Hard coating and preparation method thereof

A hard coating, low stress technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the failure of coating protection, uneven distribution of stress along the depth of the layer, affecting the film-base Combined with the service life of the strength coating and other issues, the effects of uniform stress, improved residual stress, and improved film-matrix bonding performance are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

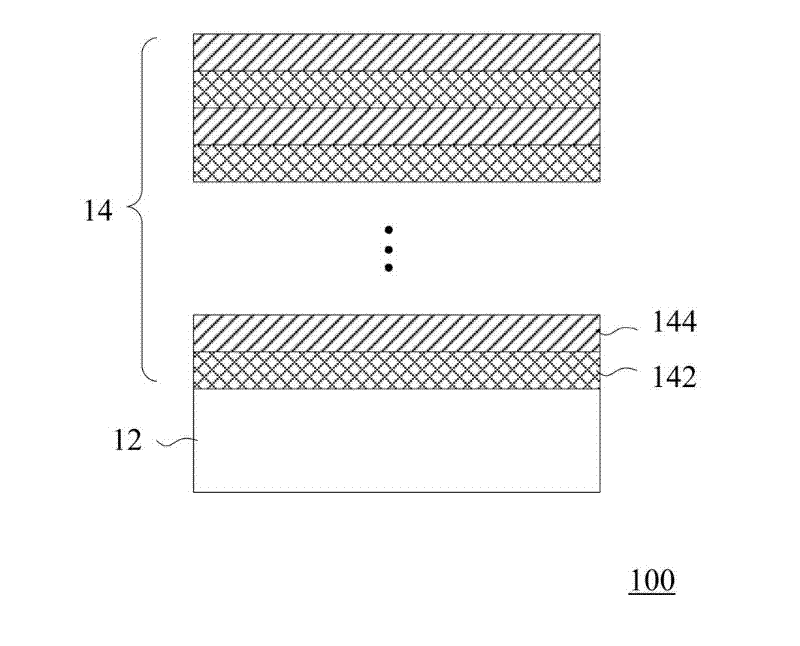

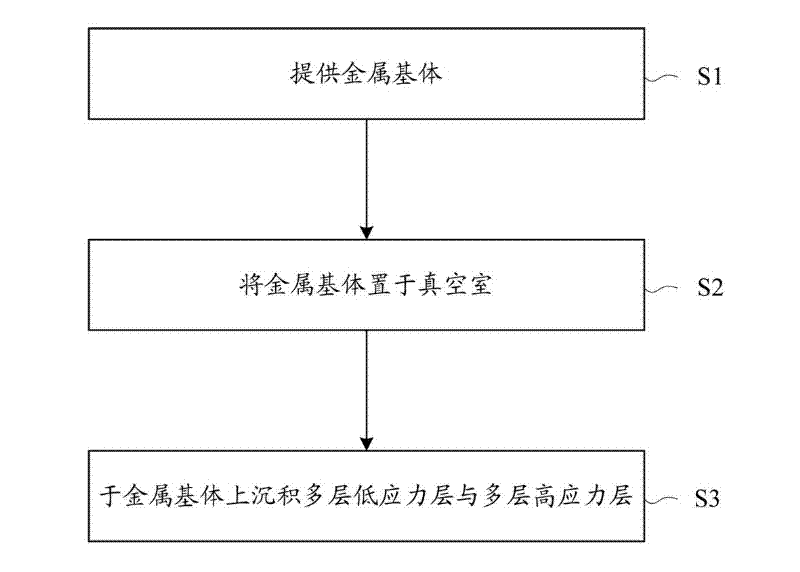

[0019] figure 2 It is a schematic flowchart of the preparation method of the hard coating according to the embodiment of the present invention. see also figure 1 and figure 2 , the preparation method of the hard coating in the embodiment of the present invention includes the following steps.

[0020] S1, the metal base 12 is provided. Wherein, the metal base 12 may be 1Cr18Ni9Ti stainless steel, alloy steel, high-speed steel or cemented carbide.

[0021] S2, after cleaning the surface of the metal substrate 12, place it in a vacuum chamber.

[0022] S3, nitrogen gas is introduced into the vacuum chamber, and the multi-layer low-stress layer 142 and the multi-layer high-stress layer 144 are deposited on the metal substrate 12 by the arc ion plating process under the condition of alternating high and low nitrogen partial pressure (or bias).

[0023] In step S3, nitrogen gas is introduced into the vacuum chamber, and arc ion plating is performed on the metal substrate by i...

Embodiment 1

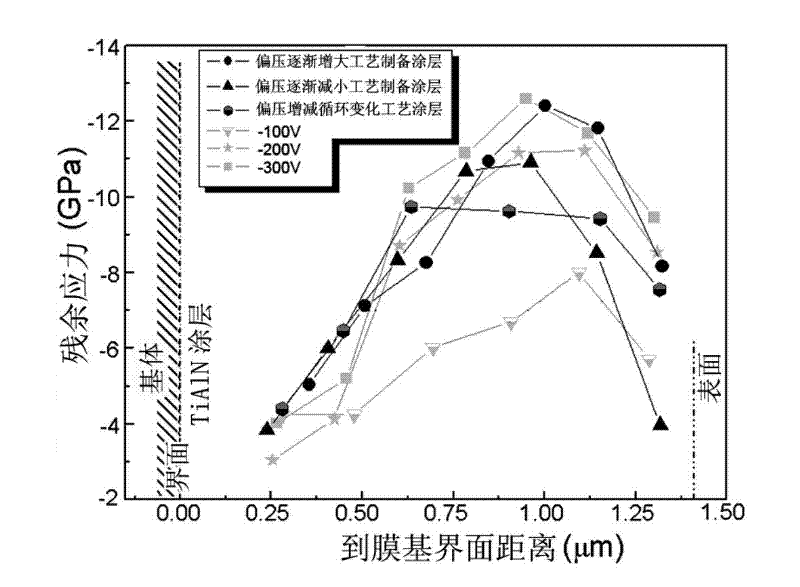

[0029] 1Cr18Ni9Ti is used as the metal matrix, and the target material of arc ion plating is titanium aluminum alloy (TiAl) (its atomic ratio is 50:50). First, ultrasonically clean the metal substrate of 1Cr18Ni9Ti (acetone, alcohol, distilled water), and put the metal substrate into a vacuum chamber, where the pre-vacuum reaches 6.0 × 10-3Pa, and heat to 100 °C; then, argon is introduced into the vacuum chamber. (Ar) pressure of about 0.5Pa, bombard the metal substrate under a large bias voltage for surface cleaning, where the bias voltage is -1000V, and the bombardment time is 2 minutes; then nitrogen is introduced into the vacuum chamber, Ar is turned off, and the metal substrate is arced Ion plating deposition. Among them, the locked N2 pressure is 8.0×101Pa, the arc current is about 60A, the arc voltage is 17V, and a pulse bias voltage with a duty cycle of 30% is used.

[0030] For the specific process of arc ion plating, see Figure 5. Using the cyclic deposition proc...

Embodiment 2

[0032] 1Cr18Ni9Ti is used as the metal matrix, and the target material of arc ion plating is titanium aluminum (TiAl) (its composition ratio is 50:50). First, ultrasonically clean the metal matrix of 1Cr18Ni9Ti, and put the metal matrix into a vacuum chamber, where the pre-vacuum reaches 6.0×10-3Pa, and the temperature is heated to 100°C; then, the pressure of argon (Ar) is introduced into the vacuum chamber at a pressure of about 0.5 Pa, bombarded the metal substrate under a large bias voltage for surface cleaning, where the bias voltage was -1000V, and the bombardment time was 2 minutes; then nitrogen was introduced into the vacuum chamber to perform arc ion plating deposition on the metal substrate. Among them, the total pressure of N2+Ar is 8.0×10-1Pa, the arc current is about 60A, the arc voltage is 18V, and the pulse bias voltage with a duty cycle of 30% is used to lock at -200V.

[0033] The specific process of arc ion plating can be: adjusting the ratio of N2 to Ar (to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com