Zirconia ceramic coating and preparation method thereof

A zirconia ceramic and zirconia technology, which is applied in the field of ion arc spraying, can solve the problems of inability to deposit and form dense coatings, blockage of spray gun conveying pipelines, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

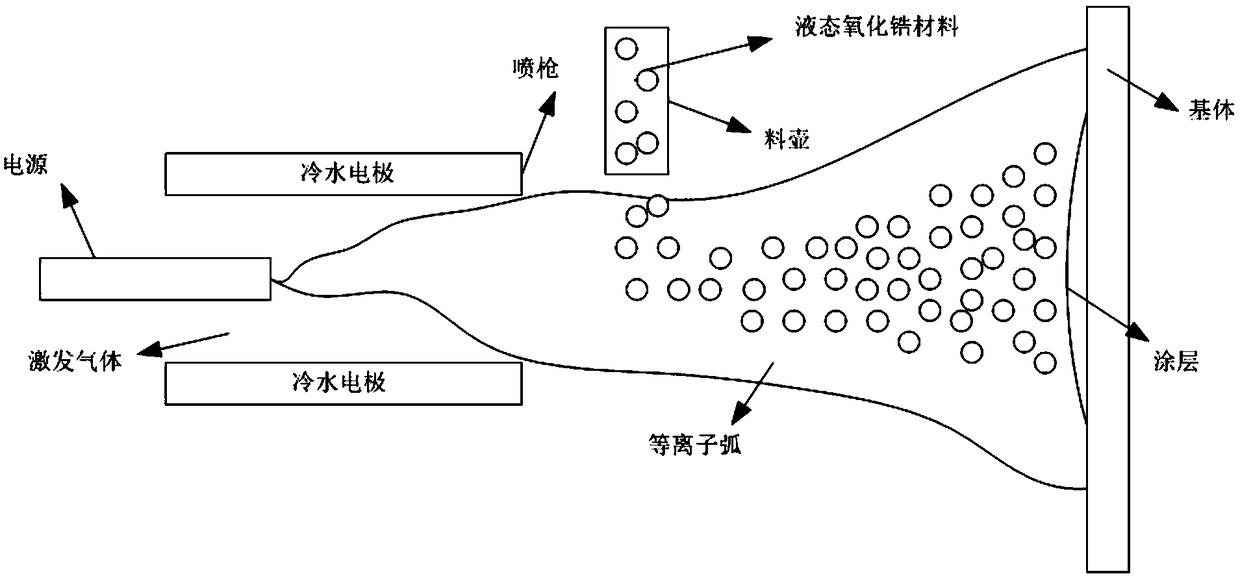

[0075] The present invention proposes a method for preparing zirconia liquid ceramics with high hardness, high wear resistance and high safety, such as Image 6 As shown, the main steps are as follows:

[0076] (1) Select the substrate:

[0077] The selection of the substrate should choose materials with wide material sources, low cost, low cutting difficulty and high strength. If necessary, materials that can still maintain certain plasticity, wear resistance and toughness after high temperature and high heat treatment should be selected. Here we give examples including wood, bamboo, metal materials, cement materials, resin materials, glass materials, carbon fiber materials and other substrates.

[0078] (2) Pretreatment of the substrate: sandblasting or frosting:

[0079] In order to allow the ceramic coating raw material and the substrate to be more closely combined, the substrate needs to be sandblasted or frosted. This step greatly increases the roughness of the substr...

Embodiment 2

[0104] A method for preparing zirconia liquid ceramics, comprising the steps of:

[0105] (1) Select the substrate:

[0106] Determine the substrate prepared by zirconia liquid ceramics. The selection of the substrate should be based on a wide range of materials, suitable for cost, low cutting difficulty and high strength. If necessary, it should still maintain a certain degree of plasticity, Abrasion-resistant and tough material.

[0107] (2) Pretreatment of the substrate: sandblasting (frosting) treatment.

[0108] Described blasting treatment refers to:

[0109] Use compressed air to beat the sand to the surface of the substrate in a sandblasting machine, and the pressure of the compressed air is about 0.7MPa. When sandblasting is used to treat the surface of the substrate, the spray gun nozzle and the substrate form an angle of 45 degrees, and move at a constant speed from one end of the substrate to the other end. After sandblasting, use compressed air to clean the sur...

Embodiment 3

[0127] All the steps are the same as in Example 1 or Example 2, the difference is that the zirconia raw material powder is obtained by the following steps:

[0128] Dissolve quantitative urea and zirconium nitrate in deionized water to prepare a zirconium nitrate mixture; add 1 part of Span-80 to a container containing 10 parts of xylene, and use electric stirring during the addition of Span-80 Stir the xylene mixed solution in the container, and when the xylene mixed solution in the container becomes uniform, add 1 part of the prepared zirconium nitrate mixed solution to the container, and obtain a white emulsion after emulsification for half an hour. Pour the emulsion into the reaction kettle, seal the reaction kettle and put it in an oven at 120 degrees Celsius for reaction. After 15 hours of reaction, take out the reaction kettle and wait for it to cool to room temperature, then open the reaction kettle to take samples to obtain white crystals; white crystals After filteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com