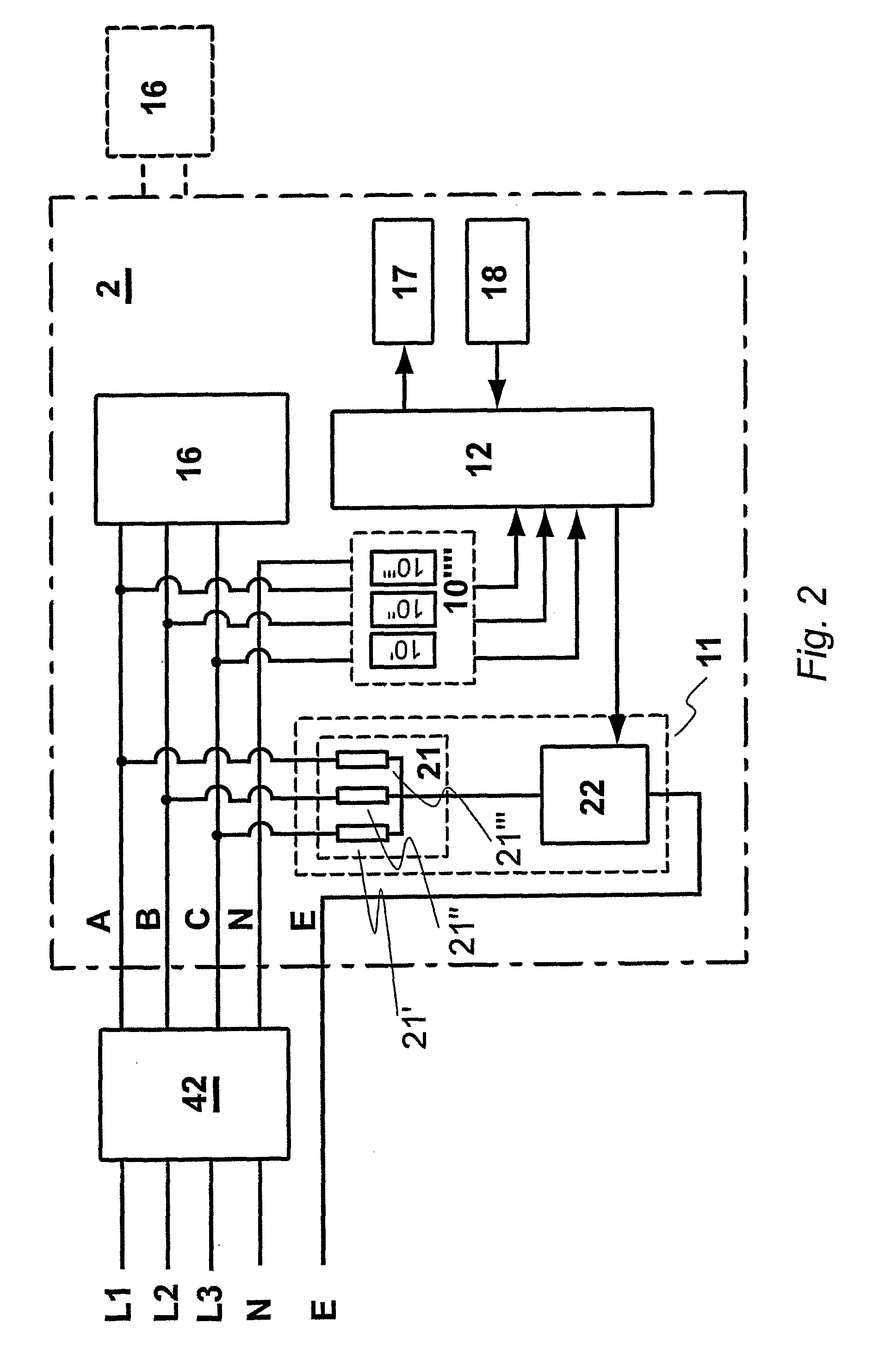

Overvoltage and/or undervoltage protection device

InactiveUS20100033887A1Avoid disruptionPortable and convenient to useEmergency protective arrangements for limiting excess voltage/currentArrangements responsive to excess voltageOvervoltageThree-phase

The overvoltage and / or undervoltage protection device (1, 2) of this invention provides a novel way in solving the problems faced by user of an existing electrical installation zone when the user adds overvoltage and / or undervoltage protection feature into the existing electrical installation. One of the key features of the invention is the tripping initiation circuit (11) that simulates an earth leakage condition to trip the earth leakage protection device (41, 42) installed in the existing electrical installation zone when an overvoltage and / or undervoltage condition is detected by the decision logic (12) of the overvoltage and / or undervoltage protection device (1, 2) of this invention. The single phase overvoltage and / or undervoltage protection device (1) of this invention can be packaged as a three-prong plug to facilitate the use of the device while, the three phase overvoltage and / or undervoltage protection device (2) can be packaged as a single DIN rail mounted device. The overvoltage and / or undervoltage protection device (1, 2) can be further provided with a test button to test integrity of the earth leakage protection device (41, 42), the overvoltage and / or undervoltage protection device (1, 2) of this invention and the wiring connections and / or annunciator to indicate the user that the tripping was caused by overvoltage or undervoltage.

Owner:FONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com