DIN-rail mount type device

A technology of rails and sliders, applied in the directions of support structure installation, elastic/clamping device, circuit layout on support structure, etc., can solve problems such as inability to place DIN rail mounted devices horizontally, damage to locking members, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

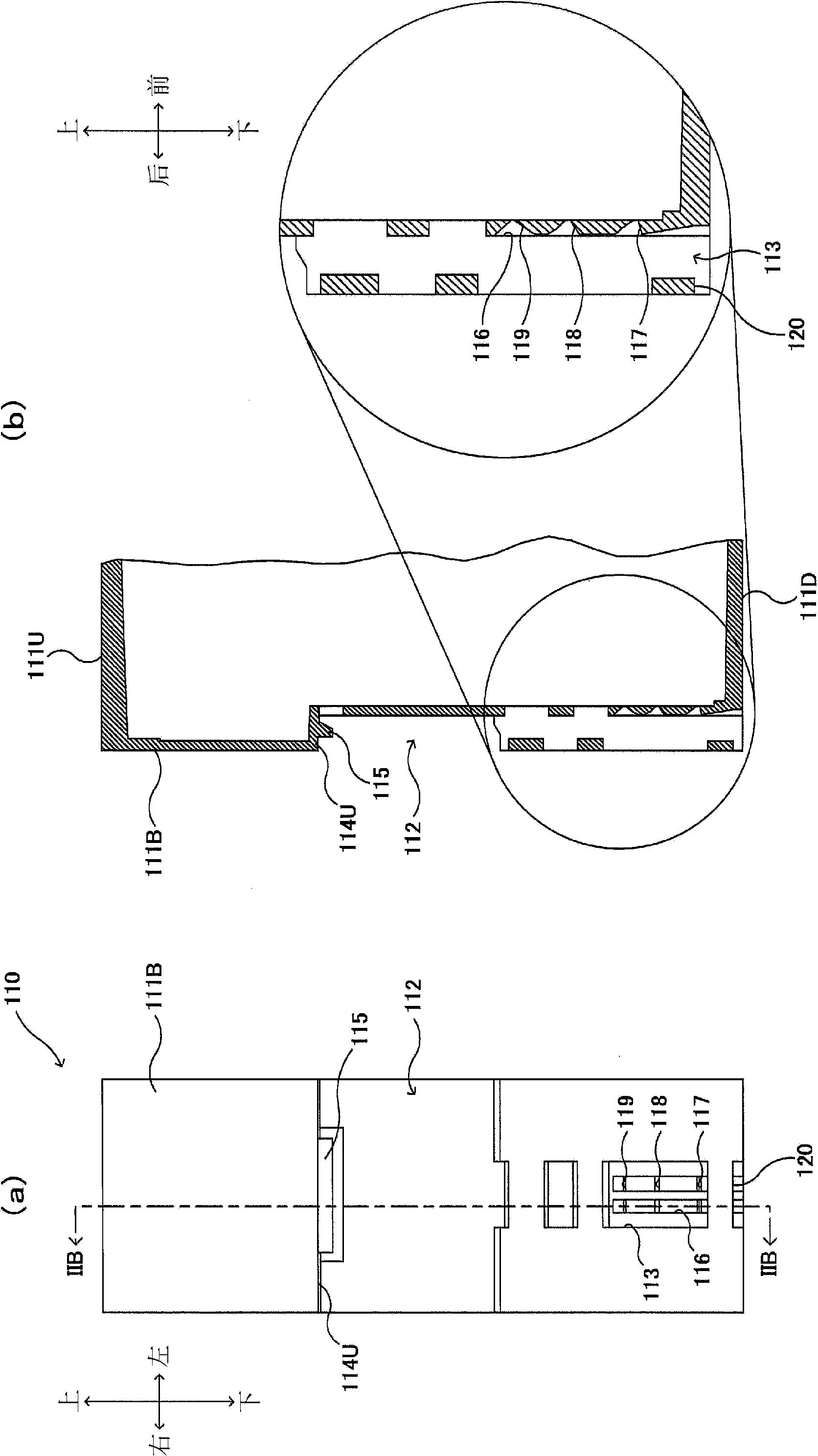

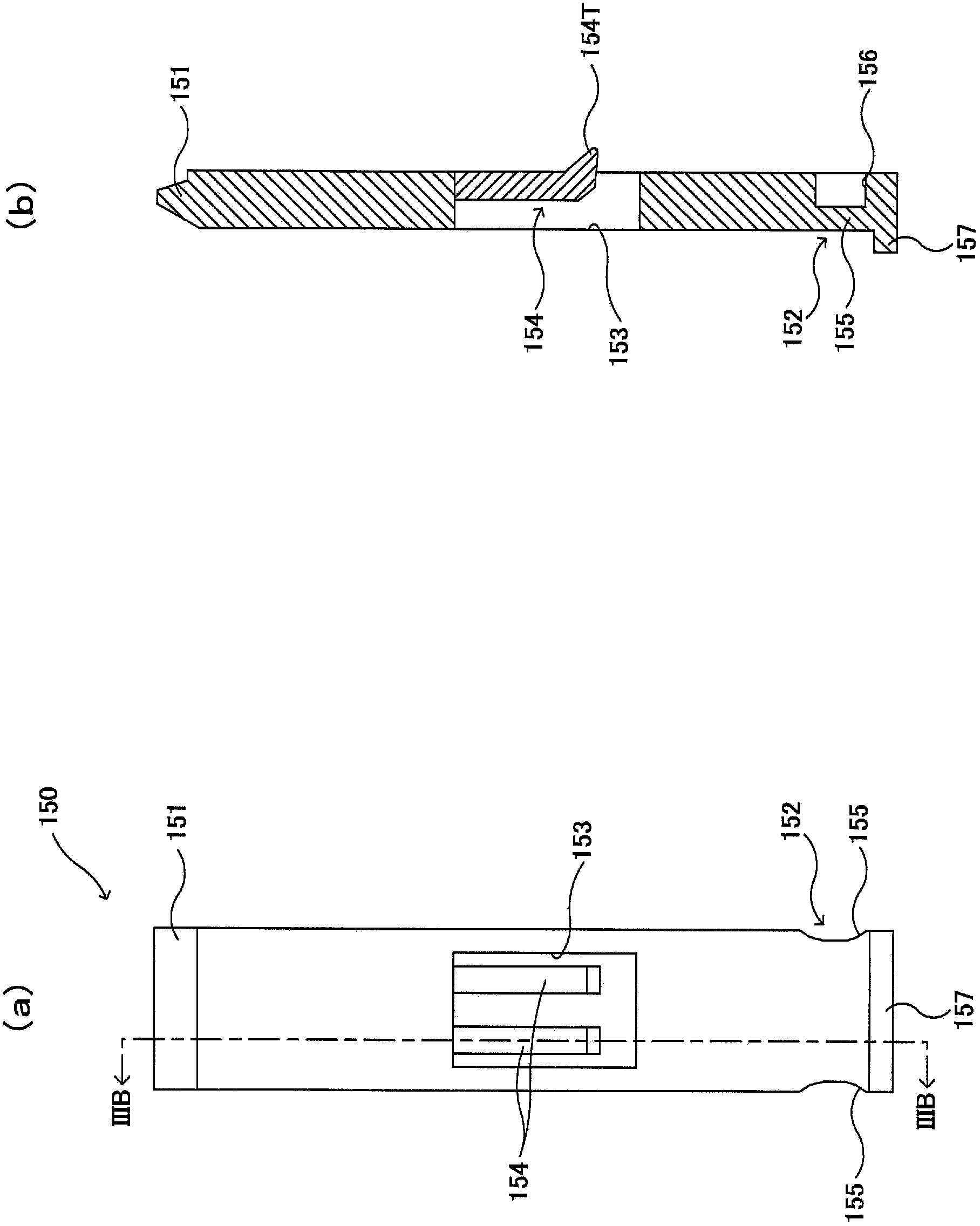

[0021] Embodiments will be described below with reference to the drawings. When referring to "front", "rear", "left", "right", "upper" and "lower" in the following figures, "forward", "backward", " Left", "Right", "Up", and "Down" to denote the pointed direction.

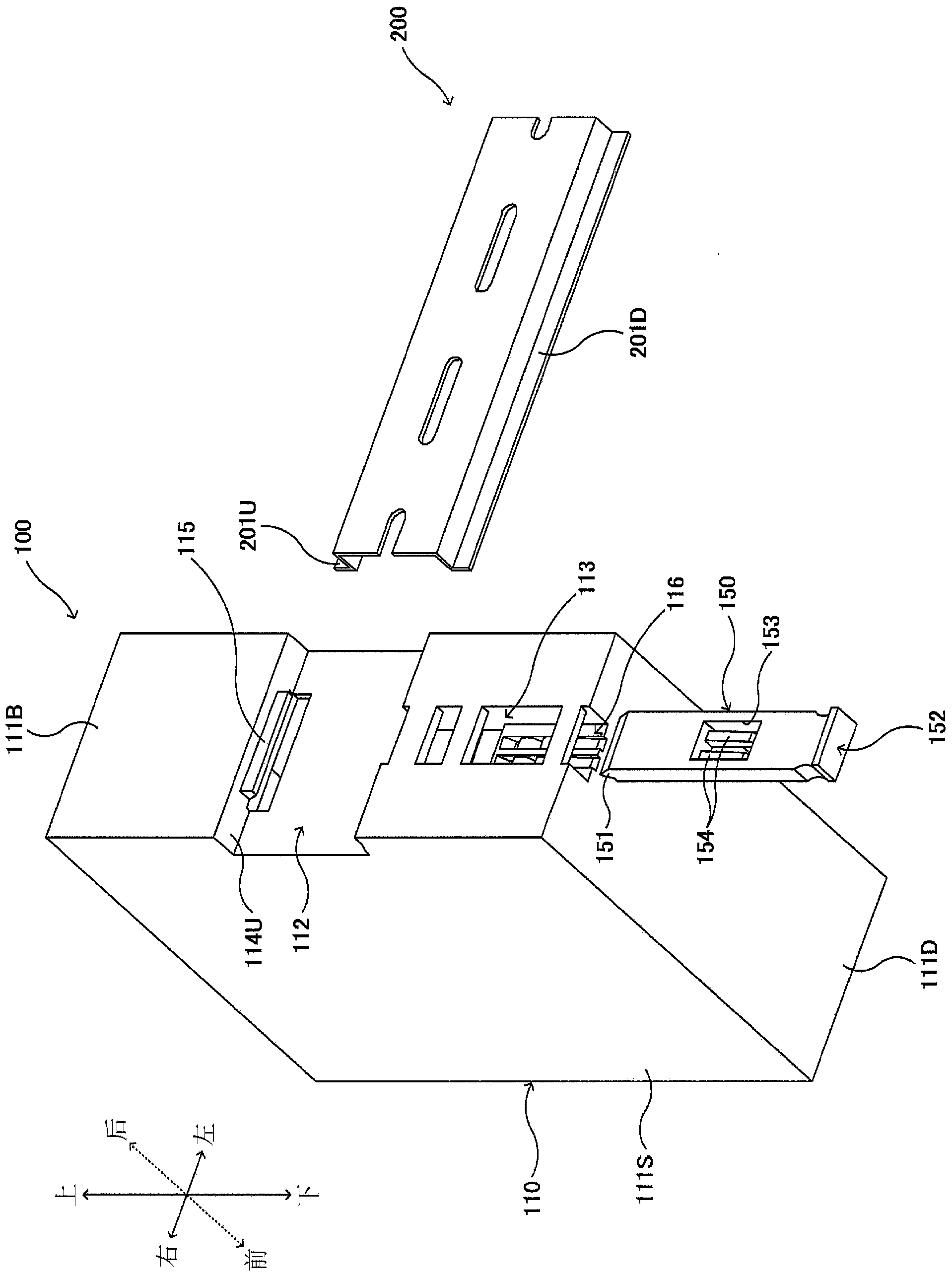

[0022] exist figure 1 , figure 2 (a), (b) of and image 3 In (a) and (b), the DIN rail-mounted device 100 according to the present embodiment refers to a DIN rail 200 that is removably mounted on a DIN standard (Deutsche Industries Noemen: German Industrial Standard) on the device. For example, control devices such as controller units, PLC (programmable logic controller) units, inverter units, servo units, power supply units, I / O units, sensor units, switch units, safety units, and relay units can be employed as DIN rail mountable device 100 . Alternatively, devices other than control devices may be employed. Such as figure 1 As shown, DIN rail mountable device 100 includes a front surface (not shown) as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com