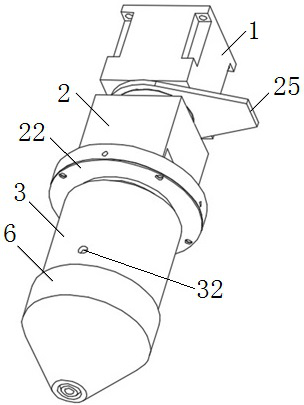

Carrier gas powder mixing type coaxial powder feeding nozzle for additive manufacturing

A technology of additive manufacturing and coaxial powder feeding, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

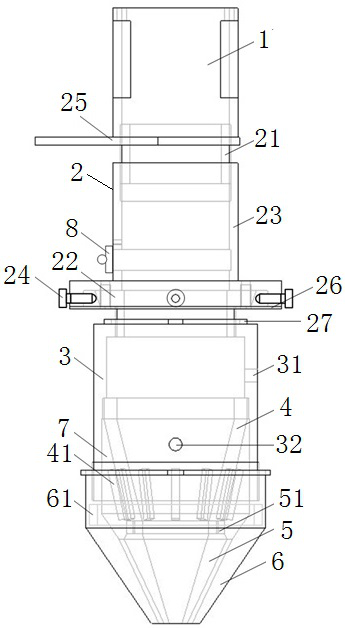

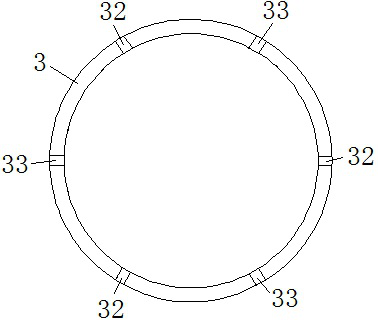

[0031] As a preferred embodiment of the present invention, the position adjustment assembly 2 includes an axial adjustment assembly and a radial adjustment assembly, the axial adjustment assembly is used to adjust the axial position of the nozzle base cylinder 3 relative to the conversion joint, the The radial adjustment component is used for the relative radial position of the nozzle base barrel to adjust the relative position between the focused spot of the laser beam generated by the laser emitting head and the converging point of the powder flow.

[0032] The axial adjustment assembly includes a first axial adjustment cylinder 21 and a second axial adjustment cylinder 22 , and the longitudinal adjustment assembly includes an inverted T-shaped connecting cylinder 23 . The first axial positioning ring 25 is threaded on the outer wall of the first axial adjustment cylinder 21 , the upper end is threaded with the inner wall of the conversion joint 1 , and the lower end is threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com