A kind of preparation method of polycrystalline cubic boron nitride composite sheet

A cubic boron nitride and polycrystalline cubic technology is applied in the field of preparation of high-quality polycrystalline cubic boron nitride (PcBN) composite sheets. PcBN tool performance, uneven sintering structure and other problems, to achieve the effect of reducing powder mixing process, high stability, uniform and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

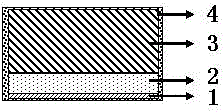

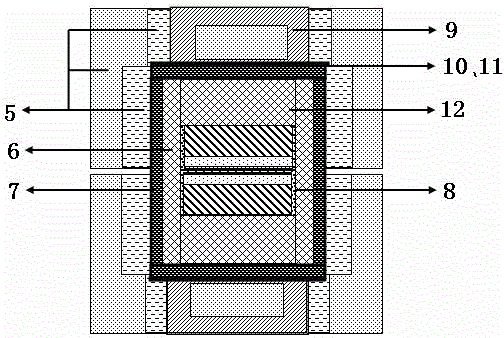

[0023] as attached figure 1 , 2 Shown: Select Ni with a thickness of 0.2mm and a diameter of 14.7mm 75 mn 16 co 9 Metal alloy sheet, cBN powder with a particle size of 3-5μm and a mass of 0.65g, and a YG8 cemented carbide substrate with the same sheet diameter as the metal sheet and a thickness of 3mm as raw materials, according to the metal sheet 1, cubic boron nitride powder 2 and cemented carbide The matrix 3 is put into a molybdenum cup 4 with an inner diameter of 14.8 mm from bottom to top, and is pre-pressed at 40 MPa. After a vacuum heat treatment at 700 ° C for 1 hour, it is placed in a heated graphite tube 7 kit with a salt tube 6 . Finally, the top two The raw materials of the sheet, the molybdenum cup assembly 8 and parts 9-12 are put into the pyrophyllite composite block 5 together, the size of the pyrophyllite composite block 5 is 37.5mm×37.5mm×37.5mm, the diameter of the synthetic cavity is 23mm, and the inner diameter of the graphite tube 7 is It is 18mm and...

Embodiment 2

[0025] as attached figure 1 , 2 Shown: Select a Ti sheet with a thickness of 0.1mm and a diameter of 14.7mm, cBN powder with a particle size of 3-5μm and a mass of 0.65g, and a YG8 cemented carbide substrate with the same sheet diameter as the metal sheet and a thickness of 3mm as the raw material. Boron powder 2 and cemented carbide substrate 3 are put into a molybdenum cup 4 with an inner diameter of 14.8 mm from bottom to top, pre-pressed at 40 MPa, vacuum 700 ° C for 1 hour, and then put into a heated graphite tube with a salt tube 6 7 kits, put the top two pieces of raw materials together with the molybdenum cup assembly 8 and parts 9-12 into the pyrophyllite composite block 5. The size of the pyrophyllite composite block 5 is 37.5mm×37.5mm×37.5mm. The body diameter is 23mm, the inner diameter of the graphite tube 7 is 18mm, and the height is 26mm. The PcBN composite sheet was synthesized under high temperature and high pressure on a six-sided top press. The synthesis c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com