Method for manufacturing non-smooth surface of organism and device

A non-smooth surface and preparation device technology, which is applied in the field of laser processing and biological non-smooth surface preparation, can solve the problems of laser manufacturing of biological non-smooth surface, changing the shape of texture, complex process and other problems without detailed description, so as to increase the durability Abrasiveness, deeper pattern depth, increased residual stress and hardness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

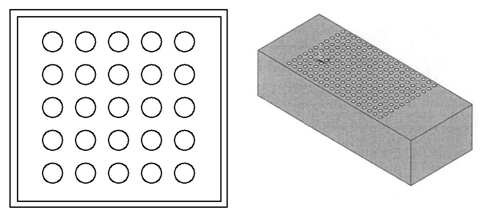

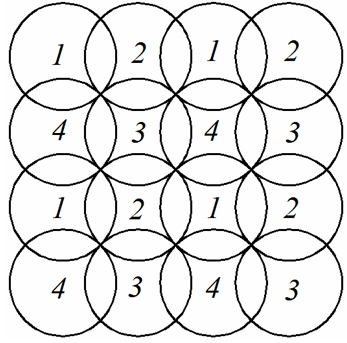

[0042] By observing the surface morphology of dung beetle pits and shell pits, the design of the mold is as follows: figure 1 As shown; the mold adopts the lost foam casting method in casting technology. According to the size of the design mold drawing, foam plastic is used for modeling, and then the surface of the model is brushed with refractory paint and dried, and then buried in dry quartz sand for vibration molding. , pouring under negative pressure, the foam model is vaporized, the liquid metal occupies the position of the model, solidifies and cools to form a casting, and makes a mold imitating the surface of the dung beetle pit.

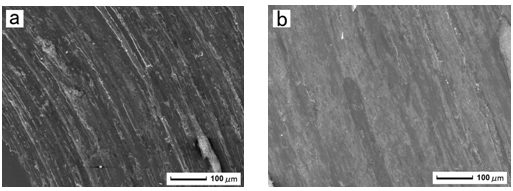

[0043] The material used in this example is AISI 8620 steel, and its dynamic aging temperature is 350°C. Figure 4 The system prepares non-smooth surface on the surface of AISI 8620 steel sample, and the surface of AISI 8620 steel sample is prepared as Figure 5 As shown, the AISI 8620 steel sample is successively equipped with a dung beetle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com