Integrated DIN rail attachment feature for superior attachment

A track, connected to the technology, applied in the direction of electrical components, substation / switch layout details, support structure installation, etc., can solve the problem of not providing redundant latches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

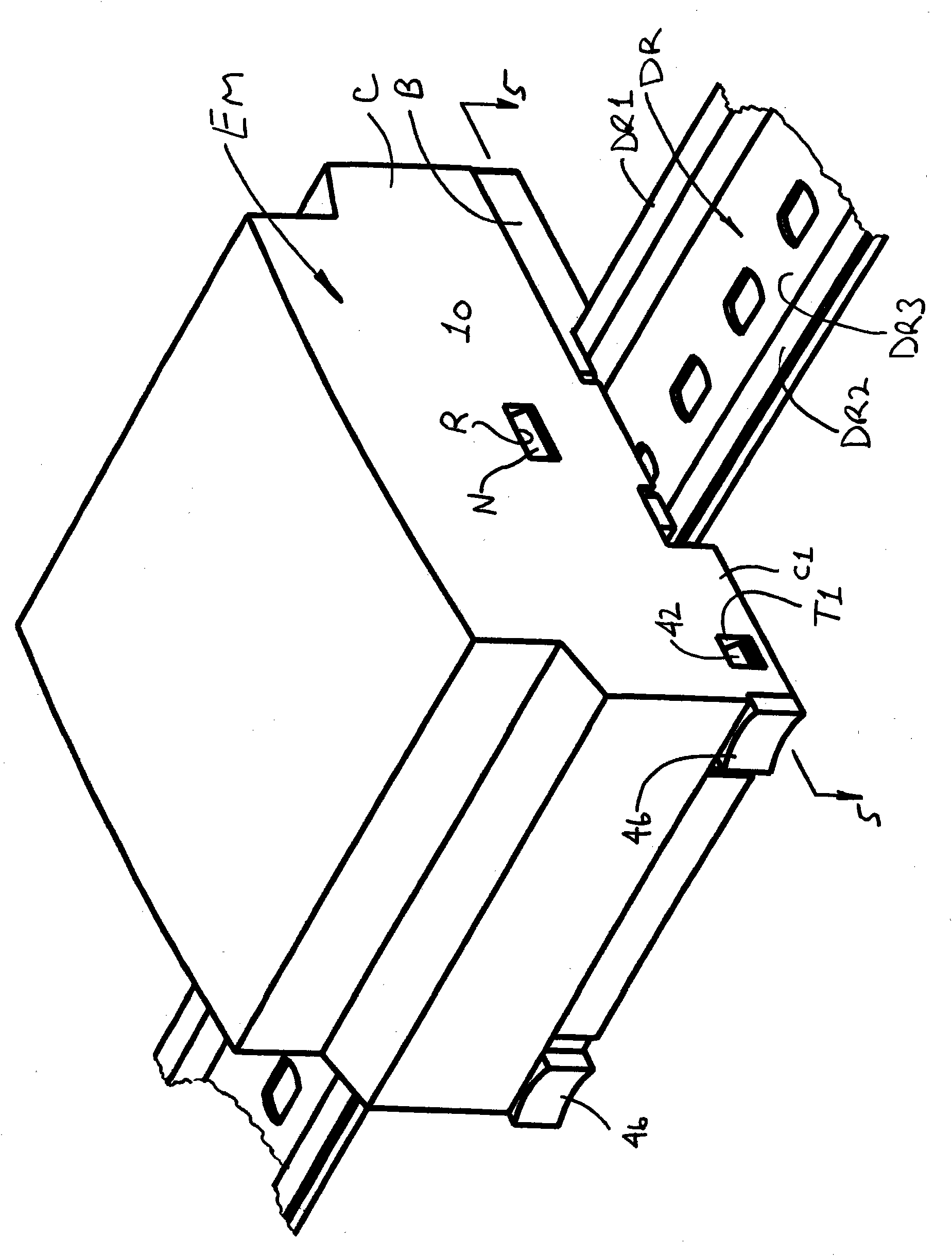

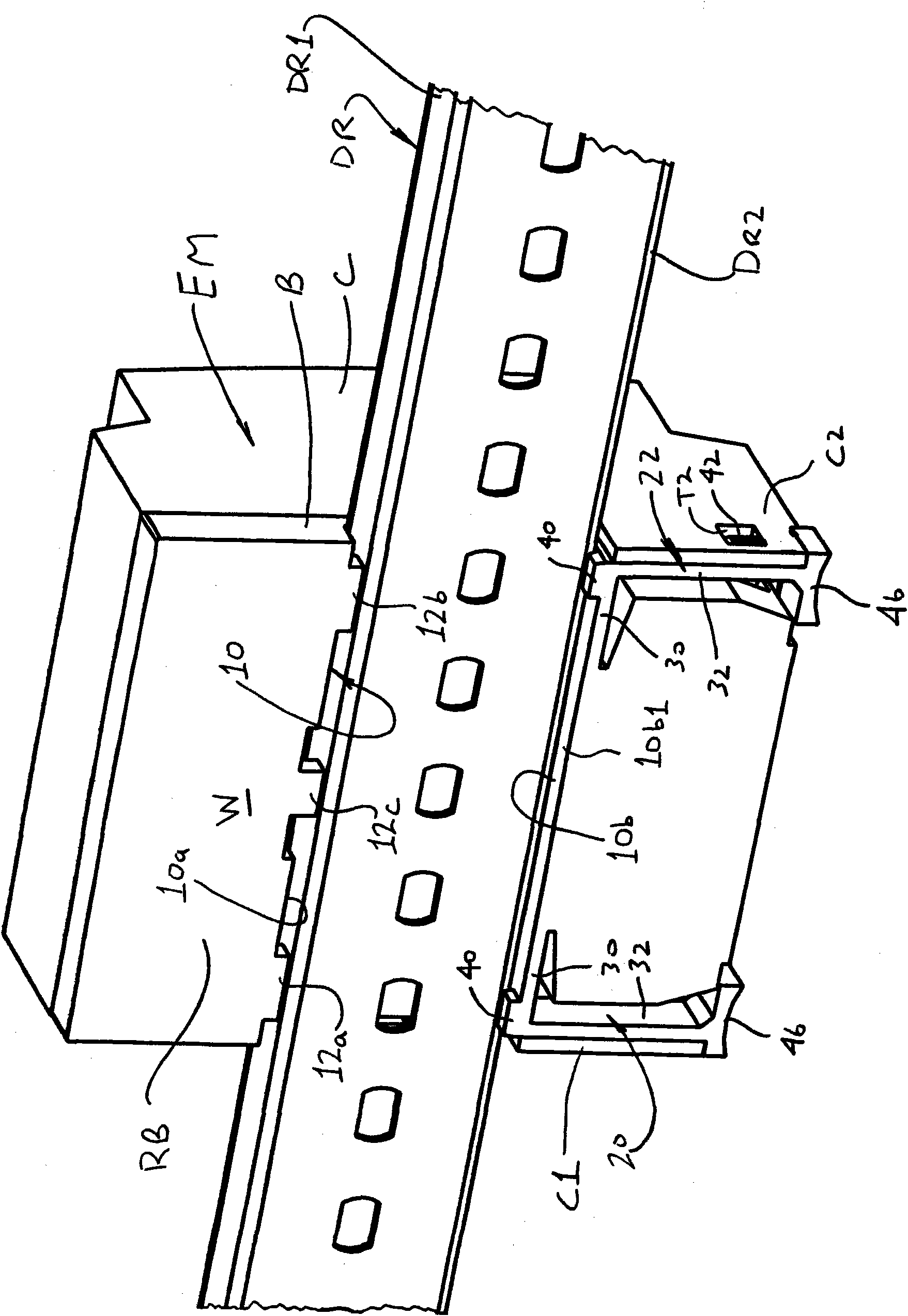

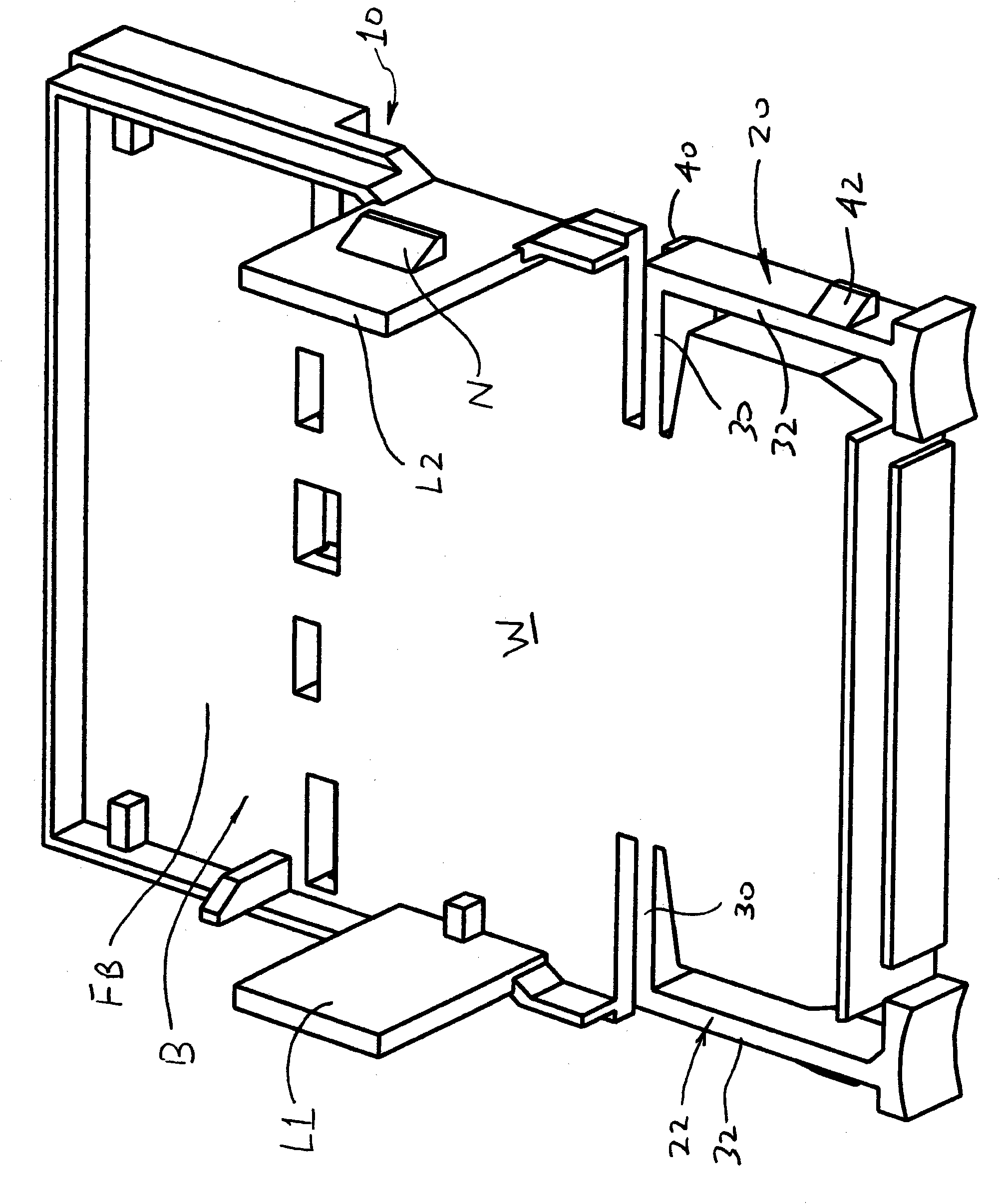

[0013] figure 1 A conventional DIN rail mounting structure DR is shown, which includes first and second flanges DR1, DR2 connected to opposite sides of the recessed central portion DR3. The electronic module EM includes the DIN rail attachment part according to the present invention, wherein the DIN rail attachment part provides a means for releasably connecting the module EM to the DIN rail DR. Combined with the rear view figure 2 , The electronic module EM includes: a base B for supporting one or more electronic circuit boards or other electronic components, and a cover C connected to the base B for sealing the electronic components connected to the base B. In the example, base B (in Figure 3A with Figure 3B Shown in) includes first and second legs L1, L2, which are accommodated in the cover C, and respectively include a clamping part that engages with the mating hole of the cover C or other regions R through a releasable snap fit N.

[0014] See also Figure 3A , 3B, 4A, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com