Method for improving surface quality of titanium and titanium alloy pipes and drawing die

A titanium alloy, high-quality technology, used in wire drawing dies and other directions to reduce oil removal, improve internal and external surface quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

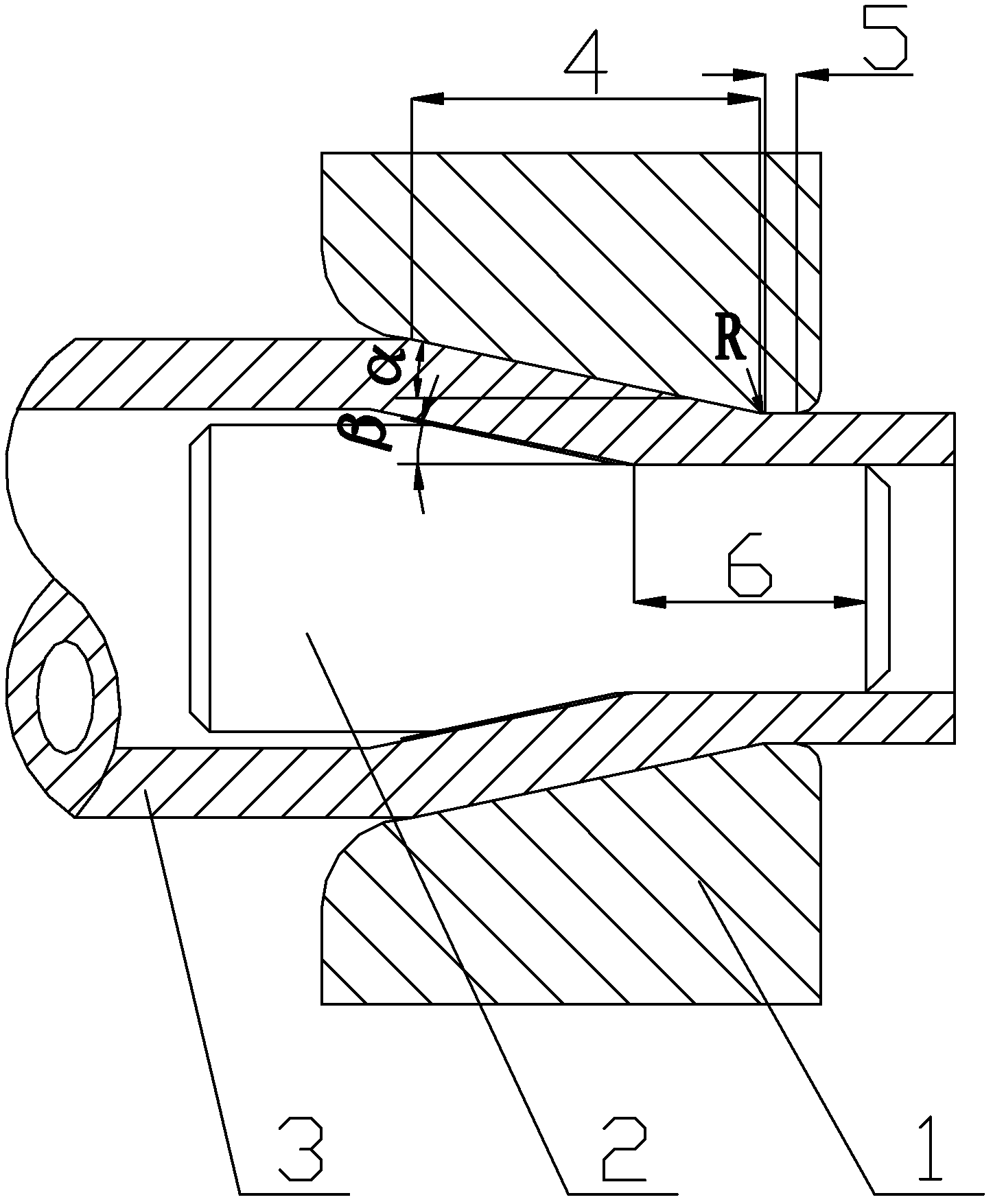

[0024] Such as figure 1 As shown, the drawing die of this embodiment includes an outer mold 1 for determining the outer diameter of the pipe material 3 and a floating core 2 for determining the inner diameter of the pipe material 3, and the outer mold half-cone angle α of the outer mold 1 is 10 °, the length of the sizing section-5 of the outer mold 1 is 0.5mm, and the radius R of the transition arc between the conical section 4 and the sizing section-5 of the outer mold 1 is 5mm; The core head half cone angle β of the core head 2 is 5°, and the length of the sizing section 2 6 of the moving core head 2 is 0.5 mm.

[0025] In this embodiment, the method for improving the surface quality of titanium pipes by using the above-mentioned drawing dies is as follows: select TA18 cold-rolled pipes with the chemical composition meeting the requirements of the GB / T3520.2-2007 standard, and the pipes are pickled and dried. Conventional heat treatment at 700°C / 1.5h to form a dense oxide ...

Embodiment 2

[0028] Such as figure 1 As shown, the drawing die of this embodiment includes an outer die 1 for determining the outer diameter of the pipe material 3 and a floating core 2 for determining the inner diameter of the pipe material 3, and the outer die half-cone angle α of the outer die 1 is 20 °, the length of the sizing section-5 of the outer mold 1 is 3mm, and the radius R of the transitional arc between the conical section 4 and the sizing section-5 of the outer mold 1 is 8mm; The core head semi-cone angle β of the head 2 is 18°, and the length of the sizing section 2 6 of the moving core head 2 is 5 mm.

[0029] In this embodiment, the method for improving the surface quality of titanium alloy pipes by using the above-mentioned drawing dies is as follows: select TA2 cold-rolled pipes with a chemical composition that meets the requirements of the GB / T3520.2-2007 standard, and degrease and pickle the pipes Dry in the air, and carry out conventional heat treatment at 600°C / 1h ...

Embodiment 3

[0032] Such as figure 1 As shown, the drawing die of this embodiment includes an outer die 1 for determining the outer diameter of the pipe material 3 and a floating core 2 for determining the inner diameter of the pipe material 3, and the outer die half-cone angle α of the outer die 1 is 15 °, the length of the sizing section-5 of the outer mold 1 is 2mm, and the radius R of the transition arc between the conical section 4 and the sizing section-5 of the outer mold 1 is 6mm; The core head semi-cone angle β of the head 2 is 9°, and the length of the sizing section 2 6 of the moving core head 2 is 3 mm.

[0033]In this embodiment, the method for improving the surface quality of titanium alloy pipes by using the above-mentioned drawing dies is as follows: select TA16 alloy cold-rolled pipes with the chemical composition meeting the requirements of GB / T3520.2-2007 standard, and carry out degreasing treatment on the pipes And 700℃ / 1.5h conventional heat treatment, so that a layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com