Automatic feeding and clamping device applied to sponge cutting mechanism

An automatic feeding and sponge cutting technology, which is applied in metal processing and other directions, can solve the problems of lower production efficiency, no device capable of cutting circles, and low accuracy of manual cutting circles, achieving good results and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

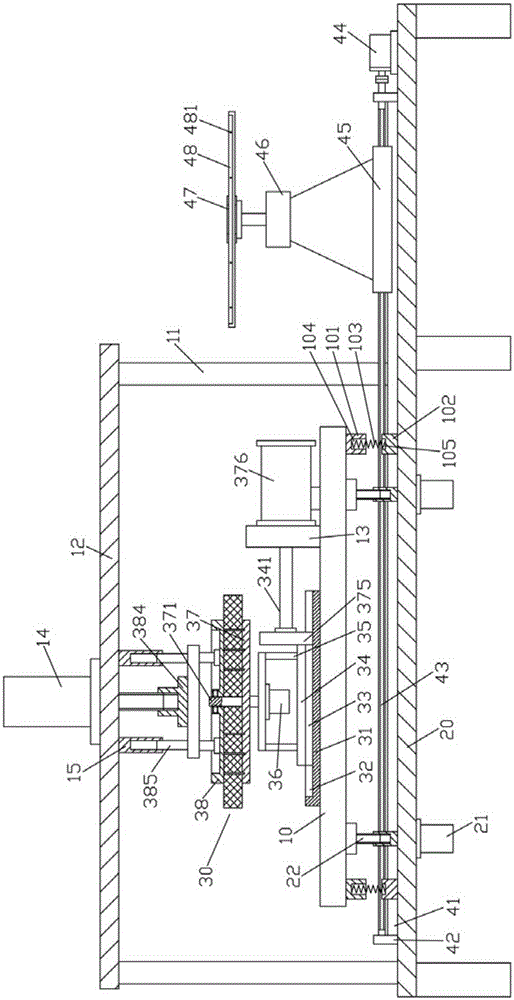

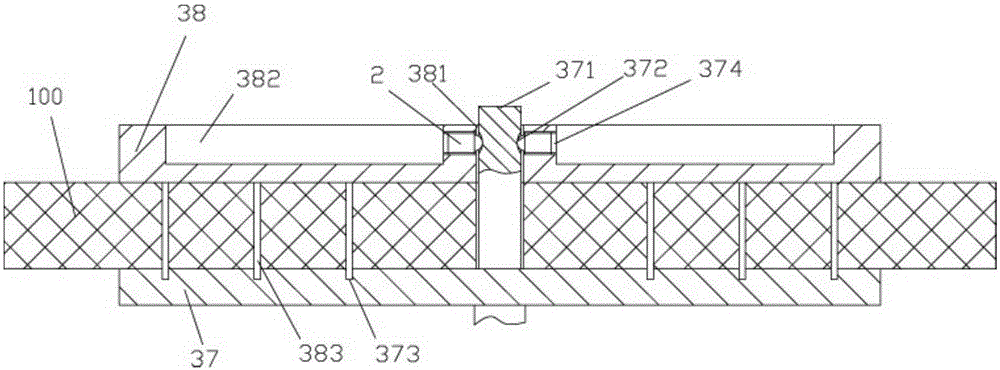

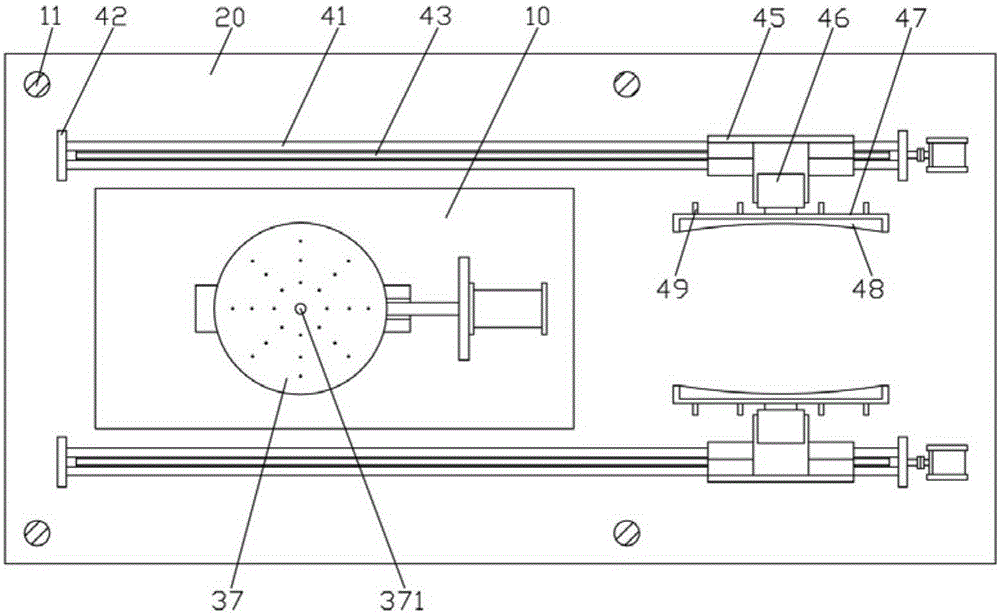

[0019] Examples, see e.g. Figure 1 to Figure 4 As shown, a kind of automatic feeding clamping device for sponge cutting mechanism includes a frame 20, a plurality of lifting motors 21 are fixed on the top plate of the frame 20, and the output shafts of the lifting motors 21 extend upwards from the top plate and screw Connected with a lifting screw 22, the lifting screw 22 is fixed on the bottom surface of the bottom lifting plate 10, a sliding track 31 is fixed on the top surface of the bottom lifting plate 10, and a pillar 11 and two feeding tracks 41 are fixed on the edge of the top plate of the frame 20 , the feed track 41 is at the front and rear sides of the lifting motor 21, the two ends of the feed track 41 are fixed with vertical support adjustment plates 42, and the two ends of the feed screw 43 are hinged on the two vertical support adjustment plates 42, and the frame 20 The right end of the top plate is fixed with a feeding motor 44, the output shaft of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com