Preparation method of diamond compact

A technology of diamond composite sheet and diamond powder is applied in the field of hard material manufacturing, which can solve the problems of poor compactness and large residual stress of products, and achieve the effects of compact and uniform sintered structure, strong operability and good synthesis repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

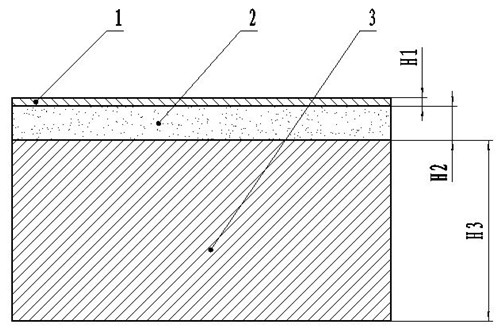

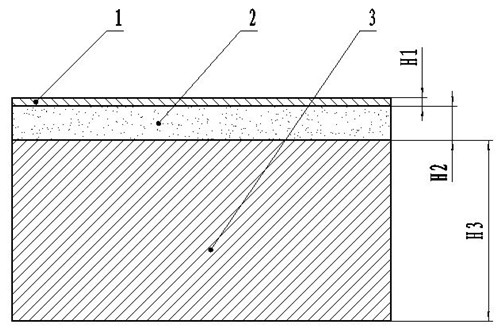

[0014] A diamond powder layer 2 with a thickness H2 of 2 mm is placed between a metal alloy sheet 1 with a thickness H1 of 0.2 mm and a hard alloy substrate 3 with a thickness H3 of 3 mm to make a sintered compact, and then the sintered compact is placed in a graphite tube Heating and pressurizing sintering in the synthetic cavity, the pressurized pressure is 5.0GPa, the sintering temperature is 1500 ± 50°C, and the time is 3 minutes. After sintering, the temperature is lowered and the pressure is relieved to produce a diamond composite sheet. The residual stress is 280MPa after testing.

Embodiment 2

[0016] A diamond powder layer 2 with a thickness H2 of 0.3 mm is placed between a metal alloy sheet 1 with a thickness H1 of 0.05 mm and a hard alloy substrate 3 with a thickness H3 of 1 mm to make a sintered compact, and then the sintered compact is placed in a graphite tube Heating and pressurizing sintering in the synthetic cavity, the pressurized pressure is 5.0GPa, the sintering temperature is 1250 ± 50°C, and the time is 3 minutes. After sintering, the temperature is lowered and the pressure is relieved to produce a diamond composite sheet. The residual stress is 290MPa after testing.

Embodiment 3

[0018] A diamond powder layer 2 with a thickness H2 of 5 mm is placed between a metal alloy sheet 1 with a thickness H1 of 0.4 mm and a hard alloy substrate 3 with a thickness H3 of 10 mm to make a sintered compact, and then the sintered compact is placed in a graphite tube Heating and pressurizing sintering in the synthetic cavity, the pressurized pressure is 6.0GPa, the sintering temperature is 1450 ± 50°C, and the time is 30 minutes. After sintering, the temperature is lowered and the pressure is relieved to produce a diamond composite sheet. The residual stress is 98MPa after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com