Welding technology of austenitic stainless steel and chrome molybdenum heat resistant steel

A technology of austenitic stainless steel and welding technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effect of shortening the construction period, improving efficiency, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Welding of austenitic stainless steel plate and chromium molybdenum heat-resistant steel plate under hydrogen working condition

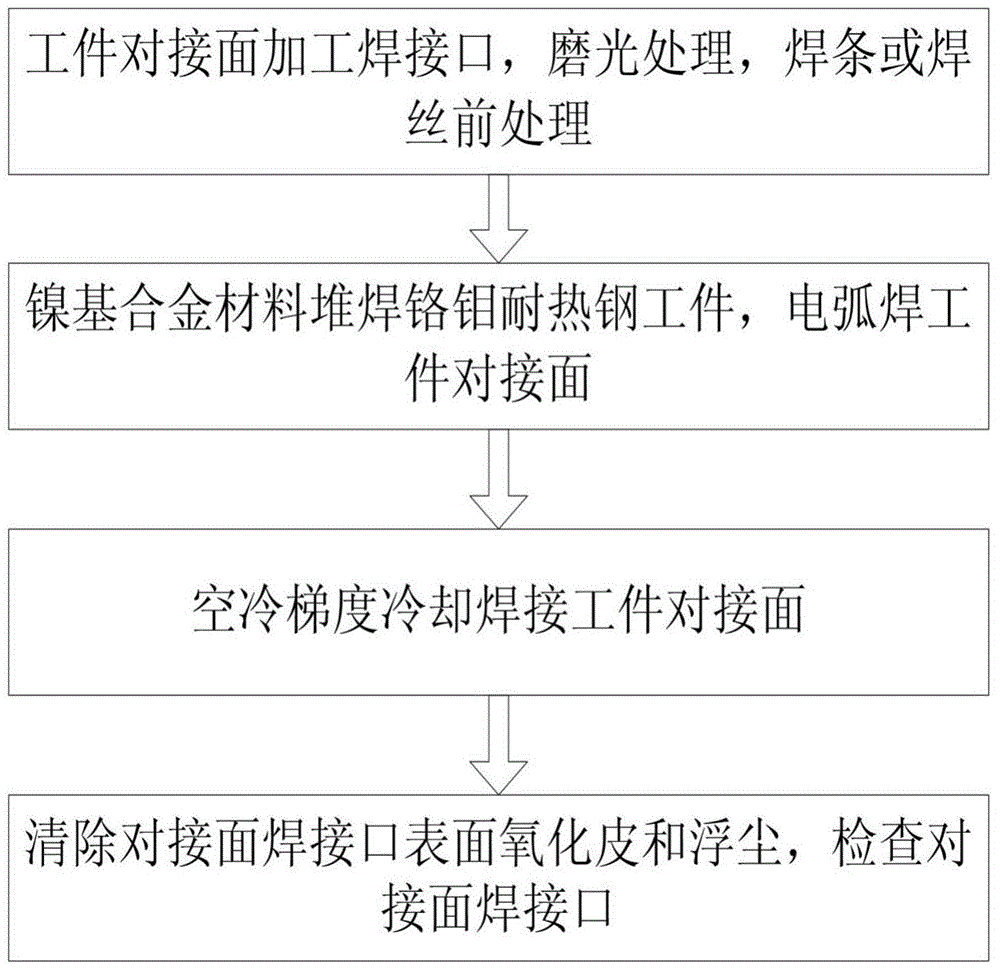

[0036] Such as figure 1 As shown, the specific implementation process includes:

[0037] Step 1, pre-welding treatment, including:

[0038] 1) Process the welding joint on the butt joint surface of the austenitic stainless steel plate and the chromium-molybdenum heat-resistant steel plate. The sum of the mouth angles is 44-54 degrees, and the blunt edge is 2.5-3.5mm;

[0039] 2) Grind the groove and blunt edge of the austenitic stainless steel plate and the chromium-molybdenum heat-resistant steel plate, first use 800#-900# sandpaper to remove bright stars, and then use 1500# sandpaper to lightly sand the sand marks , so that the surface roughness is 1.0 to 1.8 μm, cleaning the groove and the blunt edge of the butt joint surface with alcohol to remove the oil stain on the butt joint surface;

[0040] 3) Before using the welding material E...

example 2

[0045] Welding of austenitic stainless steel pipes and chrome-molybdenum heat-resistant steel pipes under hydrogen conditions

[0046] Such as figure 1 As shown, the specific implementation process includes:

[0047] Step 1, pre-welding treatment, including:

[0048] 1) Process the welding joint on the butt joint surface of the austenitic stainless steel pipe material and the chromium-molybdenum heat-resistant steel pipe material. The sum of the mouth angles is 44-54 degrees, and the blunt edge is 2.5-3.5mm;

[0049] 2) Grind the groove and blunt edge of the austenitic stainless steel pipe and the chrome-molybdenum heat-resistant steel pipe, first use 800#-900# sandpaper to remove bright stars, and then use 1500# sandpaper to lightly sand the sand marks , so that the surface roughness is 1.0 to 1.8 μm, cleaning the groove and the blunt edge of the butt joint surface with alcohol to remove the oil stain on the butt joint surface;

[0050] 3) Before using the welding materia...

example 3

[0056] Welding of austenitic stainless steel plate and chromium molybdenum heat-resistant steel plate under non-hydrogen working condition with working temperature greater than 450°C

[0057] Such as figure 1 As shown, the specific implementation process includes:

[0058] Step 1, pre-welding treatment, including:

[0059] 1) Process the welding joint on the butt joint surface of the austenitic stainless steel plate and the chromium-molybdenum heat-resistant steel plate. The sum of the mouth angles is 44-54 degrees, and the blunt edge is 2.5-3.5mm;

[0060] 2) Grind the groove and blunt edge of the austenitic stainless steel plate and the chromium-molybdenum heat-resistant steel plate, first use 800#-900# sandpaper to remove bright stars, and then use 1500# sandpaper to lightly sand the sand marks , so that the surface roughness is 1.0 to 1.8 μm, cleaning the groove and the blunt edge of the butt joint surface with alcohol to remove the oil stain on the butt joint surface; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com